check engine light INFINITI QX56 2008 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2452 of 4083

SQUEAK AND RATTLE TROUBLE DIAGNOSESINT-3

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half- clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool (Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from. Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to INT-4, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94 ×5.31 in)/76884-71L01: 60 ×85 mm (2.36× 3.35 in)/76884-71L02: 15× 25

mm (0.59 ×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50× 50 mm (1.97×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50× 50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occu r. Ideal for instrument panel applications.

Revision: March 2010 2008 QX56

Page 2476 of 4083

IP-6

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-cluth on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to IP-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A NISSAN Squeak and Rattle Kit (J-43980) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94× 5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-71L02: 15 ×25

mm (0.59× 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50× 50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTH TAPE

Used to insulate where movemen t does not occur. Ideal for instrument panel applications.

Revision: March 2010 2008 QX56

Page 2540 of 4083

![INFINITI QX56 2008 Factory Repair Manual LAN

CAN COMMUNICATION SYSTEMLAN-45

< FUNCTION DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

Engine speed signal

T RRR R R R R R

Engine status signal TR

Fuel consumption monitor signal TR

RT

ICC stee INFINITI QX56 2008 Factory Repair Manual LAN

CAN COMMUNICATION SYSTEMLAN-45

< FUNCTION DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

Engine speed signal

T RRR R R R R R

Engine status signal TR

Fuel consumption monitor signal TR

RT

ICC stee](/img/42/57030/w960_57030-2539.png)

LAN

CAN COMMUNICATION SYSTEMLAN-45

< FUNCTION DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

Engine speed signal

T RRR R R R R R

Engine status signal TR

Fuel consumption monitor signal TR

RT

ICC steering switch signal TR

Malfunction indicator lamp signal T R

Wide open throttle position signal T R

A/T CHECK indicato r lamp signal T R

A/T fluid temperature sensor signal T R

A/T position indicator lamp signal TR RR

A/T self-diagnosis signal R T

Current gear position signal TR R

Input speed signal R TR

Output shaft revolution signal R TR R

P range signal TR R RR

ICC sensor signal T R

Buzzer output signal TR

TR

ICC OD cancel request signal R RT

ICC operation signal R RT

ICC system display signal TR

System setting signal TRT

RTR

A/C switch/indicator signal TR

RT

A/C switch signal RT R

Blower fan motor switch signal RT

Day time running light request signal TR R

Door lock/unlock status signal TR

Door switch signal R R TR R R

Front fog light request signal TR

Front wiper request signal RT R

High beam request signal TR R

Horn chirp signal TR

Ignition switch signal RTR R

Key fob door unlock signal RT

Key fob ID signal RT

Key switch signal RT

Low beam request signal TR

Position light request signal TR R

Rear window defogger switch signal T RR

Sleep wake up signal RT R R

Theft warning horn request signal TR

Signal name/Connecting unit

ECM

TCM

LASER ICC

ADP AV

BCM

HVAC I-KEY M&A

STRG 4WD

ABS

IPDM-E

Revision: March 2010 2008 QX56

Page 2584 of 4083

PRECAUTIONSLU-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Liquid GasketINFOID:0000000001538839

REMOVAL OF LIQUID GASKET SEALING

• After removing the bolts and nuts, separate the mating surface and

remove the old liquid gasket sealing using Tool.

CAUTION:

Do not damage the mating surfaces.

• Tap the seal cutter to insert it (1).

• In areas where the Tool is difficult to use, lightly tap to slide it (2).

LIQUID GASKET APPLICATION PROCEDURE

1. Remove the old liquid gasket adhering to the gasket application surface and the mating surface using suitable tool.

• Remove the liquid gasket completely from the groove of the

liquid gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering moisture, grease and foreign material.

3. Attach the liquid gasket tube to the Tool. Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-15, "

Recommended Chemical Products and Sealants".

4. Apply the liquid gasket without breaks to the specified location with the specified dimensions.

• If there is a groove for the liquid gasket application, apply theliquid gasket to the groove.

• As for the bolt holes, normally apply the liquid gasket inside

the holes. If specified in the procedure, it should also be

applied outside the holes.

• Within five minutes of liquid gasket application, install the mat-

ing component.

• If the liquid gasket protrudes, wipe it off immediately.

• Do not retighten after the installation.

• Wait 30 minutes or more after installation before refilling the engine with engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

Tool number : KV10111100 (J-37228)

WBIA0566E

PBIC0003E

Tool number : WS39930000 ( — )

WBIA0567E

SEM159F

Revision: March 2010

2008 QX56

Page 2595 of 4083

LU-14

< ON-VEHICLE REPAIR >

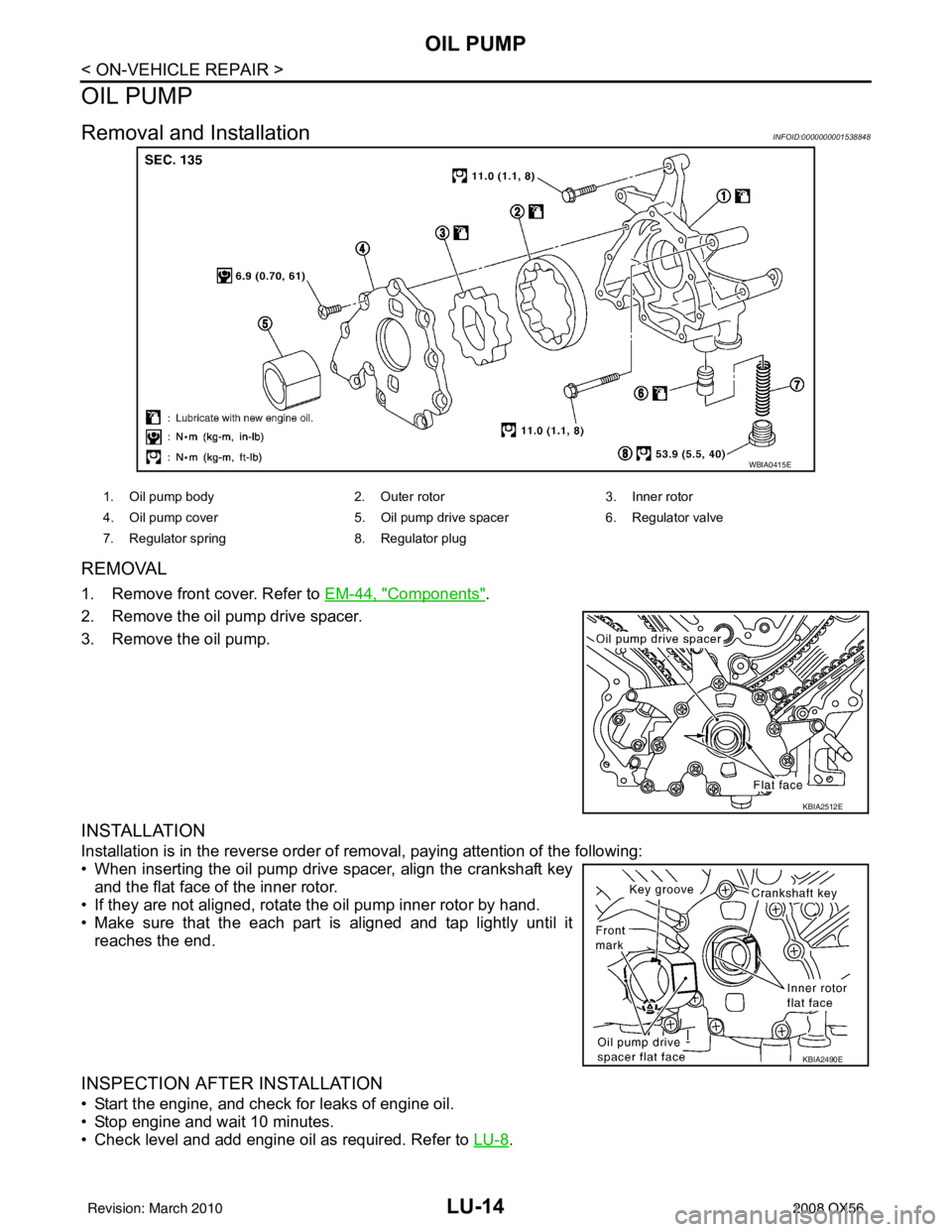

OIL PUMP

OIL PUMP

Removal and InstallationINFOID:0000000001538848

REMOVAL

1. Remove front cover. Refer to EM-44, "Components".

2. Remove the oil pump drive spacer.

3. Remove the oil pump.

INSTALLATION

Installation is in the reverse order of removal, paying attention of the following:

• When inserting the oil pump drive spacer, align the crankshaft key and the flat face of the inner rotor.

• If they are not aligned, rotate the oil pump inner rotor by hand.

• Make sure that the each part is aligned and tap lightly until it

reaches the end.

INSPECTION AFTER INSTALLATION

• Start the engine, and check for leaks of engine oil.

• Stop engine and wait 10 minutes.

• Check level and add engine oil as required. Refer to LU-8

.

WBIA0415E

1. Oil pump body2. Outer rotor 3. Inner rotor

4. Oil pump cover 5. Oil pump drive spacer 6. Regulator valve

7. Regulator spring 8. Regulator plug

KBIA2512E

KBIA2490E

Revision: March 2010 2008 QX56

Page 2614 of 4083

MA-16

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE

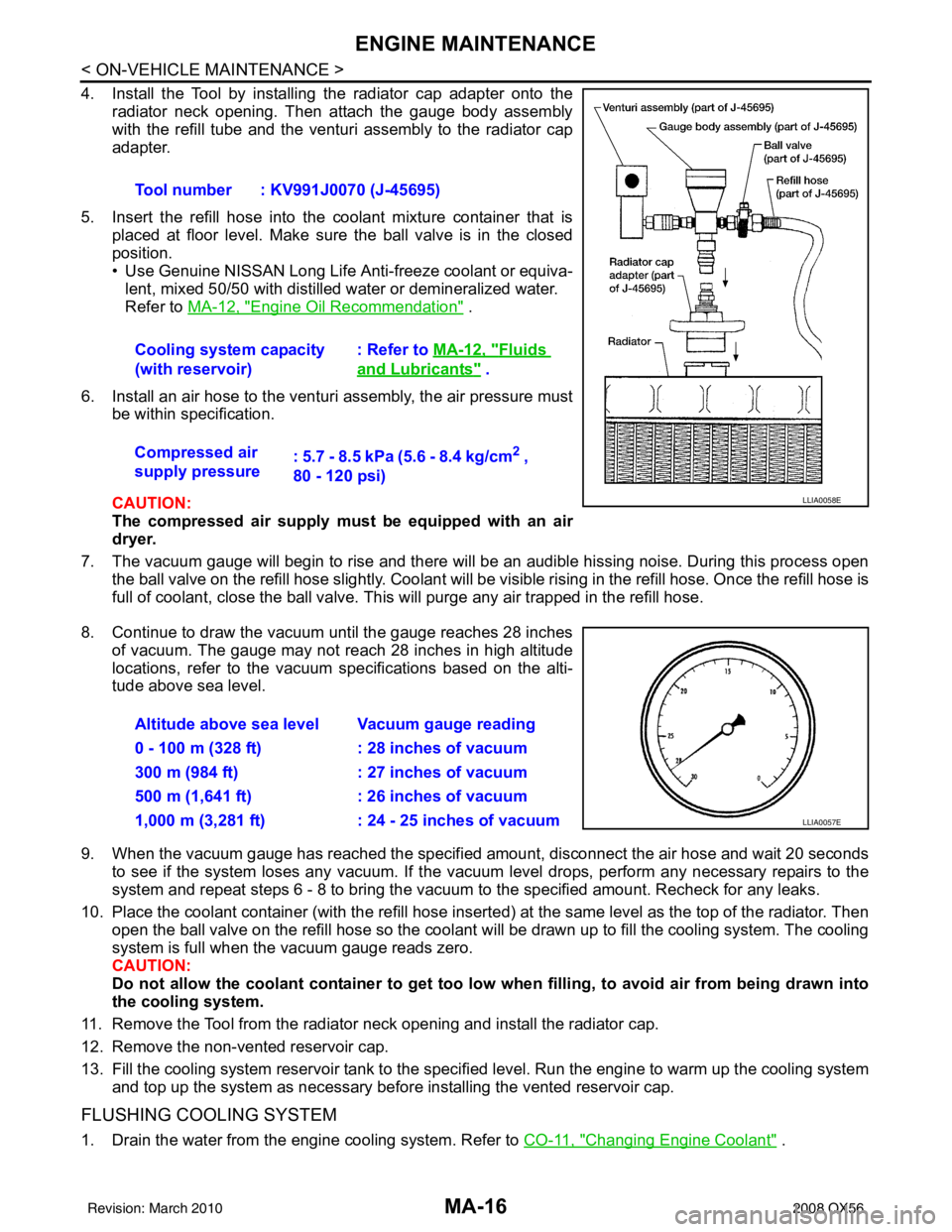

4. Install the Tool by installing the radiator cap adapter onto theradiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or equiva-

lent, mixed 50/50 with distilled water or demineralized water.

Refer to MA-12, "

Engine Oil Recommendation" .

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air

dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, refer to the vacuum specifications based on the alti-

tude above sea level.

9. When the vacuum gauge has reached the specifi ed amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

10. Place the coolant container (with the refill hose insert ed) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening and install the radiator cap.

12. Remove the non-vented reservoir cap.

13. Fill the cooling system reservoir tank to the specif ied level. Run the engine to warm up the cooling system

and top up the system as necessary before installing the vented reservoir cap.

FLUSHING COOLING SYSTEM

1. Drain the water from the engine cooling system. Refer to CO-11, "Changing Engine Coolant" .

Tool number : KV991J0070 (J-45695)

Cooling system capacity

(with reservoir)

: Refer to

MA-12, "

Fluids

and Lubricants" .

Compressed air

supply pressure : 5.7 - 8.5 kPa (5.6 - 8.4 kg/cm

2 ,

80 - 120 psi)

LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

Revision: March 2010 2008 QX56

Page 2707 of 4083

MWI-62

< ECU DIAGNOSIS >

COMBINATION METER

DTC Index

INFOID:0000000001691312

Function Specifications

Speedometer

Zero indication.

Tachometer

Fuel gauge

Engine coolant temperature gauge

Engine oil pressure gauge

Voltage gauge

A/T oil temperature gauge

Illumination control

Meter illumination Change to nighttime mode when communication is lost.

Segment LCD Odometer

Freeze current indication.

A/T position Display turns off.

Buzzer Buzzer turns off.

Warning lamp/indicator lamp ABS warning lamp

Lamp turns on when communication is lost.

Brake warning lamp

VDC OFF indicator lamp

SLIP indicator lamp

A/T CHECK warning lamp

Lamp turns off when communication is lost.

Oil pressure/coolant temperature

warning lamp

Light indicator

Malfunction indicator lamp

Master warning lamp

Air bag warning lamp

High beam indicator

Turn signal indicator lamp

CRUISE indicator lamp

Driver and passenger seat belt warn-

ing lamp

Lamp turns off when disconnected.

Charge warning lamp

Security indicator lamp

4WD indicator lamp

AT P i n d i c a t o r l a m p

CK SUSP warning lamp

Low tire pressure warning lamp

Lamp will flash every second for 1 minute and then stay on con-

tinuously thereafter.

CONSULT-III display

MalfunctionReference

page

CAN COMM CIRC

[U1000] Malfunction is detected in CAN communication.

CAUTION:

Even when there is no malfunction on CAN communication system, malfunction may be

misinterpreted when battery has low voltage (when maintaining 7 - 8 V for about 2 sec-

onds) or 10A fuse [No. 19, located in

the fuse block (J/B)] is disconnected. MWI-28

VEHICLE SPEED

CIRC

[B2205]Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction on speed signal system, malfunction may be misin-

terpreted when battery has lo

w voltage (when maintaining 7 - 8 V for about 2 seconds). MWI-29

Revision: March 2010

2008 QX56

Page 3025 of 4083

SQUEAK AND RATTLE TROUBLE DIAGNOSESRF-41

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half- clutch on M/T model, drive position A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool (Chassis Ear: J-39570, Engine Ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from. Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to RF-42, "

Inspection Procedure".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A Nissan Squeak and Rattle Kit (J-43980) is av ailable through your authorized Nissan Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

The following materials are contained in the Niss an Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94 ×5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-

71L02: 15 ×25 mm (0.59 ×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-

50Y00: 10 mm (0.39 in) thick, 50 ×50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59 ×0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Revision: March 2010 2008 QX56

Page 3119 of 4083

SCS-36

< SYMPTOM DIAGNOSIS >

SUSPENSION CONTROL SYSTEM INOPERATIVE

SUSPENSION CONTROL SYSTEM INOPERATIVE

DescriptionINFOID:0000000001732003

The suspension control system does not activate. It does not raise or lower the vehicle in response to ride

height changes.

Diagnosis ProcedureINFOID:0000000001732004

1.SUSPENSION CONTROL UNIT PO WER AND GROUND INSPECTION

Check the suspension control unit power and ground supply. Refer to SCS-17, "

SUSPENSION CONTROL

UNIT : Diagnosis Procedure".

Does the suspension control unit power and ground pass inspection?

YES >> GO TO 2

NO >> Repair or replace the malfunctioning part.

2.CHECK HEIGHT SENSOR SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Turn ignition switch ON.

2. Select "HEIGT SEN" of AI R LEVELIZER data monitor item.

3. Check the monitor status.

Is the height sensor voltage normal?

YES >> GO TO 3

NO >> Check height sensor signal circuit. Refer to SCS-22, "

Diagnosis Procedure" .

3.CHECK GENERATOR "L" CIRCUIT SIGNAL

CONSULT-III DATA MONITOR

1. Start the engine.

2. Select "ACG L" of AIR LE VELIZER data monitor item.

3. Check the monitor status.

Is the generator "L" signal operating normally?

YES >> GO TO 4.

NO >> Check generator L circuit. Refer to CHG-14, "

Diagnosis Procedure"

4.SUSPENSION AIR COMPRESSOR POWER AND GROUND INSPECTION

Check the suspension air compressor power and ground supply. Refer to SCS-17, "

SUSPENSION AIR COM-

PRESSOR : Diagnosis Procedure".

Does the suspension air compressor power and ground pass inspection?

YES >> System is operating normally.

NO >> Repair or replace the malfunctioning part. HEIGT SEN

: 0.2V - 4.8V

ACG L: OFF with charge light OFF

: ON with charge light ON

Revision: March 2010

2008 QX56

Page 3160 of 4083

SE-38

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to SE-39, "

Generic Squeak and Rattle Troubleshooting" .

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A NISSAN Squeak and Rattle Kit (J-43980) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94× 5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-71L02: 15 ×25

mm (0.59× 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50× 50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTH TAPE

Used to insulate where movemen t does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59× 0.98 in) pad/68239-13E00: 5 mm (0.20 in ) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for inst rument panel applications.

Revision: March 2010 2008 QX56