engine oil INFINITI QX56 2008 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 1831 of 4083

EM-28

< ON-VEHICLE REPAIR >

INTAKE MANIFOLD

• Tighten the intake manifold bolts in numerical order as shown.

• Install the EVAP canister purge control solenoid valve connector with it facing front of engine.

• Tighten the electronic throttle control actuator bolts of the electric throttle control actuator equally and diago-

nally in several steps.

• After installation perform procedure in "INSPECTION AFTER INSTALLATION".

• Install the water hose so that its overlap width for connection is between 27 mm (1.06 in) and 32 mm (1.26 in) (target: 27 mm 1.06 in).

Connecting Quick Connector of Fuel Tube

Install quick connector as follows (the steps are t he same for quick connectors on both engine side and vehi-

cle side except for the quick connector cap).

1. Make sure no foreign substances are deposited in and around tube and quick connector, and they are not damaged.

2. Thinly apply new engine oil around the fuel tube from tip end to the spool end.

3. Align center to insert quick connector straight into fuel tube. • Insert until the paint mark for engagement identification (white)goes completely inside quick connector so that you cannot see

it from the straight side of the connected part. Use a mirror to

check this where it is not possible to view directly from the

straight side, such as quick connector on vehicle side.

• Insert fuel tube into quick connector until top spool is com- pletely inside quick connector, and 2nd level spool exposes

right below quick connector on engine side.

CAUTION:

• Hold "A" position in illustration when inserting fuel tubeinto quick connector.

• Carefully align center to avoid inclined insertion to pre-

vent damage to O-ring inside quick connector.

• Insert until you hear a "click" sound and actually feel the

engagement.

• To avoid misidentification of engagement with a similar

sound, be sure to pe rform the next step.

4. Pull quick connector by hand holding "A" position. Make sure it is completely engaged (connected) so that

it does not come out from fuel tube.

NOTE:

Recommended pulling force is 50 N (5.1 kg, 11.2 lb).

KBIA2462E

PBIC0017E

KBIA0272E

Revision: March 2010 2008 QX56

Page 1834 of 4083

EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-31

< ON-VEHICLE REPAIR >

C

D E

F

G H

I

J

K L

M A

EM

NP

O

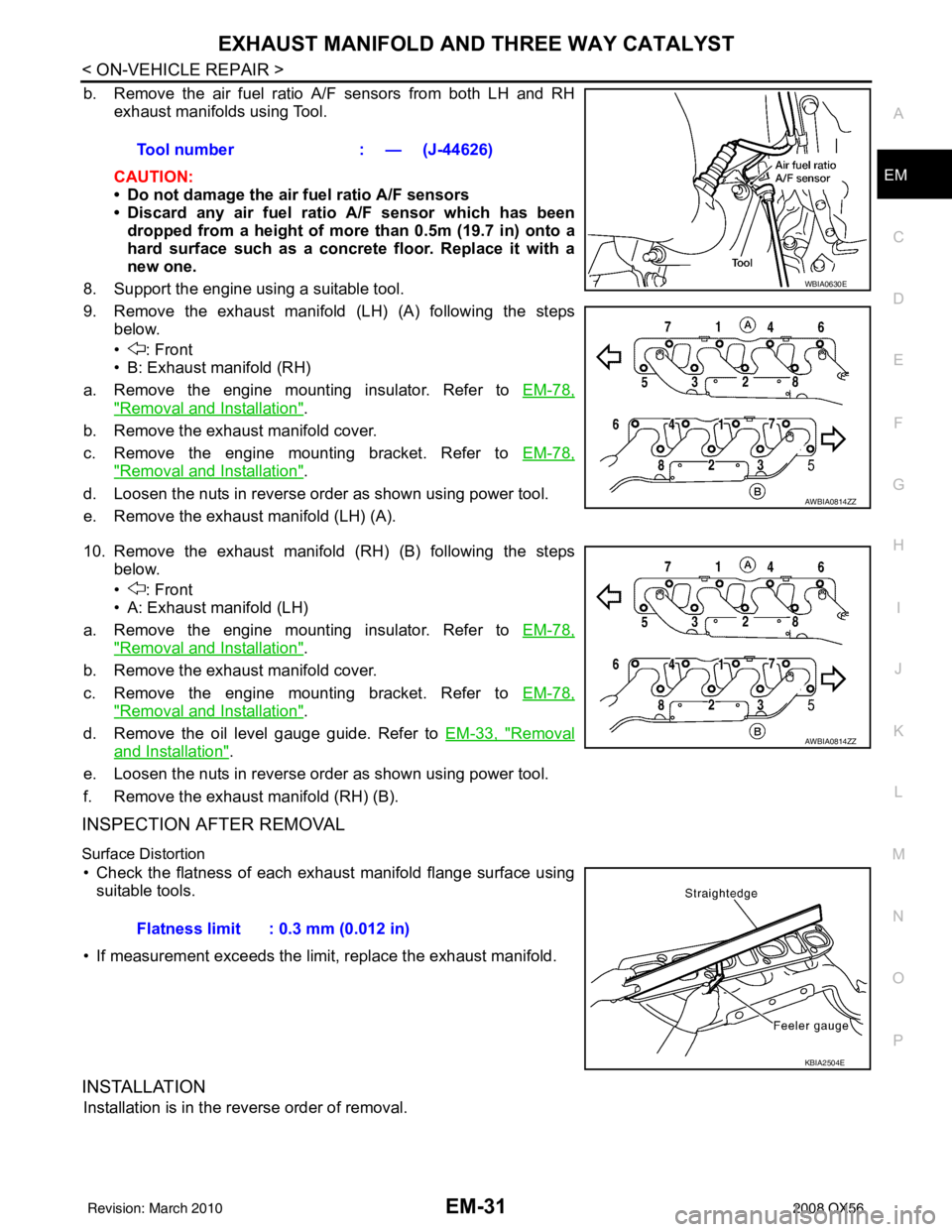

b. Remove the air fuel ratio A/F sensors from both LH and RH

exhaust manifolds using Tool.

CAUTION:

• Do not damage the air fuel ratio A/F sensors

• Discard any air fuel rati o A/F sensor which has been

dropped from a height of more than 0.5m (19.7 in) onto a

hard surface such as a concrete floor. Replace it with a

new one.

8. Support the engine using a suitable tool.

9. Remove the exhaust manifold (LH) (A) following the steps below.

• : Front

• B: Exhaust manifold (RH)

a. Remove the engine mounting insulator. Refer to EM-78,

"Removal and Installation".

b. Remove the exhaust manifold cover.

c. Remove the engine mounting bracket. Refer to EM-78,

"Removal and Installation".

d. Loosen the nuts in reverse order as shown using power tool.

e. Remove the exhaust manifold (LH) (A).

10. Remove the exhaust manifold (RH) (B) following the steps below.

• : Front

• A: Exhaust manifold (LH)

a. Remove the engine mounting insulator. Refer to EM-78,

"Removal and Installation".

b. Remove the exhaust manifold cover.

c. Remove the engine mounting bracket. Refer to EM-78,

"Removal and Installation".

d. Remove the oil level gauge guide. Refer to EM-33, "

Removal

and Installation".

e. Loosen the nuts in reverse order as shown using power tool.

f. Remove the exhaust manifold (RH) (B).

INSPECTION AFTER REMOVAL

Surface Distortion

• Check the flatness of each exhaust manifold flange surface using suitable tools.

• If measurement exceeds the limit, replace the exhaust manifold.

INSTALLATION

Installation is in the reverse order of removal. Tool number

: — (J-44626)

WBIA0630E

AWBIA0814ZZ

AWBIA0814ZZ

Flatness limit : 0.3 mm (0.012 in)

KBIA2504E

Revision: March 2010 2008 QX56

Page 1836 of 4083

OIL PAN AND OIL STRAINEREM-33

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

OIL PAN AND OIL STRAINER

Removal and InstallationINFOID:0000000001538816

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the engine oil when the engine is hot.

1. Remove the engine. Refer to

EM-78, "

Removal and Installation".

2. Remove the oil pan (lower) using the following steps.

a. Remove the oil pan (lower) bolts using power tool.

1. Oil pan (upper) 2. O-ring3. O-ring

4. O-ring 5. O-ring (with collar)6. Oil level gauge guide

7. Oil level gauge 8. O-ring9. Connector bolt

10. Oil filter 11. Oil cooler12. Relief valve

13. Oil pressure switch 14. Gasket15. Drain plug

16. Oil pan (lower) 17. Oil strainer

KBIA2465E

KBIA2466E

Revision: March 2010 2008 QX56

Page 1839 of 4083

EM-36

< ON-VEHICLE REPAIR >

OIL PAN AND OIL STRAINER

4. Install the oil pan drain plug.

5. Install engine assembly. Refer to EM-78, "

Removal and Installation".

• Do not fill the engine oil for at least 30 minutes after oil pan is installed.

INSPECTION AFTER INSTALLATION

1. Check engine oil level and add engine oil if necessary. Refer to LU-8, "Inspection".

2. Start the engine, and check for leaks of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check engine oil level again.

Revision: March 2010 2008 QX56

Page 1840 of 4083

IGNITION COILEM-37

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

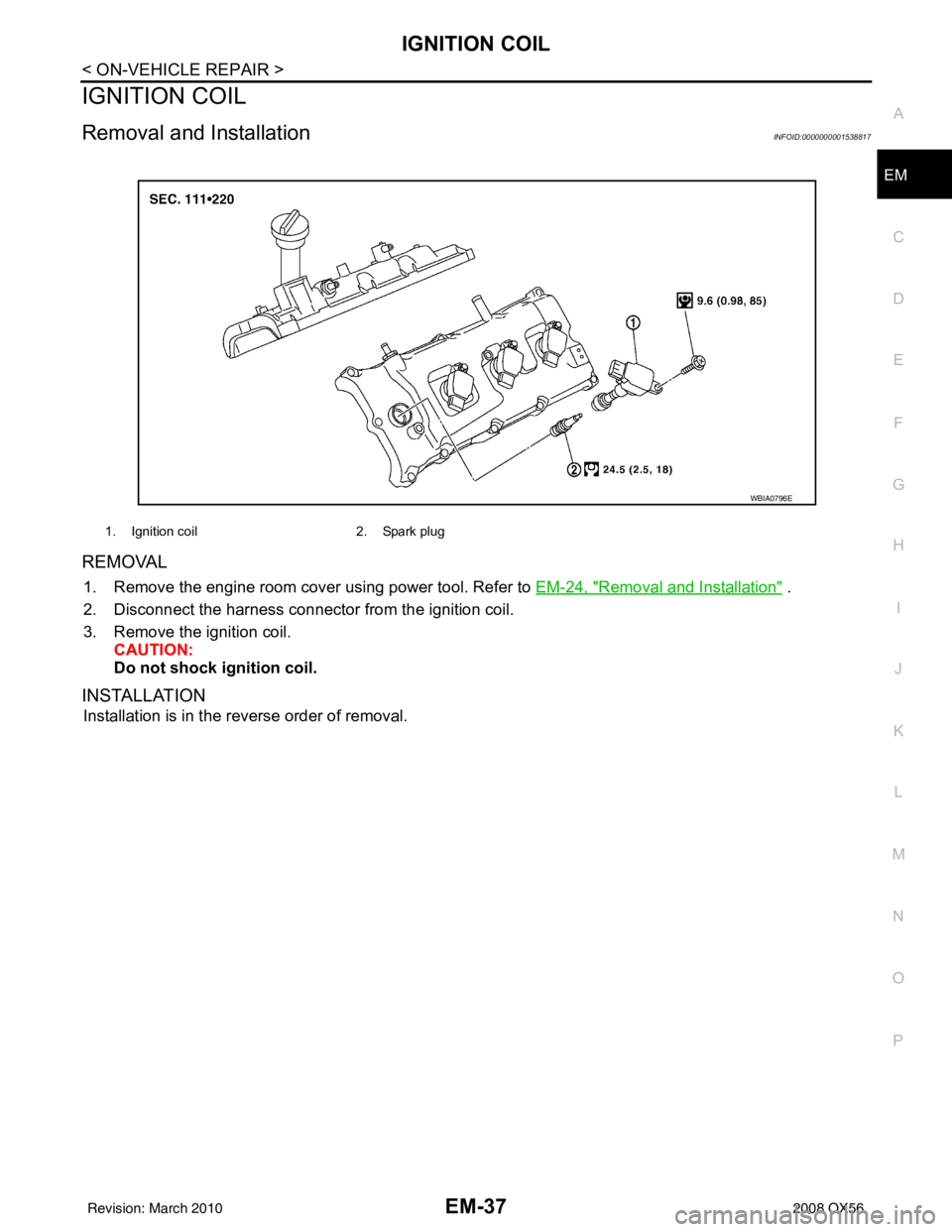

IGNITION COIL

Removal and InstallationINFOID:0000000001538817

REMOVAL

1. Remove the engine room cover using power tool. Refer to

EM-24, "Removal and Installation" .

2. Disconnect the harness connector from the ignition coil.

3. Remove the ignition coil. CAUTION:

Do not shock ignition coil.

INSTALLATION

Installation is in the reverse order of removal.

1. Ignition coil 2. Spark plug

WBIA0796E

Revision: March 2010 2008 QX56

Page 1841 of 4083

EM-38

< ON-VEHICLE REPAIR >

ROCKER COVER

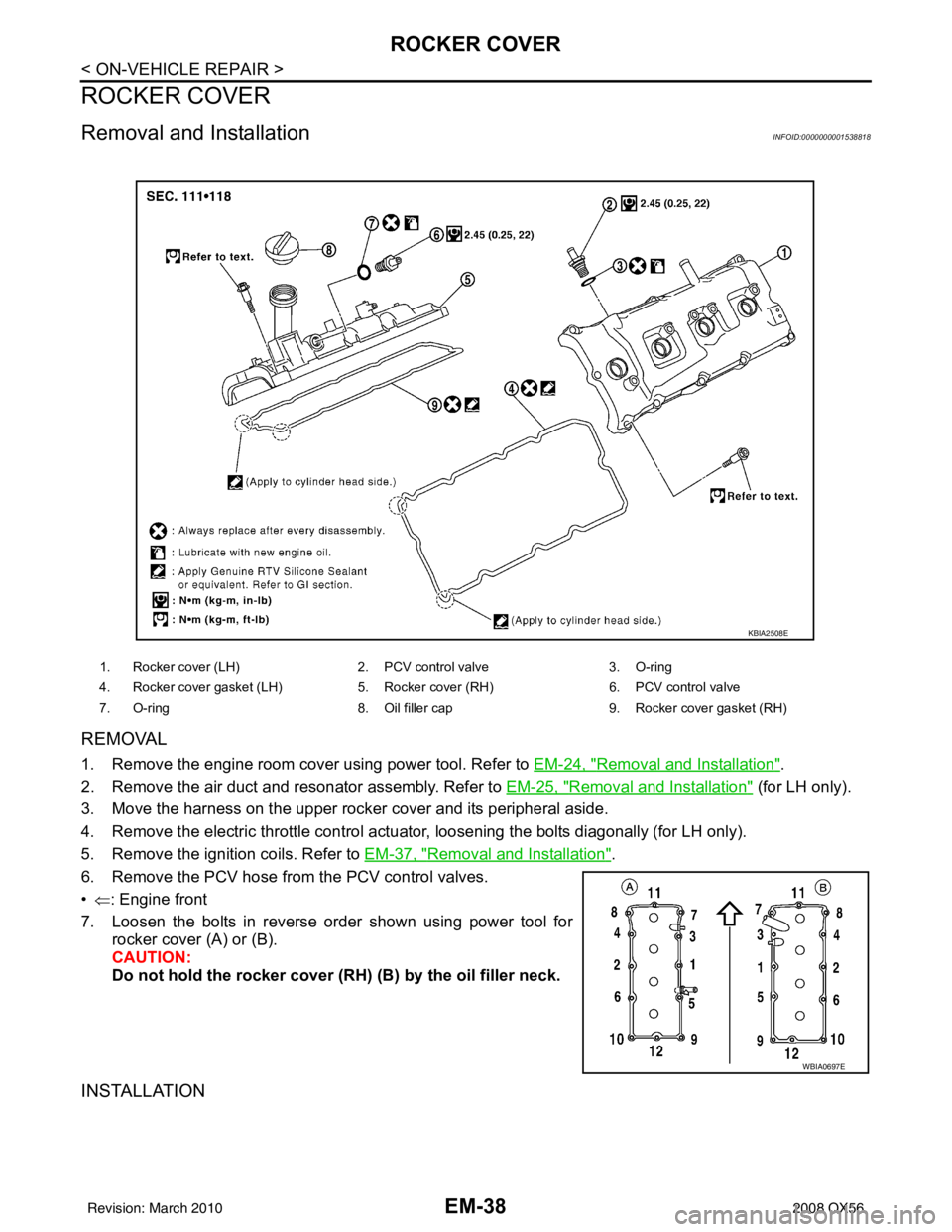

ROCKER COVER

Removal and InstallationINFOID:0000000001538818

REMOVAL

1. Remove the engine room cover using power tool. Refer to EM-24, "Removal and Installation".

2. Remove the air duct and resonator assembly. Refer to EM-25, "

Removal and Installation" (for LH only).

3. Move the harness on the upper rocker cover and its peripheral aside.

4. Remove the electric throttle control actuat or, loosening the bolts diagonally (for LH only).

5. Remove the ignition coils. Refer to EM-37, "

Removal and Installation".

6. Remove the PCV hose from the PCV control valves.

• ⇐ : Engine front

7. Loosen the bolts in reverse order shown using power tool for rocker cover (A) or (B).

CAUTION:

Do not hold the rocker cover ( RH) (B) by the oil filler neck.

INSTALLATION

1. Rocker cover (LH) 2. PCV control valve3. O-ring

4. Rocker cover gasket (LH) 5. Rocker cover (RH)6. PCV control valve

7. O-ring 8. Oil filler cap9. Rocker cover gasket (RH)

KBIA2508E

WBIA0697E

Revision: March 2010 2008 QX56

Page 1844 of 4083

FUEL INJECTOR AND FUEL TUBEEM-41

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

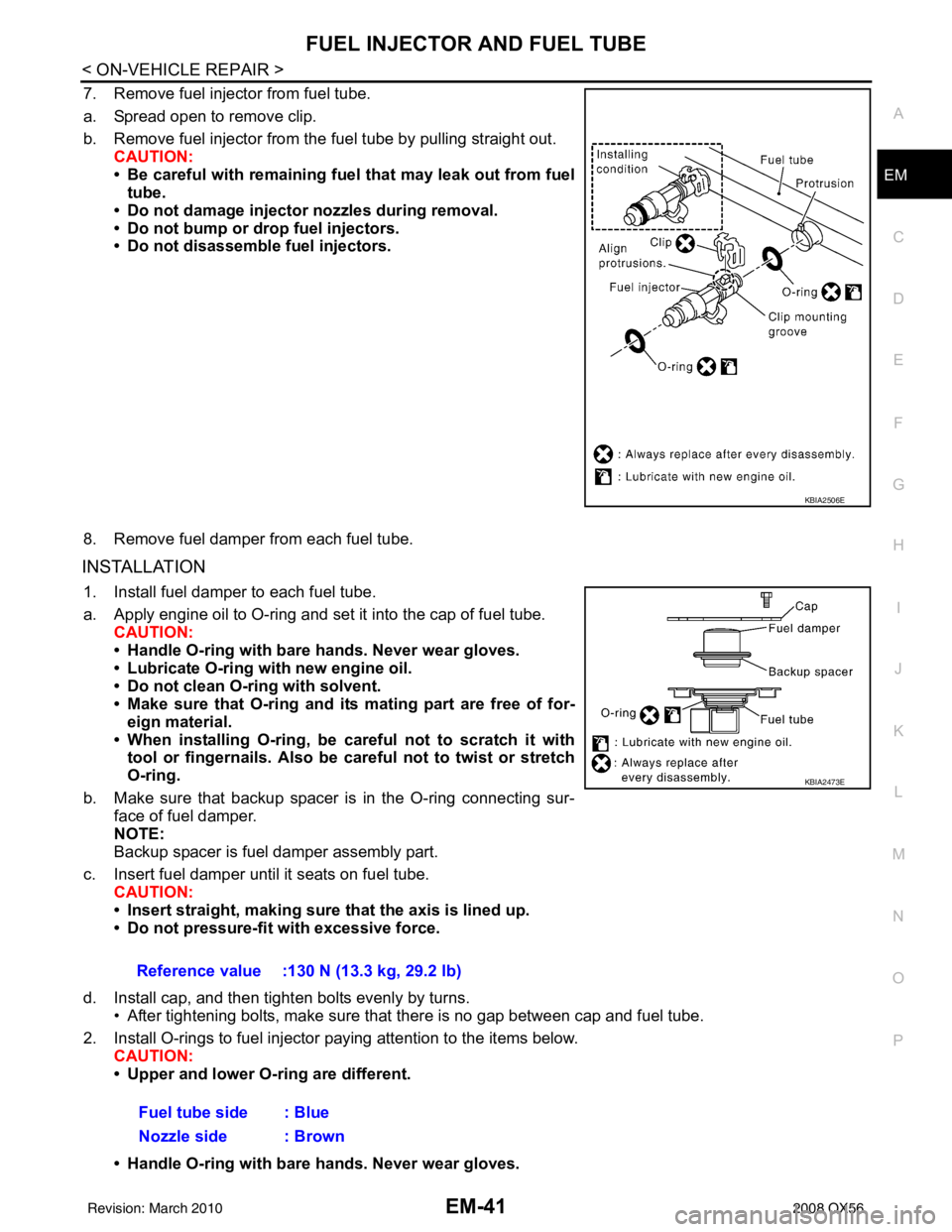

7. Remove fuel injector from fuel tube.

a. Spread open to remove clip.

b. Remove fuel injector from the

fuel tube by pulling straight out.

CAUTION:

• Be careful with remaining fuel that may leak out from fuel

tube.

• Do not damage injector nozzles during removal.

• Do not bump or drop fuel injectors.

• Do not disassemble fuel injectors.

8. Remove fuel damper from each fuel tube.

INSTALLATION

1. Install fuel damper to each fuel tube.

a. Apply engine oil to O-ring and set it into the cap of fuel tube. CAUTION:

• Handle O-ring with bare hands. Never wear gloves.

• Lubricate O-ring with new engine oil.

• Do not clean O-ring with solvent.

• Make sure that O-ring and its mating part are free of for- eign material.

• When installing O-ring, be car eful not to scratch it with

tool or fingernails. Also be careful not to twist or stretch

O-ring.

b. Make sure that backup spacer is in the O-ring connecting sur- face of fuel damper.

NOTE:

Backup spacer is fuel damper assembly part.

c. Insert fuel damper until it seats on fuel tube. CAUTION:

• Insert straight, making sure that the axis is lined up.

• Do not pressure-fit with excessive force.

d. Install cap, and then tighten bolts evenly by turns. • After tightening bolts, make sure that there is no gap between cap and fuel tube.

2. Install O-rings to fuel injector paying attention to the items below. CAUTION:

• Upper and lower O-ring are different.

• Handle O-ring with bare hands. Never wear gloves.

KBIA2506E

Reference value :130 N (13.3 kg, 29.2 lb)

Fuel tube side : Blue

Nozzle side : Brown

KBIA2473E

Revision: March 2010 2008 QX56

Page 1845 of 4083

EM-42

< ON-VEHICLE REPAIR >

FUEL INJECTOR AND FUEL TUBE

• Lubricate O-ring with new engine oil.

• Do not clean O-ring with solvent.

• Make sure that O-ring and its mating part are free of foreign material.

• When installing O-ring, be careful not to scratch it with tool or fingernails. Also be careful not to

twist or stretch O-ring. If O-ring was stretc hed while it was being attached, do not insert it

quickly into fuel tube.

• Insert O-ring straight into fuel tube. Do not angle or twist it.

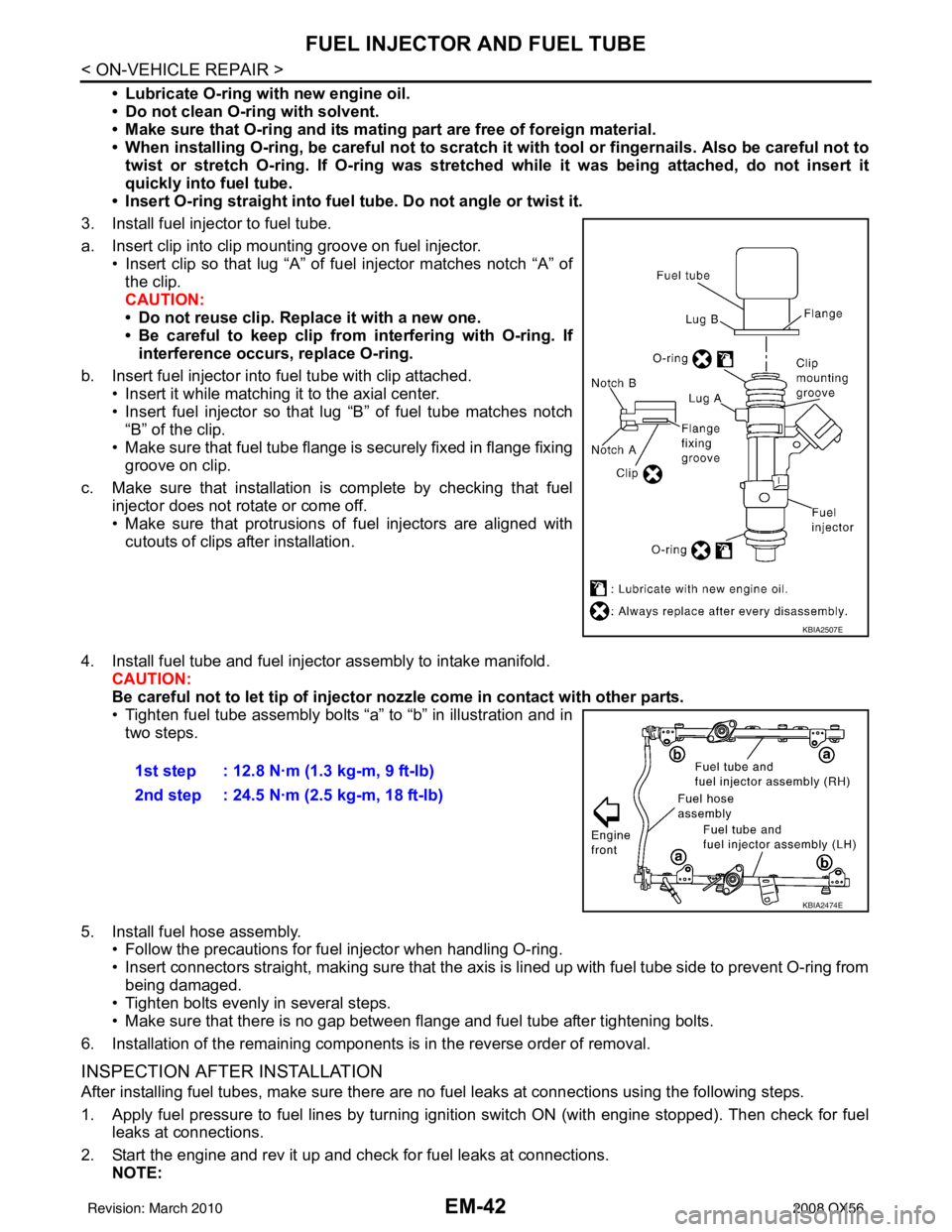

3. Install fuel injector to fuel tube.

a. Insert clip into clip mounting groove on fuel injector. • Insert clip so that lug “A” of fuel injector matches notch “A” ofthe clip.

CAUTION:

• Do not reuse clip. Replace it with a new one.

• Be careful to keep clip from interfering with O-ring. Ifinterference occurs, replace O-ring.

b. Insert fuel injector into fuel tube with clip attached. • Insert it while matching it to the axial center.

• Insert fuel injector so that lug “B” of fuel tube matches notch

“B” of the clip.

• Make sure that fuel tube flange is securely fixed in flange fixing groove on clip.

c. Make sure that installation is complete by checking that fuel injector does not rotate or come off.

• Make sure that protrusions of fuel injectors are aligned withcutouts of clips after installation.

4. Install fuel tube and fuel injector assembly to intake manifold. CAUTION:

Be careful not to let tip of injector nozzle come in contact with other parts.

• Tighten fuel tube assembly bolts “a” to “b” in illustration and in

two steps.

5. Install fuel hose assembly. • Follow the precautions for fuel injector when handling O-ring.

• Insert connectors straight, making sure that the axis is lined up with fuel tube side to prevent O-ring from

being damaged.

• Tighten bolts evenly in several steps.

• Make sure that there is no gap between flange and fuel tube after tightening bolts.

6. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

After installing fuel tubes, make sure there are no fuel leaks at connections using the following steps.

1. Apply fuel pressure to fuel lines by turning ignition switch ON (with engine stopped). Then check for fuel leaks at connections.

2. Start the engine and rev it up and check for fuel leaks at connections. NOTE:

KBIA2507E

1st step : 12.8 N·m (1.3 kg-m, 9 ft-lb)

2nd step : 24.5 N·m (2.5 kg-m, 18 ft-lb)

KBIA2474E

Revision: March 2010 2008 QX56

Page 1848 of 4083

TIMING CHAINEM-45

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Removal and InstallationINFOID:0000000001538821

NOTE:

• To remove timing chain and associated parts, start with those on the LH bank. The procedure for removing

parts on the RH bank is omitted because it is t he same as that for removal on the LH bank.

• To install timing chain and associated parts, start with those on the RH bank. The procedure for installing parts on the LH bank is omitted because it is t he same as that for installation on the RH bank.

REMOVAL

1. Remove the engine assembly from the vehicle. Refer to EM-78, "Removal and Installation".

2. Remove the following components and related parts: • Drive belt auto tensioner and idler pulley. Refer to EM-13, "

Removal and Installation".

• Thermostat housing and water hose. Refer to CO-22, "

Removal and Installation".

• Power steering oil pump bracket. Refer to ST-26, "

Removal and Installation".

• Oil pan (lower), (upper) and oil strainer. Refer to EM-33, "

Removal and Installation".

• Ignition coil. Refer to EM-37, "

Removal and Installation".

• Rocker cover. Refer to EM-38, "

Removal and Installation".

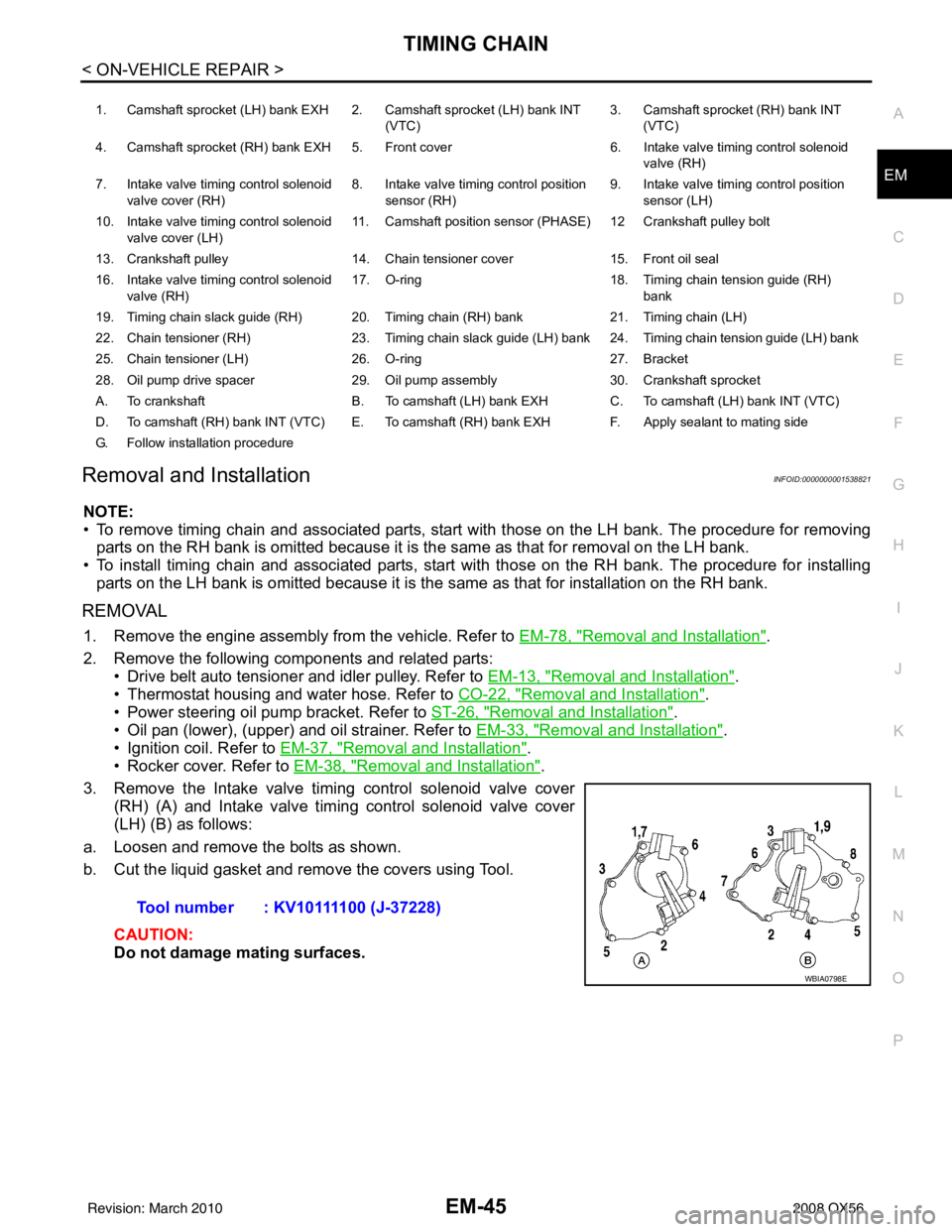

3. Remove the Intake valve timing control solenoid valve cover (RH) (A) and Intake valve timing control solenoid valve cover

(LH) (B) as follows:

a. Loosen and remove the bolts as shown.

b. Cut the liquid gasket and remove the covers using Tool.

CAUTION:

Do not damage mating surfaces.

1. Camshaft sprocket (LH) bank EXH 2. Camshaft sprocket (LH) bank INT (VTC)3. Camshaft sprocket (RH) bank INT

(VTC)

4. Camshaft sprocket (RH) bank EXH 5. Front cover 6. Intake valve timing control solenoid

valve (RH)

7. Intake valve timing control solenoid valve cover (RH) 8. Intake valve timing control position

sensor (RH) 9. Intake valve timing control position

sensor (LH)

10. Intake valve timing control solenoid valve cover (LH) 11. Camshaft position

sensor (PHASE) 12 Cran kshaft pulley bolt

13. Crankshaft pulley 14. Chain tensioner cover 15. Front oil seal

16. Intake valve timing control solenoid valve (RH) 17. O-ring

18. Timing chain tension guide (RH)

bank

19. Timing chain slack guide (RH) 20. Timing chain (RH) bank 21. Timing chain (LH)

22. Chain tensioner (RH) 23. Timing chain slack guide (LH) bank 24. Timing chain tension guide (LH) bank

25. Chain tensioner (LH) 26. O-ring 27. Bracket

28. Oil pump drive spacer 29. Oil pump assembly 30. Crankshaft sprocket

A. To crankshaft B. To camshaft (LH) bank EXH C. To camshaft (LH) bank INT (VTC)

D. To camshaft (RH) bank INT (VTC) E. To camshaft (RH) bank EXH F. Apply sealant to mating side

G. Follow installation procedure

Tool number : KV10111100 (J-37228)

WBIA0798E

Revision: March 2010 2008 QX56

Page 1853 of 4083

EM-50

< ON-VEHICLE REPAIR >

TIMING CHAIN

7. Install the oil pump drive spacer as follows:• Install so that the front mark on the front edge of the oil pumpdrive spacer faces the front of the engine.

• Insert the oil pump drive spacer according to the directions of the crankshaft key and the two flat surfaces of the oil pump

inner rotor.

• If the positional relationship does not allow the insertion, rotate the oil pump inner rotor to allow the oil pump drive spacer to

be inserted.

8. Install the front oil seal using suitable tool. CAUTION:

Do not scratch or make burrs on the circumference of the

oil seal.

9. Install the chain tensioner cover. • Apply liquid gasket as shown.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-15, "

Recommended Chemical Products and Sealants".

10. Install the front cover as follows:

a. Install a new O-ring on the cylinder block.

KBIA2490E

PBIC0059E

KBIA2547E

KBIA2516E

Revision: March 2010 2008 QX56