air bleeding INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 421 of 4083

BR-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BR

A

B

BR

N

O P

CONTENTS

BRAKE SYSTEM

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Brake System ....................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

FUNCTION DIAGNOSIS ...............................6

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

6

NVH Troubleshooting Chart ................................ ......6

BASIC INSPECTION ....................................7

FRONT DISC B RAKE .................................... .....7

BRAKE PAD .......................................................... ......7

BRAKE PAD : Inspection ..........................................7

DISC ROTOR ......................................................... ......7

DISC ROTOR : Inspection ........................................7

REAR DISC BRAKE ...................................... .....9

BRAKE PAD .......................................................... ......9

BRAKE PAD : Inspection ..........................................9

DISC ROTOR ......................................................... ......9

DISC ROTOR : Inspection ........................................9

BRAKE BOOSTER ............................................10

Inspection ............................................................ ....10

VACUUM LINES ............................................. ....11

Inspection ............................................................ ....11

BRAKE MASTER CYLINDER ..........................12

On Board Inspection ................................................12

BRAKE TUBE AND HOSE ...............................13

Hydraulic Circuit ......................................................13

FRONT BRAKE ..................................................... ....13

FRONT BRAKE : Inspection ......................... ...........13

REAR BRAKE ........................................................ ....14

REAR BRAKE : Inspection ........................ ..............14

ON-VEHICLE MAINTEN ANCE ....................15

BRAKE PEDAL .................................................15

Inspection and Adjustment .................................. ....15

BRAKE FLUID ..................................................17

On Board Inspection ............................................ ....17

Drain and Refill ........................................................17

Bleeding Brake System ...........................................17

ON-VEHICLE REPAIR .................................19

BRAKE PEDAL .................................................19

Removal and Installation ..................................... ....19

BRAKE TUBE AND HOSE ...............................21

Hydraulic Circuit ......................................................21

Removal and Installation of Front Brake Piping

and Brake Hose .......................................................

21

Removal and Installation of Rear Brake Piping

and Brake Hose .......................................................

22

Inspection After Installation .....................................23

BRAKE MASTER CYLINDER ..........................25

Removal and Installation .........................................25

BRAKE BOOSTER ...........................................26

Removal and Installation ..................................... ....26

VACUUM LINES ...............................................28

Revision: March 2010 2008 QX56

Page 437 of 4083

BRAKE FLUIDBR-17

< ON-VEHICLE MAINTENANCE >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE FLUID

On Board InspectionINFOID:0000000004894493

LEVEL CHECK

• Make sure the fluid level in reservoir tank is between MAX and MIN lines as shown.

• Visually check around reservoir tank for fluid leaks.

• If fluid level is excessively low, check brake system for leaks.

• If brake warning lamp remains illuminated after parking brake pedal is released, check brake system for fluid leaks.

Drain and RefillINFOID:0000000004894494

CAUTION:

• Refill with new brake fluid. Refer to MA-12, "

Fluids and Lubricants".

• Do not reuse drained brake fluid.

• Do not let brake fluid splash on the painted surfaces of the body. This might damage the paint, so if

splashing it, immediately wipe off the area and wash away with water.

• Before servicing, disconnect ABS actuator and electri c unit (control unit) connector or battery nega-

tive terminal.

1. Connect a vinyl tube to each bleed valve.

2. Depress brake pedal, loosen each bleed valve, and gradually remove brake fluid.

3. Make sure there is no foreign material in reservoir tank, and refill with new brake fluid.

4. Rest foot on brake pedal. Loosen bleed valve. Slowly depress pedal until it stops. Tighten bleed valve. Release brake pedal.

Repeat this process a few times, then pause to add new brake

fluid to master cylinder. Continue until new brake fluid flows out

of the bleed valve.

Bleed the air out of the brake hydraulic system. Refer to BR-17,

"Bleeding Brake System".

Bleeding Brake SystemINFOID:0000000004894495

CAUTION:

While bleeding, pay attention to master cylinder fluid level.

1. Turn ignition switch OFF and disconnect ABS actuator and electric unit (control unit) connector or battery

negative terminal.

2. Connect a vinyl tube to the rear right bleed valve.

LFIA0225E

SBR419C

SBR995

Revision: March 2010 2008 QX56

Page 443 of 4083

BRAKE TUBE AND HOSEBR-23

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

3. Remove brake tube from brake hose, using a suitable tool.

4. Remove lock plate and brake hose from bracket.

5. Remove union bolt and then remove brake hose from cylinder body.

INSTALLATION

1. Install brake hose by aligning with the protrusion on cylinderbody, then install the union bolt and new copper washers and

tighten to specification. Refer to BR-13, "

Hydraulic Circuit".

CAUTION:

Do not reuse copper washer.

2. Insert brake hose end through bracket, then secure it to bracket with lock plate.

3. Install brake tube to brake hose, then tighten the flare nut using a suitable tool. Refer to BR-13, "

Hydraulic Circuit".

4. Refill brake fluid and bleed air. Refer to BR-17, "

Bleeding Brake System".

5. Install rear wheel and tire. Refer to WT-48, "

Rotation".

Inspection After InstallationINFOID:0000000004894509

CAUTION:

Brake tubes and hoses are important safety parts. Always disassemble the parts and retighten their fit-

tings, if a brake fluid leak is detected. Replace applicable part with a new one, if a damaged part is

detected.

LFIA0213E

LFIA0212E

SFIA1137E

LFIA0213E

Revision: March 2010 2008 QX56

Page 445 of 4083

BRAKE MASTER CYLINDERBR-25

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE MASTER CYLINDER

Removal and InstallationINFOID:0000000004894510

REMOVAL

CAUTION:

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• Before removing brake master cylinder, depress the brake pedal 5-6 times with the key OFF to deplete vacuum in the booster.

1. Remove brake reservoir cap.

2. Disconnect harness connectors for fluid level sensor, front and rear pressure sensors.

3. Using suitable tool, disconnect brake tube from master cylinder assembly.

4. Remove master cylinder assembly nuts, and remove master cylinder assembly.

INSTALLATION

Installation is in the reverse order of removal.

• Refill brake fluid and bleed air. Refer to BR-17, "

Bleeding Brake System".

CAUTION:

• Refill with new brake fluid. Refer to MA-12, "

Fluids and Lubricants".

• Do not reuse drained brake fluid.

• Adjust brake pedal. Refer to BR-15, "

Inspection and Adjustment".

1. Reservoir cap 2. Fluid level sensor 3. Grommet

4. Master cylinder assembly 5. Rear pressure sensor6. Front pressure sensor

7. Seal 8. Reservoir tankB. Brake fluid

R. Rubber grease

AWFIA0415GB

Revision: March 2010 2008 QX56

Page 447 of 4083

BRAKE BOOSTERBR-27

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

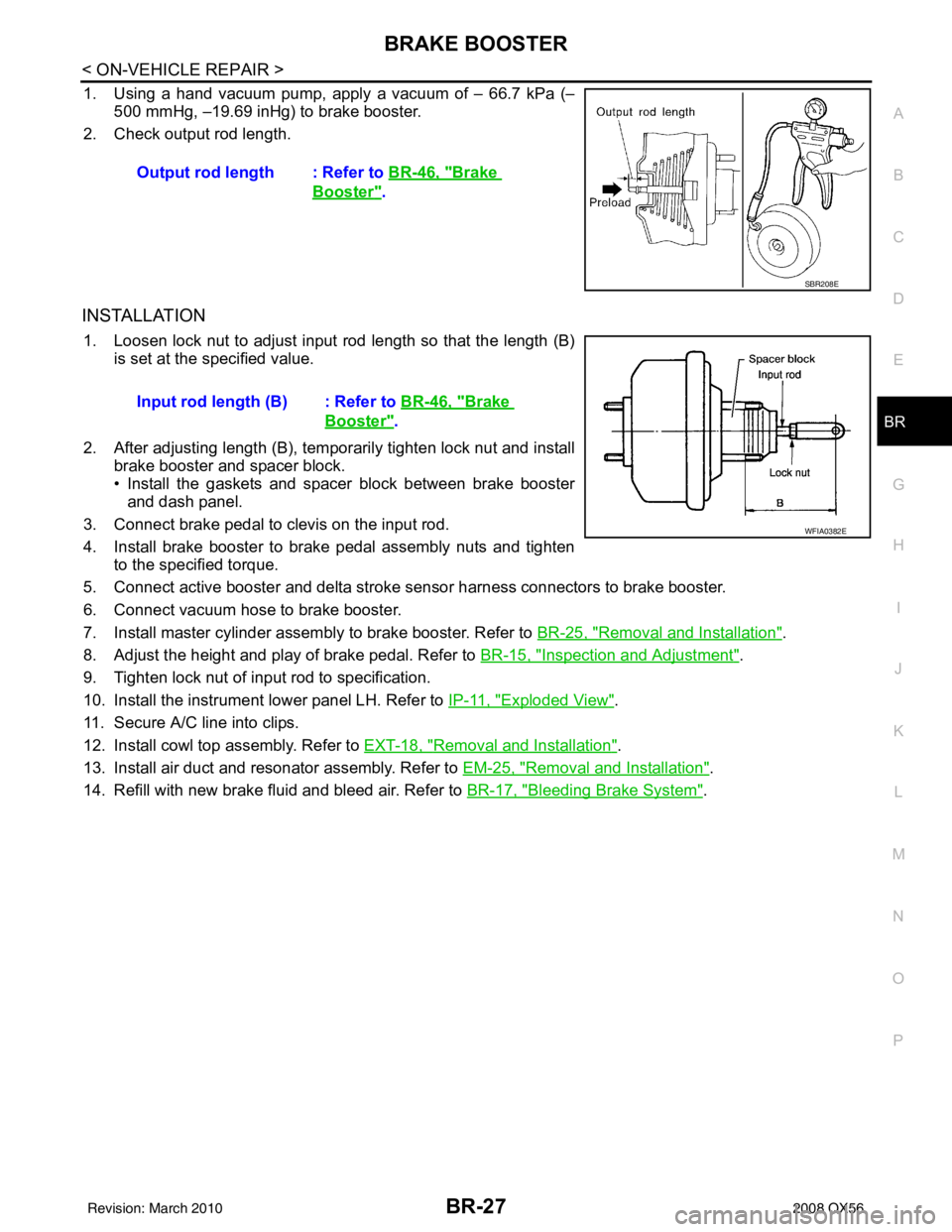

1. Using a hand vacuum pump, apply a vacuum of – 66.7 kPa (– 500 mmHg, –19.69 inHg) to brake booster.

2. Check output rod length.

INSTALLATION

1. Loosen lock nut to adjust input r od length so that the length (B)

is set at the specified value.

2. After adjusting length (B), temporarily tighten lock nut and install brake booster and spacer block.

• Install the gaskets and spacer block between brake boosterand dash panel.

3. Connect brake pedal to clevis on the input rod.

4. Install brake booster to brake pedal assembly nuts and tighten to the specified torque.

5. Connect active booster and delta stroke s ensor harness connectors to brake booster.

6. Connect vacuum hose to brake booster.

7. Install master cylinder assembly to brake booster. Refer to BR-25, "

Removal and Installation".

8. Adjust the height and play of brake pedal. Refer to BR-15, "

Inspection and Adjustment".

9. Tighten lock nut of input rod to specification.

10. Install the instrument lower panel LH. Refer to IP-11, "

Exploded View".

11. Secure A/C line into clips.

12. Install cowl top assembly. Refer to EXT-18, "

Removal and Installation".

13. Install air duct and resonator assembly. Refer to EM-25, "

Removal and Installation".

14. Refill with new brake fluid and bleed air. Refer to BR-17, "

Bleeding Brake System".

Output rod length : Refer to

BR-46, "

Brake

Booster".

SBR208E

Input rod length (B) : Refer to BR-46, "Brake

Booster".

WFIA0382E

Revision: March 2010 2008 QX56

Page 453 of 4083

FRONT DISC BRAKEBR-33

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

3. Install brake hose to brake caliper assembly using new copper washers. Align the brake hose to the projection as shown and

tighten union bolts to the specified torque.

CAUTION:

• Do not reuse copper washers.

• Securely attach brake hose to projection on cylinderbody.

4. Refill with new brake fluid and bleed air. Refer to BR-17, "

Bleeding Brake System".

5. Check front disc brake for drag and correct as necessary.

6. Install front wheel and tires. Refer to WT-48, "

Rotation".

SFIA2431E

Revision: March 2010 2008 QX56

Page 456 of 4083

BR-36

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

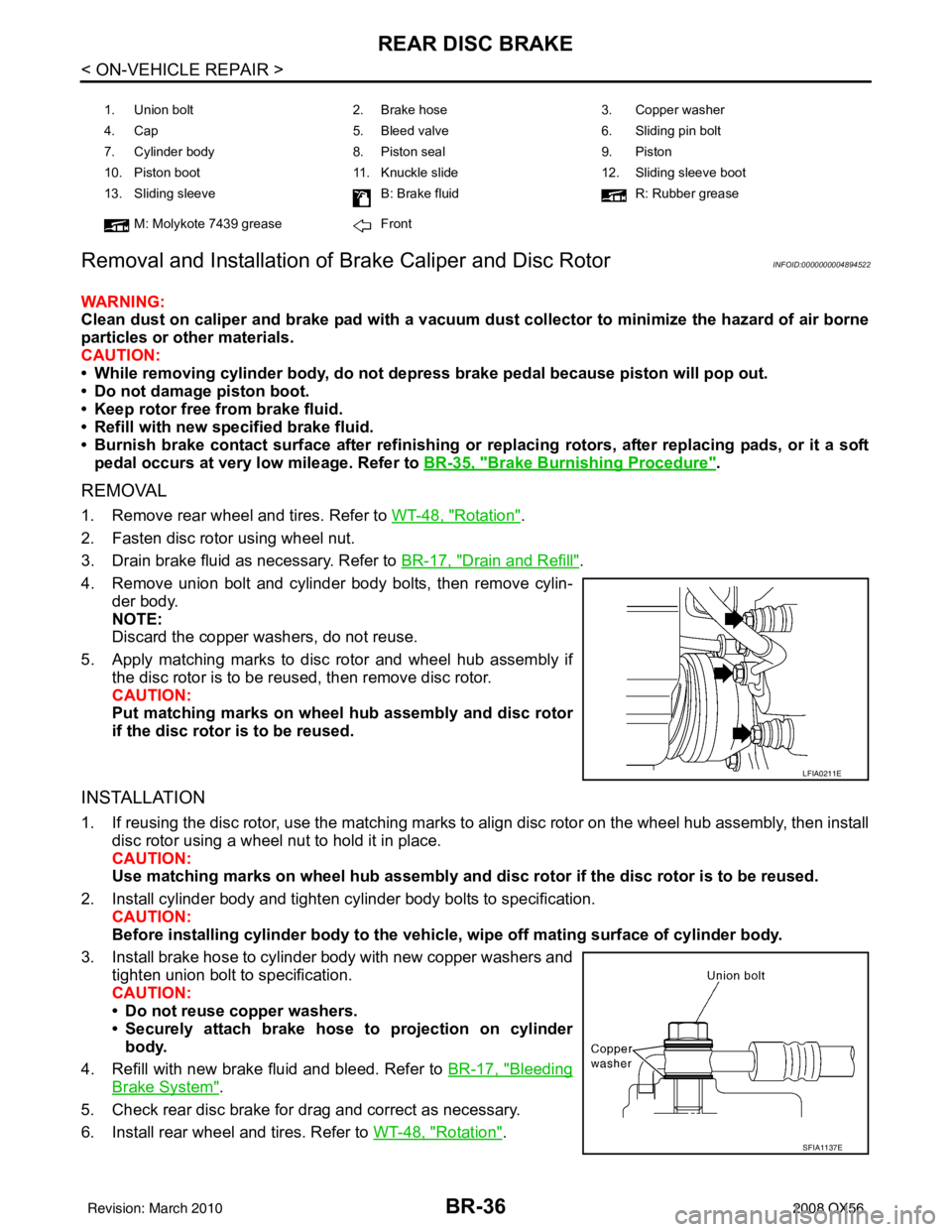

Removal and Installation of Brake Caliper and Disc Rotor

INFOID:0000000004894522

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder body, do not depress brake pedal because piston will pop out.

• Do not damage piston boot.

• Keep rotor free from brake fluid.

• Refill with new specified brake fluid.

• Burnish brake contact surface after refinishing or re placing rotors, after replacing pads, or it a soft

pedal occurs at very low mileage. Refer to BR-35, "

Brake Burnishing Procedure".

REMOVAL

1. Remove rear wheel and tires. Refer to WT-48, "Rotation".

2. Fasten disc rotor using wheel nut.

3. Drain brake fluid as necessary. Refer to BR-17, "

Drain and Refill".

4. Remove union bolt and cylinder body bolts, then remove cylin- der body.

NOTE:

Discard the copper washers, do not reuse.

5. Apply matching marks to disc rotor and wheel hub assembly if the disc rotor is to be reused, then remove disc rotor.

CAUTION:

Put matching marks on wheel hub assembly and disc rotor

if the disc rotor is to be reused.

INSTALLATION

1. If reusing the disc rotor, use the matching marks to align disc rotor on the wheel hub assembly, then install

disc rotor using a wheel nut to hold it in place.

CAUTION:

Use matching marks on wheel hub assembly and di sc rotor if the disc rotor is to be reused.

2. Install cylinder body and tighten cylinder body bolts to specification. CAUTION:

Before installing cylinder body to the vehic le, wipe off mating surface of cylinder body.

3. Install brake hose to cylinder body with new copper washers and tighten union bolt to specification.

CAUTION:

• Do not reuse copper washers.

• Securely attach brake hose to projection on cylinderbody.

4. Refill with new brake fluid and bleed. Refer to BR-17, "

Bleeding

Brake System".

5. Check rear disc brake for drag and correct as necessary.

6. Install rear wheel and tires. Refer to WT-48, "

Rotation".

1. Union bolt 2. Brake hose 3. Copper washer

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Cylinder body 8. Piston seal9. Piston

10. Piston boot 11. Knuckle slide 12. Sliding sleeve boot

13. Sliding sleeve B: Brake fluidR: Rubber grease

M: Molykote 7439 grease Front

LFIA0211E

SFIA1137E

Revision: March 2010 2008 QX56

Page 571 of 4083

![INFINITI QX56 2008 Factory Service Manual BRC-104

< SYMPTOM DIAGNOSIS >[VDC/TCS/ABS]

UNEXPECTED PEDAL REACTION

UNEXPECTED PEDAL REACTION

Diagnosis ProcedureINFOID:0000000001686376

1.CHECK BRAKE PEDAL STROKE

Check brake pedal stroke. Refer to INFINITI QX56 2008 Factory Service Manual BRC-104

< SYMPTOM DIAGNOSIS >[VDC/TCS/ABS]

UNEXPECTED PEDAL REACTION

UNEXPECTED PEDAL REACTION

Diagnosis ProcedureINFOID:0000000001686376

1.CHECK BRAKE PEDAL STROKE

Check brake pedal stroke. Refer to](/img/42/57030/w960_57030-570.png)

BRC-104

< SYMPTOM DIAGNOSIS >[VDC/TCS/ABS]

UNEXPECTED PEDAL REACTION

UNEXPECTED PEDAL REACTION

Diagnosis ProcedureINFOID:0000000001686376

1.CHECK BRAKE PEDAL STROKE

Check brake pedal stroke. Refer to BR-15, "

Inspection and Adjustment".

Is the stroke too large?

YES >> • Bleed air from brake tube and hose. Refer to BR-17, "Bleeding Brake System".

• Check brake pedal, brake booster, and master cylinder for mount play, looseness, brake system fluid leakage, etc. Refer to BR-15, "

Inspection and Adjustment" (brake pedal), BR-12, "On

Board Inspection" (master cylinder), BR-10, "Inspection" (brake booster).

NO >> GO TO 2

2.CHECK FUNCTION

Disconnect ABS actuator and electric unit (control unit) c onnector to deactivate ABS. Check if braking force is

normal in this condition. Connect connector after inspection.

Is the inspection result normal?

YES >> Normal

NO >> Check brake system.

Revision: March 2010 2008 QX56

Page 3492 of 4083

ST-1

STEERING

C

DE

F

H I

J

K L

M

SECTION ST

A

B

ST

N

O P

CONTENTS

STEERING SYSTEM

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Steering System .......................... ......4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................6

FUNCTION DIAGNOSIS ...............................7

HEATED STEERING WHEEL ........................ .....7

System Diagram .................................................. ......7

System Description ...................................................7

Component Parts Location ........................................7

Component Description .............................................8

COMPONENT DIAGNOSIS ..........................9

HEATED STEERING WHEEL ........................ .....9

Wiring Diagram ................................................... ......9

SYMPTOM DIAGNOSIS ..............................12

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ ....

12

NVH Troubleshooting Chart ................................ ....12

ON-VEHICLE MAINTENANCE ....................13

POWER STEERING FLUID ........................... ....13

Checking Fluid Level ........................................... ....13

Checking Fluid Leakage ..........................................13

Air Bleeding Hydraulic System ................................13

ON-VEHICLE REPAIR .................................15

STEERING WHEEL ..........................................15

On-Vehicle Inspection and Service ..................... ....15

POWER STEERING OIL PUMP .......................17

On-Vehicle Inspection and Service .........................17

REMOVAL AND INSTALLATION ...............18

STEERING WHEEL ..........................................18

Removal and Installation ..................................... ....18

TILT SYSTEM ...................................................19

Removal and Installation .........................................19

STEERING COLUMN ........................................20

Removal and Installation .........................................20

POWER STEERING GEAR AND LINKAGE ....23

Removal and Installation .........................................23

POWER STEERING OIL PUMP .......................26

Removal and Installation .........................................26

HYDRAULIC LINE ............................................27

Removal and Installation .........................................27

DISASSEMBLY AND ASSEMBLY ..............29

STEERING COLUMN ........................................29

Disassembly and Assembly ................................. ....29

POWER STEERING GEAR AND LINKAGE ....31

Disassembly and Assembly .....................................31

POWER STEERING OIL PUMP .......................35

Disassembly and Assembly .....................................35

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

36

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

36

Steering Wheel .................................................... ....36

Revision: March 2010 2008 QX56

Page 3504 of 4083

POWER STEERING FLUIDST-13

< ON-VEHICLE MAINTENANCE >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

ON-VEHICLE MAINTENANCE

POWER STEERING FLUID

Checking Fluid LevelINFOID:0000000001534691

Check power steering fluid level with engine off, referring to the scale

on reservoir tank.

Use HOT range for fluid temperatures of 50 ° – 80 °C (122 ° – 176 °F).

Use COLD range for fluid temperatures of 0 ° – 30 °C (32° – 86°F).

CAUTION:

• Do not overfill.

• Do not reuse any used power steering fluid.

• Recommended fluid is Genuine NISSAN PSF or equivalent. Refer to MA-12, "

Fluids and Lubricants" .

Checking Fluid LeakageINFOID:0000000001534692

Check the hydraulic piping lines for improper attachment and for

leaks, cracks, damage, loose connec tions, chafing or deterioration.

1. Run engine until fluid temperature reaches 50 ° – 80° C (122° –

176° F) in reservoir tank. Keep engine speed idle.

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each “lock” position for five seconds to check fluid leakage.

CAUTION:

Do not hold steering wheel in a locked position for more

than 10 seconds. (There is the possibility that oil pump may

be damaged.)

4. If fluid leakage at connections is noticed, then loosen flare nut and then retighten. Do not over tighten con- nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to ST-17, "

On-Vehicle Inspection and Ser-

vice".

6. Check steering gear boots for accumulation of fluid indicating a leak from the steering gear.

Air Bleeding Hydraulic SystemINFOID:0000000001534693

Incomplete air bleeding causes the following. When this happens, bleed air again.

• Air bubbles in reservoir tank.

• Clicking noise in oil pump.

• Excessive buzzing in oil pump. NOTE:

When vehicle is stationary or while steering wheel is being turned slowly, some noise may be heard from oil

pump or gear. This noise is normal and does not affect any system.

1. Stop engine, and then turn steering wheel fully to right and left several times. CAUTION:

Do not allow steering fluid reservoir tank to go below the MIN level line. Check tank frequently and

add fluid as needed.

2. Run engine at idle speed. Turn steering wheel fully right and then fully left, hold for about three seconds.

Then check for fluid leakage.

3. Repeat step 2 several times at about three second intervals. CAUTION:

Do not hold steeri ng wheel in the locked position for more than 10 seconds. (There is the possibil-

ity that oil pump may be damaged.)

4. Check for air bubbles or cloudy fluid.

LGIA0021E

SGIA0506E

Revision: March 2010 2008 QX56