light INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2084 of 4171

EXL-136

< SYMPTOM DIAGNOSIS >

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000003776211

XENON HEADLAMPS

The brightness and color of the light may vary slightly immediately after turning the headlamp ON. This condi-

tionwill remain until the xenon bulb becomes stable. This is normal.

• Illumination time lag may occur between right and left. This is normal.

AUTO LIGHT SYSTEM

The auto light system may not turn the headlamp ON/OF F immediately after passing a dark area or a bright

area (short tunnel, sky bridge, shadowed area etc.). This is normal.

Revision: December 20092009 QX56

Page 2085 of 4171

BOTH SIDE HEADLAMPS DO NOT SWITCH TO HIGH BEAM

EXL-137

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

BOTH SIDE HEADLAMPS DO NOT SWITCH TO HIGH BEAM

DescriptionINFOID:0000000003776212

The headlamps (both sides) do not switch to high beam when the lighting switch is in the HI or PASS setting.

Diagnosis ProcedureINFOID:0000000003776213

1.COMBINATION SWITCH INSPECTION

Check the combination switch. Refer to BCS-36, "

Diagnosis Procedure".

Is the combination switch normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK HEADLAMP (HI) REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "HL HI REQ" of IPDM E/R DATA MONITOR item.

2. With operating the lighting switch, check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-56, "

Removal and Installation" .

3.HEADLAMP (HI) CIRCUIT INSPECTION

Check the headlamp (HI) circuit. Refer to EXL-32, "

Description".

Is the headlamp (HI) circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation of IPDM E/R" .

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

HL HI REQ Lighting switch

(2ND)HI or PASS

ON

Except for HI or

PA S S OFF

Revision: December 20092009 QX56

Page 2086 of 4171

EXL-138

< SYMPTOM DIAGNOSIS >

BOTH SIDE HEADLAMPS (LO) ARE NOT TURNED ON

BOTH SIDE HEADLAMPS (LO) ARE NOT TURNED ON

DescriptionINFOID:0000000003776214

The headlamps (both sides) do not turn ON in any lighting switch setting.

Diagnosis ProcedureINFOID:0000000003776215

1.CHECK COMBINATION SWITCH

Check the combination switch. Refer to BCS-36, "

Diagnosis Procedure".

Is the combination switch normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK HEADLAMP (LO) REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "HL LO REQ" of IPDM E/R DATA MONITOR item.

2. With operating the lighting switch, check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-56, "

Removal and Installation" .

3.HEADLAMP (LO) CIRCUIT INSPECTION

Check the headlamp (LO) circuit. Refer to EXL-35, "

Description".

Is the headlamp (LO) circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation of IPDM E/R" .

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

HL LO REQ Lighting switch 2ND

ON

OFF OFF

Revision: December 20092009 QX56

Page 2087 of 4171

PARKING, LICENSE PLATE AND TAIL LAMPS ARE NOT TURNED ON

EXL-139

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

PARKING, LICENSE PLATE AND TA IL LAMPS ARE NOT TURNED ON

DescriptionINFOID:0000000003776216

The parking, license plate and tail lamps do not turn ON in with any lighting switch setting.

Diagnosis ProcedureINFOID:0000000003776217

1.COMBINATION SWITCH INSPECTION

Check the combination switch. Refer to BCS-36, "

Diagnosis Procedure".

Is the combination switch normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK TAIL LAMP RELAY REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "TAIL & CLR REQ" of IPDM E/R DATA MONITOR item.

2. With operating the lighting switch, check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-56, "

Removal and Installation".

3.PARK LAMP CIRCUIT INSPECTION

Check the parking lamp circuit. Refer to EXL-40, "

Description".

Is the tail lamp circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation of IPDM E/R".

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

TAIL & CLR

REQ Lighting switch 1ST

ON

OFF OFF

Revision: December 20092009 QX56

Page 2088 of 4171

EXL-140

< SYMPTOM DIAGNOSIS >

BOTH SIDE FRONT FOG LAMPS ARE NOT TURNED ON

BOTH SIDE FRONT FOG LA MPS ARE NOT TURNED ON

DescriptionINFOID:0000000003776218

The front fog lamps do not turn ON in any setting.

Diagnosis ProcedureINFOID:0000000003776219

1.COMBINATION SWITCH INSPECTION

Check the combination switch. Refer to BCS-36, "

Diagnosis Procedure".

Is the combination switch normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK FRONT FOG LAMP REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "FR FOG REQ" of IPDM E/R DATA MONITOR item.

2. With operating the front fog lamp switch, check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-56, "

Removal and Installation".

3.FRONT FOG LAMP CIRCUIT INSPECTION

Check the front fog lamp circuit. Refer to EXL-38, "

Description".

Is the front fog lamp circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation of IPDM E/R".

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

FR FOG REQ Front fog lamp switch

(Lighting switch 2ND) ON

ON

OFF OFF

Revision: December 20092009 QX56

Page 2090 of 4171

EXL-142

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

General precautions for service operationsINFOID:0000000005864679

• When removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

• When removing parts with a screw driver or other tool , protect parts by wrapping them with vinyl or tape.

• Keep removed parts protected with cloth.

• If an non-reuseable part is removed, replace it with a new one.

• After re-assembly has been completed, make sure each part functions correctly.

• Never work with wet hands.

• Turn the combination switch (lighting and turn signal switch) OFF before disconnecting and connecting the connector.

• Do not use organic solvent (paint thinner or gasoline) to clean lamps or remove sealant residue.

Revision: December 20092009 QX56

Page 2097 of 4171

AUTO LIGHT SYSTEMEXL-149

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

AUTO LIGHT SYSTEM

Removal and InstallationINFOID:0000000003776225

OPTICAL SENSOR

Removal

1. Remove defroster grille. Refer to IP-12, "Exploded View".

2. Disconnect the optical sensor connector.

3. Turn the optical sensor counterclockwise to remove it from defroster grille.

Installation

Installation is in the reverse order of removal.

WKIA1061E

Revision: December 20092009 QX56

Page 2100 of 4171

EXL-152

< REMOVAL AND INSTALLATION >

LIGHTING & TURN SIGNAL SWITCH

LIGHTING & TURN SIGNAL SWITCH

Removal and InstallationINFOID:0000000003776228

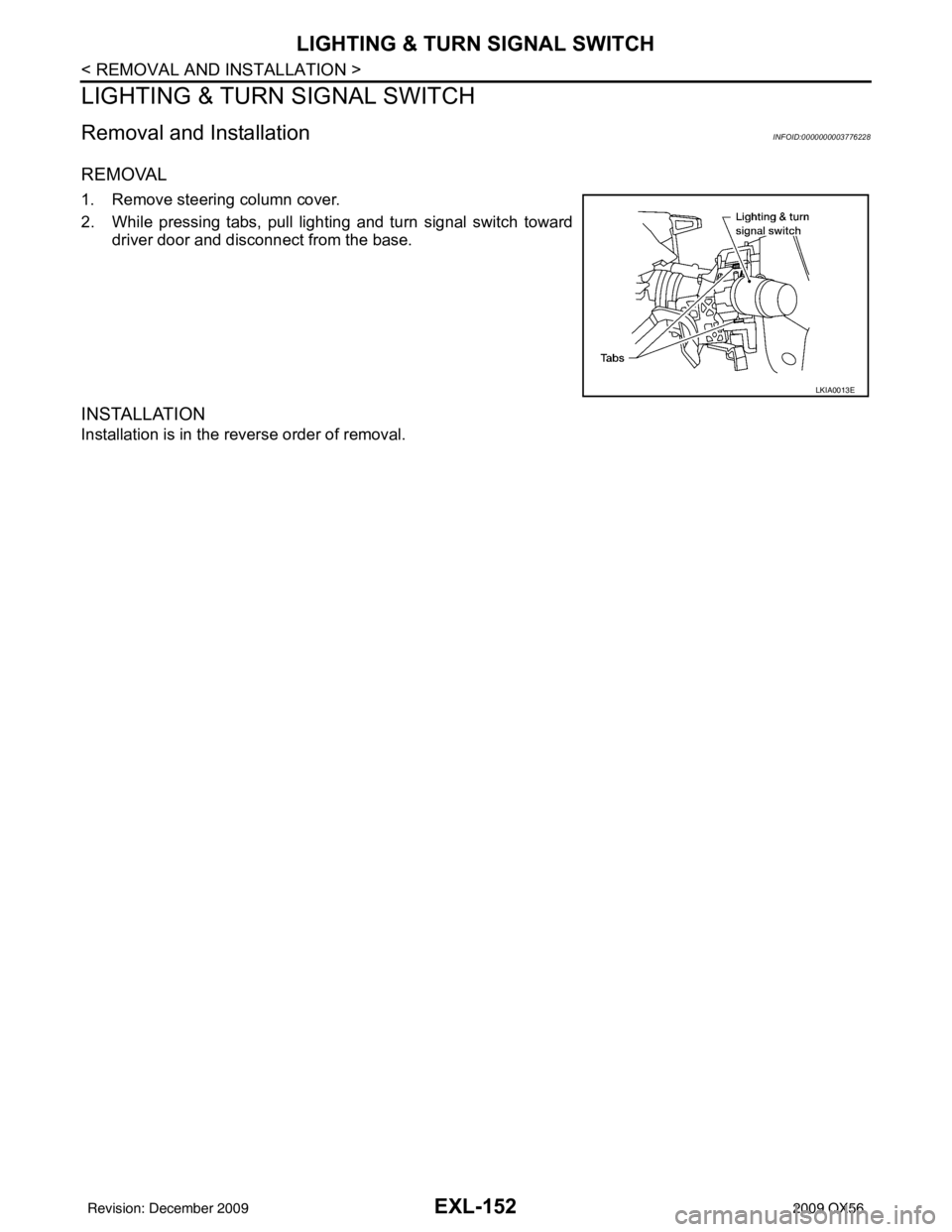

REMOVAL

1. Remove steering column cover.

2. While pressing tabs, pull lighting and turn signal switch toward

driver door and disconnect from the base.

INSTALLATION

Installation is in the reverse order of removal.

LKIA0013E

Revision: December 20092009 QX56

Page 2111 of 4171

SQUEAK AND RATTLE TROUBLE DIAGNOSESEXT-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

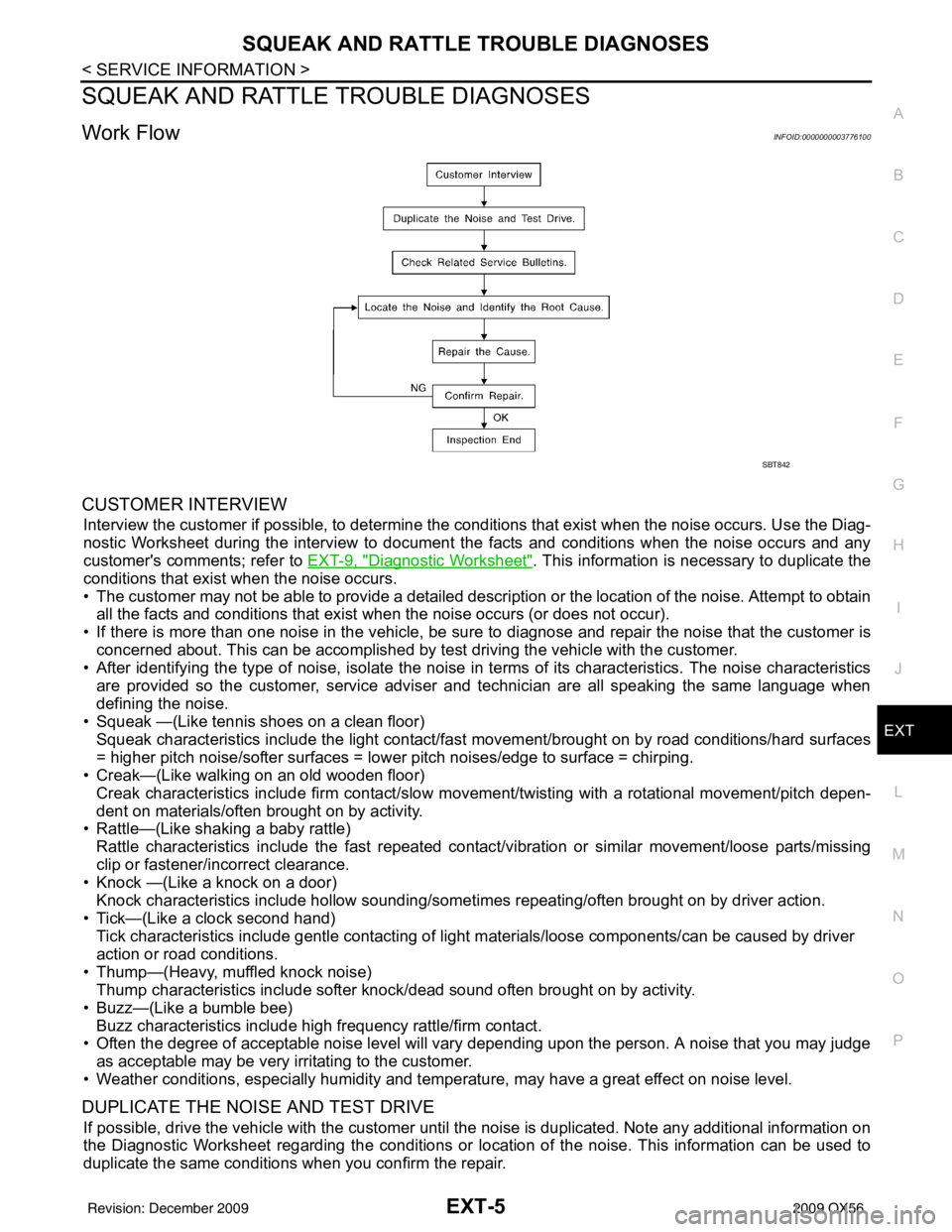

Work FlowINFOID:0000000003776100

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to EXT-9, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

Revision: December 20092009 QX56

Page 2112 of 4171

EXT-6

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to EXT-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A NISSAN Squeak and Rattle Kit (J-43980) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94× 5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-71L02: 15 ×25

mm (0.59× 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50× 50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTH TAPE

Used to insulate where movemen t does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59× 0.98 in) pad/68239-13E00: 5 mm (0.20 in ) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for inst rument panel applications.

Revision: December 20092009 QX56