bulb INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 1382 of 4171

![INFINITI QX56 2009 Factory Service Manual

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-55

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. If the ignition switch stays ON after repair work, be su

re to turn ignition switch OFF once. INFINITI QX56 2009 Factory Service Manual

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-55

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. If the ignition switch stays ON after repair work, be su

re to turn ignition switch OFF once.](/img/42/57031/w960_57031-1381.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-55

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. If the ignition switch stays ON after repair work, be su

re to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform TM-30, "OBD-II Diagnostic Trouble Code (DTC)"

. (The DTC in TCM will be erased)

3. Select Service $04 with GST (Generic Scan Tool).

No Tools

NOTE:

If the DTC is not for AT related items (see EC-456, "DTC Index"

), skip step 2.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once.

Wait at least 10 seconds and then turn it ON (engine stopped) again.

2. Perform TM-30, "OBD-II Diagnostic Trouble Code (DTC)"

. (The DTC in the TCM will be erased.)

3. Change the diagnostic test mode from Mode II to Mode I by depressing the accelerator pedal. Refer to

EC-55, "Malfunction Indicator Lamp (MIL)"

.

If the battery is disconnected, the emission-relate d diagnostic information will be lost within 24

hours.

The following data are cleared when the ECM memory is erased.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

Actual work procedures are explained using a DTC as an ex ample. Be careful so that not only the DTC, but all

of the data listed above, are cleared from the ECM memory during work procedures.

Malfunction Indicator Lamp (MIL)INFOID:0000000003771316

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to MWI-18

or see EC-41.

2. When the engine is start ed, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

SEF217U

Revision: December 20092009 QX56

Page 1383 of 4171

![INFINITI QX56 2009 Factory Service Manual

EC-56

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

When there is an open circuit on MIL circuit, the ECM c

annot warn the driver by lighting up MIL when there is

malfunction on eng INFINITI QX56 2009 Factory Service Manual

EC-56

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

When there is an open circuit on MIL circuit, the ECM c

annot warn the driver by lighting up MIL when there is

malfunction on eng](/img/42/57031/w960_57031-1382.png)

EC-56

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

When there is an open circuit on MIL circuit, the ECM c

annot warn the driver by lighting up MIL when there is

malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected as

NG for 5 trips, ECM warns the driver that engine cont rol system malfunctions and MIL circuit is open by means

of operating fail-safe function.

The fail-safe function also operates when above diagnos es except MIL circuit are detected and demands the

driver to repair the malfunction.

MIL Flashing Without DTC

When any SRT codes are not set, MIL may fl ash without DTC. For the details, refer to EC-456, "DTC Index".

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

It is better to count the ti me accurately with a clock.

It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

Always ECM returns to Diagnostic Test Mode I after ignition switch is turned OFF.

How to Set Diagnostic Test Mode II (Self-diagnostic Results)

1. Confirm that accelerator pedal is fully released, turn ignition switch ON and wait 3 seconds.

2. Repeat the following procedure quickly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

3. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 10 seconds until the MIL starts

blinking.

NOTE:

Do not release the accelerator pedal for 10 seconds if MIL may start blinking on the halfway of this

10 seconds. This blinking is displaying SRT status and is continued for another 10 seconds. For

the details, refer to EC-456, "DTC Index"

.

Diagnostic Test

ModeKEY and ENG.

Status Function Explanation of Function

Mode I Ignition switch in ON position

Engine stopped BULB CHECK This function checks the MIL bulb for damage (blown, open

circuit, etc.).

If the MIL does not come on, check MIL circuit.

Engine running MALFUNCTION WARNING This is a usual driving condition. When a malfunction is de-

tected twice in two consecutive driving cycles (two trip de-

tection logic), the MIL will light up to inform the driver that a

malfunction has been detected.

The following malfunctions will light up or blink the MIL in

the 1st trip.

Misfire (Possible three way catalyst damage)

One trip detection diagnoses

Mode II Ignition switch in ON position

Engine stopped SELF-DIAGNOSTIC

RESULTS

This function allows DTCs an

d 1st trip DTCs to be read.

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Revision: December 20092009 QX56

Page 1384 of 4171

![INFINITI QX56 2009 Factory Service Manual

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-57

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Fully release the accelerator pedal.

ECM has entered to Diagnostic Test Mode II (Self-diagnost INFINITI QX56 2009 Factory Service Manual

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-57

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Fully release the accelerator pedal.

ECM has entered to Diagnostic Test Mode II (Self-diagnost](/img/42/57031/w960_57031-1383.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-57

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Fully release the accelerator pedal.

ECM has entered to Diagnostic Test Mode II (Self-diagnostic results).

NOTE:

Wait until the same DTC (or 1st trip DTC) appears to confirm all DTCs certainly.

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

1. Set ECM in Diagnostic Test Mode II (Self-diagnostic re sults). Refer to "How to Set Diagnostic Test Mode II

(Self-diagnostic Results)".

2. Fully depress the accelerator pedal and keep it for more than 10 seconds. The emission-related diagnostic information has been erased from the backup memory in the ECM.

3. Fully release the accelerator pedal, and confirm the DTC 0000 is displayed.

DIAGNOSTIC TEST MODE I — BULB CHECK

In this mode, the MIL on the instrument panel should st ay ON. If it remains OFF, check the bulb. Refer to MWI-

18 or see EC-41.

DIAGNOSTIC TEST MODE I — MALFUNCTION WARNING

This DTC number is clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC RESULTS)

DIAGNOSTIC TEST MODE II — SELF-DIAGNOSTIC RESULTS

In this mode, the DTC and 1st trip DTC are indicated by the number of blinks of the MIL as shown below.

The DTC and 1st trip DTC are displayed at the same time. If the MIL does not illuminate in diagnostic test

mode I (Malfunction warning), all displa yed items are 1st trip DTCs. If only one code is displayed when the MIL

illuminates in diagnostic test mode II (SELF-DIAGNOSTIC RESULTS), it is a DTC; if two or more codes are

displayed, they may be either DTCs or 1st trip DTCs. DTC No. is same as that of 1st trip DTC. These uniden-

PBIB0092E

MIL Condition

ON When the malfunction is detected.

OFF No malfunction.

Revision: December 20092009 QX56

Page 1951 of 4171

EXL-3

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Diagnosis Procedure ...........................................

..

139

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON .....................................................

140

Description ............................................................140

Diagnosis Procedure .............................................140

PRECAUTION ............................................141

PRECAUTIONS .............................................. ..141

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

141

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

141

General precautions for service operations ..........142

ON-VEHICLE REPAIR .... ...........................143

ADJUSTMENT AND INSPECTION ................ ..143

HEADLAMP ........................................................... ..143

HEADLAMP : Aiming Adjustment .........................143

FRONT FOG LAMP ............................................... ..144

FRONT FOG LAMP : Aiming Adjustment .............144

REMOVAL AND INSTALLATION .............146

HEADLAMP .................................................... ..146

Bulb Replacement .................................................146

Removal and Installation .......................................147

Disassembly and Assembly ................................ ..147

AUTO LIGHT SYSTEM ....................................149

Removal and Installation ..................................... ..149

FRONT FOG LAMP ........................................150

Bulb Replacement .................................................150

Removal and Installation .......................................150

LIGHTING & TURN SIGNAL SWITCH ...........152

Removal and Installation .......................................152

HAZARD SWITCH ..........................................153

Removal and Installation .......................................153

PUDDLE LAMP ...............................................154

Removal and Installation .......................................154

Bulb Replacement .................................................154

LICENSE PLATE LAMP .................................155

Bulb Replacement .................................................155

Removal and Installation .......................................155

STOP LAMP ....................................................156

Bulb Replacement .................................................156

Removal and Installation .......................................156

REAR COMBINATION LAMP .........................157

Bulb Replacement .................................................157

Removal and Installation .......................................157

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... .

158

BULB SPECIFICATIONS ................................158

Headlamp ............................................................ ..158

Exterior Lamp ........................................................158

Revision: December 20092009 QX56

Page 1956 of 4171

EXL-8

< FUNCTION DIAGNOSIS >

HEADLAMP

A Xenon type headlamp is adapted to the low beam headlamps. Xenon bulbs do not use a filament. Instead,

they produce light when a high voltage current is pa ssed between two tungsten electrodes through a mixture

of Xenon (an inert gas) and certain other metal halides. In addition to added lighting power, electronic control

of the power supply gives the headlamps stable quality and tone color. Following are some of the advantages

of the Xenon type headlamp.

• The light produced by the headlamps is a white color comparable to sunlight that is easy on the eyes.

• Light output is nearly double that of halogen headlamps, affording increased area of illumination.

• The light features a high relative spectral distribution at wavelengths to which the human eye is most sensi- tive. This means that even in the rain, more light is reflected back from the road surface toward the vehicle,

for added visibility.

• Power consumption is approximately 25 percent less than halogen headlamps, reducing battery load.

HIGH BEAM OPERATION/FLASH-TO-PASS OPERATION

With the combination switch (lighting and turn signal switch) in the 2ND position and placed in HIGH position,

the BCM receives input requesting the headlamp high beams to illuminate. The flash to pass feature can be

used any time and also sends a signal to the BCM. This input is communicated to the IPDM E/R via the CAN

communication lines. The CPU of the combination meter c ontrols the ON/OFF status off the HIGH BEAM indi-

cator. The CPU of the IPDM E/R controls the headlamp LH high and RH high relay coils which supplies power

to the high beam headlamps.

The combination meter receives a high beam request signal (ON) via the CAN communication lines and turns

the high beam indicator lamp ON.

Revision: December 20092009 QX56

Page 1981 of 4171

HEADLAMP (HI) CIRCUITEXL-33

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

NO >> GO TO 3.

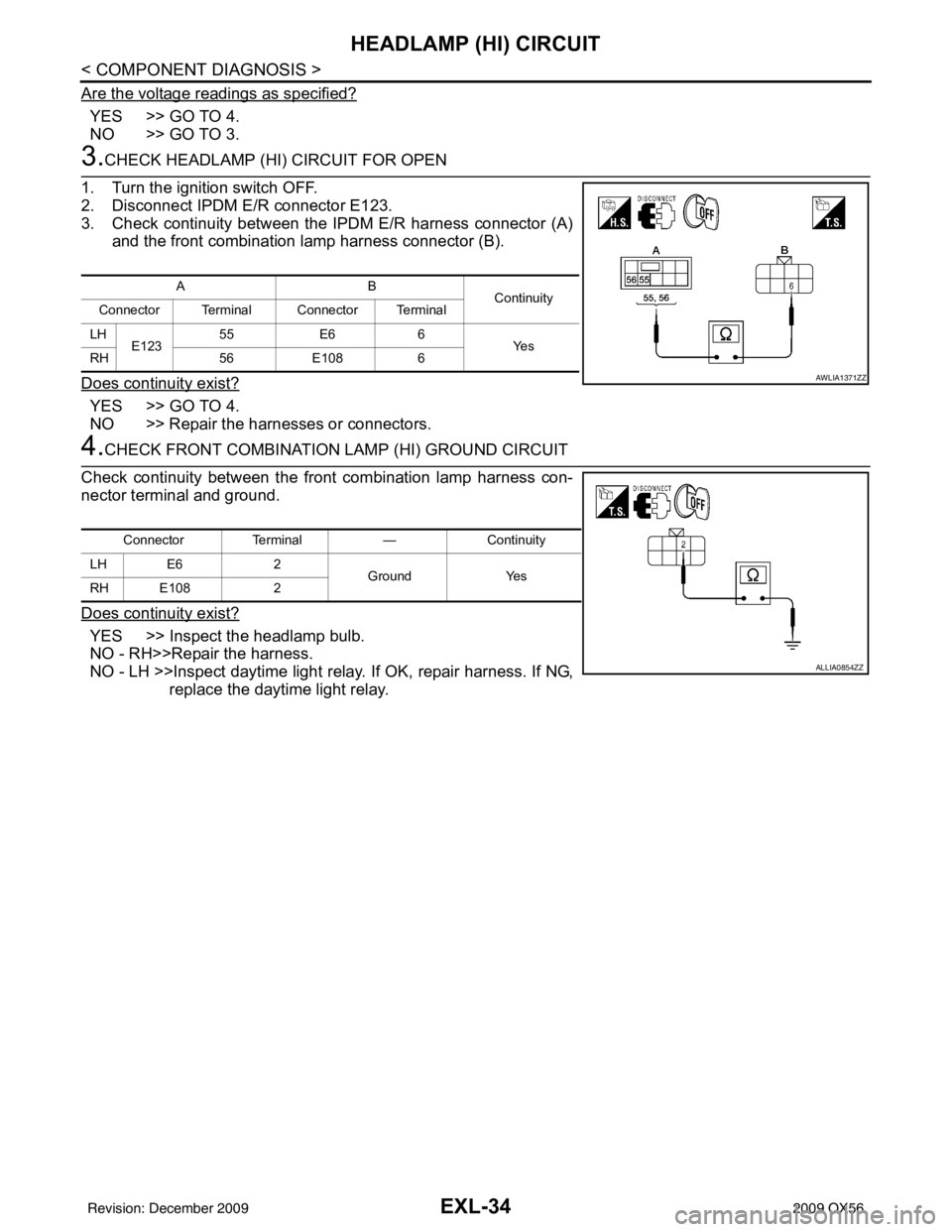

3.CHECK HEADLAMP (HI) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E123.

3. Check continuity between the IPDM E/R harness connector (A) and the front combination lamp harness connector (B).

Does continuity exist?

YES >> GO TO 4.

NO >> Repair the harnesses or connectors.

4.CHECK FRONT COMBINATION LAMP (HI) GROUND CIRCUIT

Check continuity between the front combination lamp harness con-

nector terminal and ground.

Does continuity exist?

YES >> Inspect the headlamp bulb.

NO >> Repair the harness.

Diagnosis Procedure - With Daytime Light SystemINFOID:0000000004216293

1.CHECK HEADLAMP (HI) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not open.

Is the fuse open?

YES >> Repair the harness and replace the fuse.

NO >> GO TO 2.

2.CHECK HEADLAMP (HI) OUTPUT VOLTAGE

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector E6 or E108.

3. Turn the ignition switch ON.

4. Turn the high beam headlamps ON.

5. With the high beam headlamps ON, check the voltage between the combination lamp connector and ground.

AB Continuity

Connector Terminal Connector Terminal

LH E123 55

E11 6

Ye s

RH 56E107 6

AWLIA1371ZZ

Connector Terminal —Continuity

LH E11 2

Ground Yes

RH E107 2

ALLIA0854ZZ

Unit LocationFuse No.Capacity

Headlamp HI (LH) IPDM E/R3510A

Headlamp HI (RH) IPDM E/R3410A

(+)

(−)Voltage

Connector Terminal

LH E6 6 Ground Battery voltage

RH E108 6

ALLIA0852ZZ

Revision: December 20092009 QX56

Page 1982 of 4171

EXL-34

< COMPONENT DIAGNOSIS >

HEADLAMP (HI) CIRCUIT

Are the voltage readings as specified?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK HEADLAMP (HI) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E123.

3. Check continuity between the IPDM E/R harness connector (A) and the front combination lamp harness connector (B).

Does continuity exist?

YES >> GO TO 4.

NO >> Repair the harnesses or connectors.

4.CHECK FRONT COMBINATION LAMP (HI) GROUND CIRCUIT

Check continuity between the front combination lamp harness con-

nector terminal and ground.

Does continuity exist?

YES >> Inspect the headlamp bulb.

NO - RH>>Repair the harness.

NO - LH >>Inspect daytime light rela y. If OK, repair harness. If NG,

replace the daytime light relay.

AB Continuity

Connector Terminal Connector Terminal

LH E123 55

E66

Ye s

RH 56E108 6

AWLIA1371ZZ

Connector Terminal —Continuity

LH E6 2

Ground Yes

RH E108 2

ALLIA0854ZZ

Revision: December 20092009 QX56

Page 1984 of 4171

EXL-36

< COMPONENT DIAGNOSIS >

HEADLAMP (LO) CIRCUIT

NO >> GO TO 3.

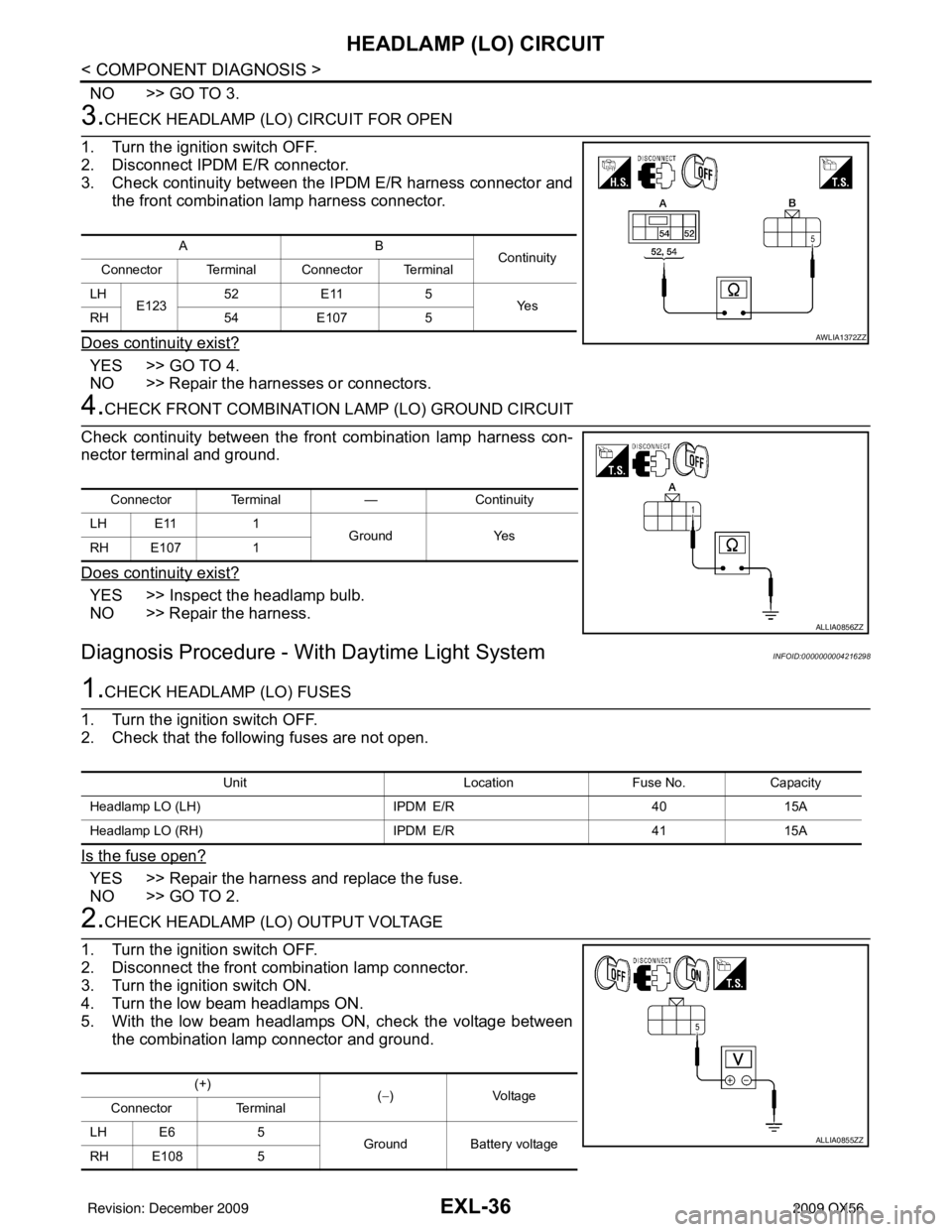

3.CHECK HEADLAMP (LO) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between the IPDM E/R harness connector and

the front combination lamp harness connector.

Does continuity exist?

YES >> GO TO 4.

NO >> Repair the harnesses or connectors.

4.CHECK FRONT COMBINATION LAMP (LO) GROUND CIRCUIT

Check continuity between the front combination lamp harness con-

nector terminal and ground.

Does continuity exist?

YES >> Inspect the headlamp bulb.

NO >> Repair the harness.

Diagnosis Procedure - With Daytime Light SystemINFOID:0000000004216298

1.CHECK HEADLAMP (LO) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not open.

Is the fuse open?

YES >> Repair the harness and replace the fuse.

NO >> GO TO 2.

2.CHECK HEADLAMP (LO) OUTPUT VOLTAGE

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector.

3. Turn the ignition switch ON.

4. Turn the low beam headlamps ON.

5. With the low beam headlamps ON, check the voltage between the combination lamp connector and ground.

AB Continuity

Connector Terminal Connector Terminal

LH E123 52

E11 5

Ye s

RH 54E107 5

AWLIA1372ZZ

Connector Terminal —Continuity

LH E11 1

Ground Yes

RH E107 1

ALLIA0856ZZ

Unit LocationFuse No.Capacity

Headlamp LO (LH) IPDM E/R4015A

Headlamp LO (RH) IPDM E/R4115A

(+)

(−)V olt a ge

Connector Terminal

LH E6 5

Ground Battery voltage

RH E108 5

ALLIA0855ZZ

Revision: December 20092009 QX56

Page 1985 of 4171

HEADLAMP (LO) CIRCUITEXL-37

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

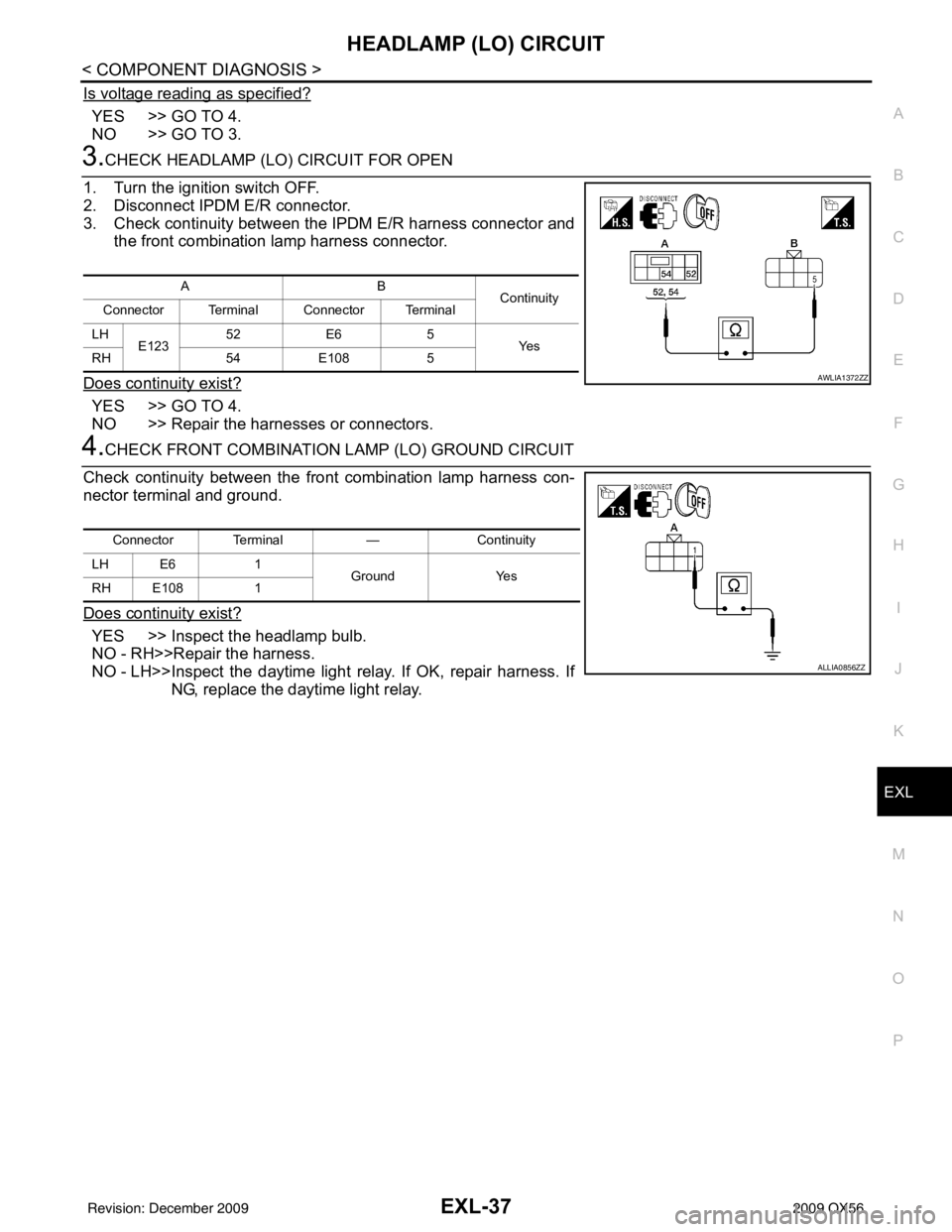

Is voltage reading as specified?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK HEADLAMP (LO) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between the IPDM E/R harness connector and the front combination lamp harness connector.

Does continuity exist?

YES >> GO TO 4.

NO >> Repair the harnesses or connectors.

4.CHECK FRONT COMBINATION LAMP (LO) GROUND CIRCUIT

Check continuity between the front combination lamp harness con-

nector terminal and ground.

Does continuity exist?

YES >> Inspect the headlamp bulb.

NO - RH>>Repair the harness.

NO - LH>>Inspect the daytime light relay. If OK, repair harness. If NG, replace the daytime light relay.

AB Continuity

Connector Terminal Connector Terminal

LH E123 52

E6 5

Ye s

RH 54E108 5

AWLIA1372ZZ

Connector Terminal —Continuity

LH E6 1

Ground Yes

RH E108 1

ALLIA0856ZZ

Revision: December 20092009 QX56

Page 1987 of 4171

FRONT FOG LAMP CIRCUITEXL-39

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

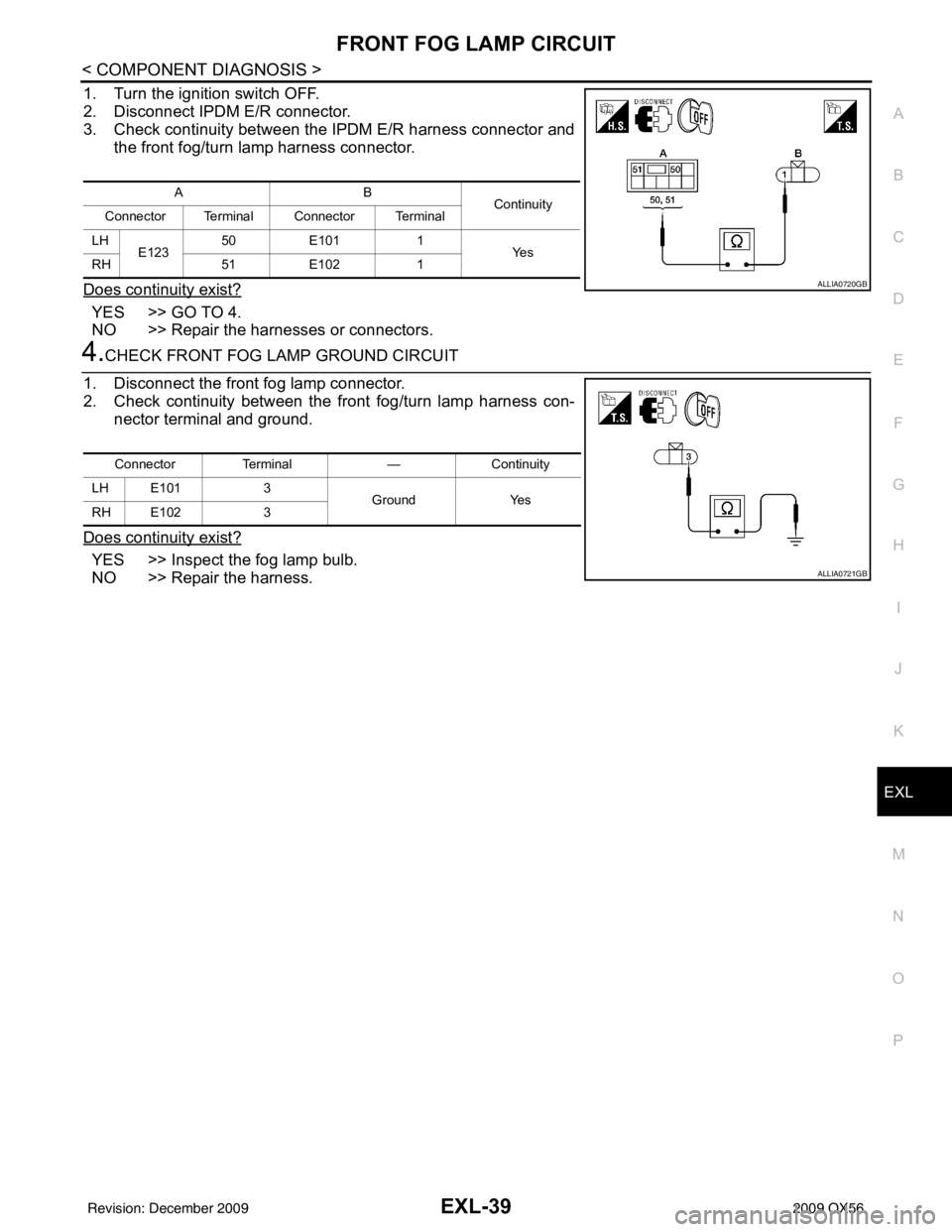

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between the IPDM E/R harness connector and the front fog/turn lamp harness connector.

Does continuity exist?

YES >> GO TO 4.

NO >> Repair the harnesses or connectors.

4.CHECK FRONT FOG LAMP GROUND CIRCUIT

1. Disconnect the front fog lamp connector.

2. Check continuity between the front fog/turn lamp harness con- nector terminal and ground.

Does continuity exist?

YES >> Inspect the fog lamp bulb.

NO >> Repair the harness.

AB Continuity

Connector Terminal Connector Terminal

LH E123 50

E101 1

Ye s

RH 51E102 1

ALLIA0720GB

Connector Terminal —Continuity

LH E101 3

Ground Yes

RH E102 3

ALLIA0721GB

Revision: December 20092009 QX56