transmission oil INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 8 of 4171

2009

QUICK REFERNCE CHART: QX56

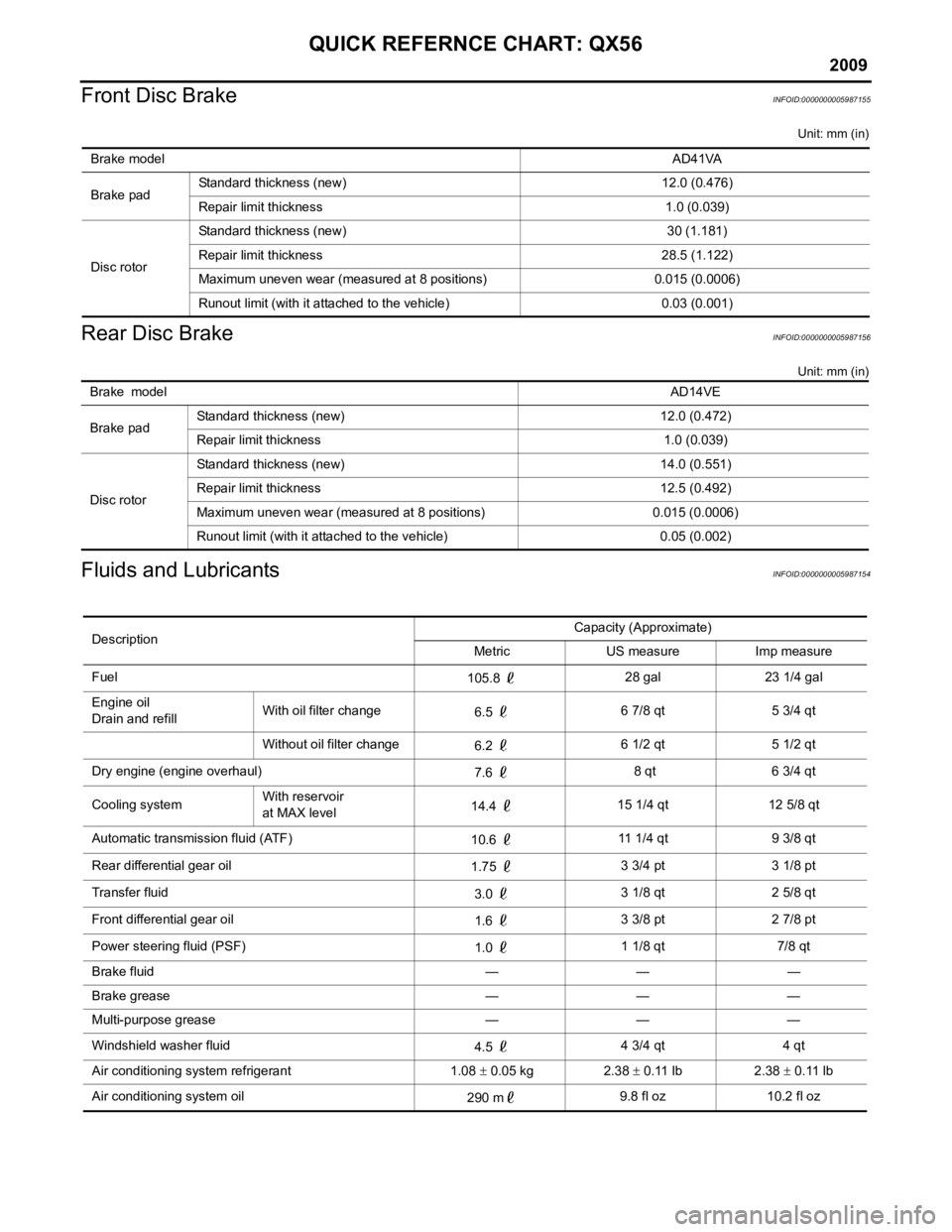

Front Disc Brake

INFOID:0000000005987155

Unit: mm (in)

Rear Disc BrakeINFOID:0000000005987156

Unit: mm (in)

Fluids and LubricantsINFOID:0000000005987154

Brake model AD41VA

Brake pad Standard thickness (new) 12.0 (0.476)

Repair limit thickness 1.0 (0.039)

Disc rotor Standard thickness (new) 30 (1.181)

Repair limit thickness 28.5 (1.122)

Maximum uneven wear (measured at 8 positions) 0.015 (0.0006)

Runout limit (with it attached to the vehicle) 0.03 (0.001)

Brake model

AD14VE

Brake pad Standard thickness (new) 12.0 (0.472)

Repair limit thickness 1.0 (0.039)

Disc rotor Standard thickness (new) 14.0 (0.551)

Repair limit thickness 12.5 (0.492)

Maximum uneven wear (measured at 8 positions) 0.015 (0.0006)

Runout limit (with it attached to the vehicle) 0.05 (0.002)

Description

Capacity (Approximate)

Metric US measure Imp measure

Fuel 105.8 28 gal 23 1/4 gal

Engine oil

Drain and refill With oil filter change

6.5 6 7/8 qt 5 3/4 qt

Without oil filter change 6.2 6 1/2 qt 5 1/2 qt

Dry engine (engine overhaul) 7.6 8 qt 6 3/4 qt

Cooling system With reservoir

at MAX level

14.4

15 1/4 qt 12 5/8 qt

Automatic transmission fluid (ATF) 10.6 11 1/4 qt 9 3/8 qt

Rear differential gear oil 1.75 3 3/4 pt 3 1/8 pt

Transfer fluid 3.0 3 1/8 qt 2 5/8 qt

Front differential gear oil 1.6 3 3/8 pt 2 7/8 pt

Power steering fluid (PSF) 1.0 1 1/8 qt 7/8 qt

Brake fluid — — —

Brake grease — — —

Multi-purpose grease — — —

Windshield washer fluid 4.5 4 3/4 qt 4 qt

Air conditioning system refrigerant 1.08 ± 0.05 kg 2.38 ± 0.11 lb 2.38 ± 0.11 lb

Air conditioning system oil 290 m9.8 fl oz 10.2 fl oz

Page 386 of 4171

![INFINITI QX56 2009 Factory Service Manual

BCS-12

< FUNCTION DIAGNOSIS >[BCM]

SIGNAL BUFFER SYSTEM

SIGNAL BUFFER SYSTEM

System DiagramINFOID:0000000003776382

System DescriptionINFOID:0000000003776383

OUTLINE

BCM has the signal transmission fu INFINITI QX56 2009 Factory Service Manual

BCS-12

< FUNCTION DIAGNOSIS >[BCM]

SIGNAL BUFFER SYSTEM

SIGNAL BUFFER SYSTEM

System DiagramINFOID:0000000003776382

System DescriptionINFOID:0000000003776383

OUTLINE

BCM has the signal transmission fu](/img/42/57031/w960_57031-385.png)

BCS-12

< FUNCTION DIAGNOSIS >[BCM]

SIGNAL BUFFER SYSTEM

SIGNAL BUFFER SYSTEM

System DiagramINFOID:0000000003776382

System DescriptionINFOID:0000000003776383

OUTLINE

BCM has the signal transmission function that output

s/transmits each input/received signal to each unit.

Signal transmission function list

ALMIA0263GB

Signal name Input Output Description

Oil pressure switch signal IPDM E/R (CAN) Combination meter (CAN) Transmits the received oil pres-

sure switch signal via CAN

communication.

Revision: December 20092009 QX56

Page 1070 of 4171

![INFINITI QX56 2009 Factory Service Manual

DLN-14

< FUNCTION DIAGNOSIS >[ATX14B]

4WD SYSTEM

Displays 4LO condition while engine is running. 4LO indi

cator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H ⇔4LO. ( INFINITI QX56 2009 Factory Service Manual

DLN-14

< FUNCTION DIAGNOSIS >[ATX14B]

4WD SYSTEM

Displays 4LO condition while engine is running. 4LO indi

cator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H ⇔4LO. (](/img/42/57031/w960_57031-1069.png)

DLN-14

< FUNCTION DIAGNOSIS >[ATX14B]

4WD SYSTEM

Displays 4LO condition while engine is running. 4LO indi

cator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H ⇔4LO. (When 4WD warning lamp is turned on, 4LO indicator lamp is

turned off.)

Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4WD WARNING LAMP

Turns on or flashes when there is a malfunction in 4WD system.

Also turns on when ignition switch is turned ON, for purpose of lamp che\

ck. Turns OFF approximately 1 sec-

ond after the engine starts if system is normal.

4WD Warning Lamp Indication

ATP WARNING LAMP

When the A/T selector lever is in P position, the vehicle may move if the transfer case is in neutral. ATP warn-

ing lamp is turned on to indicate this condition to the driver.

LINE PRESSURE SWITCH

With the transfer system design, cont rol of the oil pressure provides the transmission of drive torque to the

front wheels. The main pressure to control the oil pressure is referred to as the line pressure.

The line pressure switch determines whether or not adequate line pressure has built up under different oper-

ating conditions.

The line pressure switch closes when line pressure is produced.

The line pressure switch senses line pressure abnormalities and turns the 4WD warning lamp ON.

CLUTCH PRESSURE SWITCH

The clutch pressure switch determines whether or not adequate clutch pressure has built up under different

operating conditions.

The clutch pressure switch closes when clutch pressure is produced.

The clutch pressure switch senses clutch pressu re abnormalities and turns the 4WD warning lamp ON.

WAIT DETECTION SWITCH

The wait detection switch operates when there is circulating torque produced in the propeller shaft (L→H) or

when there is a phase difference between 2-4 sleeve and clutch drum (H →L). After the release of the circu-

lating torque, the wait detection switch helps provi de the 4WD lock gear (clutch drum) shifts. A difference

may occur between the operation of the 4WD shift swit ch and actual drive mode. At this point, the wait

detection switch senses an actual drive mode.

The wait detection switch operates as follows.

- 4WD lock gear (clutch drum) locked: ON

- 4WD lock gear (clutch drum) released: OFF

The wait detection switch senses an actual drive mode and the 4WD shift indicator lamp indicates the vehi-

cle drive mode.

ATP SWITCH

ATP switch detects if transfer case is in neutral by the position of the L-H shift fork.

NOTE:

Transfer case may be in neutral when shifting between 4H-4LO.

NEUTRAL-4LO SWITCH

The neutral-4LO switch detects that tr ansfer gear is in neutral or 4LO (or shifting from neutral to 4LO) condi-

tion by L-H shift fork position.

Condition 4WD warning lamp

System normal OFF

Lamp check Turns ON when ignition switch is turned ON.

Turns OFF after engine start.

4WD system malfunction ON

During self-diagnosis Flashes malfunction mode.

Large difference in diameter of front/

rear tires Flashes slow (1 flash / 2 seconds)

(Continues to flash until the ignition switch is turned OFF)

High fluid temperature in transfer case Flashes rapidly (2 flashes / 1 second)

(Continues to flash until fluid temperature returns to normal)

Revision: December 20092009 QX56

Page 1071 of 4171

![INFINITI QX56 2009 Factory Service Manual

4WD SYSTEMDLN-15

< FUNCTION DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

TRANSFER FLUID TEMPERATURE SENSOR

The transfer fluid temperature sensor detects the trans fer fluid temperature and s INFINITI QX56 2009 Factory Service Manual

4WD SYSTEMDLN-15

< FUNCTION DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

TRANSFER FLUID TEMPERATURE SENSOR

The transfer fluid temperature sensor detects the trans fer fluid temperature and s](/img/42/57031/w960_57031-1070.png)

4WD SYSTEMDLN-15

< FUNCTION DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

TRANSFER FLUID TEMPERATURE SENSOR

The transfer fluid temperature sensor detects the trans fer fluid temperature and sends a signal to the transfer

control unit.

TRANSFER MOTOR

The transfer motor drives the sub-oil pump to provi de proper lubrication and oil pressure control when the

vehicle is at standstill, during low-speed operations or is being driven in reverse.

The main oil pump is operated by the driving force of t he mainshaft. In other words, sufficient oil pressure

buildup does not occur when the vehicle is at standsti ll or during low-speed operations. While the vehicle is

being driven in reverse, the main oil pump rotates in the reverse direction. Therefore the main oil pump does

not discharge oil pressure. During any of the above vehi cle operations, the transfer motor drives the sub-oil

pump to compensate for insufficient oil pressure.

The transfer motor operates as follows:

- The motor relay turns OFF in the 2WD mode.

- The motor relay operates as described in the table below in modes other than the 2WD mode.

4WD shift switch, transmission range switch, Neutral-4LO switch, vehicle speed sensor and throttle position

sensor are used in conjunction with the transfer motor.

Transfer Motor Relay Operation

*: After 2.5 seconds have elapsed.

CLUTCH PRESSURE SOLENOID VALVE

The clutch pressure solenoid valve distributes front and rear torque in AUTO mode.

2-4WD SHIFT SOLENOID VALVE

The 2-4WD shift solenoid valve operates to apply oil pressure to the wet-multiplate clutch, depending on the

drive mode. The driving force is trans mitted to the front wheels through the clutch so the vehicle is set in the

4WD mode. Setting the vehicle in the 2WD mode requires no pressure buildup. In other words, pressure force

applied to the wet-multiplate clutch becomes zero.

TRANSFER CONTROL DEVICE

Integrates actuator motor and actuator position switch.

4WD shift switch A/T selector lever position Vehicle speed

(VSS) Accelerator pedal position Motor relay drive

command

2WD — — — OFF

4H (LOCK) and 4LO N position 0 — ON

P position 0

0 - 0.07/8 OFF*

0.07/8 - 1/8 HOLD 1/8 - MAX ON

Other than R position 0 < VSS

≤ 50 km/h (31 MPH)

— ON

50 km/h (31 MPH) < VSS < 55 km/h (34 MPH) HOLD

55 km/h (34 MPH) ≤ VSS OFF

R position — — ON

R position — — ON

AUTO P or N position 0

0 - 0.07/8 OFF*

0.07/8 - 1/8 HOLD 1/8 - MAX ON

0 < VSS ≤ 50 km/h (31 MPH)

— ON

50 km/h (31 MPH) < VSS < 55 km/h (34 MPH) HOLD

55 km/h (34 MPH) ≤ VSS OFF

Other than R, P and N posi-

tion 0 < VSS

≤ 50 km/h (31 MPH)

— ON

50 km/h (31 MPH) < VSS < 55 km/h (34 MPH) HOLD

55 km/h (34 MPH) ≤ VSS OFF

Revision: December 20092009 QX56

Page 1155 of 4171

![INFINITI QX56 2009 Factory Service Manual

TRANSFER CONTROL UNITDLN-99

< ECU DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

CAUTION:

If CAN COMM CIRCUIT [U1000] or CONTROL UNIT (CAN) [U1010] is displayed with other DTCs, first perfo INFINITI QX56 2009 Factory Service Manual

TRANSFER CONTROL UNITDLN-99

< ECU DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

CAUTION:

If CAN COMM CIRCUIT [U1000] or CONTROL UNIT (CAN) [U1010] is displayed with other DTCs, first perfo](/img/42/57031/w960_57031-1154.png)

TRANSFER CONTROL UNITDLN-99

< ECU DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

CAUTION:

If CAN COMM CIRCUIT [U1000] or CONTROL UNIT (CAN) [U1010] is displayed with other DTCs, first perform the trouble

diagnosis for CAN communication line.

If ABS OP SIG [P1830], VDC OP SIG [P1831] or TCS OP SIG [P1832] is displayed, first perform the trouble diagnosis for ABS system.

If VHCL SPEED SEN·AT [P1807] is displayed, firs t perform the trouble diagnosis for A/T system.

NOTE:

If SHIFT ACT POSI SW [P1818] or SHIFT ACT CIR [P1819] is disp layed, first erase self-diagnostic results. (SHIFT ACT POSI SW

[P1818] or SHIFT ACT CIR [P1819] may be displayed after installing transfer control unit or transfer assembly.)

If CL PRES SW [P1827] or LINE PRES SW [P1828] is displayed only while driving in reverse, check the continuity of R position o n

transmission range switch. When there is no malfunction found in the electrical system, check the hydraulic system.

FLASH CODE CHART

[P1826] OIL TEMP SEN Signal voltage from transfer fluid temperature sen-

sor is abnormally high (Transfer fluid temperature is

abnormally low) while driving. Refer to

DLN-67.

[P1827] CLUTCH PRES SW Improper signal from clutch pressure switch is in-

put due to open or short circuit.

Malfunction occurs in clutch pressure switch or

hydraulic circuit. Refer to

DLN-70

.

[P1828] LINE PRES SW Improper signal from line pressure switch is input

due to open or short circuit.

Malfunction occurs in line pressure switch or hy-

draulic circuit. Refer to

DLN-73

.

[P1829] THROTTLE POSI SEN Malfunction is detected in accelerator pedal posi-

tion signal that is output from ECM through CAN

communication.

Signal voltage from accelerator pedal position sensor is abnormally high or low. Refer to

DLN-76

.

[P1830] ABS OP SIG Malfunction is detected in ABS operation signal that

is output from ABS actuator and electric unit (control

unit) through CAN communication. Refer to

DLN-77

.

[P1831] VDC OP SIG Malfunction is detected in VDC operation signal that

is output from ABS actuator and electric unit (control

unit) through CAN communication.

Refer to

DLN-78

.

[P1832] TCS OP SIG Malfunction is detected in TCS operation signal that

is output from ABS actuator and electric unit (control

unit) through CAN communication. Refer to

DLN-79

.

[U1010] CONTROL UNIT (CAN) Detecting error during the initial diagnosis of CAN

controller of transfer control unit. Refer to

DLN-80

DTC CONSULT-III Diagnostic item is detected when... Reference

Flashing pattern Item Diagnostic item is detected when... Reference

2 Vehicle speed signal

(from A/T) Malfunction is detected in output shaft revolution signal

that is output from TCM through CAN communication.

Improper signal is input while driving. Refer to

DLN-26

.

3 Clutch pressure sole-

noid signal Proper voltage is not applied to clutch pressure solenoid

valve due to open or short circuit.

Refer to

DLN-53

.

4 2-4WD solenoid signal Proper voltage is not applied to 2-4WD solenoid valve due

to open or short circuit.

Refer to

DLN-57

.

5 Transfer motor Transfer motor does not operate properly due to open or

short circuit in transfer motor or transfer motor relay. Refer to

DLN-61

.

6 Vehicle speed signal

(from ABS) Malfunction is detected in vehicle speed signal that is out-

put from ABS actuator and elec tric unit (control unit)

through CAN communication.

Improper signal is input while driving. Refer to

DLN-27

.

7 CAN communication Malfunction has been detected from CAN communication

line. Refer to

LAN-51

.

Revision: December 20092009 QX56

Page 1406 of 4171

![INFINITI QX56 2009 Factory Service Manual

TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-79

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

1 INFINITI QX56 2009 Factory Service Manual

TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-79

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

1](/img/42/57031/w960_57031-1405.png)

TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-79

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect ECM harness connector. Check pin term inal and connector for damage, and then reconnect it.

>> GO TO 16.

16.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F AL PHA-B2” in “SPEC” of “DATA MONITOR” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >> INSPECTION END

NG >> Detect malfunctioning part according to EC-475, "Symptom Matrix Chart"

.

17.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” m ode, and make sure that the indication is within the

SP value.

OK or NG

OK >> INSPECTION END

NG (More than the SP value)>>GO TO 18.

NG (Less than the SP value)>>GO TO 25.

18.DETECT MALFUNCTIONING PART

1. Check for the cause of large engine friction. Refer to the following.

- Engine oil level is too high

- Engine oil viscosity

- Belt tension of power steering, alternator, A/C compressor, etc. is excessive

- Noise from engine

- Noise from transmission, etc.

2. Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

>> Repair or replace malfunctioning part, and then GO TO 30.

19.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

Crushed air ducts

Malfunctioning seal of air cleaner element

Uneven dirt of air cleaner element

Improper specification of intake air system

OK or NG

OK >> GO TO 21.

NG >> Repair or replace malfunctioning part, and then GO TO 20.

20.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1”, “A/F ALPHA-B2”, and “B/F UEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and

make sure that the each indication is within the SP value.

OK or NG

OK >> INSPECTION END

NG (“B/FUEL SCHDL” is more, “A/F ALPHA-B1”, “A /F ALPHA-B2” are less than the SP value)>>GO TO 21.

21.DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

1. Stop the engine.

Revision: December 20092009 QX56

Page 1803 of 4171

![INFINITI QX56 2009 Factory Service Manual

EC-476

< SYMPTOM DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER

Mass air flow se INFINITI QX56 2009 Factory Service Manual

EC-476

< SYMPTOM DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER

Mass air flow se](/img/42/57031/w960_57031-1802.png)

EC-476

< SYMPTOM DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER

Mass air flow sensor circuit

1

12 2

222 2 EC-103,

EC-109

Engine coolant temperature sensor circuit

333

EC-120,

EC-128

Air fuel ratio (A/F ) sensor 1 circuit EC-136

,

EC-140

,

EC-143

,

EC-146

,

EC-377

Throttle position sensor circuit 22EC-124

,

EC-185

,

EC-302

,

EC-304

,

EC-369

Accelerator pedal position sensor circuit 3 2 1 EC-280

,

EC-362

,

EC-365

,

EC-373

Knock sensor circuit 2 3 EC-195

Crankshaft position sensor (POS) circuit 2 2EC-198

Camshaft position sensor (PHASE) circuit 3 2 EC-202

Vehicle speed signal circuit 2 3 3 3 EC-271

Power steering pressure sensor circuit 2 3 3 EC-277

ECM 22333333333 EC-280,

EC-282

Intake valve timing control solenoid valve cir-

cuit 32 13223 3

EC-100

Transmission range signal circuit 3 3 3 3 3 EC-288

Refrigerant pressure sensor circuit 2 3 3 4EC-416

Electrical load signal circuit 3EC-390

Air conditioner circuit 223333333 3 2HAC-25

ABS actuator and electric unit (control unit) 4 BRC-37

SYMPTOM

Refer-

ence page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Revision: December 20092009 QX56

Page 1804 of 4171

![INFINITI QX56 2009 Factory Service Manual

ENGINE CONTROL SYSTEM SYMPTOMSEC-477

< SYMPTOM DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

INFINITI QX56 2009 Factory Service Manual

ENGINE CONTROL SYSTEM SYMPTOMSEC-477

< SYMPTOM DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT](/img/42/57031/w960_57031-1803.png)

ENGINE CONTROL SYSTEM SYMPTOMSEC-477

< SYMPTOM DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank 5

5 FL-11

Fuel piping 5 5 5 5 5 5

FL-6

Va p o r l o c k —

Valve deposit 5 555 55 5 —

Poor fuel (Heavy weight gasoline,

Low octane) —

Air Air duct

55555 5 EM-25

Air cleaner

EM-25

Air leakage from air duct

(Mass air flow sensor — electric

throttle control actuator)

5555 EM-25

Electric throttle control actuator

EM-26

Air leakage from intake manifold/

Collector/GasketEM-26

Cranking Battery

111111

11

PG-77

Generator circuit

CHG-6

Starter circuit 3STR-8

Signal plate 6EM-45

Transmission range signal 4TM-44

Engine Cylinder head

55555 55 5 EM-68

Cylinder head gasket 4 3

Cylinder block

66666 66 6 4

EM-83

Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Va l v e

mecha-

nism Timing chain

55555 55 5 EM-45

Camshaft

EM-53

Intake valve timing controlEM-53

Intake valve

3EM-68

Exhaust valve

Revision: December 20092009 QX56

Page 1875 of 4171

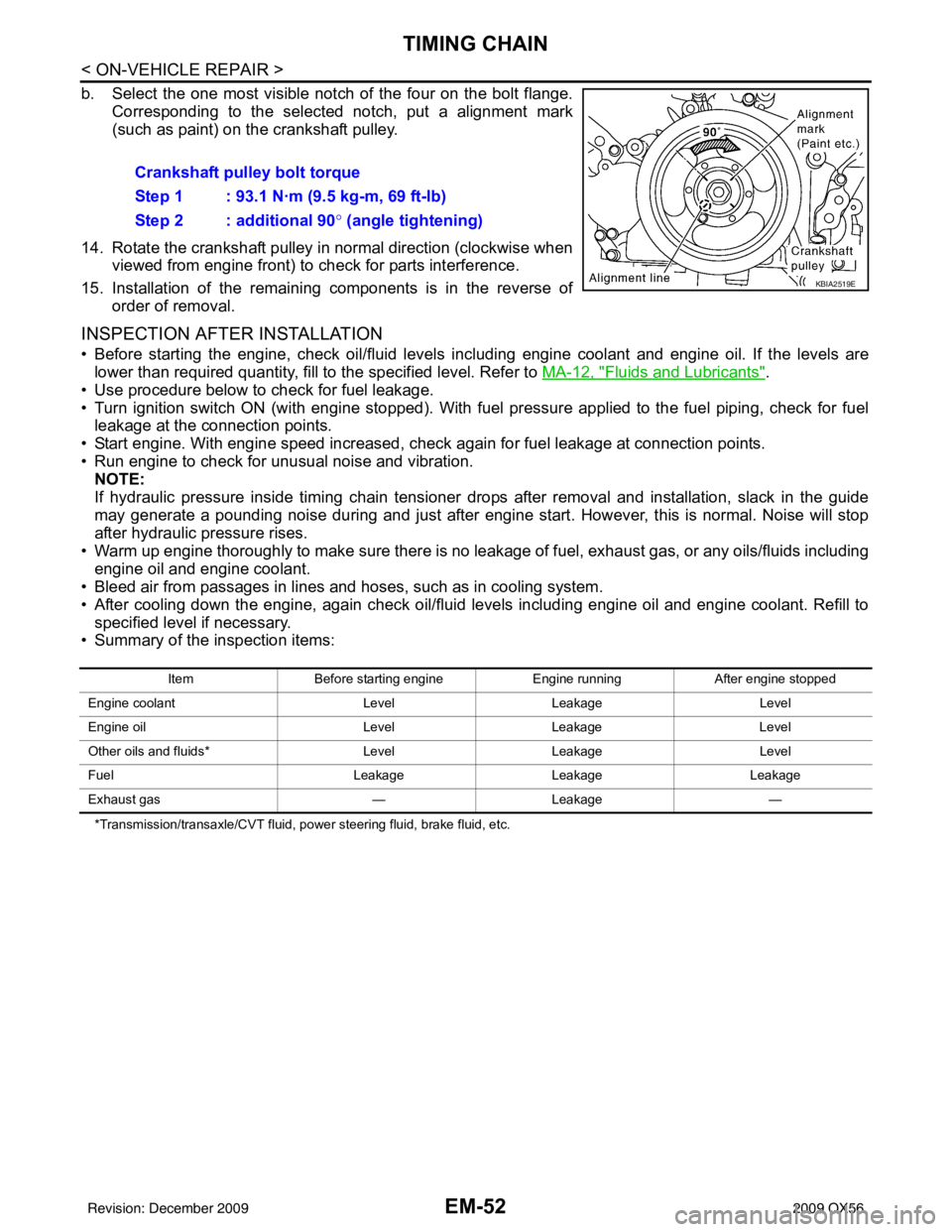

EM-52

< ON-VEHICLE REPAIR >

TIMING CHAIN

b. Select the one most visible notch of the four on the bolt flange.Corresponding to the selected notch, put a alignment mark

(such as paint) on the crankshaft pulley.

14. Rotate the crankshaft pulley in normal direction (clockwise when viewed from engine front) to check for parts interference.

15. Installation of the remaining components is in the reverse of order of removal.

INSPECTION AFTER INSTALLATION

• Before starting the engine, check oil/fluid levels in cluding engine coolant and engine oil. If the levels are

lower than required quantity, fill to the specified level. Refer to MA-12, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to the fuel piping, check for fuel leakage at the connection points.

• Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down the engine, again check oil/fluid levels including engine oil and engine coolant. Refill to

specified level if necessary.

• Summary of the inspection items:

*Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

Crankshaft pulley bolt torque

Step 1 : 93.1 N·m (9.5 kg-m, 69 ft-lb)

Step 2 : additional 90 ° (angle tightening)

KBIA2519E

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakageLeakage

Exhaust gas —Leakage —

Revision: December 20092009 QX56

Page 1889 of 4171

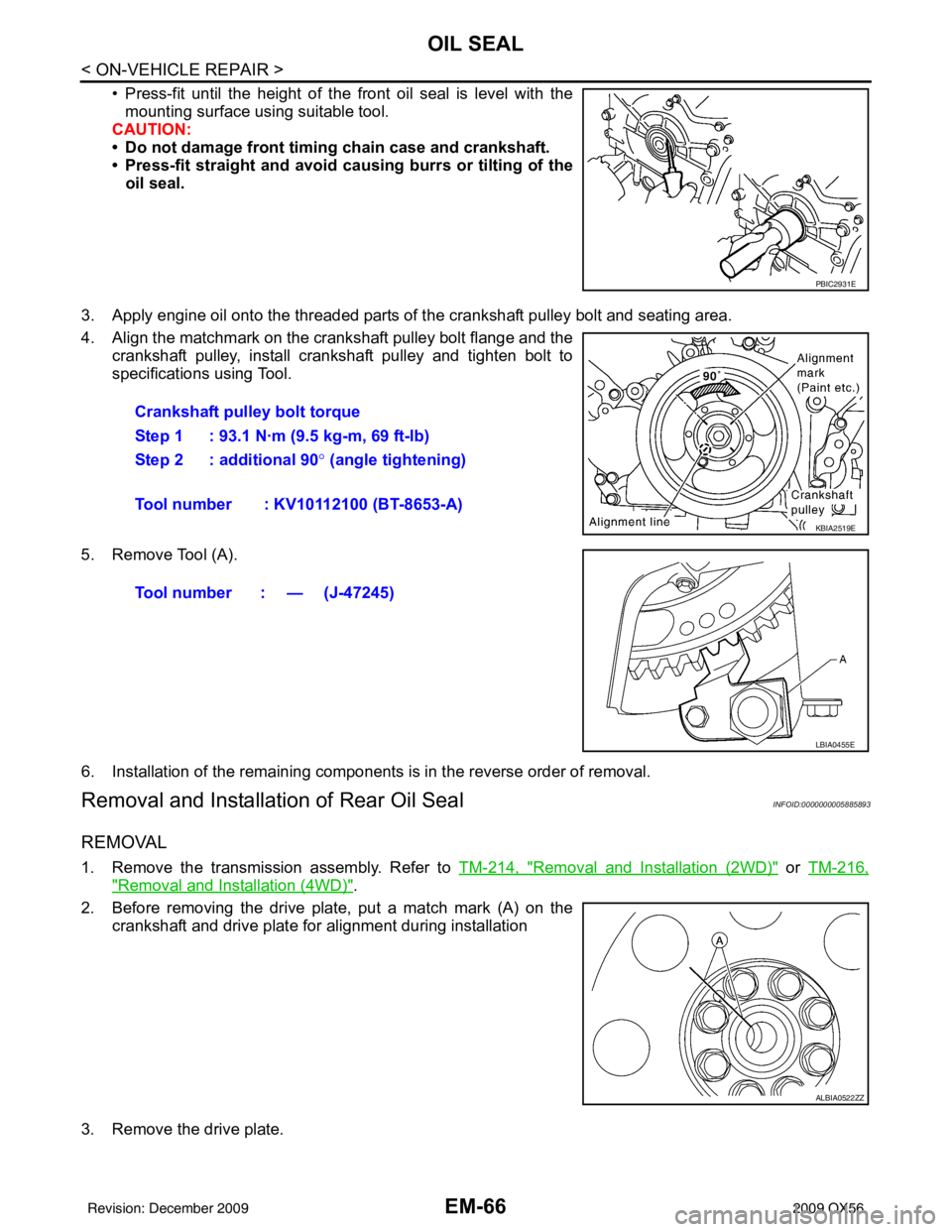

EM-66

< ON-VEHICLE REPAIR >

OIL SEAL

• Press-fit until the height of the front oil seal is level with themounting surface using suitable tool.

CAUTION:

• Do not damage front timing chain case and crankshaft.

• Press-fit straight and avoid cau sing burrs or tilting of the

oil seal.

3. Apply engine oil onto the threaded parts of the crankshaft pulley bolt and seating area.

4. Align the matchmark on the crankshaft pulley bolt flange and the crankshaft pulley, install crankshaft pulley and tighten bolt to

specifications using Tool.

5. Remove Tool (A).

6. Installation of the remaining components is in the reverse order of removal.

Removal and Installation of Rear Oil SealINFOID:0000000005885893

REMOVAL

1. Remove the transmission assembly. Refer to TM-214, "Removal and Installation (2WD)" or TM-216,

"Removal and Installation (4WD)".

2. Before removing the drive plate, put a match mark (A) on the crankshaft and drive plate for alignment during installation

3. Remove the drive plate.

PBIC2931E

Crankshaft pulley bolt torque

Step 1 : 93.1 N·m (9.5 kg-m, 69 ft-lb)

Step 2 : additional 90 ° (angle tightening)

Tool number : KV10112100 (BT-8653-A)

KBIA2519E

Tool number : — (J-47245)

LBIA0455E

ALBIA0522ZZ

Revision: December 20092009 QX56