service INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2291 of 4171

ELECTRICAL LEAK DETECTORHA-27

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

2. When checking for leaks, circle each fitting completely with the probe as shown.

3. Move the probe along each component at a speed of approxi- mately 25 - 50 mm (1 - 2 in)/second as shown.

CHECKING PROCEDURE

NOTE:

To prevent inaccurate or false readings, make sure t here is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in a calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Turn the engine OFF.

2. Connect the manifold gauge set (J-39183-C) to the A/C service ports. Refer to HA-20, "HFC-134a (R-

134a) Service Procedure".

3. Check if the A/C refrigerant pressu re is at least 345 kPa (3.52 kg/cm

2 , 50 psi) above a temperature of

16 °C (61 °F). If less than specification, recover/ev acuate and recharge the system with the specified

amount of refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure"

.

NOTE:

At temperatures below 16 °C (61 °F), leaks may not be detected sinc e the system may not reach 345 kPa

(3.52 kg/cm

2 , 50 psi) pressure.

4. Perform the leak test from the high-pressure side (f ront A/C compressor discharge “a” to evaporator inlet

“f” or rear piping connection “l”) to the low-pressure side (front A/C evaporator drain hose “g” to shaft seal

“k” and rear A/C evaporator drain hose “o” to piping connection “r”). Refer to HA-29, "Component"

. Clean

the component to be checked and carefully move the electronic refrigerant leak detector probe completely

around the following connections and components.

Check the compressor shaft seal

Check the high and low-pressure pipe and hose fitt ings, relief valve, and compressor shaft seal

Check the liquid tank

Check the refrigerant pressure sensor

Check all around the service valves. Check that the service valve caps are screwed tightly on the ser-

vice valves (to prevent leaks).

NOTE:

After removing manifold gauge set (J-39183-C) from t he service valves, wipe any residue from the ser-

vice valves to prevent any false readings by the electronic refrigerant leak detector (J-41995).

Evaporator

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in

the heater and cooling unit assembly. Wait a minimum of 10 minutes accumulation time (refer to the

manufacturer's recommended procedure for actual wait time) before inserting the electronic refrigerant

leak detector probe into the heater and cooling unit assembly drain hose.

NOTE:

SHA706E

SHA708EA

Revision: December 20092009 QX56

Page 2294 of 4171

HA-30

< ON-VEHICLE REPAIR >

REFRIGERATION SYSTEM

Rear A/C System

NOTE:

Refer to HA-5, "Precaution for Refrigerant Connection"

.

1. High-pressure service valve 2. Grommet 3. High-pressure pipe

4. Refrigerant pressure sensor 5. Condenser 6. Compressor shaft seal

7. High-pressure flexible hose 8. Low-pressure flexible hose 9. Low-pressure service valve

10. Low-pressure pipe 11. Expansion valve (front) 12. Drain hose

13. Dryer & liquid tank 14. Liquid tank bracket 15. Junction pipe

Vehicle front

AWIIA0134GB

1. Rear heater and cooling unit assembly 2. Rear A/C pipes 3. Rear A/C heater core pipes

4. Rear heater core hose 5. Rear blower motor 6. Underfloor rear A/C pipes

7. Underfloor rear heater core pipes A. Bolt torque specification B. Leak checking order (l - r)

C. Tightening torque D. Wrench size E. O-ring size

⇐Front

NOTE: The O-ring size 8 is the high-side and the O-ring size 16 is the low-side.

Revision: December 20092009 QX56

Page 2295 of 4171

COMPRESSORHA-31

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

COMPRESSOR

Removal and Installation for CompressorINFOID:0000000003775309

A/C Compressor Mounting

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Remove the front left wheel and tire assembly. Refer to WT-41, "Adjustment"

.

3. Remove the engine under cover.

4. Remove front fender protector. Refer to EXT-23, "Removal and Installation"

.

5. Remove the engine air cleaner and air ducts. Refer to EM-25, "Removal and Installation"

.

6. Remove the drive belt. Refer to EM-13, "Removal and Installation"

.

7. Disconnect the compressor electrical connector.

8. Disconnect the high-pressure flexible hose and low-pressure flexible hose from the compressor. CAUTION:

Cap or wrap the joint of the pipe with suitable mate rial such as vinyl tape to avoid the entry of air.

9. Remove the compressor bolts and nut using power tools.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

AWIIA1291GB

Revision: December 20092009 QX56

Page 2300 of 4171

HA-36

< ON-VEHICLE REPAIR >

LOW-PRESSURE FLEXIBLE HOSE

LOW-PRESSURE FLEXIBLE HOSE

Removal and Installation for Low-Pressure Flexible HoseINFOID:0000000003775311

REMOVAL

1. Remove the engine air cleaner and air ducts. Refer to EM-25, "Removal and Installation".

2. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure"

.

3. Remove the low-pressure flexible hose. CAUTION:

Cap or wrap the joint of the pipe with suitable mate rial such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-ring of the low-pr essure flexible hose with a new one, then apply compressor oil to it

when installing it.

After charging refrigerant, check for leaks.

Revision: December 20092009 QX56

Page 2301 of 4171

LOW-PRESSURE PIPEHA-37

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

LOW-PRESSURE PIPE

Removal and Installation for Low-Pressure PipeINFOID:0000000003775312

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Remove the cowl top and the cowl top extension. Refer to EXT-18, "Removal and Installation"

.

3. Remove the low-pressure pipe. CAUTION:

Cap or wrap the joint of the pipes with suitable material such as viny l tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-ring of the high/low-pressure pipe with a new one, then apply compressor oil to it

when installing it.

After charging refrigerant, check for leaks.

Removal and Installation for Rear High- and Low-Pressure A/C and Heater Core Pipes

INFOID:0000000003775313

REMOVAL

1. Discharge the refrigerant from the A/C system. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Drain the coolant from the engine cooling system. Refer to CO-11, "Changing Engine Coolant"

.

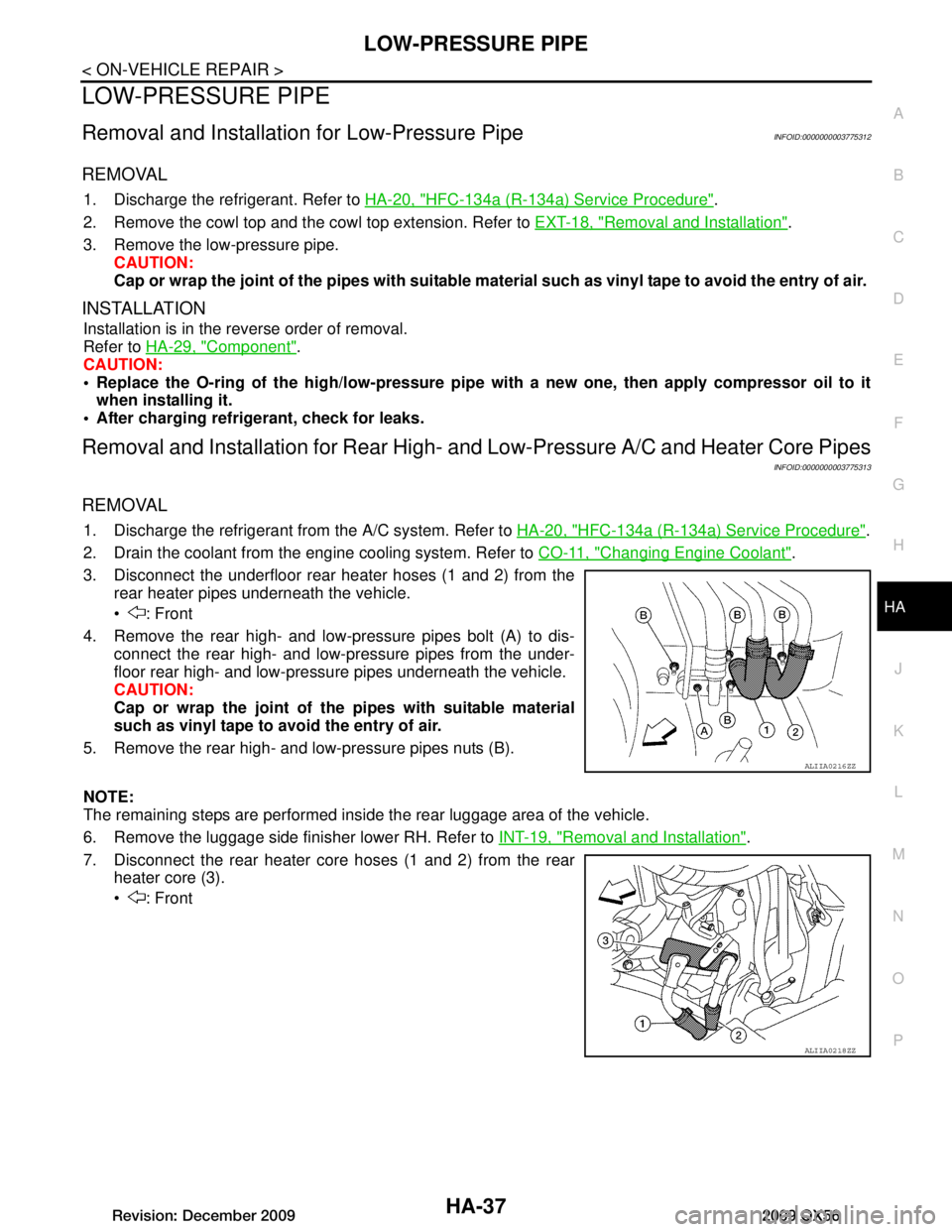

3. Disconnect the underfloor rear heater hoses (1 and 2) from the rear heater pipes underneath the vehicle.

: Front

4. Remove the rear high- and low-pressure pipes bolt (A) to dis- connect the rear high- and low-pressure pipes from the under-

floor rear high- and low-pressu re pipes underneath the vehicle.

CAUTION:

Cap or wrap the joint of the pipes with suitable material

such as vinyl tape to avoid the entry of air.

5. Remove the rear high- and low-pressure pipes nuts (B).

NOTE:

The remaining steps are performed inside the rear luggage area of the vehicle.

6. Remove the luggage side finisher lower RH. Refer to INT-19, "Removal and Installation"

.

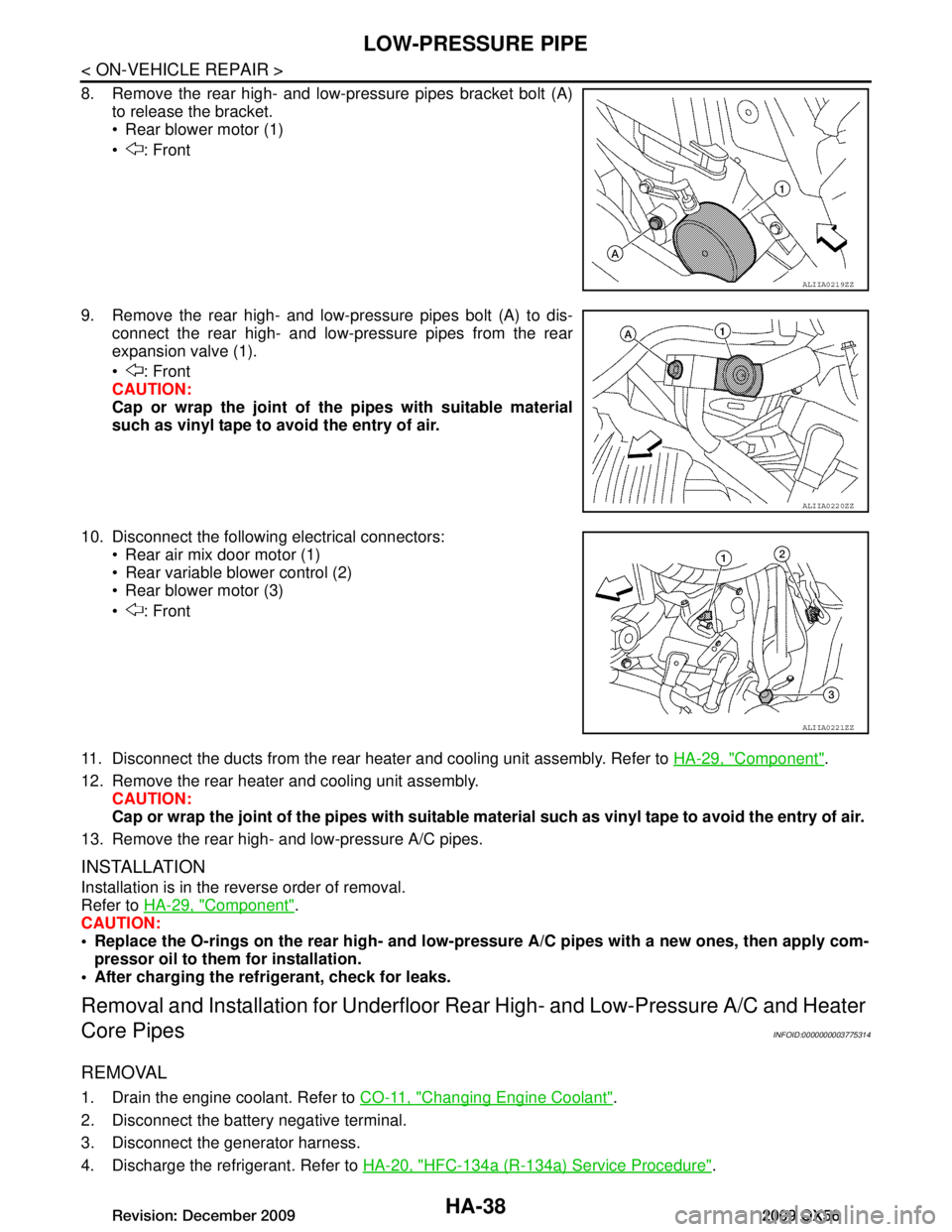

7. Disconnect the rear heater core hoses (1 and 2) from the rear heater core (3).

: Front

ALIIA0216ZZ

ALIIA0218ZZ

Revision: December 20092009 QX56

Page 2302 of 4171

HA-38

< ON-VEHICLE REPAIR >

LOW-PRESSURE PIPE

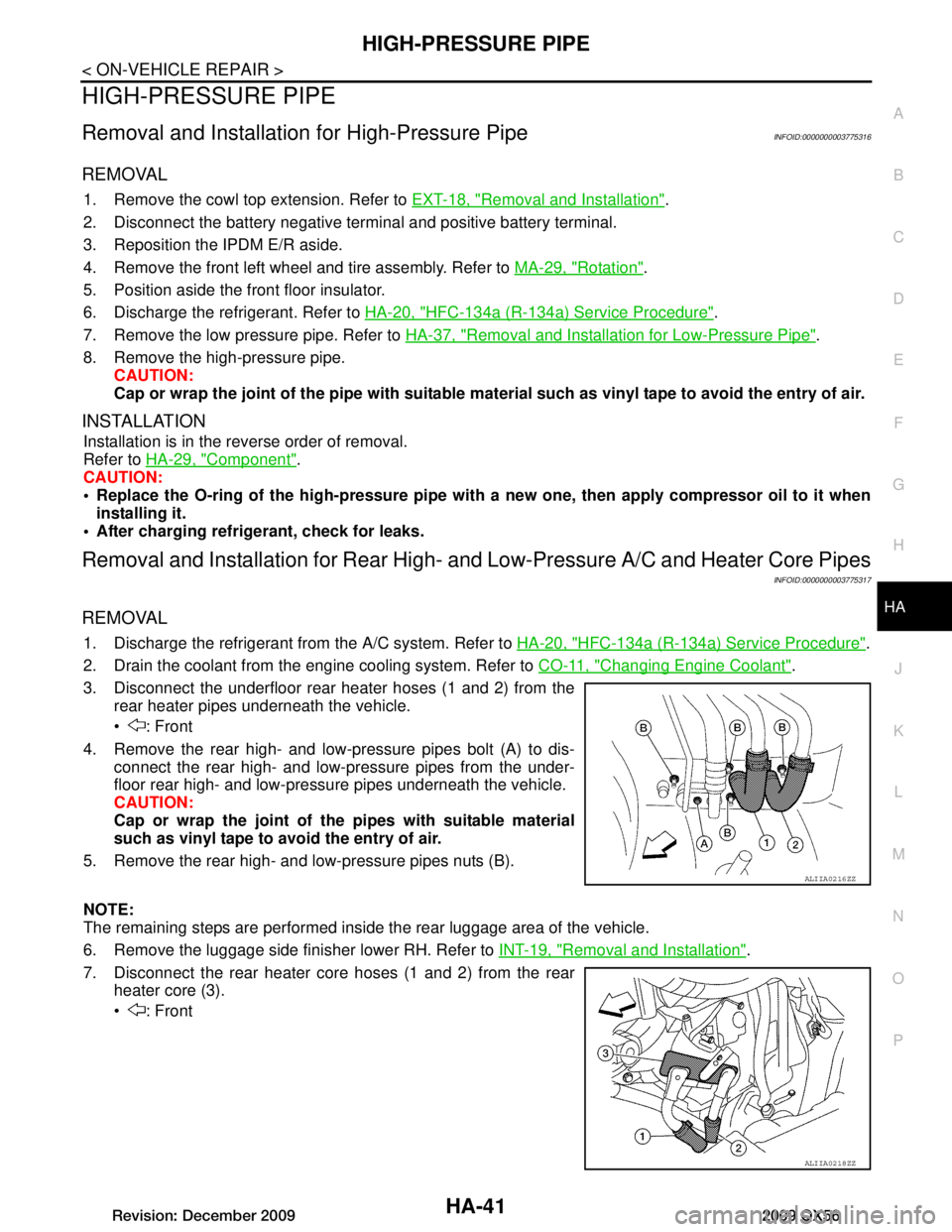

8. Remove the rear high- and low-pressure pipes bracket bolt (A)to release the bracket.

Rear blower motor (1)

: Front

9. Remove the rear high- and low-pressure pipes bolt (A) to dis- connect the rear high- and low-pressure pipes from the rear

expansion valve (1).

: Front

CAUTION:

Cap or wrap the joint of the pipes with suitable material

such as vinyl tape to avoid the entry of air.

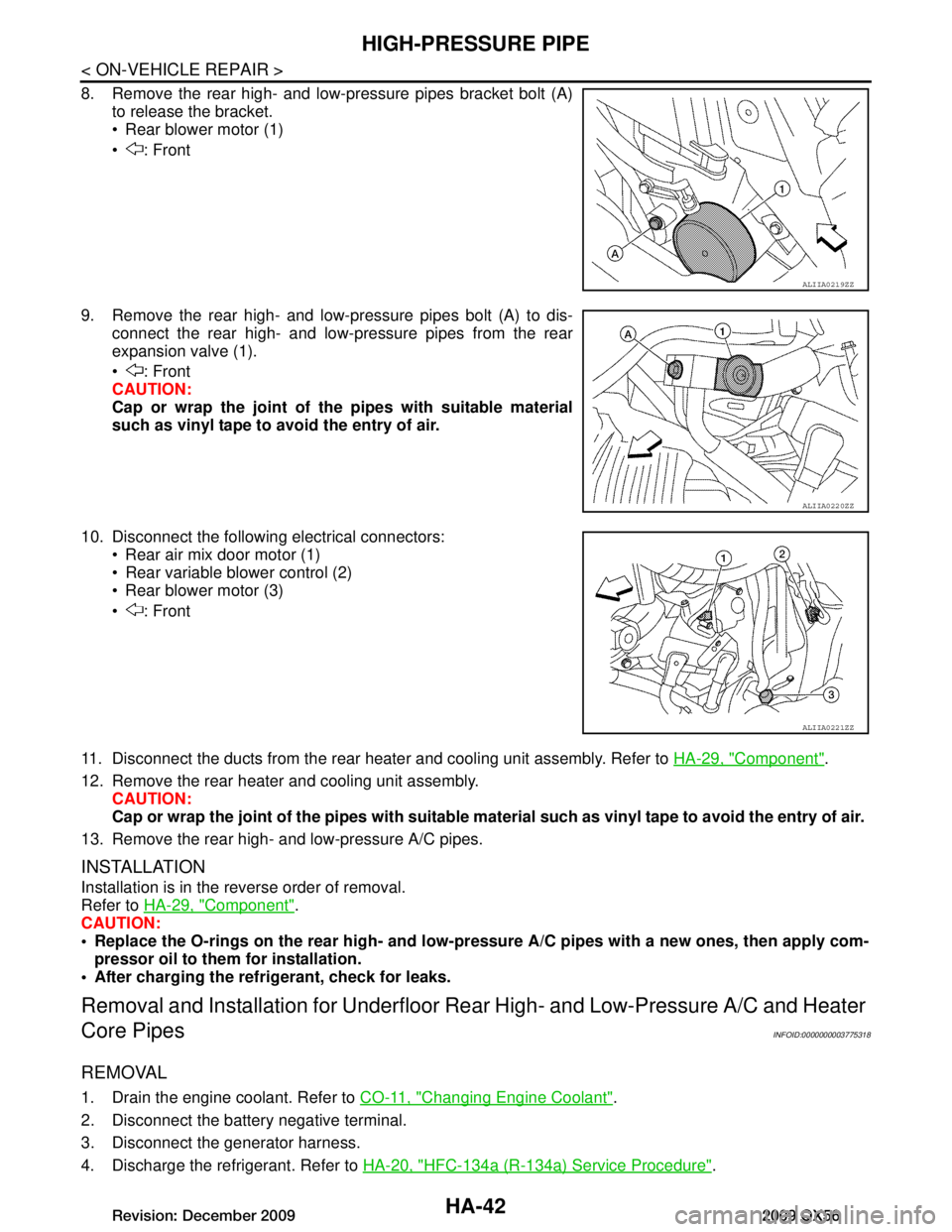

10. Disconnect the following electrical connectors: Rear air mix door motor (1)

Rear variable blower control (2)

Rear blower motor (3)

: Front

11. Disconnect the ducts from the rear heater and cooling unit assembly. Refer to HA-29, "Component"

.

12. Remove the rear heater and cooling unit assembly. CAUTION:

Cap or wrap the joint of the pipes with suitable material such as viny l tape to avoid the entry of air.

13. Remove the rear high- and low-pressure A/C pipes.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-rings on the rear high- and low-pr essure A/C pipes with a new ones, then apply com-

pressor oil to them for installation.

After charging the refrigerant, check for leaks.

Removal and Installation for Underfloor Rear High- and Lo w-Pressure A/C and Heater

Core Pipes

INFOID:0000000003775314

REMOVAL

1. Drain the engine coolant. Refer to CO-11, "Changing Engine Coolant".

2. Disconnect the battery negative terminal.

3. Disconnect the generator harness.

4. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure"

.

ALIIA0219ZZ

ALIIA0220ZZ

ALIIA0221ZZ

Revision: December 20092009 QX56

Page 2304 of 4171

HA-40

< ON-VEHICLE REPAIR >

HIGH-PRESSURE FLEXIBLE HOSE

HIGH-PRESSURE FLEXIBLE HOSE

Removal and Installation for High-Pressure Flexible HoseINFOID:0000000003775315

REMOVAL

1. Remove the engine under cover.

2. Remove the front LH fender protector. Refer to EXT-23, "Removal and Installation"

.

3. Remove the engine air cleaner and air ducts. Refer to EM-25, "Removal and Installation"

.

4. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure"

.

5. Remove the high-pressure flexible hose. CAUTION:

Cap or wrap the joint of the pipe with suitable mate rial such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-ring of the high-pr essure flexible hose with a new one, then apply compressor oil to it

when installing it.

After charging refrigerant, check for leaks.

Revision: December 20092009 QX56

Page 2305 of 4171

HIGH-PRESSURE PIPEHA-41

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

HIGH-PRESSURE PIPE

Removal and Installation for High-Pressure PipeINFOID:0000000003775316

REMOVAL

1. Remove the cowl top extension. Refer to EXT-18, "Removal and Installation".

2. Disconnect the battery negative termi nal and positive battery terminal.

3. Reposition the IPDM E/R aside.

4. Remove the front left wheel and tire assembly. Refer to MA-29, "Rotation"

.

5. Position aside the front floor insulator.

6. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure"

.

7. Remove the low pressure pipe. Refer to HA-37, "Removal and Installation for Low-Pressure Pipe"

.

8. Remove the high-pressure pipe. CAUTION:

Cap or wrap the joint of the pipe with suitable mate rial such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-ring of the high-pressure pipe with a new one, then apply compressor oil to it when

installing it.

After charging refrigerant, check for leaks.

Removal and Installation for Rear High- and Low-Pressure A/C and Heater Core Pipes

INFOID:0000000003775317

REMOVAL

1. Discharge the refrigerant from the A/C system. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Drain the coolant from the engine cooling system. Refer to CO-11, "Changing Engine Coolant"

.

3. Disconnect the underfloor rear heater hoses (1 and 2) from the rear heater pipes underneath the vehicle.

: Front

4. Remove the rear high- and low-pressure pipes bolt (A) to dis- connect the rear high- and low-pressure pipes from the under-

floor rear high- and low-pressu re pipes underneath the vehicle.

CAUTION:

Cap or wrap the joint of the pipes with suitable material

such as vinyl tape to avoid the entry of air.

5. Remove the rear high- and low-pressure pipes nuts (B).

NOTE:

The remaining steps are performed inside the rear luggage area of the vehicle.

6. Remove the luggage side finisher lower RH. Refer to INT-19, "Removal and Installation"

.

7. Disconnect the rear heater core hoses (1 and 2) from the rear heater core (3).

: Front

ALIIA0216ZZ

ALIIA0218ZZ

Revision: December 20092009 QX56

Page 2306 of 4171

HA-42

< ON-VEHICLE REPAIR >

HIGH-PRESSURE PIPE

8. Remove the rear high- and low-pressure pipes bracket bolt (A)to release the bracket.

Rear blower motor (1)

: Front

9. Remove the rear high- and low-pressure pipes bolt (A) to dis- connect the rear high- and low-pressure pipes from the rear

expansion valve (1).

: Front

CAUTION:

Cap or wrap the joint of the pipes with suitable material

such as vinyl tape to avoid the entry of air.

10. Disconnect the following electrical connectors: Rear air mix door motor (1)

Rear variable blower control (2)

Rear blower motor (3)

: Front

11. Disconnect the ducts from the rear heater and cooling unit assembly. Refer to HA-29, "Component"

.

12. Remove the rear heater and cooling unit assembly. CAUTION:

Cap or wrap the joint of the pipes with suitable material such as viny l tape to avoid the entry of air.

13. Remove the rear high- and low-pressure A/C pipes.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-rings on the rear high- and low-pr essure A/C pipes with a new ones, then apply com-

pressor oil to them for installation.

After charging the refrigerant, check for leaks.

Removal and Installation for Underfloor Rear High- and Lo w-Pressure A/C and Heater

Core Pipes

INFOID:0000000003775318

REMOVAL

1. Drain the engine coolant. Refer to CO-11, "Changing Engine Coolant".

2. Disconnect the battery negative terminal.

3. Disconnect the generator harness.

4. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure"

.

ALIIA0219ZZ

ALIIA0220ZZ

ALIIA0221ZZ

Revision: December 20092009 QX56

Page 2308 of 4171

HA-44

< ON-VEHICLE REPAIR >

CONDENSER

CONDENSER

Removal and Installation for CondenserINFOID:0000000003775319

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Remove the radiator. Refer to CO-15, "Removal and Installation"

.

CAUTION:

Be careful not to damage the core su rface of the condenser and the radiator.

3. Disconnect the high-pressure flexible hose and the high-pressure pipe from the condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable ma terial such as vinyl tape to avoid the entry of air.

4. Disconnect the refrigerant pressure sensor connector. Remove the refrigerant pressure sensor from the condenseras necessary.

5. Lift the condenser out of the mounting grommets to remove the condenser.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-rings of the high-p ressure pipe, refrigerant pressure sensor, and high-pressure flexi-

ble hose with new ones, then apply compr essor oil to them when installing them.

After charging refrigerant, check for leaks.

Replace the grommets as necessary.

LJIA0145E

Revision: December 20092009 QX56