service INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2232 of 4171

GI-38

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

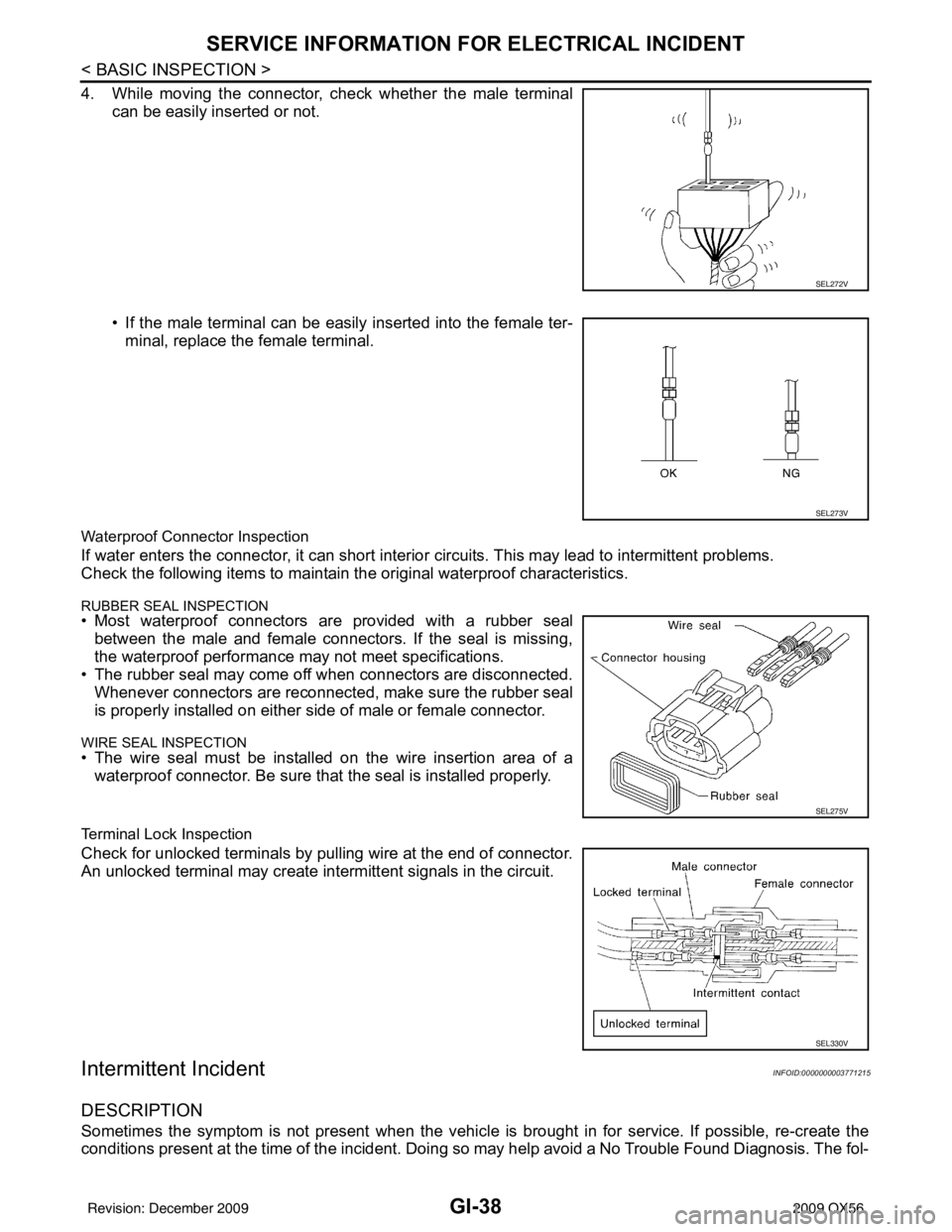

4. While moving the connector, check whether the male terminalcan be easily inserted or not.

• If the male terminal can be easily inserted into the female ter-minal, replace the female terminal.

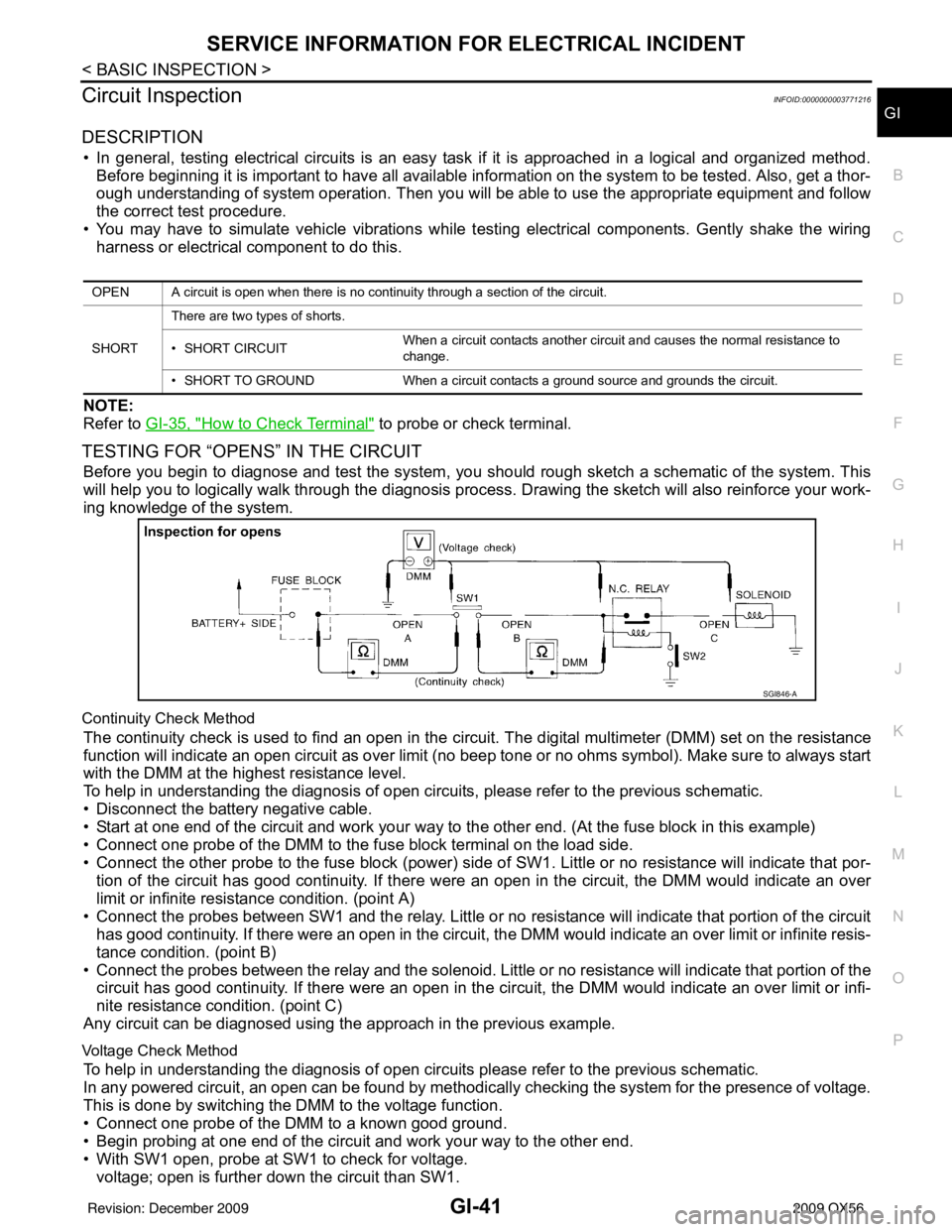

Waterproof Connector Inspection

If water enters the connector, it can short interior circuits. This may lead to intermittent problems.

Check the following items to maintain the original waterproof characteristics.

RUBBER SEAL INSPECTION• Most waterproof connectors are provided with a rubber seal between the male and female connectors. If the seal is missing,

the waterproof performance may not meet specifications.

• The rubber seal may come off when connectors are disconnected.

Whenever connectors are reconnected, make sure the rubber seal

is properly installed on either side of male or female connector.

WIRE SEAL INSPECTION• The wire seal must be installed on the wire insertion area of awaterproof connector. Be sure that the seal is installed properly.

Terminal Lock Inspection

Check for unlocked terminals by pulling wire at the end of connector.

An unlocked terminal may create intermittent signals in the circuit.

Intermittent IncidentINFOID:0000000003771215

DESCRIPTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doi ng so may help avoid a No Trouble Found Diagnosis. The fol-

SEL272V

SEL273V

SEL275V

SEL330V

Revision: December 20092009 QX56

Page 2233 of 4171

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-39

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

lowing section illustrates ways to simulate the c onditions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:• Vehicle vibration

• Heat sensitive

• Freezing

• Water intrusion

• Electrical load

• Cold or hot start up

Get a thorough description of the incident from the customer . It is important for simulating the conditions of the

problem.

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the following illustra-

tion.

Connector & Harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the syst em for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosi on. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

Sensor & Relay

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

Engine Compartment

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

• Connectors not fully seated.

• Wiring harness not long enough and is being stressed due to engine vibrations or rocking.

• Wires laying across brackets or moving components.

• Loose, dirty or corroded ground wires.

• Wires routed too close to hot components.

To inspect components under the hood, start by verifyi ng the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previous ly explained. Using the wiring diagrams inspect the

wiring for continuity.

Behind the Instrument Panel

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

Under Seating Areas

SGI839

Revision: December 20092009 QX56

Page 2234 of 4171

GI-40

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under s eating areas, inspect wire routing for possible damage or

pinching.

HEAT SENSITIVE

• The customer's concern may occur during hot weather or after car has sat for a short time. In such cases you will want to check for a

heat sensitive condition.

• To determine if an electrical component is heat sensitive, heat the component with a heat gun or equivalent.

CAUTION:

Do not heat components above 60 °C (140° ).

• If incident occurs while heating the unit, either replace or properly insulate the component.

FREEZING

• The customer may indicate the incident goes away after the carwarms up (winter time). The cause could be related to water freez-

ing somewhere in the wiring/electrical system.

• There are two methods to check for this. The first is to arrange for the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked out-

side overnight. In the morning, do a quick and thorough diagnosis

of those electrical components which could be affected.

• The second method is to put the suspect component into a freezer long enough for any water to freeze. Reinstall the part into the car

and check for the reoccurrence of the incident. If it occurs, repair or

replace the component.

WATER INTRUSION

The incident may occur only during high humidity or in rainy/snowy

weather. In such cases the incident could be caused by water intru-

sion on an electrical part. This can be simulated by soaking the car

or running it through a car wash.

CAUTION:

Do not spray water directly on any electrical components.

ELECTRICAL LOAD

The incident may be electrical load sensitive. Perform diagnosis with

all accessories (including A/C, rear window defogger, radio, fog

lamps) turned on.

COLD OR HOT START UP

On some occasions an electrical incident may occur only when the car is started cold, or it may occur when

the car is restarted hot shortly after being turned off. In these cases you may have to keep the car overnight to

make a proper diagnosis.

SGI842

SGI843

SGI844

SGI845

Revision: December 20092009 QX56

Page 2235 of 4171

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-41

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Circuit InspectionINFOID:0000000003771216

DESCRIPTION

• In general, testing electrical circuits is an easy task if it is approached in a logical and organized method. Before beginning it is important to have all available information on the system to be tested. Also, get a thor-

ough understanding of system operation. Then you will be able to use the appropriate equipment and follow

the correct test procedure.

• You may have to simulate vehicle vibrations while te sting electrical components. Gently shake the wiring

harness or electrical component to do this.

NOTE:

Refer to GI-35, "

How to Check Terminal" to probe or check terminal.

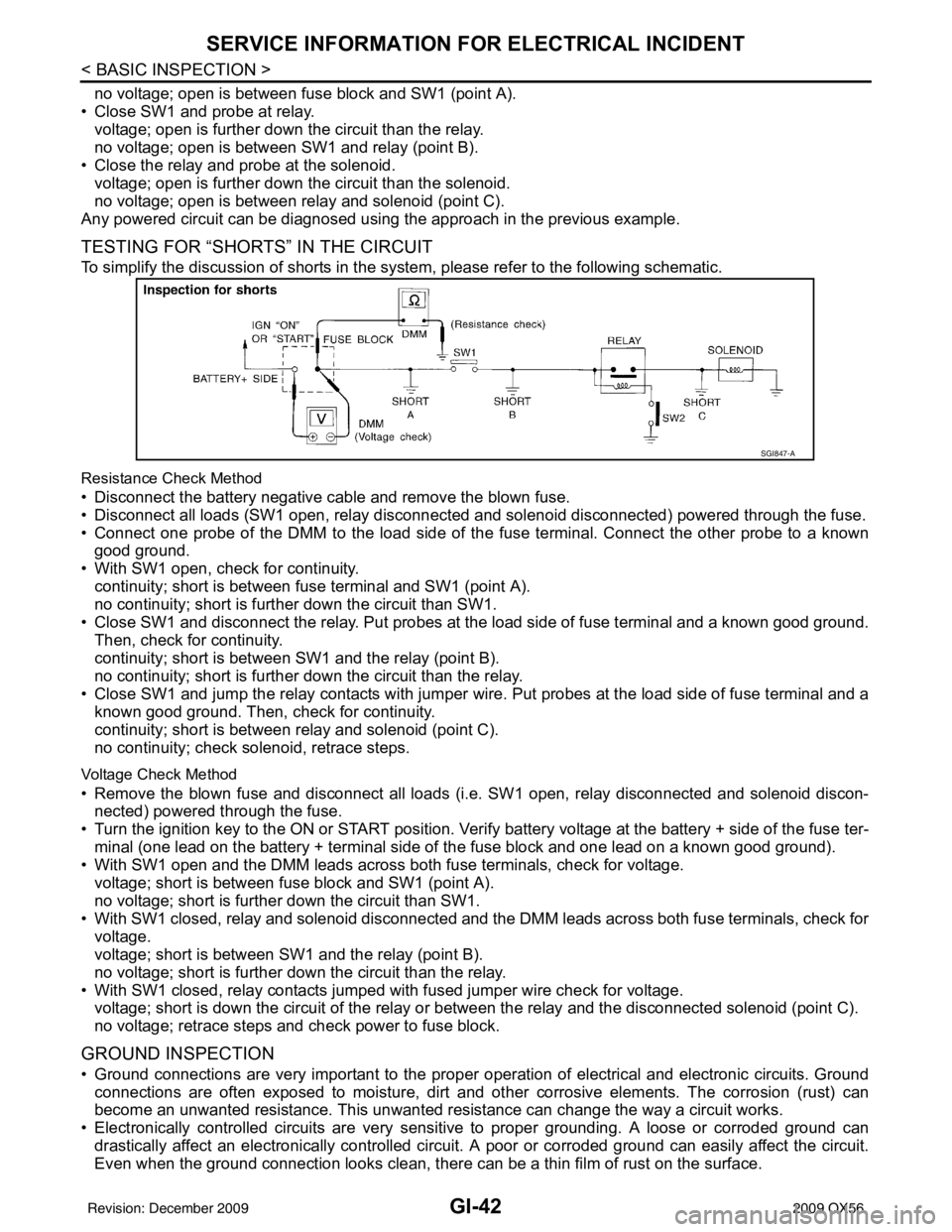

TESTING FOR “OPENS” IN THE CIRCUIT

Before you begin to diagnose and test the system, you should rough sketch a schematic of the system. This

will help you to logically walk through the diagnosis process. Drawing the sketch will also reinforce your work-

ing knowledge of the system.

Continuity Check Method

The continuity check is used to find an open in the circui t. The digital multimeter (DMM) set on the resistance

function will indicate an open circuit as over limit (no beep tone or no ohms symbol). Make sure to always start

with the DMM at the highest resistance level.

To help in understanding the diagnosis of open circui ts, please refer to the previous schematic.

• Disconnect the battery negative cable.

• Start at one end of the circuit and work your way to the other end. (At the fuse block in this example)

• Connect one probe of the DMM to the fuse block terminal on the load side.

• Connect the other probe to the fuse block (power) side of SW1. Little or no resistance will indicate that por-

tion of the circuit has good continuity. If there were an open in the circuit, the DMM would indicate an over

limit or infinite resistance condition. (point A)

• Connect the probes between SW1 and the relay. Little or no resistance will indicate that portion of the circuit

has good continuity. If there were an open in the circuit, t he DMM would indicate an over limit or infinite resis-

tance condition. (point B)

• Connect the probes between the relay and the solenoid. Little or no resistance will indicate that portion of the

circuit has good continuity. If there were an open in the ci rcuit, the DMM would indicate an over limit or infi-

nite resistance condition. (point C)

Any circuit can be diagnosed using the approach in the previous example.

Voltage Check Method

To help in understanding the diagnosis of open circuits please refer to the previous schematic.

In any powered circuit, an open can be found by methodica lly checking the system for the presence of voltage.

This is done by switching the DMM to the voltage function.

• Connect one probe of the DMM to a known good ground.

• Begin probing at one end of the circuit and work your way to the other end.

• With SW1 open, probe at SW1 to check for voltage. voltage; open is further down the circuit than SW1.

OPEN A circuit is open when there is no continuity through a section of the circuit.

SHORT There are two types of shorts.

• SHORT CIRCUIT

When a circuit contacts another circuit and causes the normal resistance to

change.

• SHORT TO GROUND When a circuit contacts a ground source and grounds the circuit.

SGI846-A

Revision: December 20092009 QX56

Page 2236 of 4171

GI-42

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

no voltage; open is between fuse block and SW1 (point A).

• Close SW1 and probe at relay. voltage; open is further down the circuit than the relay.

no voltage; open is between SW1 and relay (point B).

• Close the relay and probe at the solenoid. voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

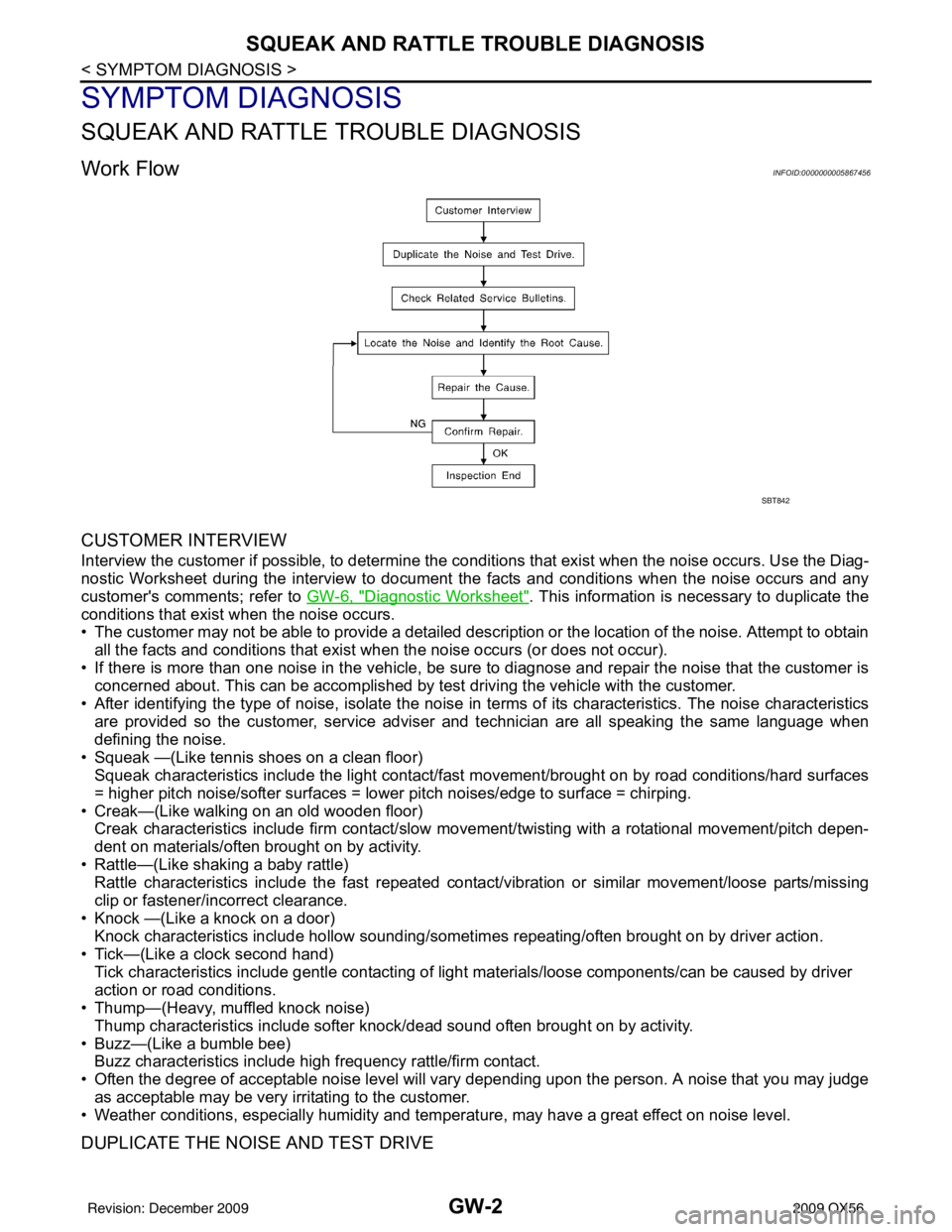

TESTING FOR “SHORTS” IN THE CIRCUIT

To simplify the discussion of shorts in the system, please refer to the following schematic.

Resistance Check Method

• Disconnect the battery negative cable and remove the blown fuse.

• Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the fuse.

• Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a known good ground.

• With SW1 open, check for continuity. continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

• Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good ground. Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

• Close SW1 and jump the relay contacts with jumper wire. Put probes at the load side of fuse terminal and a known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

Voltage Check Method

• Remove the blown fuse and disconnect all loads (i.e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

• Turn the ignition key to the ON or START position. Verify battery voltage at the battery + side of the fuse ter- minal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

• With SW1 open and the DMM leads across both fuse terminals, check for voltage. voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

• With SW1 closed, relay and solenoid disconnected and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

• With SW1 closed, relay contacts jumped with fused jumper wire check for voltage. voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

GROUND INSPECTION

• Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

• Electronically controlled circuits are very sens itive to proper grounding. A loose or corroded ground can

drastically affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit.

Even when the ground connection looks clean, there c an be a thin film of rust on the surface.

SGI847-A

Revision: December 20092009 QX56

Page 2237 of 4171

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-43

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

• When inspecting a ground connection follow these rules:

- Remove the ground bolt or screw.

- Inspect all mating surfaces for tarnish, dirt, rust, etc.

- Clean as required to assure good contact.

- Reinstall bolt or screw securely.

- Inspect for “add-on” accessories which may be interfering with the ground circuit.

- If several wires are crimped into one ground eyelet terminal, check for proper crimps. Make sure all of the wires are clean, securely fastened and providing a good ground path. If multiple wires are cased in one eye-

let make sure no ground wires have excess wire insulation.

• For detailed ground distribution information, refer to “Ground Distribution” in PG section.

VOLTAGE DROP TESTS

• Voltage drop tests are often used to find components or circuits which have excessive resistance. A voltage drop in a circuit is caused by a resistance when the circuit is in operation.

• Check the wire in the illustration. When measuring re sistance with DMM, contact by a single strand of wire

will give reading of 0 ohms. This would indicate a good circuit. When the circuit operates, this single strand

of wire is not able to carry the current. The single strand will have a high resistance to the current. This will

be picked up as a slight voltage drop.

• Unwanted resistance can be caused by many situations as follows:

- Undersized wiring (single strand example)

- Corrosion on switch contacts

- Loose wire connections or splices.

• If repairs are needed always use wire that is of the same or larger gauge.

Measuring Voltage Drop — Accumulated Method

• Connect the DMM across the connector or part of the ci rcuit you want to check. The positive lead of the

DMM should be closer to power and the negative lead closer to ground.

• Operate the circuit.

• The DMM will indicate how many volts are being used to “push” current through that part of the circuit.

SGI853

Revision: December 20092009 QX56

Page 2238 of 4171

GI-44

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Note in the illustration that there is an excessive 4.1 volt drop between the battery and the bulb.

Measuring Voltage Drop — Steb-by-Step

• The step-by-step method is most useful for isolating excessive drops in low voltage systems (such as those

in “Computer Controlled Systems”).

• Circuits in the “Computer Controlled System” operate on very low amperage.

• The (Computer Controlled) system oper ations can be adversely affected by any variation in resistance in the

system. Such resistance variation may be caused by poor connection, improper installation, improper wire

gauge or corrosion.

• The step by step voltage drop test can identify a component or wire with too much resistance.

CONTROL UNIT CIRCUIT TEST

System Description

• When the switch is ON, the control unit lights up the lamp.

CASE 1

SGI974

SAIA0258E

MGI034A

Revision: December 20092009 QX56

Page 2239 of 4171

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-45

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

INPUT-OUTPUT VOLTAGE CHART

• The voltage value is based on the body ground.

• *: If high resistance exists in the switch side circuit (caused by a single strand), terminal 1 does not detect battery voltag e. Control unit

does not detect the switch is ON even if the switch does not turn ON. Therefore, the control unit does not supply power to ligh t up the

lamp.

CASE 2

INPUT-OUTPUT VOLTAGE CHART

• The voltage value is based on the body ground.

• *: If high resistance exists in the switch side circuit (caused by a single strand), terminal 2 does not detect approx. 0V. Co ntrol unit

does not detect the switch is ON even if the switch does not turn ON. Therefore, the control unit does not control ground to li ght up the

lamp. Terminal No. Description

Condition Value (Approx.)In case of high resistance such as single

strand (V) *

+ −Signal name Input/

Output

1 Body

ground Switch Input Switch ON

Battery voltageLower than battery voltage Approx. 8 (Ex-

ample)

Switch OFF 0 V Approx. 0

2 Body

ground Lamp Output Switch ON

Battery voltage App rox. 0 (Inoperative lamp)

Switch OFF 0 V Approx. 0

Terminal No. Description

Condition Value (Approx.)In case of high resistance such as single

strand (V) *

+ −Signal name Input/

Output

1 Body

ground Lamp Output Switch ON

0VBattery voltage (Inoperative lamp)

Switch OFF Battery voltage Battery voltage

2 Body

ground Switch Input Switch ON

0 V Higher than 0 Approx. 4 (Example)

Switch OFF 5 V Approx. 5

MGI035A

Revision: December 20092009 QX56

Page 2243 of 4171

GW-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

DE

F

G H

I

J

L

M

SECTION GW

A

B

GW

N

O P

CONTENTS

GLASS & WINDOW SYSTEM

SYMPTOM DIAGNOSIS ..... ..........................2

SQUEAK AND RATTLE TROUBLE DIAGNO-

SIS .................................................................. .....

2

Work Flow ........................................................... ......2

Generic Squeak and Rattle Troubleshooting ............4

Diagnostic Worksheet ...............................................6

PRECAUTION ...............................................8

PRECAUTIONS .............................................. .....8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

8

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

8

Handling for Adhesive and Primer ............................9

PREPARATION ...........................................10

PREPARATION .................................................10

Special Service Tool ............................................ ....10

Commercial Service Tool ........................................10

ON-VEHICLE REPAIR .................................11

WINDSHIELD GLASS .......................................11

Removal and Installation ..................................... ....11

REAR WINDOW GLASS AND MOLDING ........13

Removal and Installation .........................................13

Rear Window Stay Disposal ....................................14

FRONT DOOR GLASS AND REGULATOR .....15

Removal and Installation .........................................15

REAR DOOR GLASS AND REGULATOR .......19

Removal and Installation .........................................19

SIDE WINDOW GLASS ....................................22

Removal and Installation .........................................22

Revision: December 20092009 QX56

Page 2244 of 4171

GW-2

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

Work FlowINFOID:0000000005867456

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to GW-6, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist w hen the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee) Buzz characteristics include hi gh frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: December 20092009 QX56