wheel INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 4081 of 4171

PREPARATIONWT-39

< PREPARATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000003772400

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000003772401

Tool number

(Kent-Moore No.)

Tool name Description

KV991B1000

(J-45295)

Transmitter activation tool • Transmitter wake up operation

• ID registration procedure

WEIA0144E

Tool name

Description

Power tool Removing wheel nuts

PBIC0190E

Revision: December 20092009 QX56

Page 4082 of 4171

WT-40

< ON-VEHICLE MAINTENANCE >

WHEEL

ON-VEHICLE MAINTENANCE

WHEEL

InspectionINFOID:0000000003772402

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. Ifdeformed, remove wheel and check wheel runout.

a. Remove tire from wheel and mount wheel on a tire balance machine.

b. Set dial indicator as shown. Refer to WT-45, "

Road Wheel" .

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

SFA975B

Revision: December 20092009 QX56

Page 4083 of 4171

WHEEL AND TIRE ASSEMBLYWT-41

< ON-VEHICLE REPAIR >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

ON-VEHICLE REPAIR

WHEEL AND TIRE ASSEMBLY

AdjustmentINFOID:0000000005873223

BALANCING WHEELS (ADH ESIVE WEIGHT TYPE)

Preparation Before Adjustment

Remove inner and outer balance weights from the r oad wheel using releasing agent, remove double-faced

adhesive tape from the road wheel.

CAUTION:

• Be careful not scratch the road wheel during removal.

• After removing double-faced adhesive tape, wipe clean traces of releasing agent from the road

wheel.

Wheel Balance Adjustment

CAUTION:

• Use canter hole cone-type clampi ng machines due to clad wheels.

• If a balancer machine has an adhesive weight mode setting, select the adhesive weight mode setting and

skip Step 2. below. If a balancer machine only has the clip-on (rim flange) weight mode setting, follow Step 2.

to calculate the correct size adhesive weight.

1. Set road wheel on balancer machine using the cent er hole as a guide. Start the balancer machine.

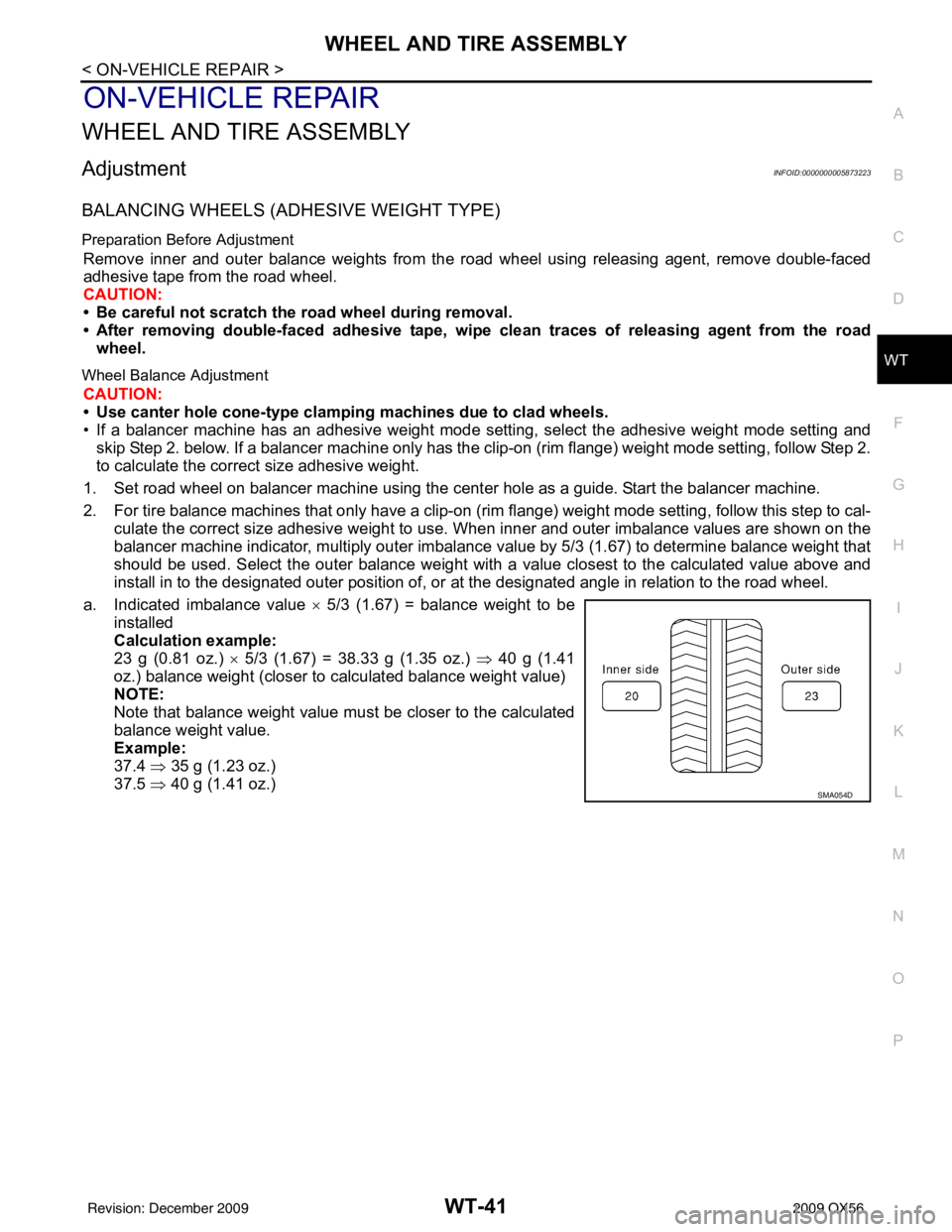

2. For tire balance machines that only have a clip-on (ri m flange) weight mode setting, follow this step to cal-

culate the correct size adhesive weight to use. When inner and outer imbalance values are shown on the

balancer machine indicator, multiply outer imbalance value by 5/3 (1.67) to determine balance weight that

should be used. Select the outer balance weight with a value closest to the calculated value above and

install in to the designated outer position of, or at the designated angle in relation to the road wheel.

a. Indicated imbalance value × 5/3 (1.67) = balance weight to be

installed

Calculation example:

23 g (0.81 oz.) × 5/3 (1.67) = 38.33 g (1.35 oz.) ⇒ 40 g (1.41

oz.) balance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4 ⇒ 35 g (1.23 oz.)

37.5 ⇒ 40 g (1.41 oz.)

SMA054D

Revision: December 20092009 QX56

Page 4084 of 4171

WT-42

< ON-VEHICLE REPAIR >

WHEEL AND TIRE ASSEMBLY

3. Install balance weight in the position shown.CAUTION:

• Do not install the inner bala nce weight before installing

the outer balance weight.

• Before installing the balance weight, be sure to clean the mating surface of the road wheel.

• When installing balance weight (1) to road wheel, set it into the grooved area (A) on the inner wall of the road wheel as shown

so that the balance weight center (B) is aligned with the bal-

ancer machine indication position (angle) (C).

CAUTION:

• Always use genuine NISSAN adhesive balance weights.

• Balance weights are non-reusable; always replace withnew ones.

• Do not install more than three sheets of balance weight.

4. If calculated balance weight value exceeds 50 g (1.76 oz.), install two balance weight sheets in line with each other as

shown.

CAUTION:

Do not install one balance weight sheet on top another.

5. Start balancer machine again.

6. Install balance weight on inner side of road wheel in the bal- ancer machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

7. Start balancer machine. Make sure that inner and outer residual imbalance values are 5 g (0.17 oz.) each or below.

8. If either residual imbalance value exceeds 5 g (0.17 oz.), repeat installation procedures.

TIRE ROTATION

• Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-6, "

General Maintenance".

• When installing the wheel, tighten wheel nuts to the specified

torque.

CAUTION:

• Do not include the spare tire when rotating the tires.

• When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

• Be careful not to tighten wheel nut at torque exceeding the criteria for preventing strain of disc rotor.

• Use NISSAN genuine wheel nuts for aluminum wheels.

JPEIC0040ZZ

Wheel balance Dynamic (At flange) Static (At flange)

Maximum allowable un-

balance Refer to

WT-45, "

Road Wheel".

PEIA0033E

Wheel nut tightening

torque : 133 N·m (14 kg-m, 98 ft-lb)

SMA829C

Revision: December 20092009 QX56

Page 4085 of 4171

REMOVAL AND INSTALLATIONWT-43

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Transmitter (Pressure Sensor)INFOID:0000000003772405

REMOVAL

1. Deflate tire. Unscrew transmitter retaining nut and allow transmitter to fall into tire.

2. Gently bounce tire so that transmitter falls to bottom of tire. Place wheel and tire assembly on tire changing machine and

break both tire beads. Ensure that the transmitter remains at the

bottom of the tire while breaking the bead.

3. Turn tire so that valve hole is at bottom, and gently bounce the tire to ensure transmitter is near valve hole. Carefully lift tire onto

turntable and position valve hole (and transmitter) 270 degrees

from mounting/dismounting head.

4. Lubricate tire well, and remove top side of tire. Reach inside the tire and remove the transmitter.

5. Remove the second side of the tire as normal.

INSTALLATION

1. Place first side of tire onto rim.

2. Mount transmitter on rim and tighten nut to specification.

SEIA0047E

WEIA0046E

SEIA0049E

Transmitter nut : 7.7 N·m (0.79 kg-m, 68 in-lb)

WEIA0137E

Revision: December 20092009 QX56

Page 4086 of 4171

WT-44

< REMOVAL AND INSTALLATION >

REMOVAL AND INSTALLATION

3. Place wheel on turntable of tire machine. Ensure that transmitteris 270 degrees from mounting/dismounting head.

NOTE:

Do not touch transmitter with mounting head.

4. Lubricate tire well, and install second side of tire as normal. Ensure that tire does not rotate relative to rim.

5. Inflate tire and balance the wheel and tire assembly. Refer to WT-41, "

Adjustment".

6. Install Wheel and tire assembly in appropriate wheel position on vehicle.

NOTE:

If replacing the transmitter, then transmitter wake up operation

must be performed. Refer to WT-5, "

Transmitter Wake Up Operation" .

7. Adjust neutral position of steering angle sensor. Refer to BRC-8, "

ADJUSTMENT OF STEERING ANGLE

SENSOR NEUTRAL POSITION : Special Repair Requirement" .

WEIA0046E

Revision: December 20092009 QX56

Page 4087 of 4171

SERVICE DATA AND SPECIFICATIONS (SDS)WT-45

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DF

G H

I

J

K L

M A

B

WT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

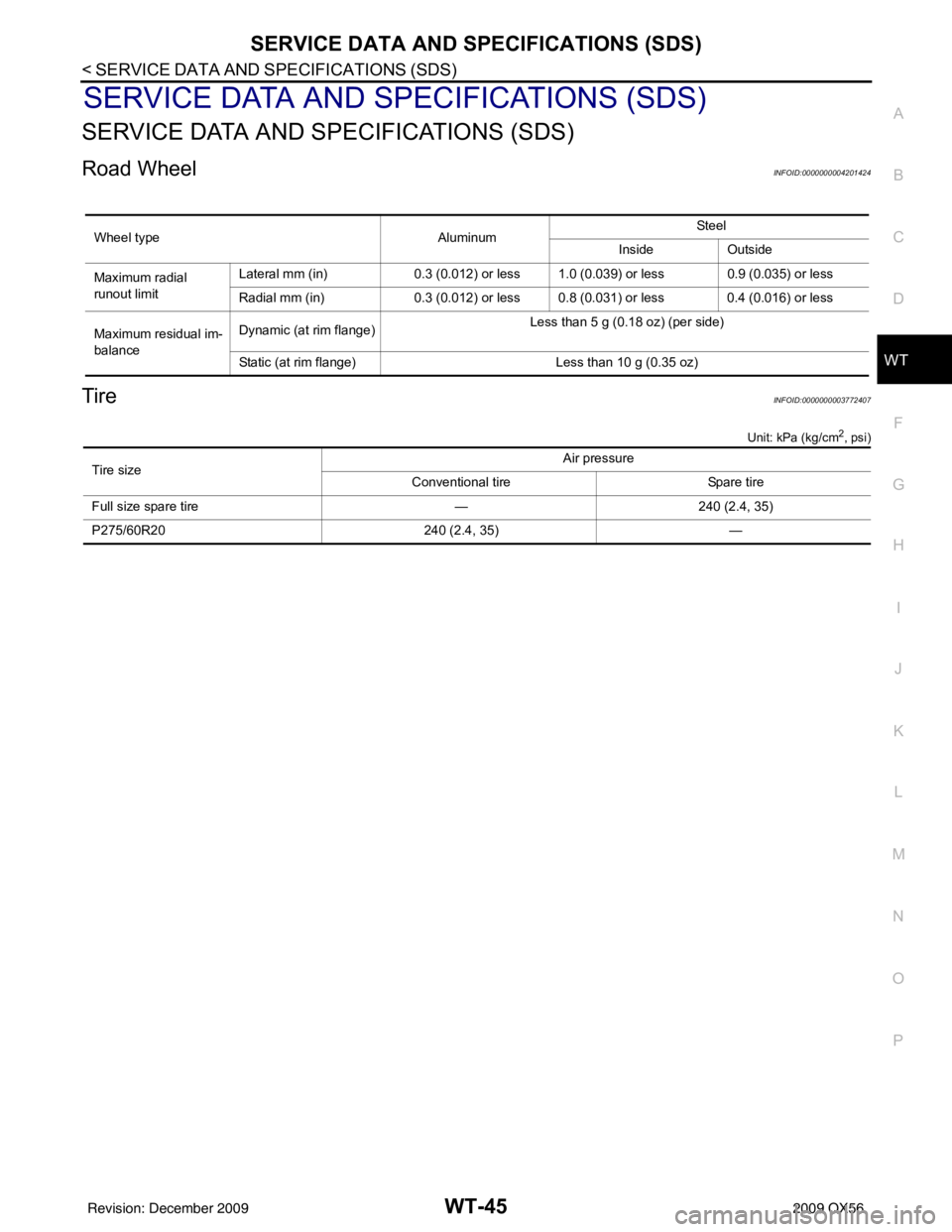

Road WheelINFOID:0000000004201424

TireINFOID:0000000003772407

Unit: kPa (kg/cm2, psi)

Wheel type AluminumSte el

Inside Outside

Maximum radial

runout limit Lateral mm (in)

0.3 (0.012) or less 1.0 (0.039) or less 0.9 (0.035) or less

Radial mm (in) 0.3 (0.012) or less 0.8 (0.031) or less 0.4 (0.016) or less

Maximum residual im-

balance Dynamic (at rim flange)

Less than 5 g (0.18 oz) (per side)

Static (at rim flange) Less than 10 g (0.35 oz)

Tire size Air pressure

Conventional tire Spare tire

Full size spare tire —240 (2.4, 35)

P275/60R20 240 (2.4, 35)—

Revision: December 20092009 QX56

Page 4089 of 4171

WW-2

Wiring Diagram .......................................................61

Fail Safe .................................................................64

SYMPTOM DIAGNOSIS .............................66

WIPER AND WASHER SYSTEM SYMPTOMS

...

66

Symptom Table ................................................... ...66

NORMAL OPERATING CONDITION ................69

Description ........................................................... ...69

FRONT WIPER DOES NOT OPERATE ............70

Description ........................................................... ...70

Diagnosis Procedure ..............................................70

PRECAUTION .............................................72

PRECAUTION ... .............................................. ...72

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ...

72

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ..................................

72

ON-VEHICLE REPAIR ................................74

FRONT WIPER ARM ...................................... ...74

Front Wiper Arms ................................................ ...74

FRONT WIPER DRIVE ASSEMBLY .................75

Wiper Motor and Linkage ..................................... ...75

FRONT WASHER TUBE ...................................76

Washer Tube Layout ............................................ ...76

FRONT WASHER NOZZLE ..............................77

Washer Nozzle Adjustment .................................. ...77

WASHER TANK ................................................78

Washer Fluid Reservoir ..........................................78

FRONT WASHER PUMP ..................................79

Washer Motor ...................................................... ...79

FRONT WIPER AND WASHER SWITCH .........80

Wiper and Washer Switch .................................... ...80

REAR WIPER AND WASHER SYSTEM ...........81

Rear Wiper Arm ................................................... ...81

Rear Wiper Motor ....................................................81

Rear Washer Nozzle Adjustment ............................82

Rear Washer Tube Layout ......................................83

Rear Washer Nozzle ...............................................83

Rear Wiper and Washer Switch ..............................83

Washer Fluid Reservoir ....................................... ...84

Washer Motor .........................................................84

Revision: December 20092009 QX56

Page 4159 of 4171

WW-72

< PRECAUTION >

PRECAUTION

PRECAUTION

PRECAUTION

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005867715

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005867716

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56