wheel INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3953 of 4171

BLOWER MOTORVTL-13

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

VTL

N

O P

Installation is in the reverse order of removal.

REAR BLOWER MOTOR

Removal

1. Remove the rear heater and cooling unit assembly. Refer to VTL-16, "Removal and Installation".

2. Disconnect the rear blower motor electrical connector.

3. Remove the three screws and remove the rear blower motor.

4. Remove blower motor wheel as necessary to transfer to new blower motor.

Installation

Installation is in the reverse order of removal.

Revision: December 20092009 QX56

Page 4043 of 4171

WT-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION WT

A

B

WT

N

O PCONTENTS

ROAD WHEELS & TIRES

BASIC INSPECTION ....... .............................3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

Repair Work Flow ................................................ ......3

INSPECTION AND ADJUSTMENT .....................5

Preliminary Check ............................................... ......5

Transmitter Wake Up Operation ...............................5

ID Registration Procedure .........................................6

FUNCTION DIAGNOSIS ...............................8

TPMS .............................................................. .....8

System Diagram .................................................. ......8

System Description ...................................................8

System Component .................................................10

DIAGNOSIS SYSTEM (BCM) ............................11

CONSULT-III Function (BCM) ............................. ....11

Self-Diagnosis (With CONSULT-III) ........................12

Self-Diagnosis (Without CONSULT-III) ...................13

COMPONENT DIAGNOSIS .........................14

C1708 - C1711 DATA FROM TRANSMITTER

NOT BEING RECEIVED ................................. ....

14

Description .......................................................... ....14

DTC Logic ...............................................................14

Data from Transmitter Not Being Received ............14

Special Repair Requirement ...................................15

C1712 - C1715, C1720 - C1723, C1724 -

C1727 TRANSMITTER MALFUNCTION ....... ....

16

Description .......................................................... ....16

DTC Logic ...............................................................16

Transmitter Malfunction ...........................................16

Special Repair Requirement ...................................17

C1716 - C1719 TRANSMITTER PRESSURE

MALFUNCTION .............................................. ....

18

Description .......................................................... ....18

DTC Logic ...............................................................18

Transmitter Pressure Malfunction ............................18

Special Repair Requirement ................................ ....18

C1729 VEHICLE SPEED SIGNAL ....................19

Description ...............................................................19

DTC Logic ................................................................19

Vehicle Speed Signal ..............................................19

C1735 IGNITION SIGNAL .................................20

Description ...............................................................20

DTC Logic ................................................................20

Diagnosis Procedure ...............................................20

ECU DIAGNOSIS .........................................21

BCM (BODY CONTROL MODULE) .................21

Reference Value .................................................. ....21

Wiring Diagram ........................................................23

Self-Diagnosis (With CONSULT-III) ........................26

Self-Diagnosis (Without CONSULT-III) ...................27

SYMPTOM DIAGNOSIS ..............................29

TPMS .................................................................29

Symptom Table ................................................... ....29

LOW TIRE PRESSURE WARNING LAMP

DOES NOT TURN ON .......................................

30

Low Tire Pressure Warning Lamp Does Not Come

On When Ignition Switch Is Turned On ...................

30

LOW TIRE PRESSURE WARNING LAMP

STAYS ON ........................................................

31

Low Tire Pressure Warning Lamp Stays On When

Ignition Switch Is Turned On ............................... ....

31

LOW TIRE PRESSURE WARNING LAMP

BLINKS .............................................................

32

Low Tire Pressure Warning Lamp Flashes When

Ignition Switch Is Turned On ...................................

32

HAZARD WARNING LAMPS FLASH ..............33

Revision: December 20092009 QX56

Page 4044 of 4171

WT-2

Hazard Warning Lamps Flash When Ignition

Switch Is Turned On ...............................................

33

"TIRE PRESSURE" INFORMATION IN DIS-

PLAY UNIT DOES NOT EXIST .........................

34

"TIRE PRESSURE" Information in Display Unit

Does Not Exist ..................................................... ...

34

ID REGISTRATION CANNOT BE COMPLET-

ED ......................................................................

35

ID Registration Cannot Be Completed ................ ...35

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ......................... ...

36

NVH Troubleshooting Chart ................................ ...36

PRECAUTION .............................................37

PRECAUTIONS .............................................. ...37

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ...

37

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ..................................

37

PREPARATION ...........................................39

PREPARATION .............................................. ...39

Special Service Tool ............................................ ...39

Commercial Service Tool ........................................39

ON-VEHICLE MAINTENANCE ..................40

WHEEL ........................................................... ...40

Inspection ............................................................. ...40

ON-VEHICLE REPAIR ...............................41

WHEEL AND TIRE ASSEMBLY .................... ...41

Adjustment ........................................................... ...41

REMOVAL AND INSTALLATION ..............43

REMOVAL AND INSTALLATION .................. ...43

Transmitter (Pressure Sensor) ............................. ...43

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................. ...............

45

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

45

Road Wheel ......................................................... ...45

Tire ..........................................................................45

Revision: December 20092009 QX56

Page 4048 of 4171

WT-6

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

3. When the BCM finishes assigning each tire ID, the BCM flashes the hazard warning lamps and sendsflashing indicator status by CAN according to the following time chart.

4. After completing wake up of all transmitters, make sure low tire pressure warning lamp goes out.

ID Registration ProcedureINFOID:0000000003772366

ID REGISTRATION WITH TRANSMITTER ACTIVATION TOOL

NOTE:

This procedure must be done after replacement of a low tire pressure warning transmitter or BCM.

New replacement transmitters are provided "asleep" and must first be "woken up" using Transmitter

Activation Tool J-45295 before ID registration can be performed.

1. Connect CONSULT-III.

2. Select "ID REGIST" under BCM.

3. Push the transmitter activation tool against the tire near the front left transmitter. Press the button for 5 seconds.

4. Register the IDs in order from FR LH, FR RH, RR RH and RR LH. When ID registration of each wheel has been completed, the hazard warning lamps flash.

5. After completing all ID registrations, press “END” to complete the procedure.

NOTE:

Be sure to register all of the IDs in order from FR LH, FR RH, RR RH, to RR LH, or the self-diagnostic results

display will not function properly.

ID REGISTRATION WITHOUT TRANSMITTER ACTIVATION TOOL

NOTE:

WEIA0177E

Tool number : (J-45295)

LEIA0036E

Step Activation tire position Hazard warning lamp CONSULT-III

1 Front LH

2 times flashing “YET”

↓

“DONE”

2F

ro n t R H

3R ear R H

4 Rear LH

Revision: December 20092009 QX56

Page 4050 of 4171

WT-8

< FUNCTION DIAGNOSIS >

TPMS

FUNCTION DIAGNOSIS

TPMS

System DiagramINFOID:0000000003772367

System DescriptionINFOID:0000000003772368

BODY CONTROL MODULE (BCM)

The BCM is shown with the lower instrument panel LH removed. The

BCM reads the air pressure signal received by the remote keyless

entry receiver, and controls the low tire pressure warning lamp as

shown below. It also has a self-d iagnosis function to detect a system

malfunction.

TRANSMITTER

A sensor-transmitter integrated with a valve is installed in each

wheel, and transmits a detected air pr essure signal in the form of a

radio wave. The radio signal is received by the remote keyless entry

receiver.

REMOTE KEYLESS ENTRY RECEIVER

ALEIA0004GB

Condition Low tire pressure warning lamp

System normal On for 1 second after ignition ON

Tire less than 193 kPa (2.0 kg/cm

2 , 28 psi)

[Flat tire] ON

TPMS malfunction After key ON, flashes once per sec-

ond for 1 minute, then stays ON

LEIA0068E

WEIA0137E

Revision: December 20092009 QX56

Page 4051 of 4171

TPMSWT-9

< FUNCTION DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

The remote keyless entry receiver is shown with the instrument

panel RH removed. The remote keyless entry receiver receives the

air pressure signal transmitted by the transmitter in each wheel.

COMBINATION METER

The combination meter receives tire pressure status from the BCM

using CAN communication. When a low tire pressure condition is

sensed by the BCM, the combination meter low tire pressure warn-

ing lamp is activated.

TIRE PRESSURE WARNING CHECK CONNECTOR

The tire pressure warning check connector can be grounded in order

to initiate self-diagnosis without a CONSULT-III. The tire pressure

warning check connector is located behind the lower portion of the

instrument panel LH. Refer to WT-27, "

Self-Diagnosis (Without

CONSULT-III)".

DISPLAY UNIT

Displays the air pressure of each tire.

NOTE:

After the ignition switch is turned on, the pressure values will not be

displayed until the data of each wheel is received.

LEIA0069E

LEIA0055E

LEIA0068E

AWEIA0017GB

Revision: December 20092009 QX56

Page 4053 of 4171

DIAGNOSIS SYSTEM (BCM)WT-11

< FUNCTION DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

DIAGNOSIS SYSTEM (BCM)

CONSULT-III Function (BCM)INFOID:0000000003772370

CONSULT-III DIAGNOSTIC MODES

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

DESCRIPTION

During driving, the tire pressure monitoring system receives the signal transmitted from the transmitter

installed in each wheel, and turns on the low tire pressure warning lamp when the tire pressure becomes low.

The control unit (BCM) for this system has pr essure judgement and self-diagnosis functions.

FUNCTION

When the tire pressure monitoring system detects low infl ation pressure or an internal malfunction, the low tire

pressure warning lamp in the combination meter comes on. The malfunction is indicated by the low tire pres-

sure warning lamp flashing.

CONSULT-III Application to Ti re Pressure Monitoring System

× : Applicable

– : Not applicable

Data Monitor Mode

Diagnostic mode Description

WORK SUPPORT Supports inspections and adjustments. Commands are transmitted to the BCM

for setting the status suitable for required operation, input/output signals are re-

ceived from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

ITEMSELF-DIAGNOSTIC RESULTS DATA MONITOR

Front - Left transmitter ××

Front - Right transmitter ××

Rear - Left transmitter ××

Rear - Right transmitter ××

Warning lamp —×

Vehicle speed ××

CAN Communication ××

MONITORCONDITION SPECIFICATION

VHCL SPEED Drive vehicle. Vehicle speed (km/h or MPH)

AIR PRESS FL

AIR PRESS FR

AIR PRESS RR

AIR PRESS RL • Drive vehicle for a few minutes.

Tire pressure (kPa or psi)

or

• Ignition switch ON and activation tool is transmitting activation signals.

Revision: December 20092009 QX56

Page 4054 of 4171

WT-12

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

NOTE:

Before performing the self-diagnosis, be sure to register the ID, or the actual malfunction location may be different from that displayed on

CONSULT-III.

Self-Diagnosis (With CONSULT-III)INFOID:0000000003772371

DESCRIPTION

During driving, the tire pressure monitoring system receives the signal trans mitted from the transmitter

installed in each wheel, and turns on the low tire pressure warning lamp when the tire pressure becomes low.

The control unit (BCM) for this system has pressure judgement and self-diagnosis functions.

FUNCTION

When the tire pressure monitoring system detects low inflation pressure or an internal malfunction, the low tire

pressure warning lamp in the combination meter comes on. The malfunction is indicated by the low tire pres-

sure warning lamp flashing.

CONSULT-III Application to Tire Pressure Monitoring System

× : Applicable

– : Not applicable

Data Monitor Mode

NOTE:

Before performing the self-diagnosis, be sure to register the ID, or the actual malfunction location may be different from that displayed on

CONSULT-III. ID REGST FL1

ID REGST FR1

ID REGST RR1

ID REGST RL1

Ignition switch ON ID not registered: YET

ID registered: DONE

WARNING LAMP Low tire pressure

warning lamp on: ON

Low tire pressure warning lamp off: OFF

MONITOR

CONDITION SPECIFICATION

ITEMSELF-DIAGNOSTIC RESULTS DATA MONITOR

Front - Left transmitter ××

Front - Right transmitter ××

Rear - Left transmitter ××

Rear - Right transmitter ××

Warning lamp —×

Vehicle speed ××

CAN Communication ××

MONITORCONDITION SPECIFICATION

VHCL SPEED Drive vehicle. Vehicle speed (km/h or MPH)

AIR PRESS FL

AIR PRESS FR

AIR PRESS RR

AIR PRESS RL • Drive vehicle for a few minutes.

Tire pressure (kPa or psi)

or

• Ignition switch ON and activation tool is transmitting activation signals.

ID REGST FL1

ID REGST FR1

ID REGST RR1

ID REGST RL1 Ignition switch ON ID not registered: YET

ID registered: DONE

WARNING LAMP Low tire pressure

warning lamp on: ON

Low tire pressure warning lamp off: OFF

Revision: December 20092009 QX56

Page 4078 of 4171

WT-36

< SYMPTOM DIAGNOSIS >

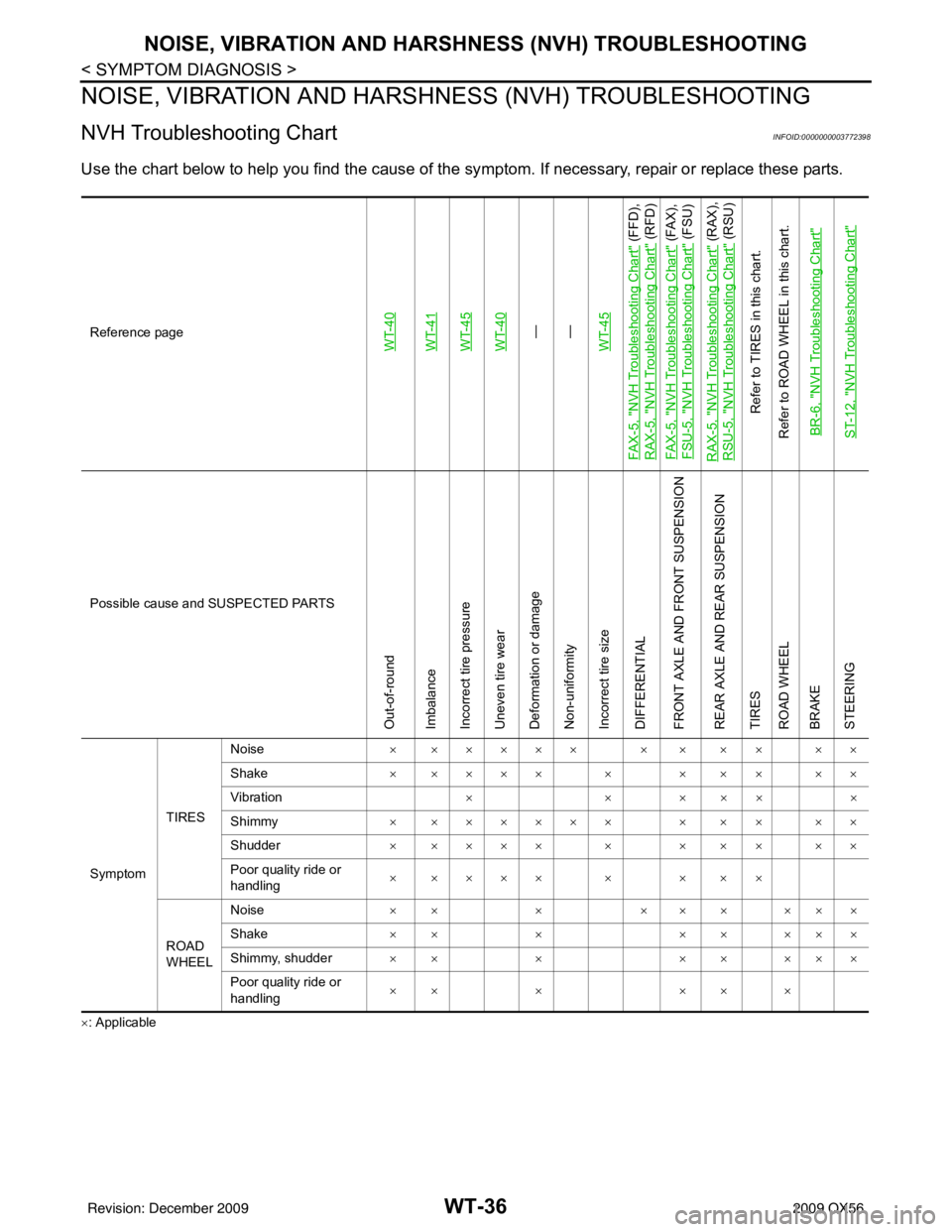

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003772398

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: ApplicableReference page

WT-40WT-41WT-45WT-40—

—

WT-45

FA X - 5 , "

NVH Troubleshooting Chart

" (FFD),

RAX-5, "

NVH Troubleshooting Chart

" (RFD)

FA X - 5 , "

NVH Troubleshooting Chart

" (FAX),

FSU-5, "

NVH Troubleshooting Chart

" (FSU)

RAX-5, "

NVH Troubleshooting Chart

" (RAX),

RSU-5, "

NVH Troubleshooting Chart

" (RSU)

Refer to TIRES in this chart.

Refer to ROAD WHEEL in this chart.

BR-6, "

NVH Troubleshooting Chart

"

ST-12, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

DIFFERENTIAL

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEEL

BRAKE

STEERING

Symptom TIRESNoise

× ××××× × × × × ××

Shake × ×××× × × × × ××

Vibration ××× ×××

Shimmy × ×××××× × × × ××

Shudder × ×××× × × × × ××

Poor quality ride or

handling × ×××× × × × ×

ROAD

WHEEL Noise

×× × ××× ×××

Shake ×× × ×× ×××

Shimmy, shudder ×× × ×× ×××

Poor quality ride or

handling ×× ×

×× ×

Revision: December 20092009 QX56

Page 4079 of 4171

PRECAUTIONSWT-37

< PRECAUTION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005873220

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005873221

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56