wheel INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3607 of 4171

ST-16

< ON-VEHICLE REPAIR >

STEERING WHEEL

5. Check steering wheel turning force using Tool when steeringwheel has been turned 360 ° from the neutral position.

6. If steering wheel turning force is out of s pecification, inspect steering column. Refer to ST-29, "Disassem-

bly and Assembly" .

7. If steering column meets specification, repair steering gear. Refer to ST-32, "Disassembly and Assembly"

.

CHECKING FRONT WHEEL TURNING ANGLE

When checking front wheel turning angle, refer to FSU-23, "Wheel Alignment (Unladen*1)".

Tool number — (J-44372)

Steering wheel turning force : Refer to

ST-36, "Steering

Wheel"

WGIA0035E

Revision: December 20092009 QX56

Page 3609 of 4171

ST-18

< REMOVAL AND INSTALLATION >

STEERING WHEEL

REMOVAL AND INSTALLATION

STEERING WHEEL

Removal and InstallationINFOID:0000000004187593

REMOVAL

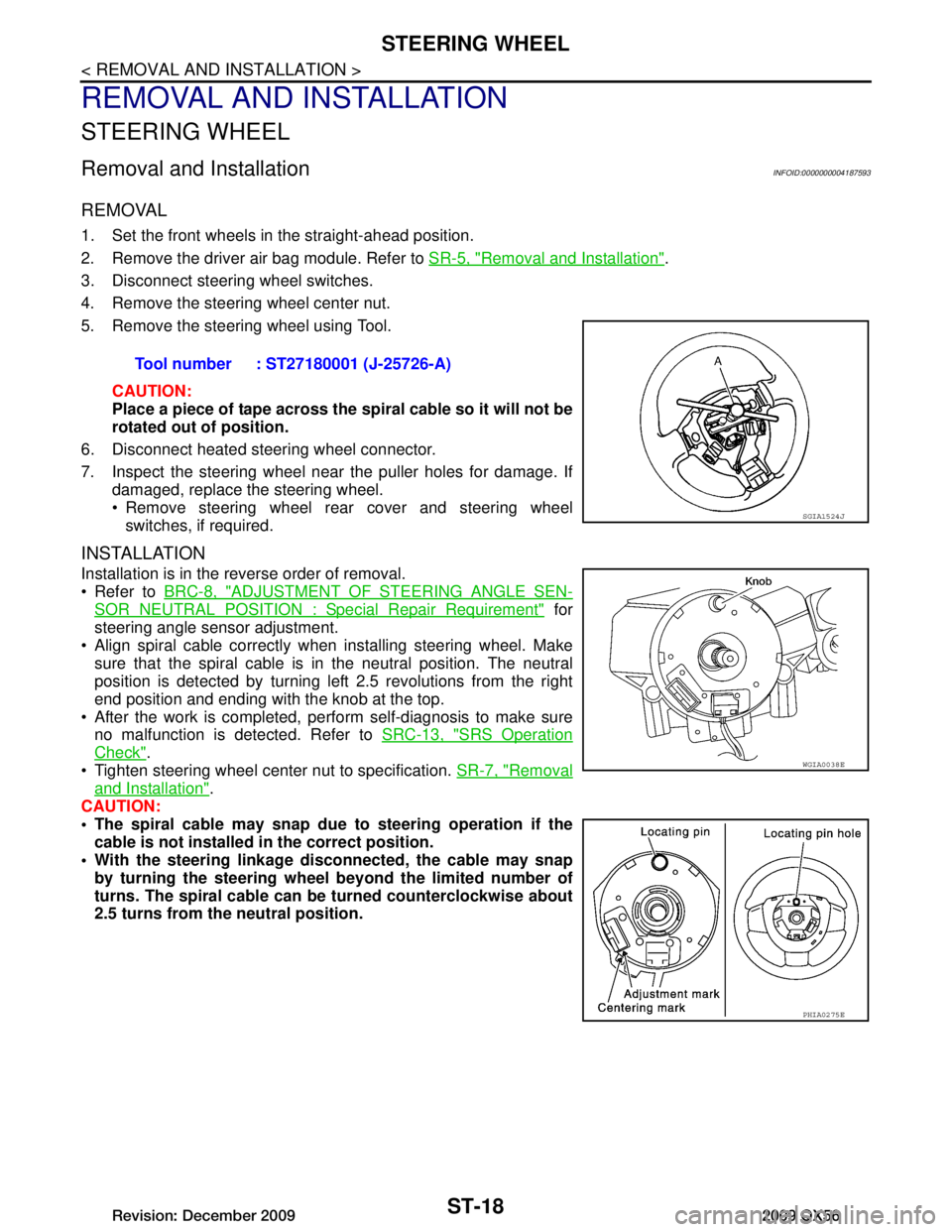

1. Set the front wheels in the straight-ahead position.

2. Remove the driver air bag module. Refer to SR-5, "Removal and Installation"

.

3. Disconnect steering wheel switches.

4. Remove the steering wheel center nut.

5. Remove the steering wheel using Tool.

CAUTION:

Place a piece of tape across the sp iral cable so it will not be

rotated out of position.

6. Disconnect heated steering wheel connector.

7. Inspect the steering wheel near the puller holes for damage. If damaged, replace the steering wheel.

Remove steering wheel rear cover and steering wheelswitches, if required.

INSTALLATION

Installation is in the reverse order of removal.

Refer to BRC-8, "ADJUSTMENT OF STEERING ANGLE SEN-

SOR NEUTRAL POSITION : Special Repair Requirement" for

steering angle sensor adjustment.

Align spiral cable correctly when installing steering wheel. Make sure that the spiral cable is in the neutral position. The neutral

position is detected by turning left 2.5 revolutions from the right

end position and ending with the knob at the top.

After the work is completed, perform self-diagnosis to make sure no malfunction is detected. Refer to SRC-13, "SRS Operation

Check".

Tighten steering wheel center nut to specification. SR-7, "Removal

and Installation".

CAUTION:

The spiral cable may snap due to steering operation if the

cable is not installed in the correct position.

With the steering linkage di sconnected, the cable may snap

by turning the steering wheel beyond the limited number of

turns. The spiral cable can be turned counterclockwise about

2.5 turns from the neutral position. Tool number : ST27180001 (J-25726-A)

SGIA1524J

WGIA0038E

PHIA0275E

Revision: December 20092009 QX56

Page 3611 of 4171

ST-20

< REMOVAL AND INSTALLATION >

STEERING COLUMN

STEERING COLUMN

Removal and InstallationINFOID:0000000004187595

CAUTION:

Any time the ignition switch has been disconnected, removed or inst alled, the keys must be re-regis-

tered in the BCM. Refer to Consult-III operations IVIS/NVIS.

Do not exert any load or impact in the axial dir ection immediately before or after column removal.

Do not to move steering gear during removal of steering column assembly.

REMOVAL

1. Remove combination switch and spiral cable from steering column assembly. Refer to SR-7, "Removal

and Installation".

2. Remove the tilt motor and tilt sensor. Refer to ST-19, "Removal and Installation"

.

3. Remove steering column cover. Refer to ST-20, "Removal and Installation"

.

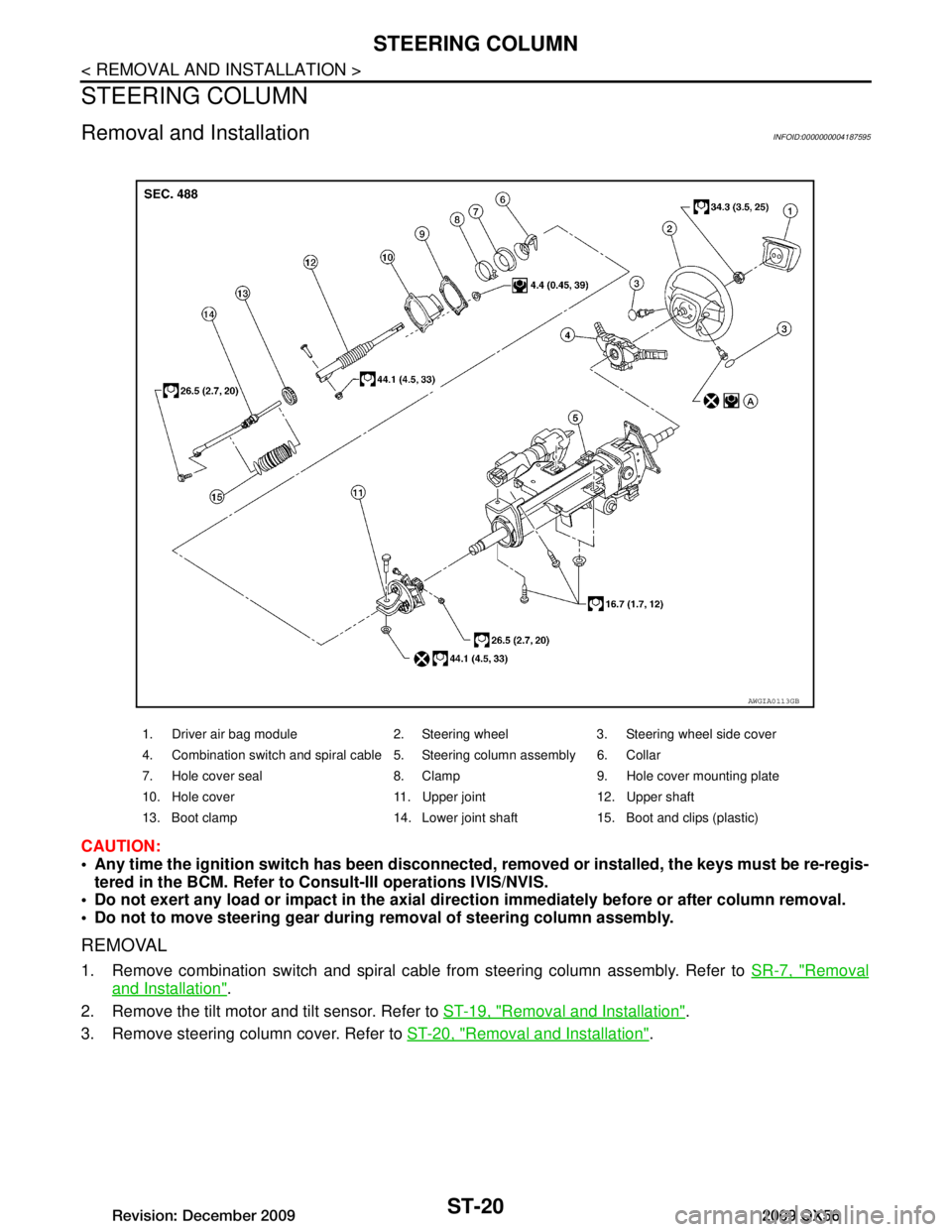

1. Driver air bag module 2. Steering wheel 3. Steering wheel side cover

4. Combination switch and spiral cable 5. Steering column assembly 6. Collar

7. Hole cover seal 8. Clamp 9. Hole cover mounting plate

10. Hole cover 11. Upper joint 12. Upper shaft

13. Boot clamp 14. Lower joint shaft 15. Boot and clips (plastic)

AWGIA0113GB

Revision: December 20092009 QX56

Page 3612 of 4171

STEERING COLUMNST-21

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

4. Remove lock nut and bolt, then separate upper shaft from upper joint.

5. Remove two nuts and two bolts, then remove steering column assembly from steering member.

6. Remove hole cover seal and clamp.

7. Remove mounting nuts, then remove hole cover from dash panel.

8. Raise vehicle, then remove mounting bolt (lower side) of lower joint shaft and remove lower joint shaft and upper shaft as an

assembly.

INSPECTION AFTER REMOVAL

Check for damage to steering column jacket tube. If damage is found, replace steering column with new

one.

If vehicle has been in a collision, check column length (L), (L

1) and L2) as shown. If out of specification,

replace steering column with new one.

LGIA0027E

LGIA0028E

LGIA0029E

Steering column length

L : Refer to ST-36, "Steering

Wheel"

L1: Refer to ST-36, "Steering

Wheel"

L2: Refer to ST-36, "Steering

Wheel"

WGIA0080E

Revision: December 20092009 QX56

Page 3613 of 4171

ST-22

< REMOVAL AND INSTALLATION >

STEERING COLUMN

Check for proper lubrication, apply grease as necessary.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

When installing the steering column, finger-tighten all of the lower bracket and joint retaining bolts;

then tighten them to specifi cation. Do not apply undue st ress to the steering column.

The lower nut on the upper joint may not be reused.

After installation, turn steering wheel to make sure it moves smoothly. Make sure the number of turns are the

same from the straight-forward position to left and right locks. Make sure that the steering wheel is in a neu-

tral position when driving straight ahead.

When installing steering column to steering mem ber, install nut from front side of vehicle.

INSPECTION AFTER INSTALLATION

After installing steering column to vehicle, check tilt device operation range is within specification.

Check if steering wheel operation can turn to the end of the left and right stops smoothly.

SGIA0475E

Range "A" : ST-36, "Steering Col-

umn"

WGIA0083E

Revision: December 20092009 QX56

Page 3614 of 4171

POWER STEERING GEAR AND LINKAGEST-23

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

POWER STEERING GEAR AND LINKAGE

Removal and InstallationINFOID:0000000004187596

CAUTION:

Spiral cable may snap due to steering operation if steering column is separated from steering gear

assembly. Therefore secure steer ing wheel to avoid turning.

REMOVAL

1. Turn wheels to the straight-ahead position.

2. Remove tires from vehicle using power tool.

3. Remove undercover using power tool.

4. On 4WD models, remove front final drive, then support drive shafts with wire. Refer to DLN-215,

"Removal and Installation".

5. Make sure slit of lower joint fits with the projection on rear cover cap, while checking that mark on steering gear assembly aligns

with mark on rear cover cap.

6. Remove cotter pin at steering outer socket and discard, then loosen nut.

1. Cotter pin 2. Steering Gear Bracket 3. Steering gear insulator

4. Steering gear assembly 5. Washer Front

AWGIA0114GB

SST491C

Revision: December 20092009 QX56

Page 3615 of 4171

ST-24

< REMOVAL AND INSTALLATION >

POWER STEERING GEAR AND LINKAGE

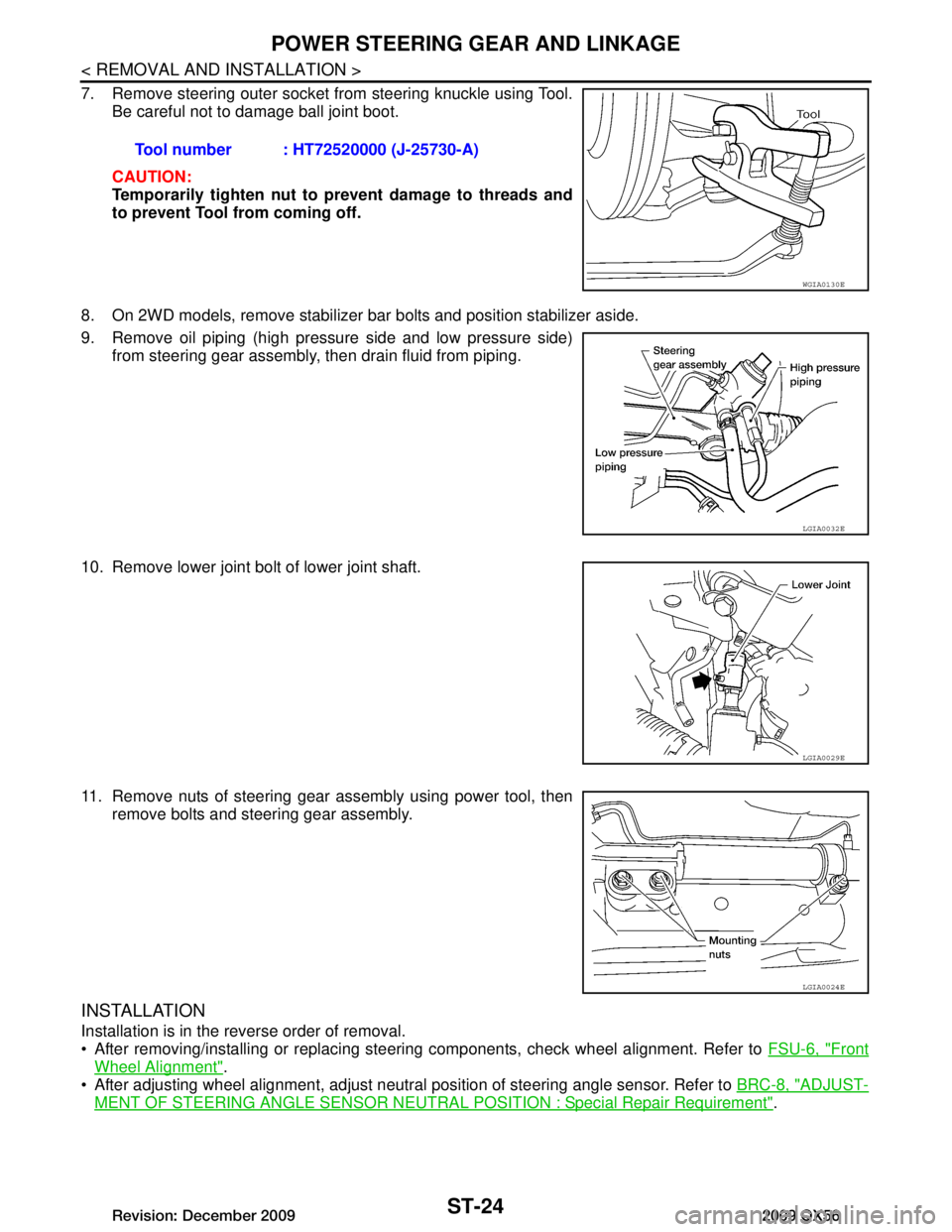

7. Remove steering outer socket from steering knuckle using Tool.Be careful not to damage ball joint boot.

CAUTION:

Temporarily tighten nut to prevent damage to threads and

to prevent Tool from coming off.

8. On 2WD models, remove stabilizer bar bolts and position stabilizer aside.

9. Remove oil piping (high pressure side and low pressure side) from steering gear assembly, then drain fluid from piping.

10. Remove lower joint bolt of lower joint shaft.

11. Remove nuts of steering gear assembly using power tool, then remove bolts and steering gear assembly.

INSTALLATION

Installation is in the reverse order of removal.

After removing/installing or replacing steering components, check wheel alignment. Refer to FSU-6, "Front

Wheel Alignment".

After adjusting wheel alignment, adjust neutral position of steering angle sensor. Refer to BRC-8, "ADJUST-

MENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Special Repair Requirement".

Tool number : HT72520000 (J-25730-A)

WGIA0130E

LGIA0032E

LGIA0029E

LGIA0024E

Revision: December 20092009 QX56

Page 3616 of 4171

POWER STEERING GEAR AND LINKAGEST-25

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

With steering wheel in straight ahead position, make sure slit of lower joint "A" fits with the projection on rear cover cap "B", while

checking that mark on steering gear assembly aligns with mark on

rear cover cap

After installation, bleed the air from the steering hydraulic system. Refer to ST-13, "Air Bleeding Hydraulic

System".

INSPECTION AFTER INSTALLATION

Check if steering wheel turns smoothly when it is turned several times fully to the left and right lock positions.

SST491C

Revision: December 20092009 QX56

Page 3620 of 4171

STEERING COLUMNST-29

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

DISASSEMBLY AND ASSEMBLY

STEERING COLUMN

Disassembly and AssemblyINFOID:0000000004187599

DISASSEMBLY

1. Remove bolt from upper joint, then remove upper joint from steering column assembly.

2. Remove ignition switch tamper resistant self-s hear screws with a drill or other suitable tool.

ASSEMBLY

Assembly is in the reverse order of disassembly.

Install new tamper resistant self-shear screws.

CAUTION:

Any time the ignition switch has been disconnected, removed

or installed, the keys must be re -registered in the BCM. Refer to

CONSULT-III operation manual IVIS/NVIS.

INSPECTION AFTER ASSEMBLY

When the steering wheel does not turn smoothl y, check the steering column as follows:

1. Steering column assembly 2. Upper joint 3. Ignition switch

4. Tamper resistant self-shear screw

WGIA0091E

WGIA0009E

Revision: December 20092009 QX56

Page 3622 of 4171

STEERING COLUMNST-31

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

Do not exert any load in the axi al direction immediately before or after column removal.

After installation, check smoo th steering wheel rotation, without any catches or noise.

Revision: December 20092009 QX56