check engine INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2703 of 4171

MA-30

< ON-VEHICLE MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

Checking Brake Fluid Level and Leaks

INFOID:0000000003777006

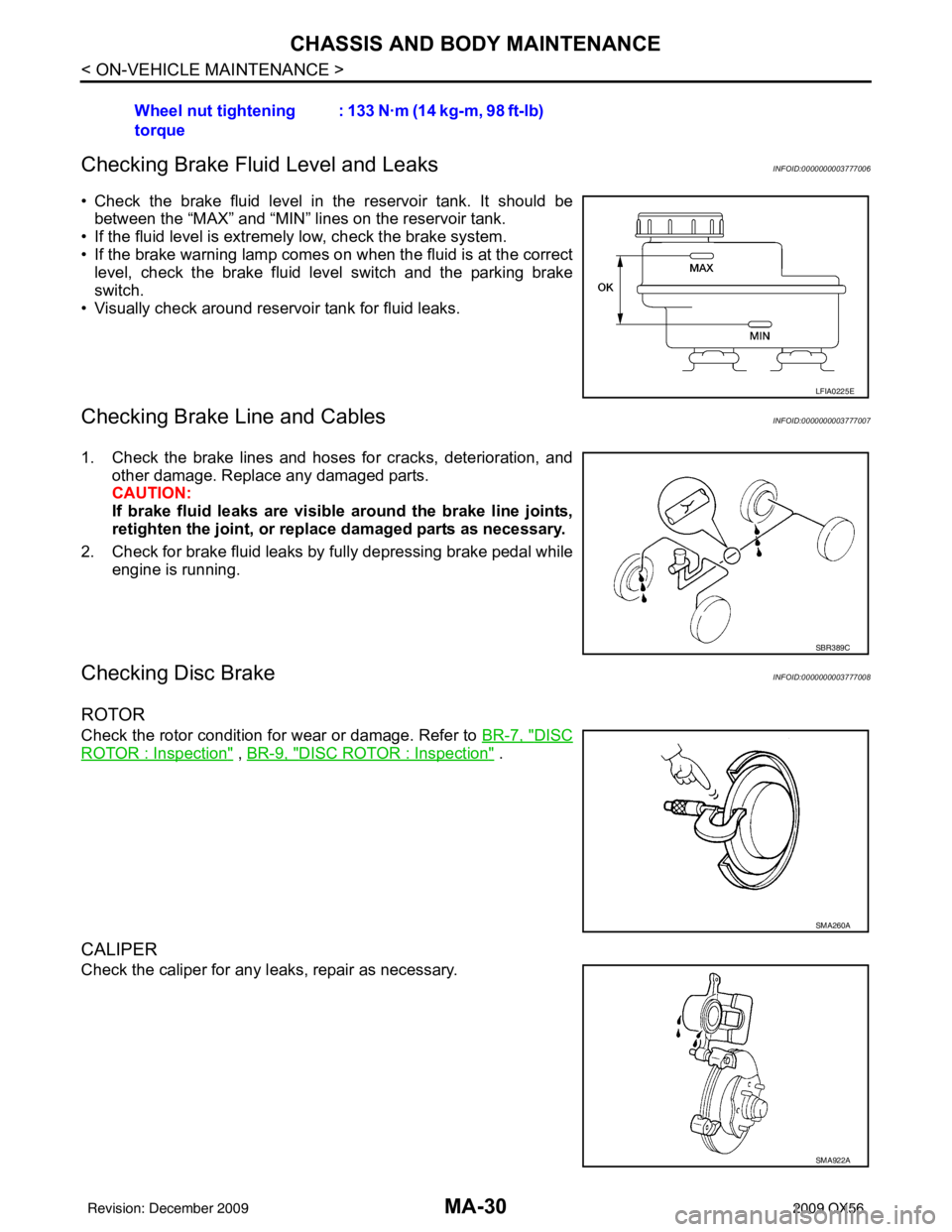

• Check the brake fluid level in the reservoir tank. It should be between the “MAX” and “MIN” lines on the reservoir tank.

• If the fluid level is extremely low, check the brake system.

• If the brake warning lamp comes on when the fluid is at the correct level, check the brake fluid level switch and the parking brake

switch.

• Visually check around reservoir tank for fluid leaks.

Checking Brake Line and CablesINFOID:0000000003777007

1. Check the brake lines and hoses for cracks, deterioration, and other damage. Replace any damaged parts.

CAUTION:

If brake fluid leaks are visible around the brake line joints,

retighten the joint, or replace damaged parts as necessary.

2. Check for brake fluid leaks by fully depressing brake pedal while engine is running.

Checking Disc BrakeINFOID:0000000003777008

ROTOR

Check the rotor condition for wear or damage. Refer to BR-7, "DISC

ROTOR : Inspection" , BR-9, "DISC ROTOR : Inspection" .

CALIPER

Check the caliper for any l eaks, repair as necessary.

Wheel nut tightening

torque

: 133 N·m (14 kg-m, 98 ft-lb)

LFIA0225E

SBR389C

SMA260A

SMA922A

Revision: December 20092009 QX56

Page 2704 of 4171

CHASSIS AND BODY MAINTENANCEMA-31

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

PA D

Check the pads for wear or damage. Refer to

BR-7, "BRAKE PAD :

Inspection" , BR-9, "BRAKE PAD : Inspection" .

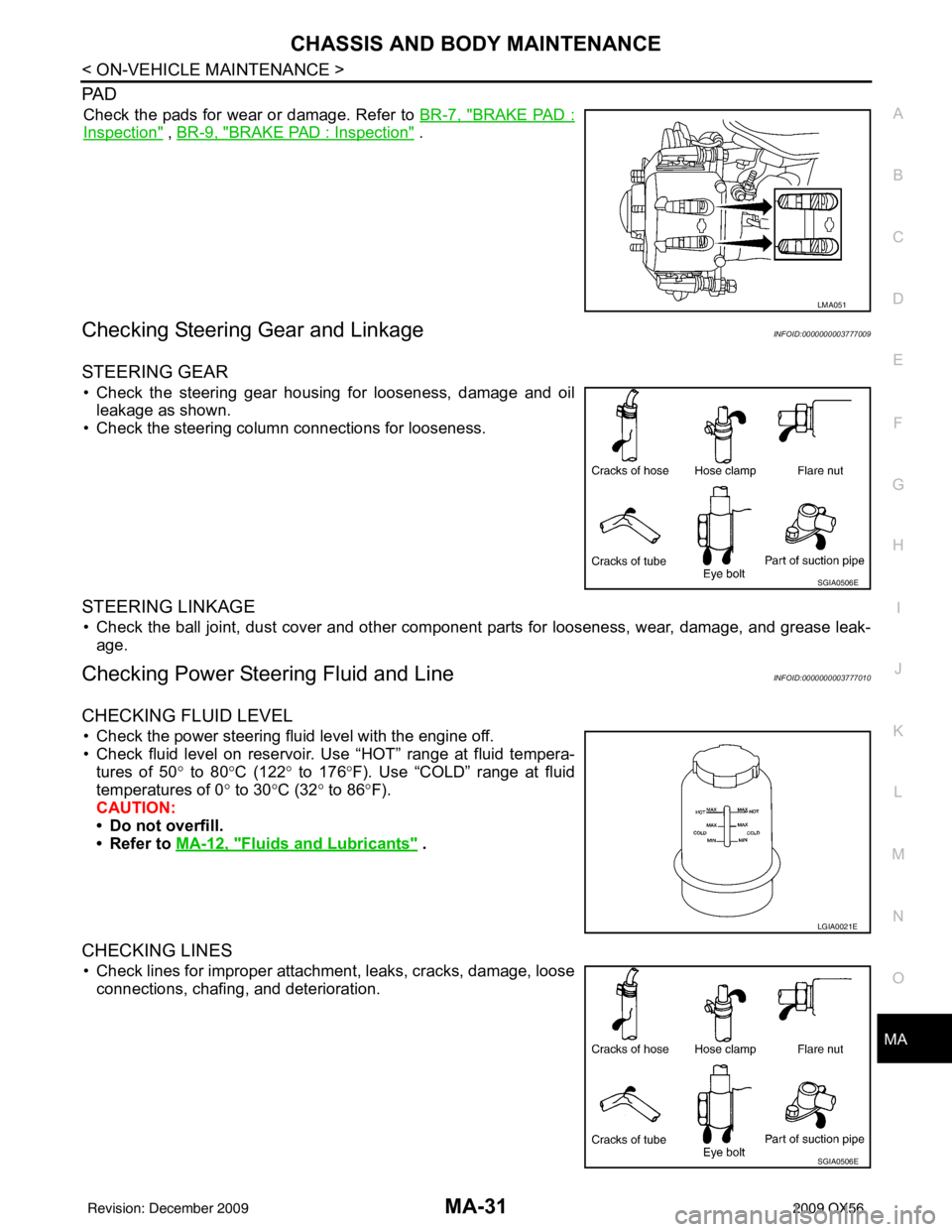

Checking Steering Ge ar and LinkageINFOID:0000000003777009

STEERING GEAR

• Check the steering gear housing for looseness, damage and oil

leakage as shown.

• Check the steering column connections for looseness.

STEERING LINKAGE

• Check the ball joint, dust cover and other component parts for looseness, wear, damage, and grease leak-

age.

Checking Power Steering Fluid and LineINFOID:0000000003777010

CHECKING FLUID LEVEL

• Check the power steering fluid level with the engine off.

• Check fluid level on reservoir. Use “HOT” range at fluid tempera- tures of 50 ° to 80° C (122° to 176° F). Use “COLD” range at fluid

temperatures of 0 ° to 30° C (32° to 86° F).

CAUTION:

• Do not overfill.

• Refer to MA-12, "

Fluids and Lubricants" .

CHECKING LINES

• Check lines for improper attachment, leaks, cracks, damage, loose

connections, chafing, and deterioration.

LMA051

SGIA0506E

LGIA0021E

SGIA0506E

Revision: December 20092009 QX56

Page 2724 of 4171

MWI-2

INFORMATION DISPLAY .........................................19

INFORMATION DISPLAY : System Diagram .........20

INFORMATION DISPLAY : System Description ....20

INFORMATION DISPLAY : Component Parts Lo-

cation ................................................................... ...

21

INFORMATION DISPLAY : Component Descrip-

tion ....................................................................... ...

21

COMPASS .........................................................22

Description (Early Production) ............................. ...22

DIAGNOSIS SYSTEM (METER) .......................24

Diagnosis Description .......................................... ...24

CONSULT-III Function (METER/M&A) ................ ...25

COMPONENT DIAGNOSIS ........................28

DTC U1000 CAN COMMUNICATION ............ ...28

DTC Logic ............................................................ ...28

Diagnosis Procedure .............................................28

DTC B2205 VEHICLE SPEED CIRCUIT ...........29

Description ........................................................... ...29

DTC Logic ...............................................................29

Diagnosis Procedure .............................................29

POWER SUPPLY AND GROUND CIRCUIT .....30

COMBINATION METER ........................................ ...30

COMBINATION METER : Diagnosis Procedure ....30

BCM (BODY CONTROL MODULE) ...................... ...30

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ...............................................................

31

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) .......................... ...

31

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure .....................................................................

31

FUEL LEVEL SENSOR SIGNAL CIRCUIT .......33

Description ........................................................... ...33

Component Function Check ...................................33

Diagnosis Procedure .............................................33

Component Inspection ............................................34

OIL PRESSURE SWITCH SIGNAL CIRCUIT ...35

Description ..............................................................35

Component Function Check ...................................35

Diagnosis Procedure ..............................................35

Component Inspection ............................................35

PARKING BRAKE SWITCH SIGNAL CIR-

CUIT ...................................................................

36

Description ........................................................... ...36

Component Function Check ...................................36

Diagnosis Procedure ..............................................36

Component Inspection ............................................36

WASHER LEVEL SWITCH SIGNAL CIRCUIT ...37

Description ........................................................... ...37

Diagnosis Procedure ............................................ ...37

Component Inspection ............................................37

COMPASS .........................................................38

Wiring Diagram (Early Production) ...................... ...38

CLOCK ..............................................................40

Wiring Diagram .................................................... ...40

ECU DIAGNOSIS .......................................42

COMBINATION METER ................................. ...42

Reference Value .................................................. ...42

Wiring Diagram .......................................................44

Fail Safe ..................................................................61

DTC Index ...............................................................62

BCM (BODY CONTROL MODULE) ..................64

Reference Value .................................................. ...64

Terminal Layout ......................................................66

Physical Values .......................................................66

Wiring Diagram .......................................................72

Fail Safe .................................................................76

DTC Inspection Priority Chart ...............................77

DTC Index ..............................................................77

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

79

Reference Value .................................................. ...79

Terminal Layout ......................................................81

Physical Values .......................................................81

Wiring Diagram .......................................................86

Fail Safe .................................................................89

DTC Index ..............................................................91

SYMPTOM DIAGNOSIS ............................92

THE FUEL GAUGE POINTER DOES NOT

MOVE .............................................................. ...

92

Description ........................................................... ...92

Diagnosis Procedure ...............................................92

THE FUEL GAUGE POINTER DOES NOT

MOVE TO "F" WHEN REFUELING ..................

93

Description ........................................................... ...93

Diagnosis Procedure ...............................................93

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN ON .................................... ...

94

Description ........................................................... ...94

Diagnosis Procedure ...............................................94

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN OFF .................................. ...

95

Description ........................................................... ...95

Diagnosis Procedure ...............................................95

THE PARKING BRAKE RELEASE WARNING

CONTINUES DISPLAYING, OR DOES NOT

DISPLAY ............................................................

96

Description ........................................................... ...96

Revision: December 20092009 QX56

Page 2727 of 4171

MWI

METER SYSTEMMWI-5

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

FUNCTION DIAGNOSIS

METER SYSTEM

METER SYSTEM

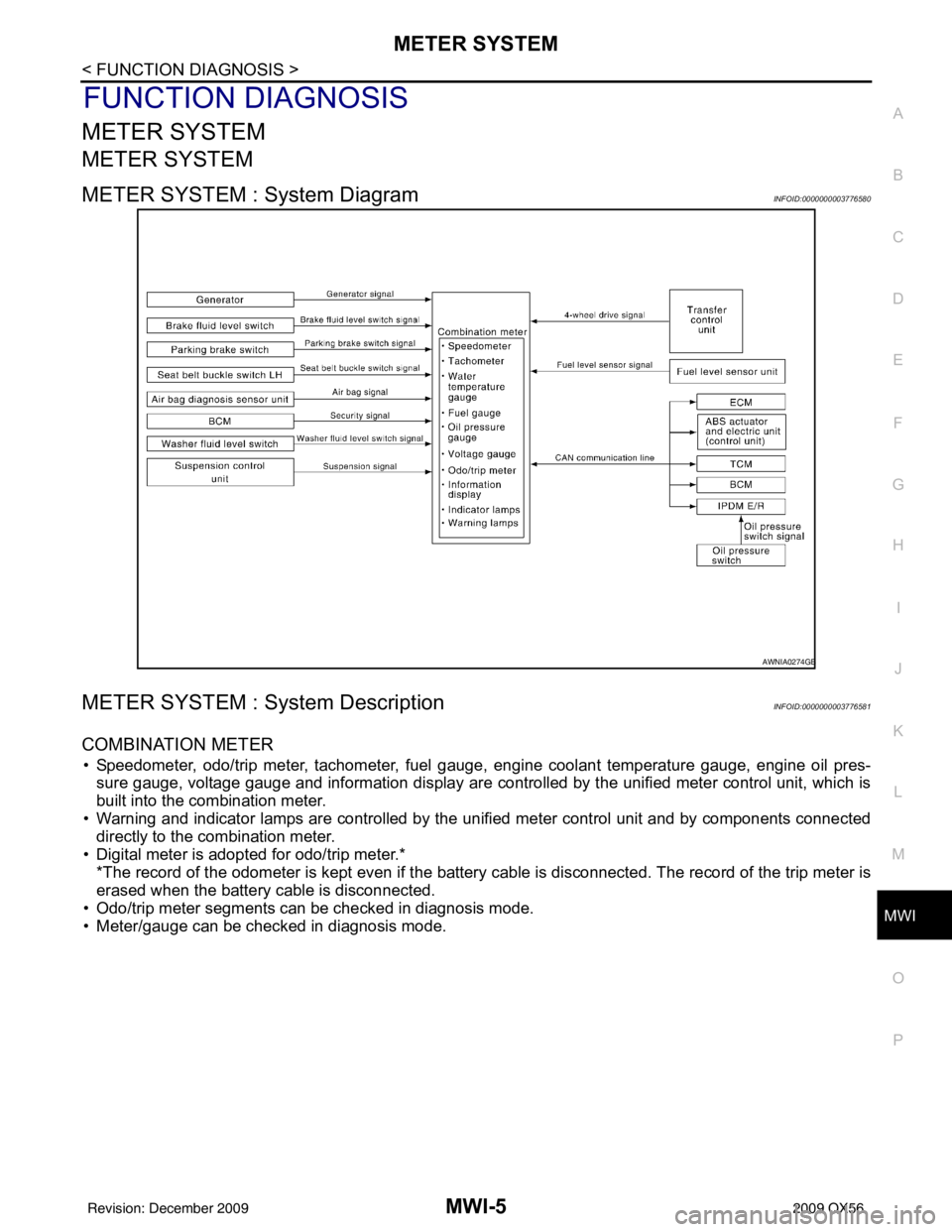

METER SYSTEM : System DiagramINFOID:0000000003776580

METER SYSTEM : System DescriptionINFOID:0000000003776581

COMBINATION METER

• Speedometer, odo/trip meter, tachometer, fuel gauge, engine coolant temperature gauge, engine oil pres-

sure gauge, voltage gauge and information display are controlled by the unified meter control unit, which is

built into the combination meter.

• Warning and indicator lamps are controlled by the unified meter control unit and by components connected directly to the combination meter.

• Digital meter is adopted for odo/trip meter.* *The record of the odometer is kept even if the battery cable is disconnected. The record of the trip meter is

erased when the battery cable is disconnected.

• Odo/trip meter segments can be checked in diagnosis mode.

• Meter/gauge can be checked in diagnosis mode.

AWNIA0274GB

Revision: December 20092009 QX56

Page 2748 of 4171

![INFINITI QX56 2009 Factory Service Manual MWI-26

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (METER)

X: Applicable

Display item [Unit]MAIN

SIGNALS SELECTION

FROM MENU Description

SPEED METER [km/h] or [mph] X X Displays the value of vehicle spee INFINITI QX56 2009 Factory Service Manual MWI-26

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (METER)

X: Applicable

Display item [Unit]MAIN

SIGNALS SELECTION

FROM MENU Description

SPEED METER [km/h] or [mph] X X Displays the value of vehicle spee](/img/42/57031/w960_57031-2747.png)

MWI-26

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (METER)

X: Applicable

Display item [Unit]MAIN

SIGNALS SELECTION

FROM MENU Description

SPEED METER [km/h] or [mph] X X Displays the value of vehicle speed signal.

SPEED OUTPUT [km/h] or [mph] X XDisplays the value of vehicle speed signal, which is transmitted to

each unit with

CAN communication.

TACHO METER [rpm] XX Displays the value of engine speed signal, which is input from ECM.

FUEL METER [lit.] XXDisplays the value, which processes a resistance signal from fuel

gauge.

W TEMP METER [ °C] or [° F] X XDisplays the value of engine coolant temperature signal, which is in-

put from ECM.

ABS W/L [ON/OFF] X Displays [ON/OFF] condition of ABS warning lamp.

VDC/TCS IND [ON/OFF] X Displays [ON/OFF] condition of VDC OFF indicator lamp.

SLIP IND [ON/OFF] X Displays [ON/OFF] condition of SLIP indicator lamp.

BRAKE W/L [ON/OFF] X Displays [ON/OFF] condition of brake warning lamp.*

DOOR W/L [ON/OFF] X Displays [ON/OFF] condition of door warning lamp.

TRUNK W/L [ON/OFF] X Displays [ON/OFF] condition of glass hatch warning lamp.

HI-BEAM IND [ON/OFF] X Displays [ON/OFF] condition of high beam indicator.

TURN IND [ON/OFF] X Displays [ON/OFF] conditio n of turn indicator.

OIL W/L [ON/OFF] X Displays [ON/OFF] condition of oil pressure warning lamp.

C-ENG W/L [ON/OFF] X Displays [ON/OFF] condition of malfunction indicator lamp.

CRUISE IND [ON/OFF] X Displays [ON/OFF] condition of CRUISE indicator.

SET IND [ON/OFF] X Displays [ON/OFF] condition of SET indicator.

AT CHECK W/L [ON/OFF] X Displays [ON/OFF] condition of AT CHECK warning lamp.

FUEL W/L [ON/OFF] XX Displays [ON/OFF] condition of low-fuel warning lamp.

AIR PRES W/L [ON/OFF] X Displays [ON/OFF] condition of tire pressure warning lamp.

KEY G/Y W/L [ON/OFF] X Displays [ON/OFF] condition of key green warning lamp.

KEY R W/L [ON/OFF] X Displays [ON/OFF] condition of key red warning lamp.

KEY KNOB W/L [ON/OFF] X Displays [ON/OFF] condition of key knob warning lamp.

M RANGE SW [ON/OFF] XX Displays [ON/OFF] condition of manual mode range switch.

NM RANGE SW [ON/OFF] XXDisplays [ON/OFF] condition of except for manual mode range

switch.

AT SFT UP SW [ON/OFF] XX Displays [ON/OFF] condition of A/T shift-up switch.

AT SFT DWN SW [ON/OFF] XX Displays [ON/OF F] condition of A/T shift-down switch.

DISTANCE [km] or [mile] XXDisplays the value, which is calculated by vehicle speed signal, fuel

gauge and fuel consumption from ECM.

BUZZER [ON/OFF] XX Displays [ON/ OFF] condition of buzzer.

BRAKE SW [ON/OFF] X Indicates [ON/OFF] condition of parking brake switch.

AT-M GEAR [1, 2, 3, 4, 5] XX Indicates [1, 2, 3, 4, 5] condition of A/T manual mode gear position.

P RANGE IND [ON/OFF] XX Indicates [ON/OFF] condition of A/T shift P range indicator.

R RANGE IND [ON/OFF] XX Indicates [ON/OFF] condition of A/T shift R range indicator.

N RANGE IND [ON/OFF] XX Indicates [ON/OFF] condition of A/T shift N range indicator.

D RANGE IND [ON/OFF] XX Indicates [ON/OFF] condition of A/T shift D range indicator.

4 RANGE IND [ON/OFF] XX Indicates [ON/OFF] condition of A/T shift 4 range indicator.

3 RANGE IND [ON/OFF] XX Indicates [ON/OFF] condition of A/T shift 3 range indicator.

2 RANGE IND [ON/OFF] XX Indicates [ON/OFF] condition of A/T shift 2 range indicator.

1 RANGE IND [ON/OFF] XX Indicates [ON/OFF] condition of A/T shift 1range indicator.

Revision: December 20092009 QX56

Page 2751 of 4171

MWI

DTC B2205 VEHICLE SPEED CIRCUITMWI-29

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

DTC B2205 VEHICLE SPEED CIRCUIT

DescriptionINFOID:0000000003776630

The ABS actuator and electric unit (control unit) provi des a vehicle speed signal to the combination meter via

CAN communication lines.

DTC LogicINFOID:0000000003776631

Diagnosis ProcedureINFOID:0000000003776632

Symptom: Displays “VEHICLE SPEED CIRC [B2205]” as a self-diagnosis result of combination meter.

1.CHECK COMBINATION METER INPUT SIGNAL

1. Start engine and select “M ETER/M&A” on CONSULT-III.

2. Using “SPEED METER” on “DATA MONITOR”, compare the value of DATA MONITOR with speedometer

pointer of combination meter. Speedometer and DATA MONITOR indications should be close.

Is the inspection result normal?

YES >> Perform ABS actuator and electric uni t (control unit) self-diagnosis. Refer to BRC-24, "CONSULT-

III Function (ABS)".

NO >> Replace combination meter. Refer to MWI-102, "

Removal and Installation".

DTC CONSULT-III display Detection condition

B2205 VEHICLE SPEED CIRC

[B2205]

Malfunction is detected when an erroneous speed signal is received for 2 seconds or more.

Revision: December 20092009 QX56

Page 2753 of 4171

MWI

POWER SUPPLY AND GROUND CIRCUITMWI-31

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000004225393

1. CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> Inspection End.

NO >> Repair or replace harness.

IPDM E/R (INTELLIGENT POWER DIST RIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM) : Di-

Terminal No. Signal nameFuses and fusible link No.

57 Battery power supply 22 (15A)

70 F (50A)

11 Ignition ACC or ON 4 (10A)

38 Ignition ON or START 59 (10A)

ConnectorTe r m i n a l s

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or

ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch

OFF Battery voltage

LIIA2415E

BCM

GroundContinuity

Connector Terminal

M20 67 Yes

LIIA0915E

Revision: December 20092009 QX56

Page 2757 of 4171

MWI

OIL PRESSURE SWITCH SIGNAL CIRCUIT

MWI-35

< COMPONENT DIAGNOSIS >

C

D E

F

G H

I

J

K L

M B A

O P

OIL PRESSURE SWITCH SIGNAL CIRCUIT

DescriptionINFOID:0000000003776640

Detects the engine oil pressure and transmits the oil pressure switch signal to the IPDM E/R.

Component Function CheckINFOID:0000000003776641

1.COMBINATION METER INPUT SIGNAL

1. Select “METER/M&A” on CONSULT-III.

2. Monitor “OIL W/L” of “DATA MONITOR” while operating ignition switch.

>> Inspection End.

Diagnosis ProcedureINFOID:0000000003776642

1.CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector E122 and oil pressure switch

connector F4.

3. Check continuity between IPDM E/R harness connector E122

(A) terminal 42 and oil pressure switch harness connector F4 (B)

terminal 1.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair harness or connector.

Component InspectionINFOID:0000000003776643

1.CHECK OIL PRESSURE SWITCH

Check continuity between oil pressure switch and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Replace the oil pressure switch. OIL W/L

When ignition switch is in ON

position (Engine stopped)

: ON

When engine is running : OFF

Continuity should exist.

WKIA5607E

Condition Oil pressure [kPa (kg/cm2, psi)]Continuity

Engine stopped Less than 29 (0.3, 4) Yes Engine running More than 29 (0.3, 4) No

ELF0044D

Revision: December 20092009 QX56

Page 2758 of 4171

MWI-36

< COMPONENT DIAGNOSIS >

PARKING BRAKE SWITCH SIGNAL CIRCUIT

PARKING BRAKE SWITCH SIGNAL CIRCUIT

DescriptionINFOID:0000000003776644

Transmits the parking brake switch signal to the combination meter.

Component Function CheckINFOID:0000000003776645

1.COMBINATION METER INPUT SIGNAL

1. Start engine.

2. Monitor “BRAKE” warning lamp while applying and releasing the parking brake.

>> Inspection End.

Diagnosis ProcedureINFOID:0000000003776646

1.CHECK PARKING BRAKE SWITCH CIRCUIT

1. Disconnect combination meter connector and parking brake switch connector.

2. Check continuity between combination meter harness connector M24 (A) terminal 31 and parking brake switch harness connec-

tor M11 (B) terminal 1.

3. Check continuity between combination meter harness connector M24 (A) terminal 31 and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair harness or connector.

Component InspectionINFOID:0000000003776647

1.CHECK PARKING BRAKE SWITCH

Check continuity between parking brake switch terminal 1 and switch

case ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Replace parking brake switch. BRAKE warning lamp

Parking brake applied : ON

Parking brake released : OFF

31 - 1

: Continuity should exist.

31 - Ground : Continuity should not exist.

AWNIA0208ZZ

Component Terminal Condition Continuity

Parking brake switch 1 Parking brake applied

Yes

Parking brake released No

AWNIA0018ZZ

Revision: December 20092009 QX56

Page 2784 of 4171

MWI-62

< ECU DIAGNOSIS >

COMBINATION METER

DTC Index

INFOID:0000000003776656

Function Specifications

Speedometer

Zero indication.

Tachometer

Fuel gauge

Engine coolant temperature gauge

Engine oil pressure gauge

Voltage gauge

A/T oil temperature gauge

Illumination control

Meter illumination Change to nighttime mode when communication is lost.

Segment LCD Odometer

Freeze current indication.

A/T position Display turns off.

Buzzer Buzzer turns off.

Warning lamp/indicator lamp ABS warning lamp

Lamp turns on when communication is lost.

Brake warning lamp

VDC OFF indicator lamp

SLIP indicator lamp

A/T CHECK warning lamp

Lamp turns off when communication is lost.

Oil pressure/coolant temperature

warning lamp

Light indicator

Malfunction indicator lamp

Master warning lamp

Air bag warning lamp

High beam indicator

Turn signal indicator lamp

CRUISE indicator lamp

Driver and passenger seat belt warn-

ing lamp

Lamp turns off when disconnected.

Charge warning lamp

Security indicator lamp

4WD indicator lamp

AT P i n d i c a t o r l a m p

CK SUSP warning lamp

Low tire pressure warning lamp

Lamp will flash every second for 1 minute and then stay on con-

tinuously thereafter.

CONSULT-III display

MalfunctionReference

page

CAN COMM CIRC

[U1000] Malfunction is detected in CAN communication.

CAUTION:

Even when there is no malfunction on CAN communication system, malfunction may be

misinterpreted when battery has low voltage (when maintaining 7 - 8 V for about 2 sec-

onds) or 10A fuse [No. 3, located in

the fuse block (J/B)] is disconnected. MWI-28

VEHICLE SPEED

CIRC

[B2205]Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction on speed signal system, malfunction may be misin-

terpreted when battery has lo

w voltage (when maintaining 7 - 8 V for about 2 seconds). MWI-29

Revision: December 20092009 QX56