lock INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 1 of 4171

A

B

C

D

E

F

G

H

I

J

K

L

M

N

P

O

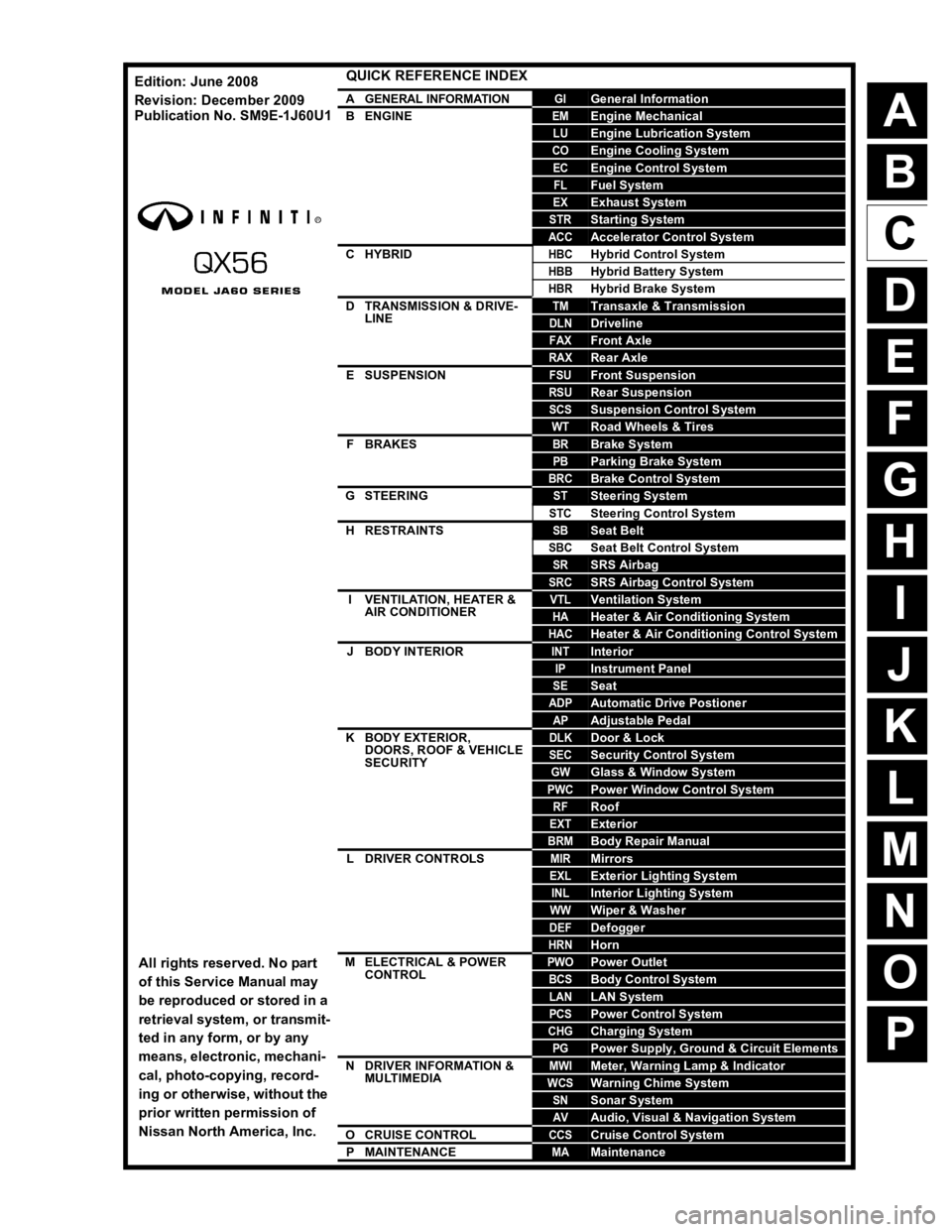

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

STRStarting System

ACCAccelerator Control System

CHYBRIDHBCHybrid Control System

HBBHybrid Battery System

HBRHybrid Brake System

DTRANSMISSION & DRIVE-

LINETMTransaxle & Transmission

DLNDriveline

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

SCSSuspension Control System

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGSTSteering System

STCSteering Control System

HRESTRAINTSSBSeat Belt

SBCSeat Belt Control System

SRSRS Airbag

SRCSRS Airbag Control System

IVENTILATION, HEATER &

AIR CONDITIONERVTLVentilation System

HAHeater & Air Conditioning System

HACHeater & Air Conditioning Control System

JBODY INTERIORINTInterior

IPInstrument Panel

SESeat

ADPAutomatic Drive Postioner

APAdjustable Pedal

KBODY EXTERIOR,

DOORS, ROOF & VEHICLE

SECURITYDLKDoor & Lock

SECSecurity Control System

GWGlass & Window System

PWCPower Window Control System

RFRoof

EXTExterior

BRMBody Repair Manual

LDRIVER CONTROLSMIRMirrors

EXLExterior Lighting System

INLInterior Lighting System

WWWiper & Washer

DEFDefogger

HRNHorn

MELECTRICAL & POWER

CONTROLPWOPower Outlet

BCSBody Control System

LANLAN System

PCSPower Control System

CHGCharging System

PGPower Supply, Ground & Circuit Elements

NDRIVER INFORMATION &

MULTIMEDIAMWIMeter, Warning Lamp & Indicator

WCSWarning Chime System

SNSonar System

AVAudio, Visual & Navigation System

OCRUISE CONTROLCCSCruise Control System

PMAINTENANCEMAMaintenance

All rights reserved. No part

of this Service Manual may

be reproduced or stored in a

retrieval system, or transmit-

ted in any form, or by any

means, electronic, mechani-

cal, photo-copying, record-

ing or otherwise, without the

prior written permission of

Nissan North America, Inc.

Edition: June 2008

Revision: December 2009

Publication No. SM9

E-1J60U1

Page 10 of 4171

ACC-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005851830

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005851831

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 11 of 4171

PRECAUTIONSACC-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

ACC

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Revision: December 20092009 QX56

Page 12 of 4171

ACC-4

< REMOVAL AND INSTALLATION >

ACCELERATOR CONTROL SYSTEM

REMOVAL AND INSTALLATION

ACCELERATOR CONTROL SYSTEM

Removal and InstallationINFOID:0000000003771801

Adjustable Accelerator Pedal

CAUTION:

• Do not disassemble the accelerator pedal adjusting mechanism.

• Before removal and installation the accelerator and brake pedals must be in the frontmost position.

This is to align the base position of the accelerator and brake pedals.

• Do not disassemble the accelerator pedal assembly.

• Do not remove the accelerator pedal position sensor from the accelerator pedal bracket.

• Avoid damage from dropping the accel erator pedal assembly during handling.

• Keep the accelerator pedal assembly away from water.

REMOVAL

1. Move the accelerator and brake pedals to the frontmost position.

2. Turn the ignition switch OFF and disconnect the negative battery terminal.

3. Disconnect the adjustable brake pedal cable from the adjustable brake pedal. • Unlock, then pull the adjustable brake pedal cable to disconnect it from the adjustable brake pedal.

LBIA0379E

1. Adjustable accelerator pedal assem-

bly 2. A/T control cable mounting bracket (part

of the accelerator pedal assembly) 3. Adjustable pedal electric motor (part

of the accelerator pedal assembly)

4. Adjustable brake pedal cable (part of the accelerator pedal assembly)

Revision: December 20092009 QX56

Page 27 of 4171

AUTOMATIC DRIVE POSITIONER SYSTEMADP-13

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

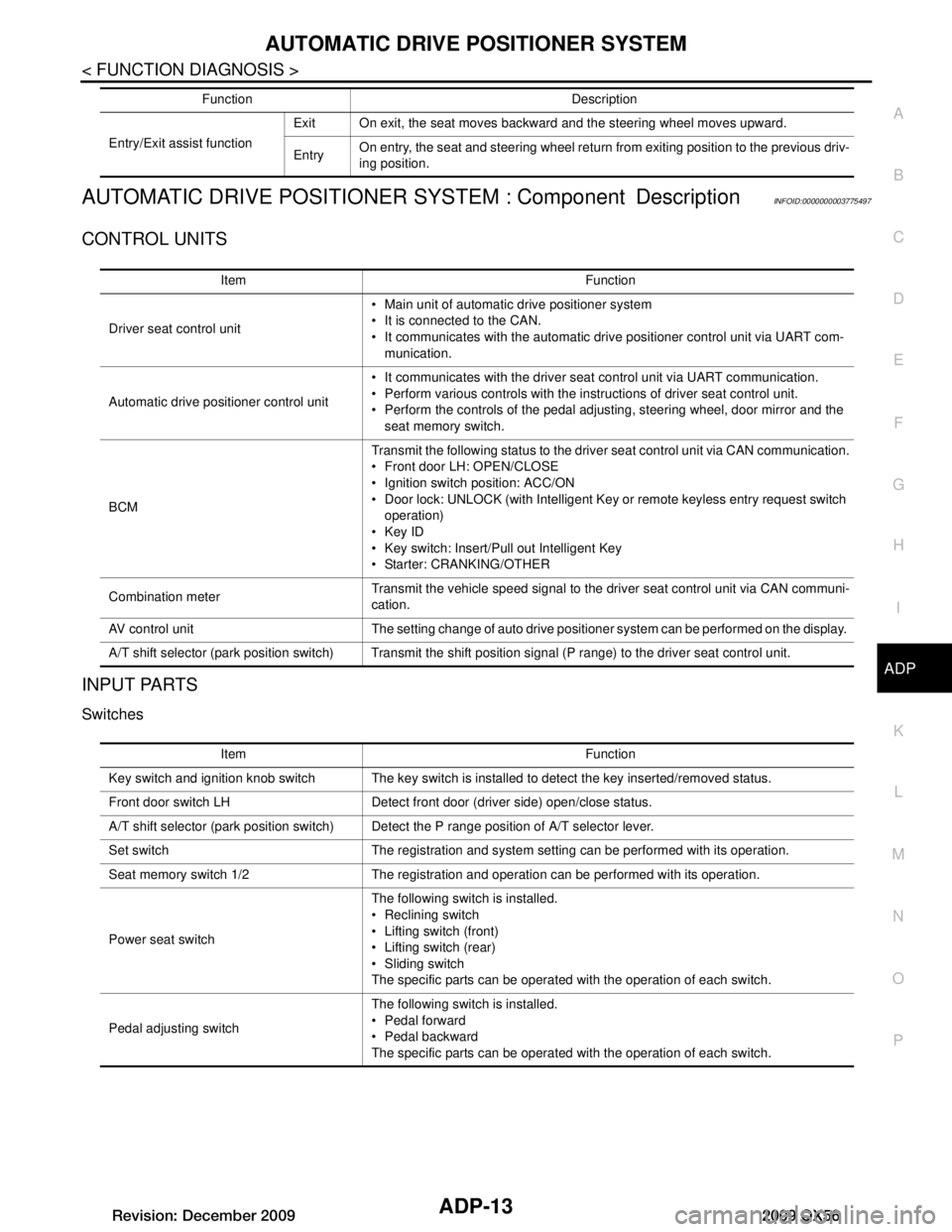

AUTOMATIC DRIVE POSITIONER SYSTEM : Component DescriptionINFOID:0000000003775497

CONTROL UNITS

INPUT PARTS

Switches

Entry/Exit assist functionExit On exit, the seat moves backward and the steering wheel moves upward.

Entry

On entry, the seat and steering wheel return from exiting position to the previous driv-

ing position.

Function Description

Item Function

Driver seat control unit Main unit of automatic drive positioner system

It is connected to the CAN.

It communicates with the automatic drive positioner control unit via UART com-

munication.

Automatic drive positioner control unit It communicates with the driver seat control unit via UART communication.

Perform various controls with the instructions of driver seat control unit.

Perform the controls of the pedal adjusting, steering wheel, door mirror and the

seat memory switch.

BCM Transmit the following status to the driver seat control unit via CAN communication.

Front door LH: OPEN/CLOSE

Ignition switch position: ACC/ON

Door lock: UNLOCK (with Intelligent Key or remote keyless entry request switch

operation)

Key ID

Key switch: Insert/Pull out Intelligent Key

Starter: CRANKING/OTHER

Combination meter Transmit the vehicle speed signal to the driver seat control unit via CAN communi-

cation.

AV control unit The setting change of auto drive positioner system can be performed on the display.

A/T shift selector (park position switch) Transmit the shift position signal (P range) to the driver seat control unit.

Item Function

Key switch and ignition knob switch The key switch is installed to detect the key inserted/removed status.

Front door switch LH Detect front door (driver side) open/close status.

A/T shift selector (park position switch) Detect the P range position of A/T selector lever.

Set switch The registration and system setting can be performed with its operation.

Seat memory switch 1/2 The registration and operation can be performed with its operation.

Power seat switch The following switch is installed.

Reclining switch

Lifting switch (front)

Lifting switch (rear)

Sliding switch

The specific parts can be operated with the operation of each switch.

Pedal adjusting switch The following switch is installed.

Pedal forward

Pedal backward

The specific parts can be operated with the operation of each switch.

Revision: December 20092009 QX56

Page 61 of 4171

POWER SUPPLY AND GROUND CIRCUITADP-47

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

DRIVER SEAT CONTROL UNIT : Diagnosis ProcedureINFOID:0000000003775549

NOTE:

Do not disconnect the battery negative terminal and the dr iver seat control unit connector until DTC is con-

firmed with CONSULT-III.

1. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconeect driver seat control unit.

3. Check voltage between driver s eat control unit harness connec-

tor and ground.

Is the inspection result normal?

YES >> GO TO 2

NO >> Check the following. Repair or replace harness between driver seat control unit and fuse block (J/B).

Circuit breaker.

2. CHECK GROUND CIRCUIT

Check continuity between the driv er seat control unit harness con-

nector and ground.

Is the inspection result normal?

YES >> Driver seat control unit power supply and ground circuit are OK.

NO >> Repair or replace harness.

DRIVER SEAT CONTROL UNIT : Special Repair RequirementINFOID:0000000003775550

1. PERFORM ADDITIONAL SERVICE

Perform additional service when removing battery negative terminal.

>> Refer to Owner’s Manual.

AUTOMATIC DRIVE POSITIONER CONTROL UNIT

AUTOMATIC DRIVE POSITIONER CO NTROL UNIT : Diagnosis Procedure

INFOID:0000000003775551

NOTE:

Do not disconnect the battery negative terminal and the dr iver seat control unit connector until DTC is con-

firmed with CONSULT-III.

Te r m i n a l s

Power

source ConditionVoltage (V)

(Approx.)

(+)

(–)

Driver seat

control unit connector Terminal

B202 6 GroundSTART

power sup-

ply Ignition

switch

START Battery

voltage

B203 33 Battery

power sup-ply Ignition

switch OFF

40

LIIA1897E

Driver seat control unit

connector Te r m i n a l

Ground Continuity

B202 32 Ye s

B203 48

PIIA4542E

Revision: December 20092009 QX56

Page 160 of 4171

ADP-146

< ECU DIAGNOSIS >

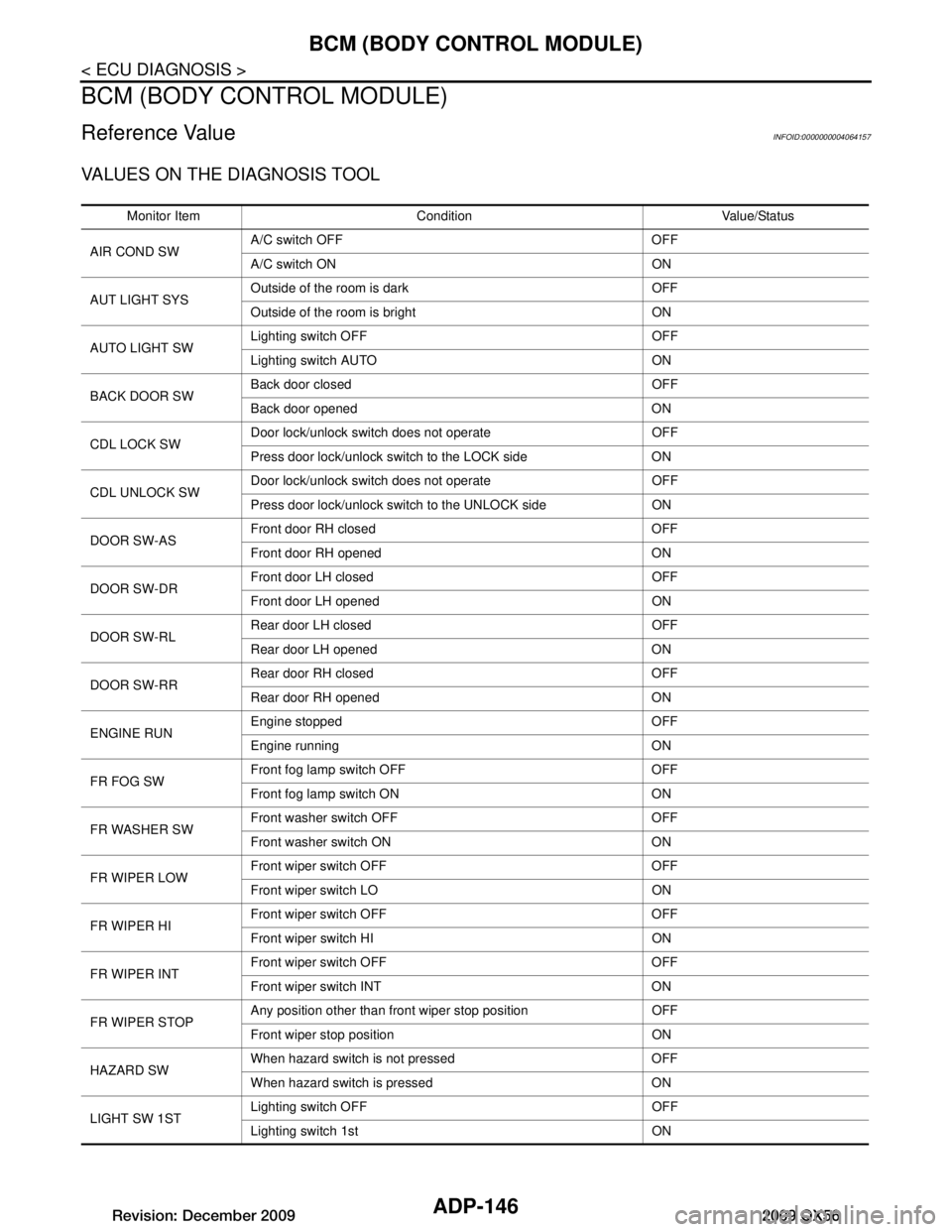

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE)

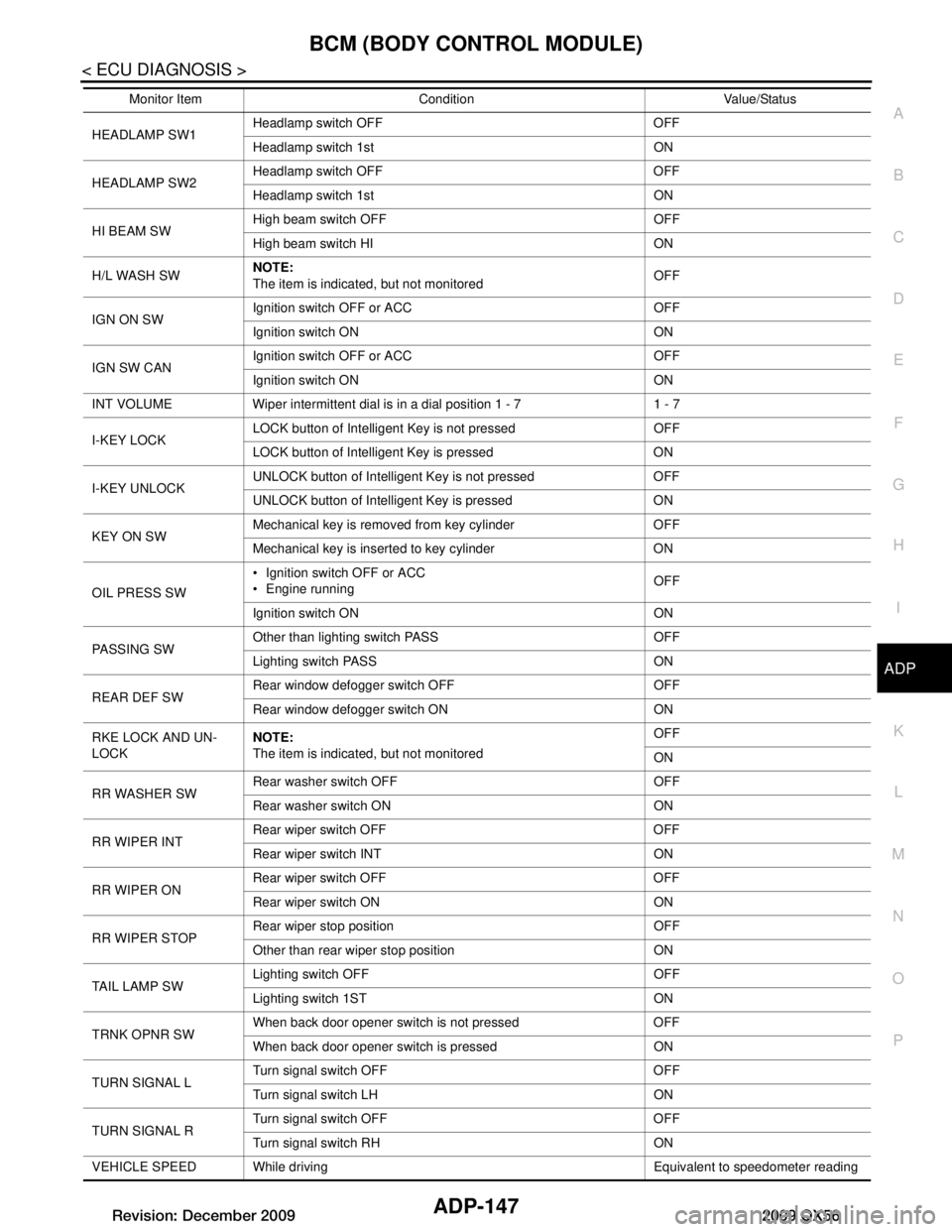

Reference ValueINFOID:0000000004064157

VALUES ON THE DIAGNOSIS TOOL

Monitor Item Condition Value/Status

AIR COND SW A/C switch OFF OFF

A/C switch ON ON

AUT LIGHT SYS Outside of the room is dark OFF

Outside of the room is bright ON

AUTO LIGHT SW Lighting switch OFF OFF

Lighting switch AUTO ON

BACK DOOR SW Back door closed OFF

Back door opened ON

CDL LOCK SW Door lock/unlock switch does not operate OFF

Press door lock/unlock switch to the LOCK side ON

CDL UNLOCK SW Door lock/unlock switch does not operate OFF

Press door lock/unlock switch to the UNLOCK side ON

DOOR SW-AS Front door RH closed OFF

Front door RH opened ON

DOOR SW-DR Front door LH closed OFF

Front door LH opened ON

DOOR SW-RL Rear door LH closed OFF

Rear door LH opened ON

DOOR SW-RR Rear door RH closed OFF

Rear door RH opened ON

ENGINE RUN Engine stopped OFF

Engine running ON

FR FOG SW Front fog lamp switch OFF OFF

Front fog lamp switch ON ON

FR WASHER SW Front washer switch OFF OFF

Front washer switch ON ON

FR WIPER LOW Front wiper switch OFF OFF

Front wiper switch LO ON

FR WIPER HI Front wiper switch OFF OFF

Front wiper switch HI ON

FR WIPER INT Front wiper switch OFF OFF

Front wiper switch INT ON

FR WIPER STOP Any position other than front wiper stop position OFF

Front wiper stop position ON

HAZARD SW When hazard switch is not pressed OFF

When hazard switch is pressed ON

LIGHT SW 1ST Lighting switch OFF OFF

Lighting switch 1st ON

Revision: December 20092009 QX56

Page 161 of 4171

BCM (BODY CONTROL MODULE)ADP-147

< ECU DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

HEADLAMP SW1 Headlamp switch OFF OFF

Headlamp switch 1st ON

HEADLAMP SW2 Headlamp switch OFF OFF

Headlamp switch 1st ON

HI BEAM SW High beam switch OFF OFF

High beam switch HI ON

H/L WASH SW NOTE:

The item is indicated, but not monitored OFF

IGN ON SW Ignition switch OFF or ACC OFF

Ignition switch ON ON

IGN SW CAN Ignition switch OFF or ACC OFF

Ignition switch ON ON

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7 1 - 7

I-KEY LOCK LOCK button of Intelligent Key is not pressed OFF

LOCK button of Intelligent Key is pressed ON

I-KEY UNLOCK UNLOCK button of Intelligent Key is not pressed OFF

UNLOCK button of Intelligent Key is pressed ON

KEY ON SW Mechanical key is removed from key cylinder OFF

Mechanical key is inserted to key cylinder ON

OIL PRESS SW Ignition switch OFF or ACC

Engine running

OFF

Ignition switch ON ON

PASSING SW Other than lighting switch PASS OFF

Lighting switch PASS ON

REAR DEF SW Rear window defogger switch OFF OFF

Rear window defogger switch ON ON

RKE LOCK AND UN-

LOCK NOTE:

The item is indicated, but not monitored OFF

ON

RR WASHER SW Rear washer switch OFF OFF

Rear washer switch ON ON

RR WIPER INT Rear wiper switch OFF OFF

Rear wiper switch INT ON

RR WIPER ON Rear wiper switch OFF OFF

Rear wiper switch ON ON

RR WIPER STOP Rear wiper stop position OFF

Other than rear wiper stop position ON

TAIL LAMP SW Lighting switch OFF OFF

Lighting switch 1ST ON

TRNK OPNR SW When back door opener switch is not pressed OFF

When back door opener switch is pressed ON

TURN SIGNAL L Turn signal switch OFF OFF

Turn signal switch LH ON

TURN SIGNAL R Turn signal switch OFF OFF

Turn signal switch RH ON

VEHICLE SPEED While driving Equiv alent to speedometer reading

Monitor Item Condition Value/Status

Revision: December 20092009 QX56

Page 163 of 4171

BCM (BODY CONTROL MODULE)ADP-149

< ECU DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

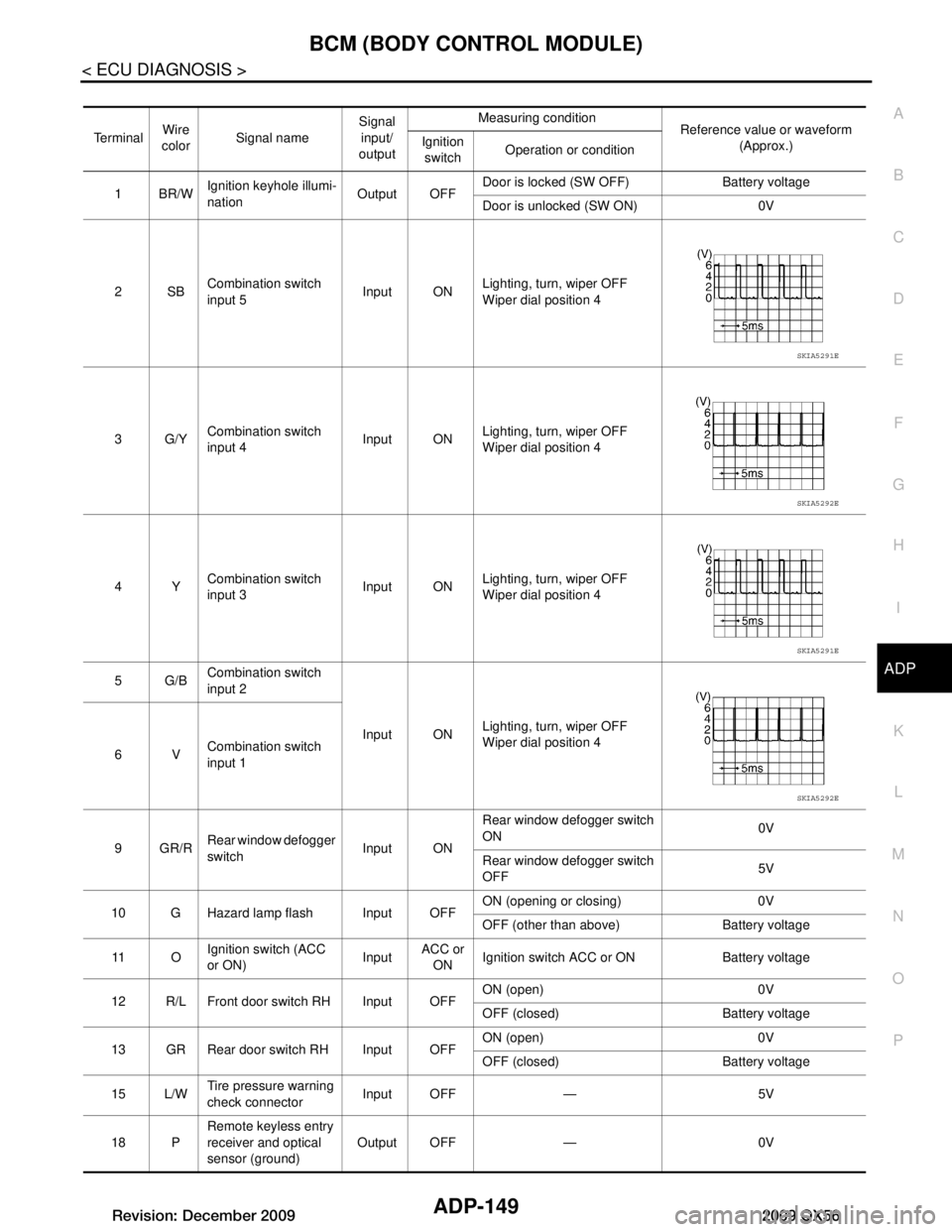

Te r m i n a l Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

1BR/W Ignition keyhole illumi-

nation Output OFFDoor is locked (SW OFF) Battery voltage

Door is unlocked (SW ON) 0V

2SB Combination switch

input 5 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

3G/Y Combination switch

input 4 Input ONLighting, turn, wiper OFF

Wiper dial position 4

4Y Combination switch

input 3 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

5G/B Combination switch

input 2

Input ONLighting, turn, wiper OFF

Wiper dial position 4

6V Combination switch

input 1

9GR/R Rear window defogger

switch

Input ONRear window defogger switch

ON

0V

Rear window defogger switch

OFF 5V

10 G Hazard lamp flash Input OFF ON (opening or closing) 0V

OFF (other than above) Battery voltage

11 O Ignition switch (ACC

or ON)

InputACC or

ON Ignition switch ACC or ON Battery voltage

12 R/L Front door switch RH Input OFF ON (open) 0V

OFF (closed) Battery voltage

13 GR Rear door switch RH Input OFF ON (open) 0V

OFF (closed) Battery voltage

15 L/W Tire pressure warning

check connector

Input OFF — 5V

18 P Remote keyless entry

receiver and optical

sensor (ground)

Output OFF — 0V

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Revision: December 20092009 QX56

Page 164 of 4171

ADP-150

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

19 V/WRemote keyless entry

receiver (power sup-

ply) Output OFF Ignition switch OFF

20 G/W Remote keyless entry

receiver (signal) Input OFFStand-by (keyfob buttons re-

leased)

When remote keyless entry

receiver receives signal from

keyfob (keyfob buttons

pressed)

21 G NATS antenna amp. Input OFF

→

ON Ignition switch (OFF

→ ON) Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then return to battery voltage.

22 W/V BUS — — Ignition switch ON or power

window timer operates

23 G/O Security indicator

lamp Output OFF

Goes OFF

→ illuminates (Ev-

ery 2.4 seconds) Battery voltage

→ 0V

25 BR NATS antenna amp. Input OFF

→

ON Ignition switch (OFF

→ ON) Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then return to battery voltage.

26 Y/L Rear wiper auto stop

switch 2 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) 0V

Forward sweep (counterclock-

wise direction) Fluctuating

B Position (full counterclock-

wise stop position) Battery voltage

Reverse sweep (clockwise di-

rection) Fluctuating

27 W/R Compressor ON sig-

nal Input ONA/C switch OFF 5V

A/C switch ON 0V

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

LIIA1893E

LIIA1894E

LIIA1895E

PIIA2344E

Revision: December 20092009 QX56