200 INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3854 of 4171

TM-206

< ON-VEHICLE REPAIR >

CONTROL VALVE WITH TCM

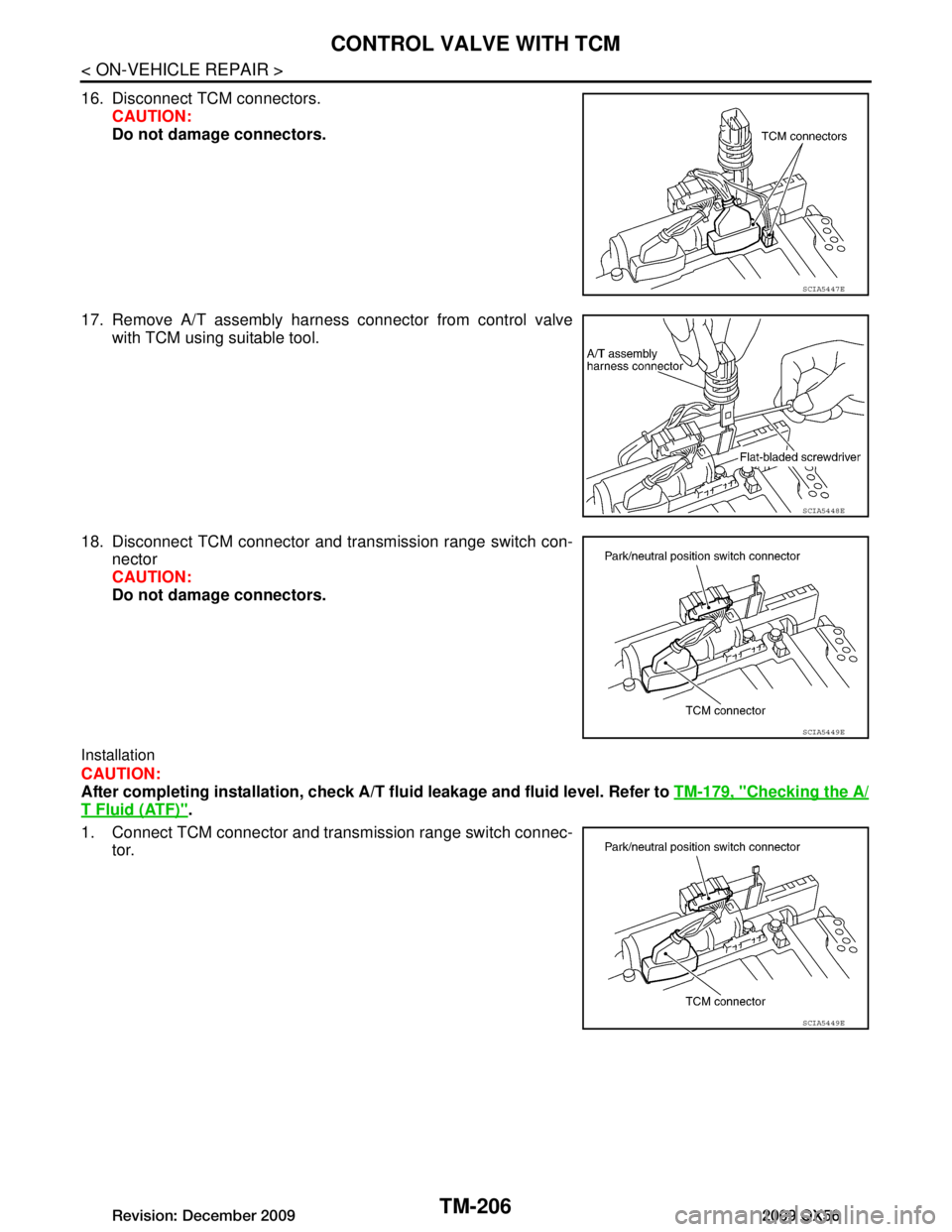

16. Disconnect TCM connectors.CAUTION:

Do not damage connectors.

17. Remove A/T assembly harness connector from control valve with TCM using suitable tool.

18. Disconnect TCM connector and transmission range switch con- nector

CAUTION:

Do not damage connectors.

Installation

CAUTION:

After completing installation, check A/T fluid leakage and fluid level. Refer to TM-179, "Checking the A/

T Fluid (ATF)".

1. Connect TCM connector and trans mission range switch connec-

tor.

SCIA5447E

SCIA5448E

SCIA5449E

SCIA5449E

Revision: December 20092009 QX56

Page 3855 of 4171

CONTROL VALVE WITH TCMTM-207

< ON-VEHICLE REPAIR >

CEF

G H

I

J

K L

M A

B

TM

N

O P

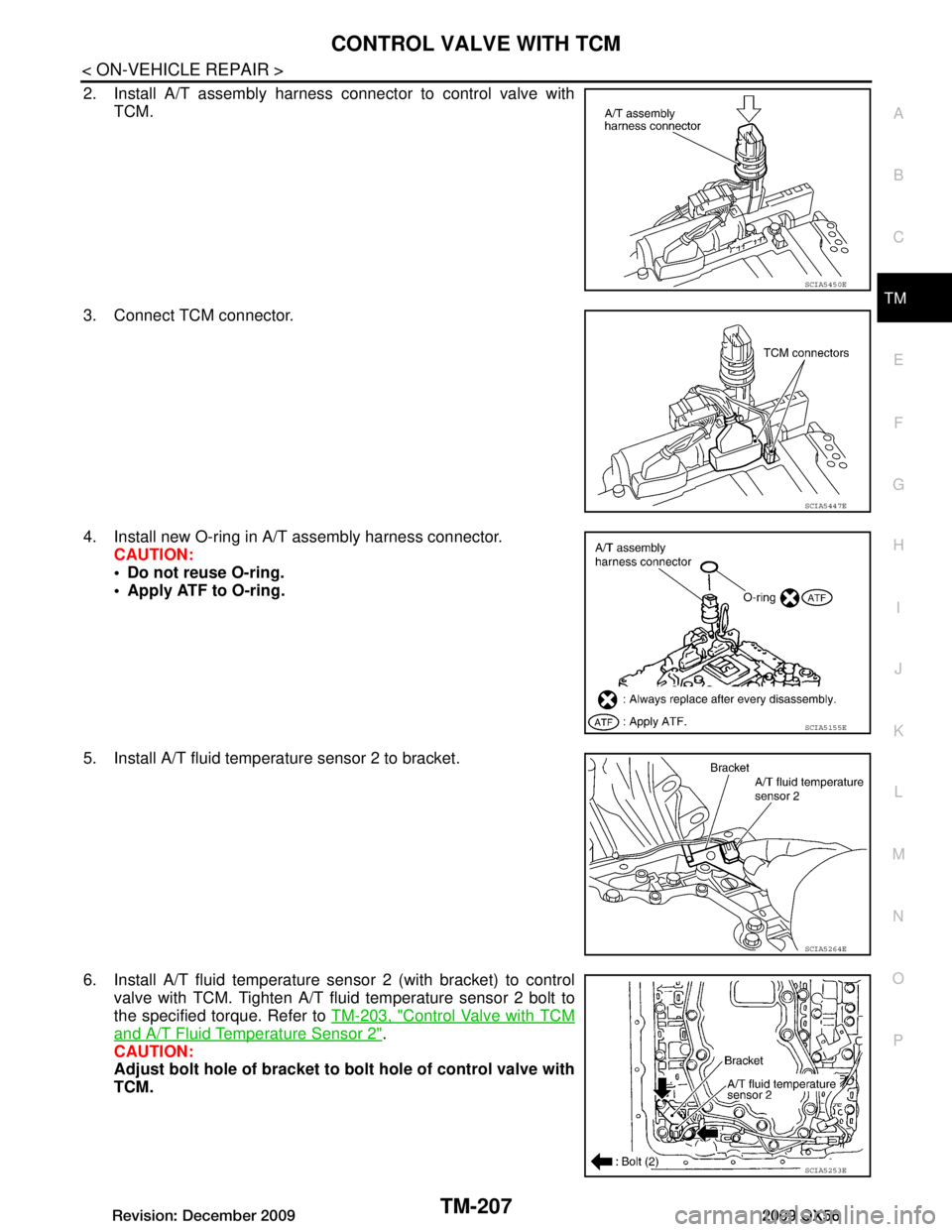

2. Install A/T assembly harness connector to control valve with TCM.

3. Connect TCM connector.

4. Install new O-ring in A/T assembly harness connector. CAUTION:

Do not reuse O-ring.

Apply ATF to O-ring.

5. Install A/T fluid temperature sensor 2 to bracket.

6. Install A/T fluid temperature sensor 2 (with bracket) to control valve with TCM. Tighten A/T flui d temperature sensor 2 bolt to

the specified torque. Refer to TM-203, "Control Valve with TCM

and A/T Fluid Temperature Sensor 2".

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve with

TCM.

SCIA5450E

SCIA5447E

SCIA5155E

SCIA5264E

SCIA5253E

Revision: December 20092009 QX56

Page 3856 of 4171

TM-208

< ON-VEHICLE REPAIR >

CONTROL VALVE WITH TCM

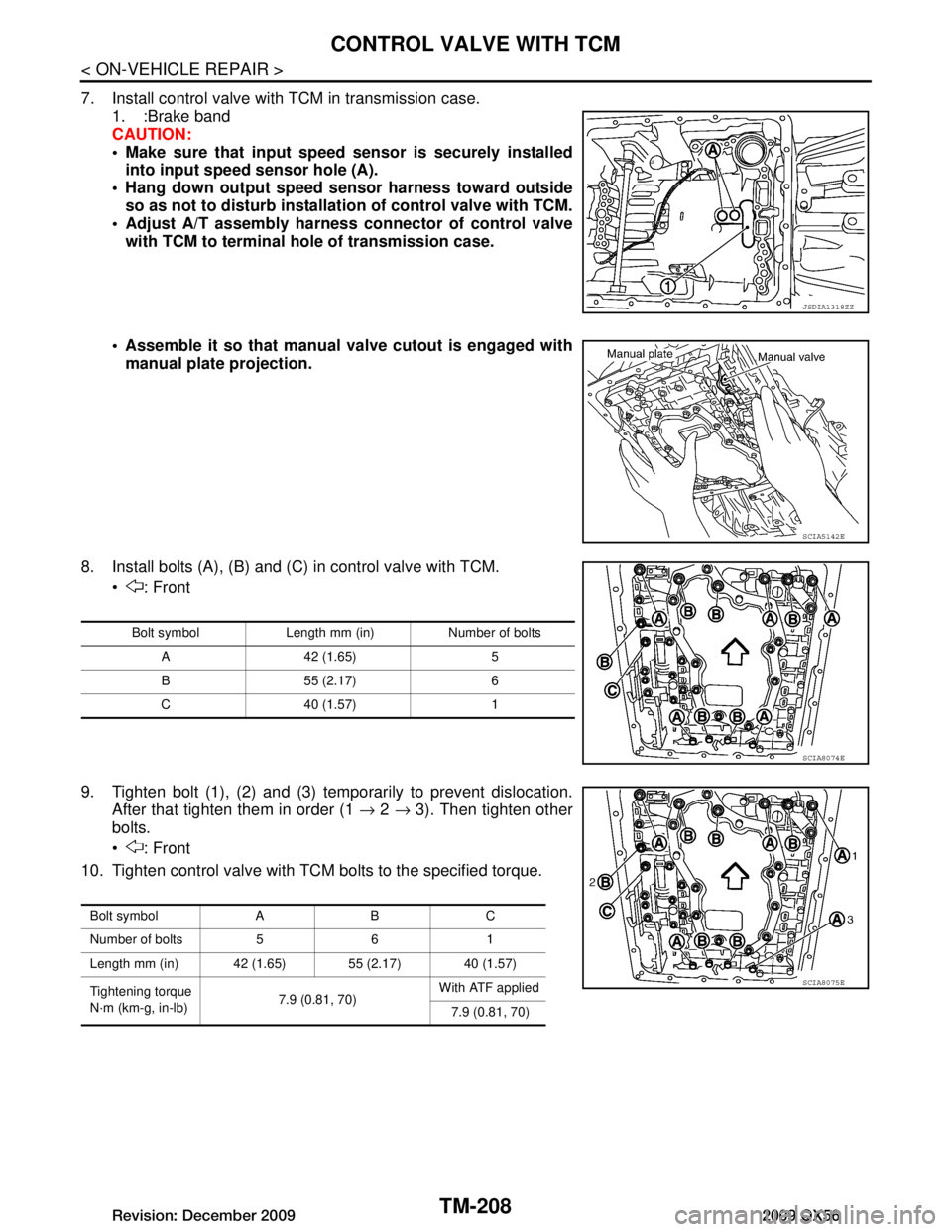

7. Install control valve with TCM in transmission case.1. :Brake band

CAUTION:

Make sure that input speed sensor is securely installed

into input speed sensor hole (A).

Hang down output speed sen sor harness toward outside

so as not to disturb installati on of control valve with TCM.

Adjust A/T assembly harness co nnector of control valve

with TCM to terminal hole of transmission case.

Assemble it so that manual valve cutout is engaged with manual plate projection.

8. Install bolts (A), (B) and (C) in control valve with TCM. : Front

9. Tighten bolt (1), (2) and (3) temporarily to prevent dislocation. After that tighten them in order (1 → 2 → 3). Then tighten other

bolts.

: Front

10. Tighten control valve with TCM bolts to the specified torque.

JSDIA1318ZZ

SCIA5142E

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA8074E

Bolt symbol A B C

Number of bolts 5 6 1

Length mm (in) 42 (1.65) 55 (2.17) 40 (1.57)

Tightening torque

N·m (km-g, in-lb) 7.9 (0.81, 70)With ATF applied

7.9 (0.81, 70)

SCIA8075E

Revision: December 20092009 QX56

Page 3857 of 4171

CONTROL VALVE WITH TCMTM-209

< ON-VEHICLE REPAIR >

CEF

G H

I

J

K L

M A

B

TM

N

O P

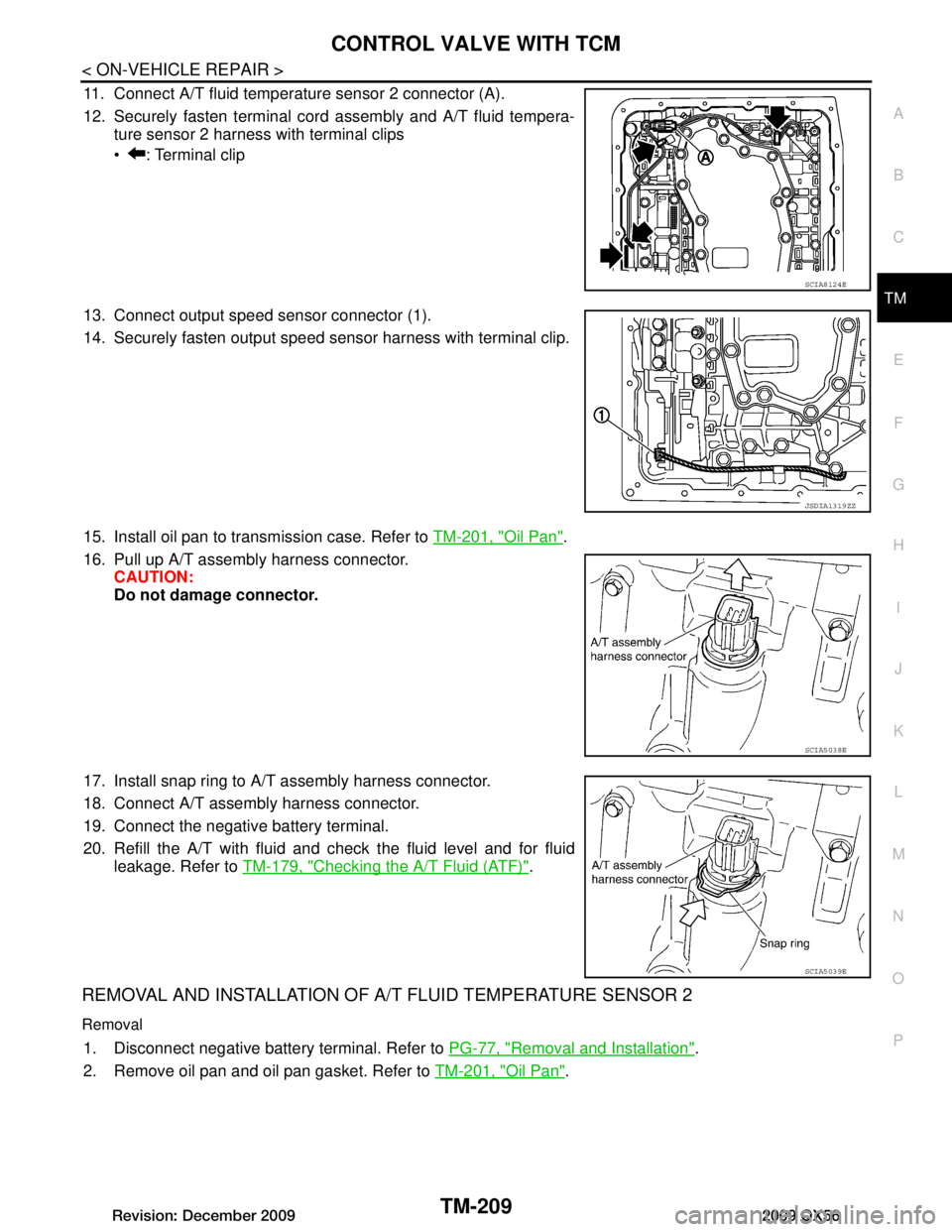

11. Connect A/T fluid temperature sensor 2 connector (A).

12. Securely fasten terminal cord assembly and A/T fluid tempera- ture sensor 2 harness with terminal clips

: Terminal clip

13. Connect output speed sensor connector (1).

14. Securely fasten output speed sensor harness with terminal clip.

15. Install oil pan to transmission case. Refer to TM-201, "Oil Pan"

.

16. Pull up A/T assembly harness connector. CAUTION:

Do not damage connector.

17. Install snap ring to A/T assembly harness connector.

18. Connect A/T assembly harness connector.

19. Connect the negative battery terminal.

20. Refill the A/T with fluid and check the fluid level and for fluid leakage. Refer to TM-179, "Checking the A/T Fluid (ATF)"

.

REMOVAL AND INSTALLATION OF A/ T FLUID TEMPERATURE SENSOR 2

Removal

1. Disconnect negative battery terminal. Refer to PG-77, "Removal and Installation".

2. Remove oil pan and oil pan gasket. Refer to TM-201, "Oil Pan"

.

SCIA8124E

JSDIA1319ZZ

SCIA5038E

SCIA5039E

Revision: December 20092009 QX56

Page 3858 of 4171

TM-210

< ON-VEHICLE REPAIR >

CONTROL VALVE WITH TCM

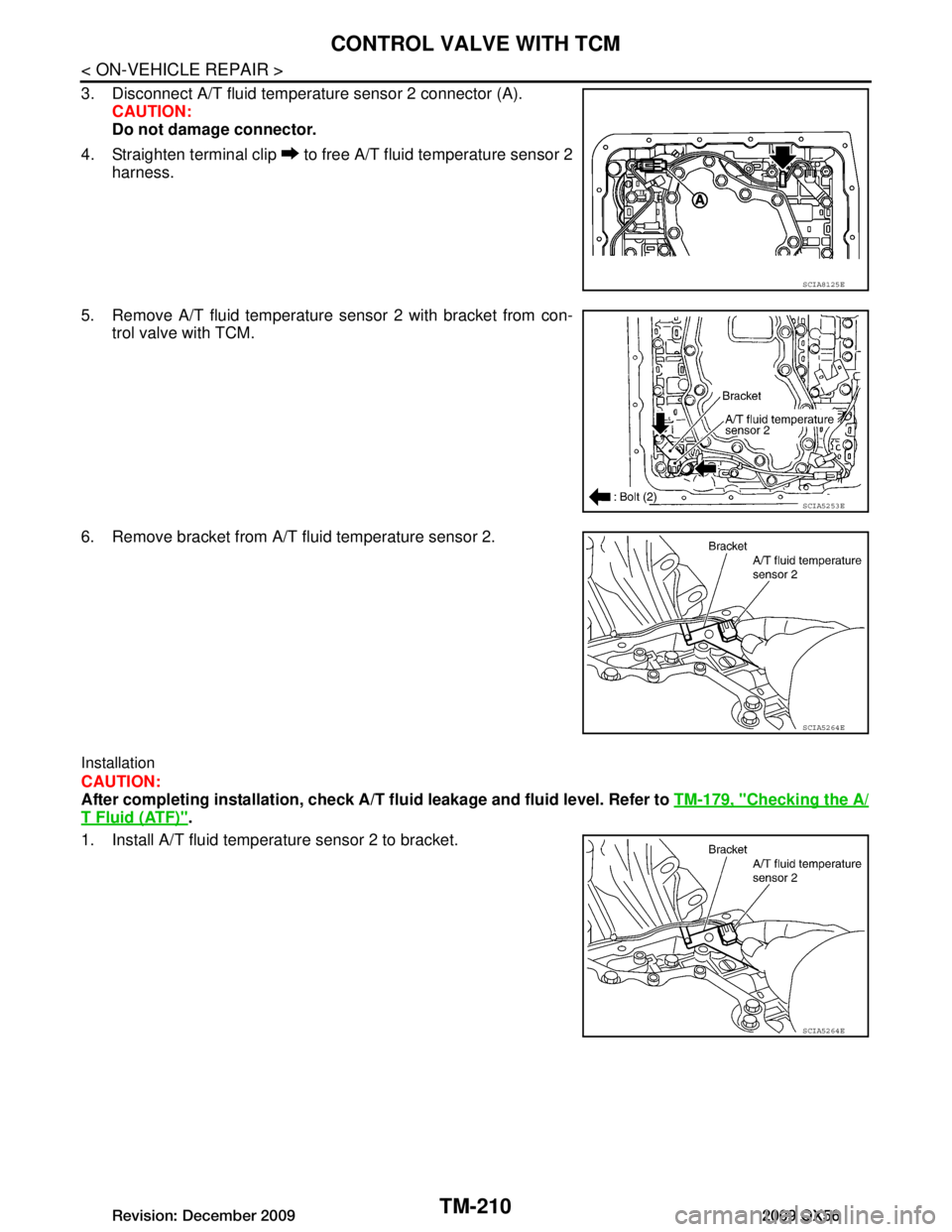

3. Disconnect A/T fluid temperature sensor 2 connector (A).

CAUTION:

Do not damage connector.

4. Straighten terminal clip to free A/T fluid temperature sensor 2 harness.

5. Remove A/T fluid temperature sensor 2 with bracket from con- trol valve with TCM.

6. Remove bracket from A/T fluid temperature sensor 2.

Installation

CAUTION:

After completing installation, check A/T fluid leakage and fluid level. Refer to TM-179, "Checking the A/

T Fluid (ATF)".

1. Install A/T fluid temperature sensor 2 to bracket.

SCIA8125E

SCIA5253E

SCIA5264E

SCIA5264E

Revision: December 20092009 QX56

Page 3859 of 4171

CONTROL VALVE WITH TCMTM-211

< ON-VEHICLE REPAIR >

CEF

G H

I

J

K L

M A

B

TM

N

O P

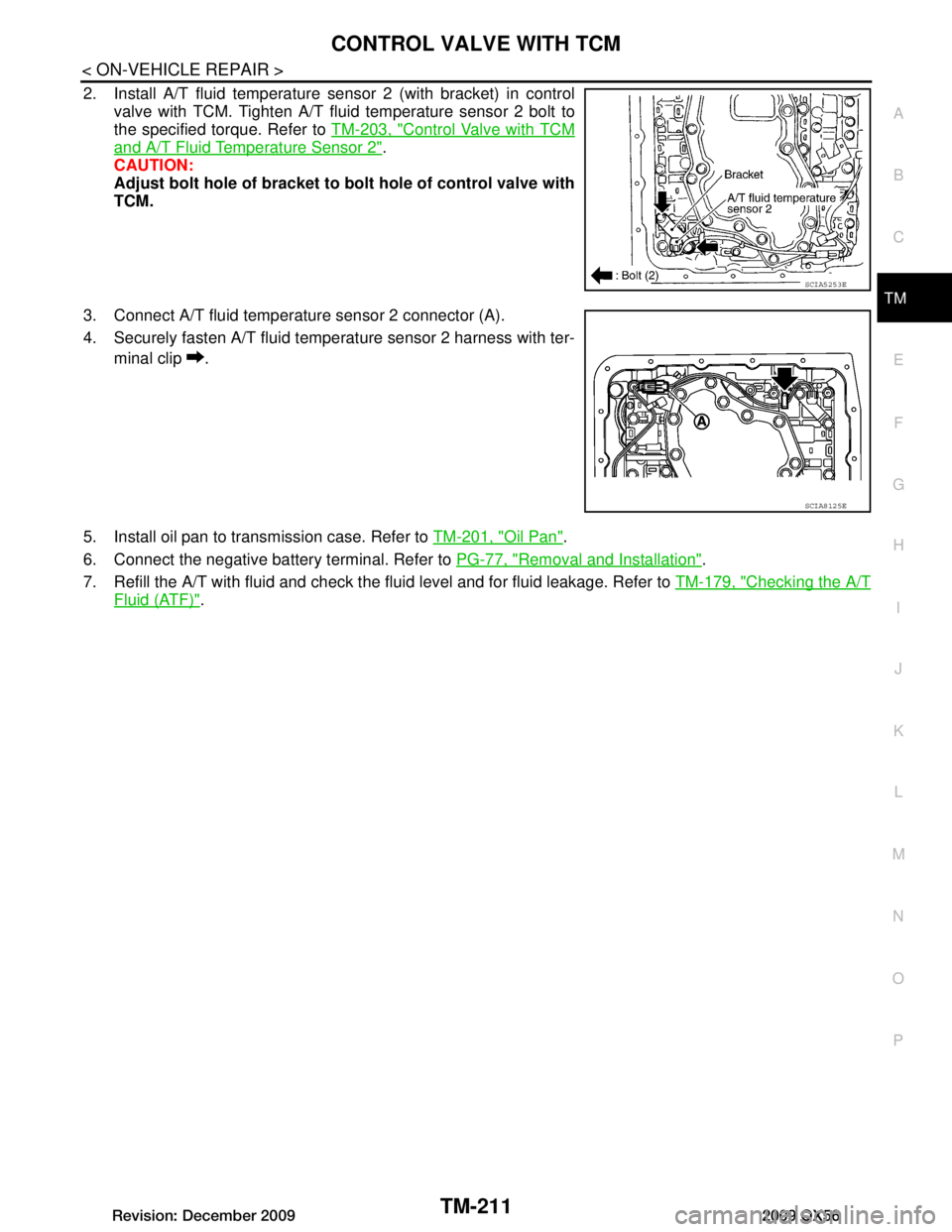

2. Install A/T fluid temperature sens or 2 (with bracket) in control

valve with TCM. Tighten A/T flui d temperature sensor 2 bolt to

the specified torque. Refer to TM-203, "Control Valve with TCM

and A/T Fluid Temperature Sensor 2".

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve with

TCM.

3. Connect A/T fluid temperature sensor 2 connector (A).

4. Securely fasten A/T fluid temperature sensor 2 harness with ter- minal clip .

5. Install oil pan to transmission case. Refer to TM-201, "Oil Pan"

.

6. Connect the negative battery terminal. Refer to PG-77, "Removal and Installation"

.

7. Refill the A/T with fluid and check the fluid level and for fluid leakage. Refer to TM-179, "Checking the A/T

Fluid (ATF)".

SCIA5253E

SCIA8125E

Revision: December 20092009 QX56

Page 3860 of 4171

TM-212

< ON-VEHICLE REPAIR >

REAR OIL SEAL

REAR OIL SEAL

Rear Oil SealINFOID:0000000004187482

REMOVAL AND INSTALLATION

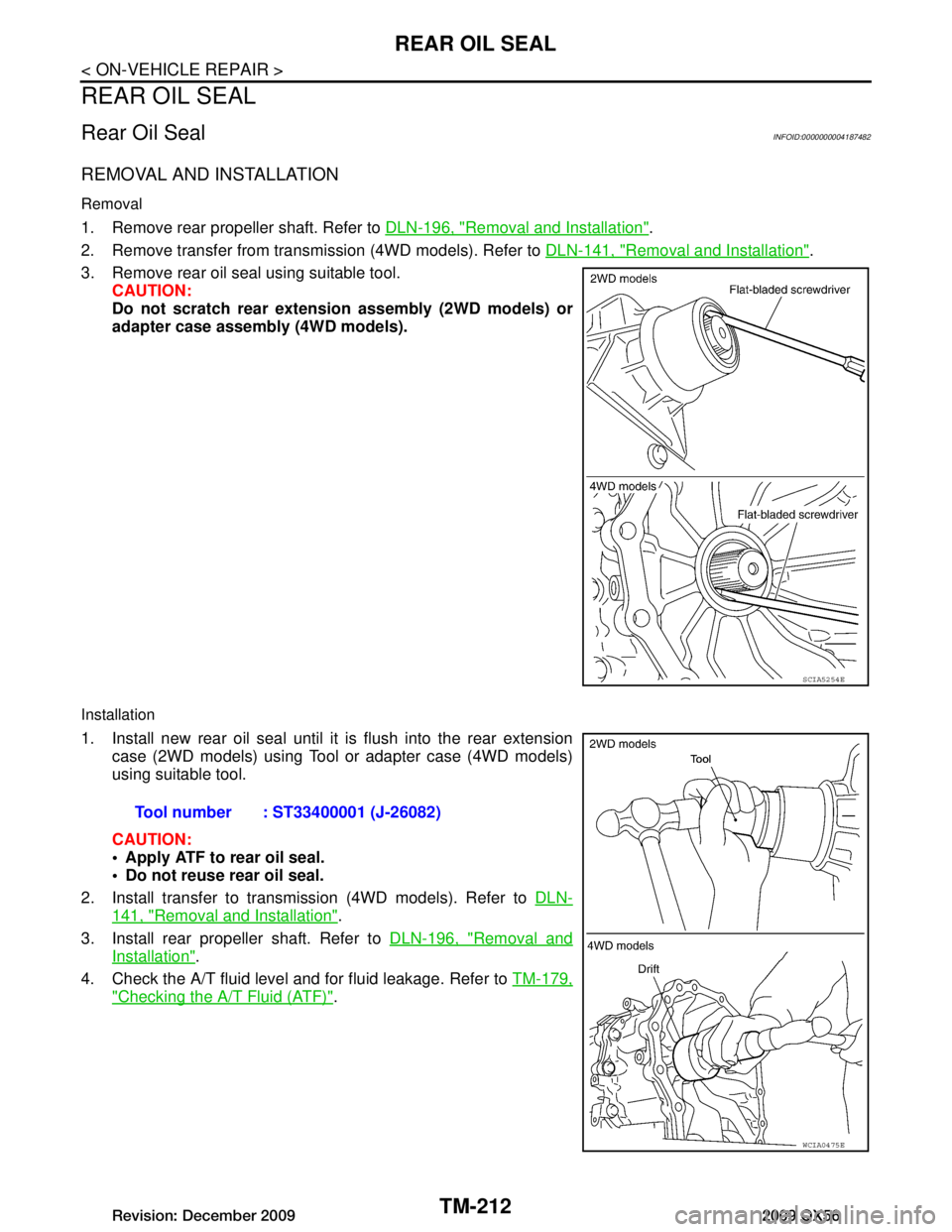

Removal

1. Remove rear propeller shaft. Refer to DLN-196, "Removal and Installation".

2. Remove transfer from transmission (4WD models). Refer to DLN-141, "Removal and Installation"

.

3. Remove rear oil seal using suitable tool. CAUTION:

Do not scratch rear extension assembly (2WD models) or

adapter case assembly (4WD models).

Installation

1. Install new rear oil seal until it is flush into the rear extension

case (2WD models) using Tool or adapter case (4WD models)

using suitable tool.

CAUTION:

Apply ATF to rear oil seal.

Do not reuse rear oil seal.

2. Install transfer to transmission (4WD models). Refer to DLN-

141, "Removal and Installation".

3. Install rear propeller shaft. Refer to DLN-196, "Removal and

Installation".

4. Check the A/T fluid level and for fluid leakage. Refer to TM-179,

"Checking the A/T Fluid (ATF)".

SCIA5254E

Tool number : ST33400001 (J-26082)

WCIA0475E

Revision: December 20092009 QX56

Page 3861 of 4171

FLUID COOLER SYSTEMTM-213

< ON-VEHICLE REPAIR >

CEF

G H

I

J

K L

M A

B

TM

N

O P

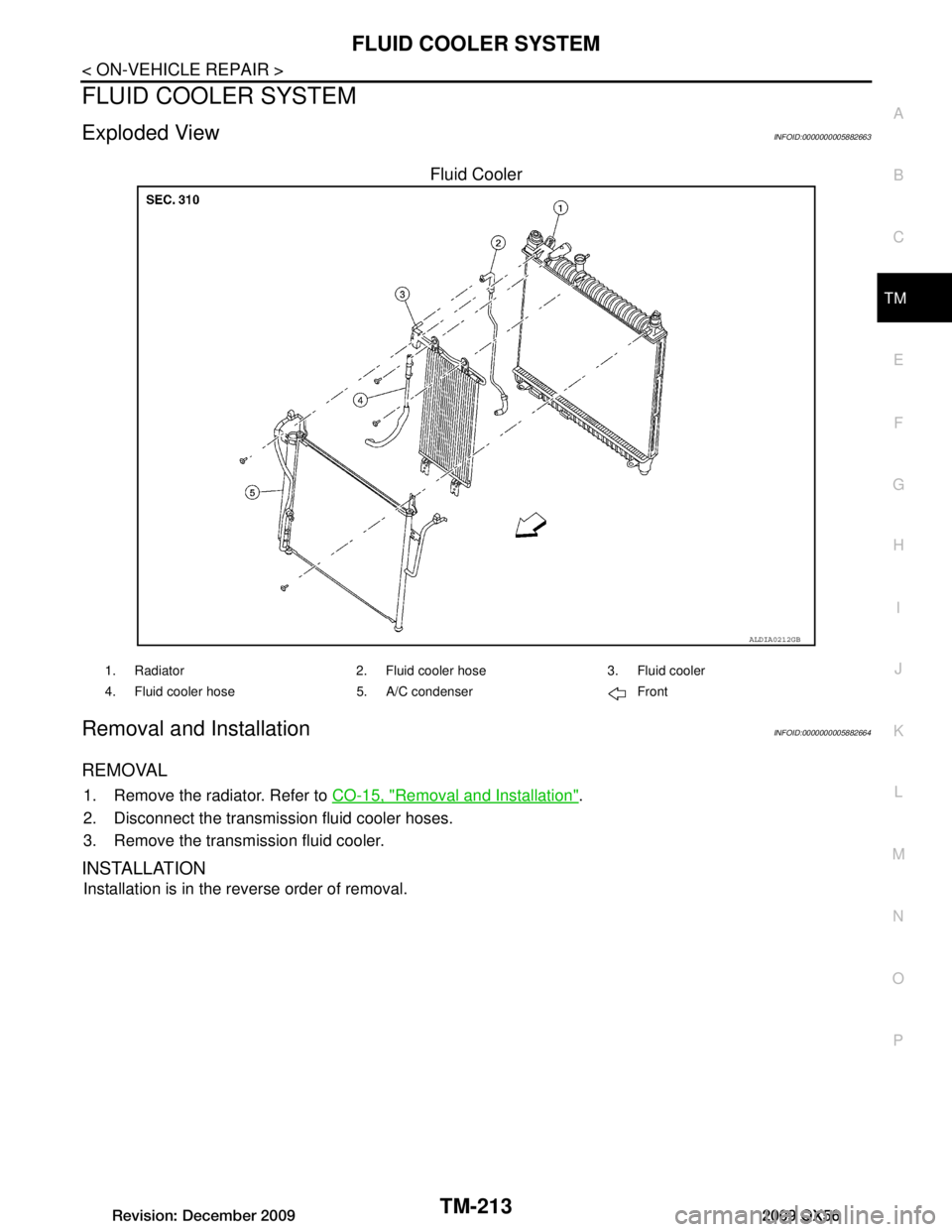

FLUID COOLER SYSTEM

Exploded ViewINFOID:0000000005882663

Fluid Cooler

Removal and InstallationINFOID:0000000005882664

REMOVAL

1. Remove the radiator. Refer to CO-15, "Removal and Installation".

2. Disconnect the transmission fluid cooler hoses.

3. Remove the transmission fluid cooler.

INSTALLATION

Installation is in the reverse order of removal.

ALDIA0212GB

1. Radiator 2. Fluid cooler hose 3. Fluid cooler

4. Fluid cooler hose 5. A/C condenser Front

Revision: December 20092009 QX56

Page 3862 of 4171

TM-214

< REMOVAL AND INSTALLATION >

TRANSMISSION ASSEMBLY

REMOVAL AND INSTALLATION

TRANSMISSION ASSEMBLY

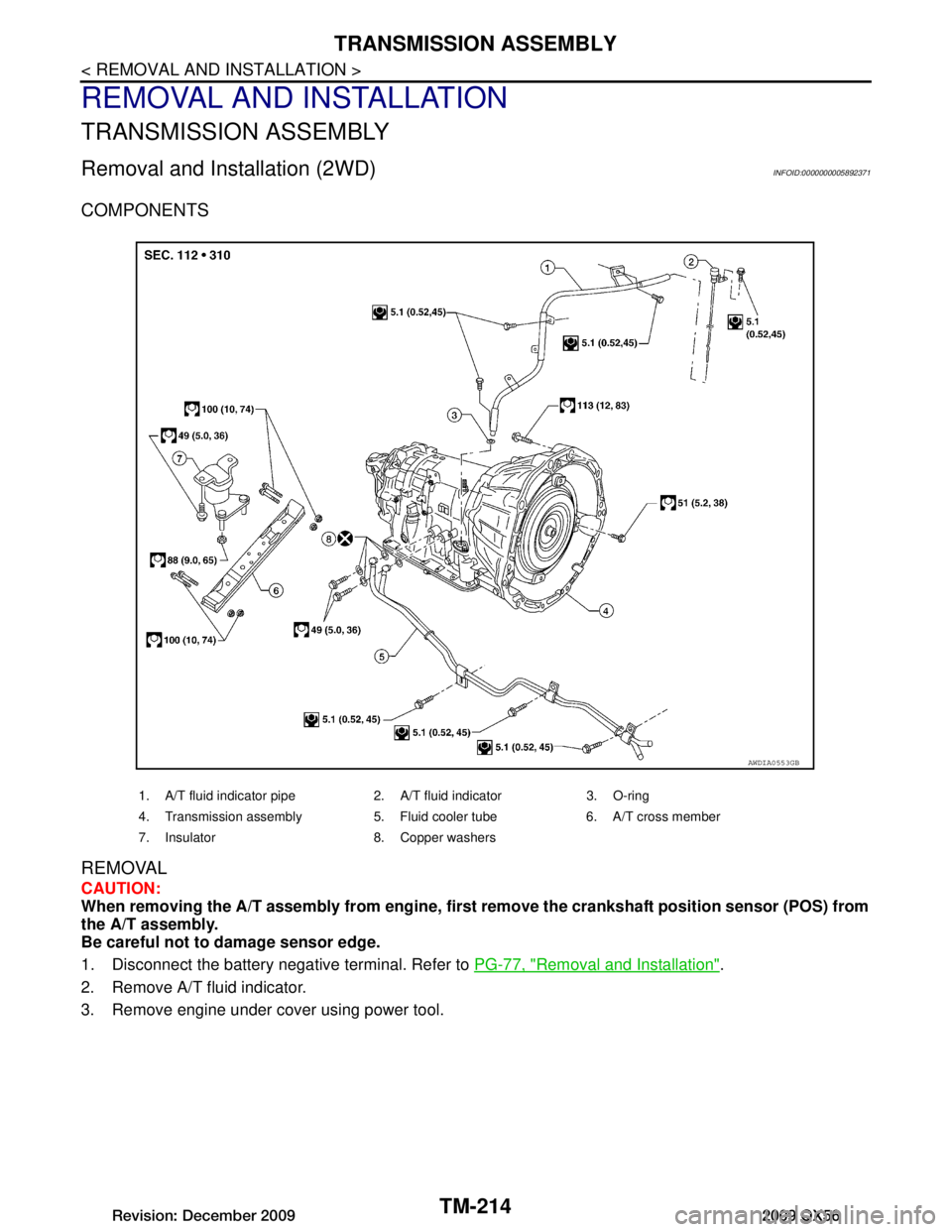

Removal and Installation (2WD)INFOID:0000000005892371

COMPONENTS

REMOVAL

CAUTION:

When removing the A/T assembly from engine, first remove the crankshaft position sensor (POS) from

the A/T assembly.

Be careful not to damage sensor edge.

1. Disconnect the battery negative terminal. Refer to PG-77, "Removal and Installation"

.

2. Remove A/T fluid indicator.

3. Remove engine under cover using power tool.

1. A/T fluid indicator pipe 2. A/T fluid indicator 3. O-ring

4. Transmission assembly 5. Fluid cooler tube 6. A/T cross member

7. Insulator 8. Copper washers

AWDIA0553GB

Revision: December 20092009 QX56

Page 3863 of 4171

TRANSMISSION ASSEMBLYTM-215

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

TM

N

O P

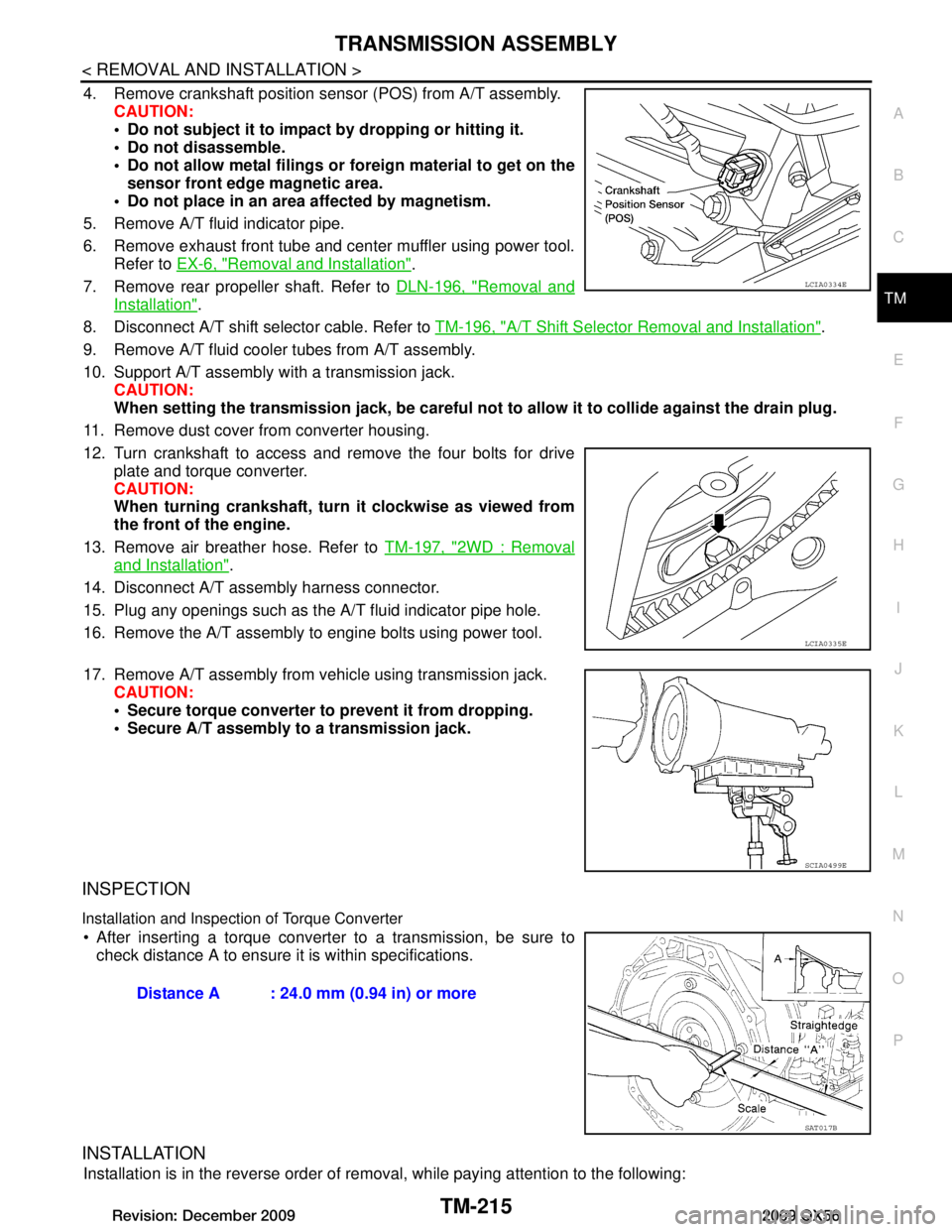

4. Remove crankshaft position sensor (POS) from A/T assembly. CAUTION:

Do not subject it to impact by dropping or hitting it.

Do not disassemble.

Do not allow metal filings or foreign material to get on the

sensor front edge magnetic area.

Do not place in an area affected by magnetism.

5. Remove A/T fluid indicator pipe.

6. Remove exhaust front tube and center muffler using power tool. Refer to EX-6, "Removal and Installation"

.

7. Remove rear propeller shaft. Refer to DLN-196, "Removal and

Installation".

8. Disconnect A/T shift selector cable. Refer to TM-196, "A/T Shift Selector Removal and Installation"

.

9. Remove A/T fluid cooler tubes from A/T assembly.

10. Support A/T assembly with a transmission jack. CAUTION:

When setting the transmission jack, be careful not to allow it to collide against the drain plug.

11. Remove dust cover from converter housing.

12. Turn crankshaft to access and remove the four bolts for drive plate and torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of the engine.

13. Remove air breather hose. Refer to TM-197, "2WD : Removal

and Installation".

14. Disconnect A/T assembly harness connector.

15. Plug any openings such as the A/T fluid indicator pipe hole.

16. Remove the A/T assembly to engine bolts using power tool.

17. Remove A/T assembly from vehicle using transmission jack. CAUTION:

Secure torque converter to prevent it from dropping.

Secure A/T assembly to a transmission jack.

INSPECTION

Installation and Inspection of Torque Converter

After inserting a torque converter to a transmission, be sure to check distance A to ensure it is within specifications.

INSTALLATION

Installation is in the reverse order of removal, while paying attention to the following:

LCIA0334E

LCIA0335E

SCIA0499E

Distance A : 24.0 mm (0.94 in) or more

SAT017B

Revision: December 20092009 QX56