clock INFINITI QX56 2009 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2102 of 4171

EXL-154

< REMOVAL AND INSTALLATION >

PUDDLE LAMP

PUDDLE LAMP

Removal and InstallationINFOID:0000000005864680

REMOVAL

1. Depress tab (1) on outer edge of puddle lamp housing.

2. Lower outer edge and slide puddle lamp housing out of door mirror.

3. Twist puddle lamp socket (1) counterclockwise to remove frompuddle lamp housing (2).

INSTALLATION

Installation is in the reverse order of removal.

Bulb ReplacementINFOID:0000000005864681

REMOVAL

1. Remove puddle lamp housing. Refer to EXL-154, "Removal and Installation".

2. Pull puddle lamp bulb (2) straight out from puddle lamp socket (1) to remove.

INSTALLATION

Installation is in the reverse order of removal.

LKIA0671E

LKIA0672E

LKIA0673E

Revision: December 20092009 QX56

Page 2103 of 4171

LICENSE PLATE LAMPEXL-155

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

LICENSE PLATE LAMP

Bulb ReplacementINFOID:0000000003776230

LICENSE PLATE LAMP

Removal

1. Remove back door lower finisher. Refer to EXT-24, "Removal and Installation".

2. Turn bulb socket counterclockwise to remove it.

3. Pull bulb from socket.

Installation

Installation is in the reverse order of removal.

Removal and InstallationINFOID:0000000003776231

LICENSE PLATE LAMP

Removal

1. Remove back door lower finisher. Refer to INT-21, "Removal and Installation".

2. Remove license plate lamp screws.

3. Remove license plate lamp.

Installation

Installation is in the reverse order of removal.

Revision: December 20092009 QX56

Page 2105 of 4171

REAR COMBINATION LAMPEXL-157

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

REAR COMBINATION LAMP

Bulb ReplacementINFOID:0000000003776234

REMOVAL

1. Remove rear combination lamp bolts.

2. Pull rear combination lamp to remove.

3. Turn bulb socket counterclockwise and unlock it.

4. Remove bulb.

INSTALLATION

Installation is in the reverse order of removal.

Removal and InstallationINFOID:0000000003776235

REMOVAL

1. Remove rear combination lamp bolts.

2. Pull rear combination lamp to remove.

3. Disconnect rear combination lamp connector.

INSTALLATION

Installation is in the reverse order of removal.

WKIA1393E

WKIA1393E

Revision: December 20092009 QX56

Page 2111 of 4171

SQUEAK AND RATTLE TROUBLE DIAGNOSESEXT-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

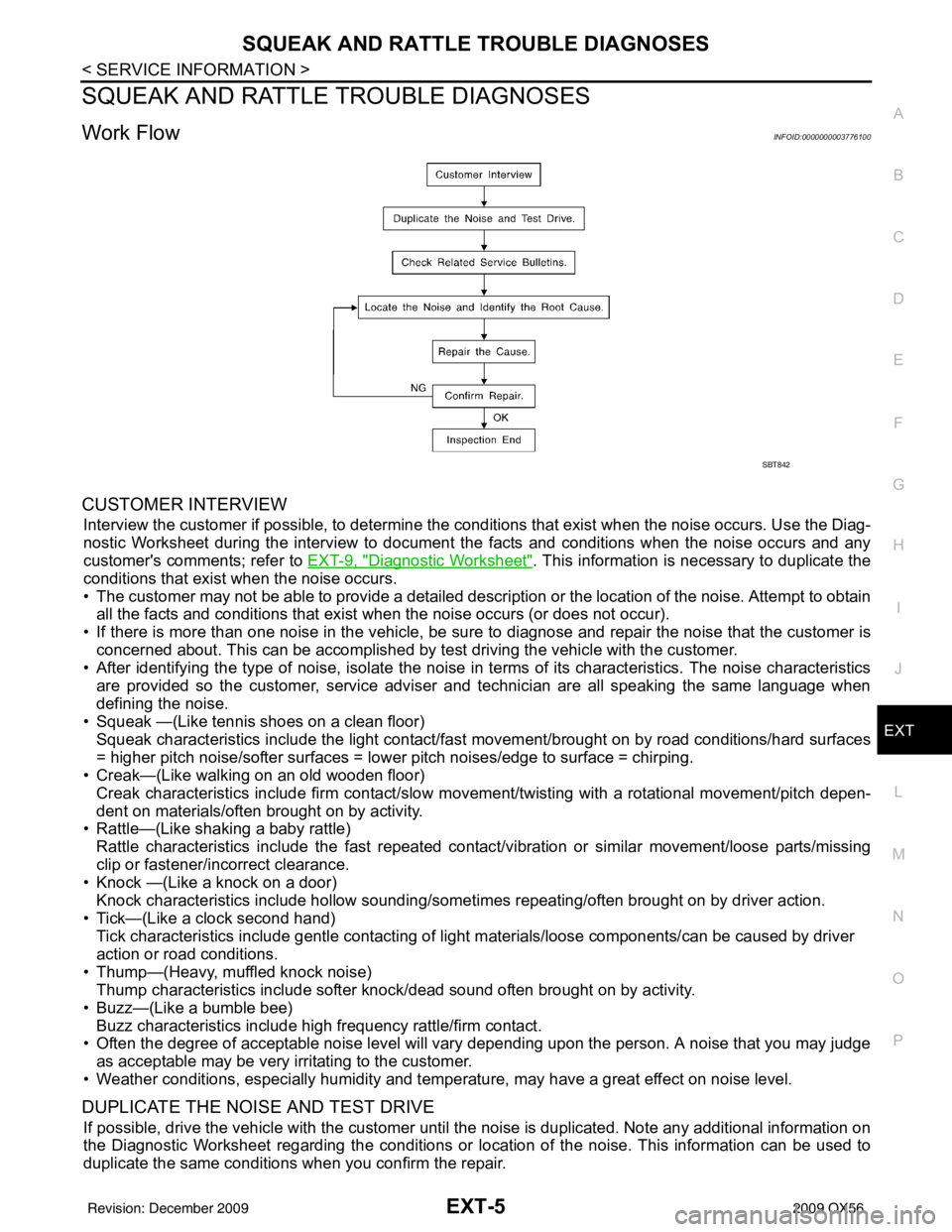

Work FlowINFOID:0000000003776100

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer's comments; refer to EXT-9, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed descr iption or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

Revision: December 20092009 QX56

Page 2161 of 4171

FL-8

< REMOVAL AND INSTALLATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

9. Remove the inspection hole cover by turning the retainers 90 °

degrees clockwise.

• Remove the O-ring.

10. Disconnect the fuel level sensor, fuel filter, and fuel pump assembly electrical connector, the EVAP hose, and the fuel feed

hose.

Disconnect the quick connector as follows:

• Hold the sides of the connector, push in tabs and pull out the

tube.

• If the connector and the tube are stuck together, push and pull several times until they start to move. Then disconnect them

by pulling.

CAUTION:

LBIA0382E

LBIA0383E

SFE562A

Revision: December 20092009 QX56

Page 2166 of 4171

FUEL TANKFL-13

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

13. Remove the inspection hole cover by turning the retainers 90

°

degrees clockwise.

• Remove the O-ring.

14. Disconnect the fuel level sensor, fuel filter, and fuel pump assembly electrical connector, the EVAP hose, and the fuel feed

hose.

Disconnect the quick connector as follows:

• Hold the sides of the connector, push in tabs and pull out the

tube.

• If the connector and the tube are stuck together, push and pull several times until they start to move. Then disconnect them

by pulling.

CAUTION:

LBIA0382E

LBIA0383E

SFE562A

Revision: December 20092009 QX56

Page 2244 of 4171

GW-2

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

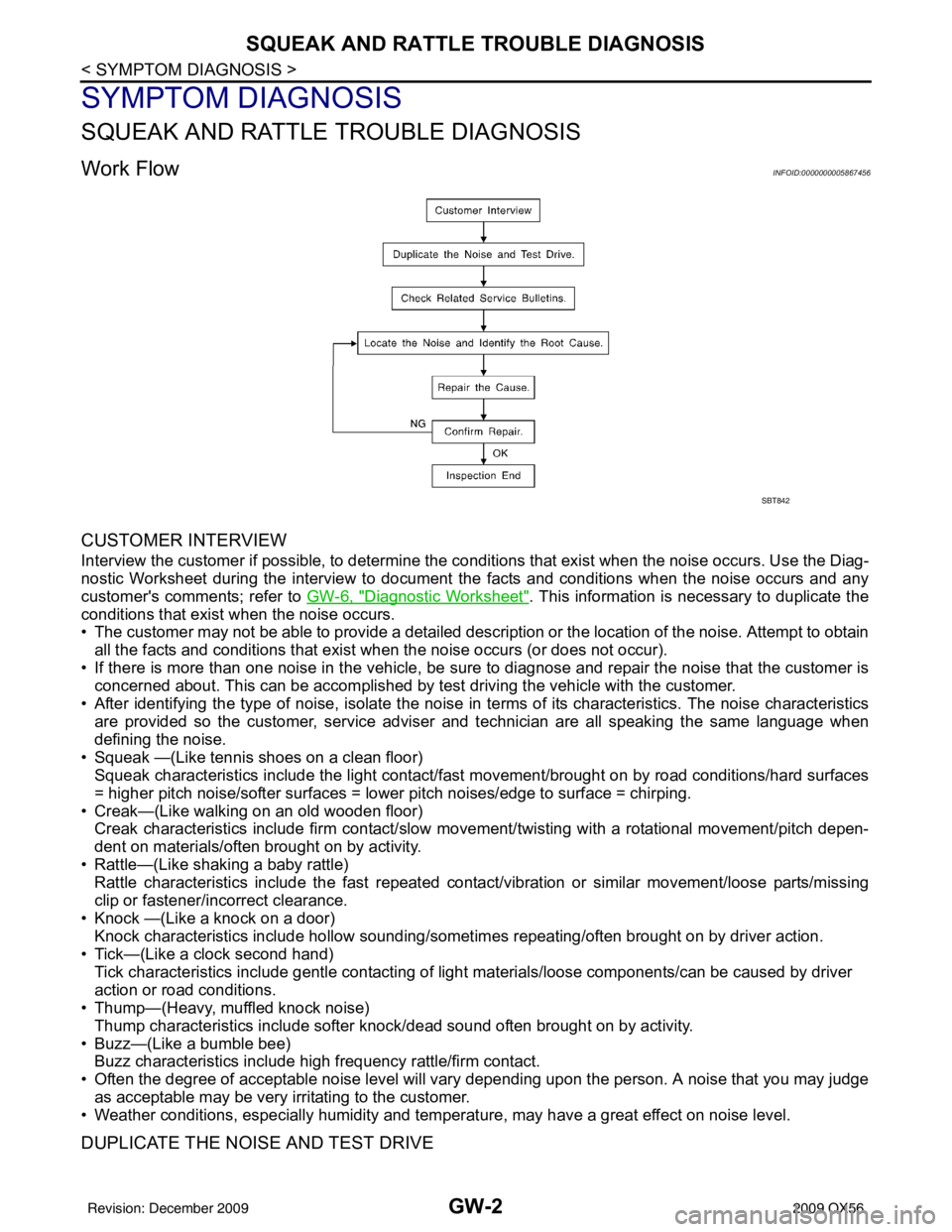

Work FlowINFOID:0000000005867456

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to GW-6, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist w hen the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor) Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor) Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle) Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door) Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

• Tick—(Like a clock second hand) Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer k nock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee) Buzz characteristics include hi gh frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: December 20092009 QX56

Page 2259 of 4171

FRONT DOOR GLASS AND REGULATORGW-17

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

• Removal and installation of the power window motor from the regulator.

• Installation of a new glass window.

• Installation of a new glass run.

Check the label on the power window motor for the part number. If the power window motor part number

matches one of the following, the limit switch must be reset using the “INSTALLATION WITHOUT RESET

SWITCH” procedure.

• 80730-ZT01A

• 80731-ZT01A

• 80730-ZM70B

• 80731-ZM70B

If the power window motor part number does not match one of the part numbers above, the limit switch must

be reset using the “INSTALLATION WITH RESET SWITCH” procedure.

NOTE:

Some of the power window motors with the part num bers above may appear to have a reset switch, but it will

not reset the limit switch.

INSTALLATION WITHOUT RESET SWITCH - (Motors listed above)

Check the label on the power window motor for the pa rt number. If the power window motor part number does

not match one of the above, use the “INSTALLATION WITH RESET SWITCH” procedure.

NOTE:

Some of the power window motors may appear to have a re set switch, but it will not reset the limit switch.

1. Connect the door harness connector to the power window motor, and rotate the motor more than 5 turns

in the glass raising (up) direction.

2. Install the power window motor onto the regulator.

3. Install the regulator assembly into the door and secure regulator assembly with the nuts and bolt.

4. Install the glass into the door and align with the regulator, then install the glass bolts.

5. Raise the glass to the top position. CAUTION:

Do not operate the glass automatical ly to raise the glass to the top.

6. Reposition the vapor barrier.

7. Install the front door finisher panel. Refer to INT-11, "

Removal and Installation".

INSTALLATION WITH RESET SWITCH - (Motors not listed above)

1. Install the power window motor onto the regulator.

2. Install the regulator assembly into the door and secure regulator assembly with the nuts and bolt.

3. Connect the door harness connector to the power window motor.

4. Install the glass into the door and align with the regulator, then install the glass bolts.

Power Window Motor Up Direction

• LH motor rotate counterclockwise

• RH motor rotate clockwise

Regulator assembly nuts

and bolt : 7.5 N·m (0.77 kg-m, 66 in-lb)

Glass bolts : 6.1 N·m (0.62 kg-m, 54 in-lb)

Regulator assembly nuts

and bolt : 7.5 N·m (0.77 kg-m, 66 in-lb)

Glass bolts : 6.1 N·m (0.62 kg-m, 54 in-lb)

Revision: December 20092009 QX56

Page 2276 of 4171

HA-12

< PRECAUTION >

PRECAUTIONS

Never attempt to connect HFC-134a (R-134a) service couplers to a

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. If an improper

connection is attempted, discharging and contamination may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC134a (R-134a) and specified

oils have been used with the scale. If the scale controls refrigerant

flow electronically, the hose fitting must be 1/2”-16 ACME.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder's top valve

when filling the cylinder with refrigerant. Also, the accu racy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Shut-off valve rotati on A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Revision: December 20092009 QX56

Page 2313 of 4171

SERVICE DATA AND SPECIFICATIONS (SDS)

HA-49

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

J

K L

M A

B

HA

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Service Data and Specification (SDS)INFOID:0000000003775323

COMPRESSOR

OIL

REFRIGERANT

Make ZEXEL VALEO CLIMATE CONTROL

Model DKS-17D

Typ e Swash plate

Displacement 175.5 cm

3 (10.7 in3 ) / revolution

Cylinder bore × stroke 30.5 mm (1.20 in) x 24.0 mm (0.94 in)

Direction of rotation Clockwise (viewed from drive end)

Drive belt Poly V

Name NISSAN A/C System Oil Type S

Capacity 290 m (9.8 US fl oz, 10.2 Imp fl oz)

Typ eHFC 134a (R-134a)

Capacity 1.08 ± 0.05 kg (2.38 ± 0.11 lb)

Revision: December 20092009 QX56