INFINITI QX56 2009 Factory Workshop Manual

Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 51 of 4171

B2117 ADJ PEDAL MOTORADP-37

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

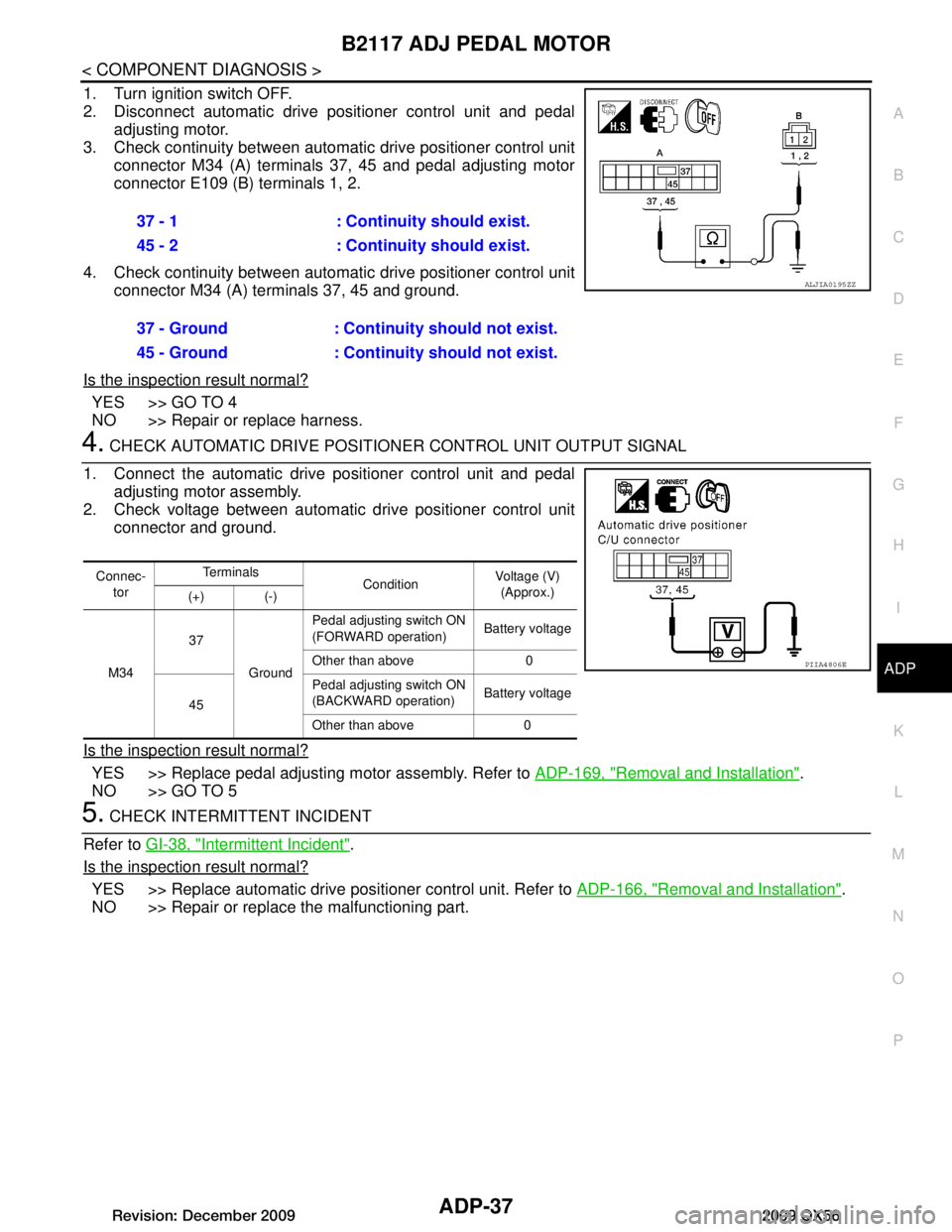

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit and pedal adjusting motor.

3. Check continuity between automat ic drive positioner control unit

connector M34 (A) terminals 37, 45 and pedal adjusting motor

connector E109 (B) terminals 1, 2.

4. Check continuity between automat ic drive positioner control unit

connector M34 (A) terminals 37, 45 and ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair or replace harness.

4. CHECK AUTOMATIC DRIVE POSITION ER CONTROL UNIT OUTPUT SIGNAL

1. Connect the automatic drive positioner control unit and pedal adjusting motor assembly.

2. Check voltage between automatic drive positioner control unit

connector and ground.

Is the inspection result normal?

YES >> Replace pedal adjusting motor assembly. Refer to ADP-169, "Removal and Installation".

NO >> GO TO 5

5. CHECK INTERMITTENT INCIDENT

Refer to GI-38, "Intermittent Incident"

.

Is the inspection result normal?

YES >> Replace automatic drive posit ioner control unit. Refer to ADP-166, "Removal and Installation".

NO >> Repair or replace the malfunctioning part. 37 - 1 : Continuity should exist.

45 - 2 : Continuity should exist.

37 - Ground : Continuity should not exist.

45 - Ground : Continuity should not exist.

ALJIA0195ZZ

Connec-

tor Te r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

M34 37

Ground Pedal adjusting switch ON

(FORWARD operation)

Battery voltage

Other than above 0

45 Pedal adjusting switch ON

(BACKWARD operation)

Battery voltage

Other than above 0

PIIA4806E

Revision: December 20092009 QX56

Page 52 of 4171

ADP-38

< COMPONENT DIAGNOSIS >

B2118 TILT SENSOR

B2118 TILT SENSOR

DescriptionINFOID:0000000003775535

The tilt sensor is installed to the steering column assembly.

The resistance of tilt sensor is changed according to the up/down position of steering column.

The terminal voltage of automatic drive positioner c ontrol unit will be changed according to a change of tilt

sensor resistance. Automatic drive positioner contro l unit calculates the tilt position from the voltage.

DTC LogicINFOID:0000000003775536

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. STEP 1

Turn ignition switch ON.

>> GO TO 2

2. STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-38, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000003775537

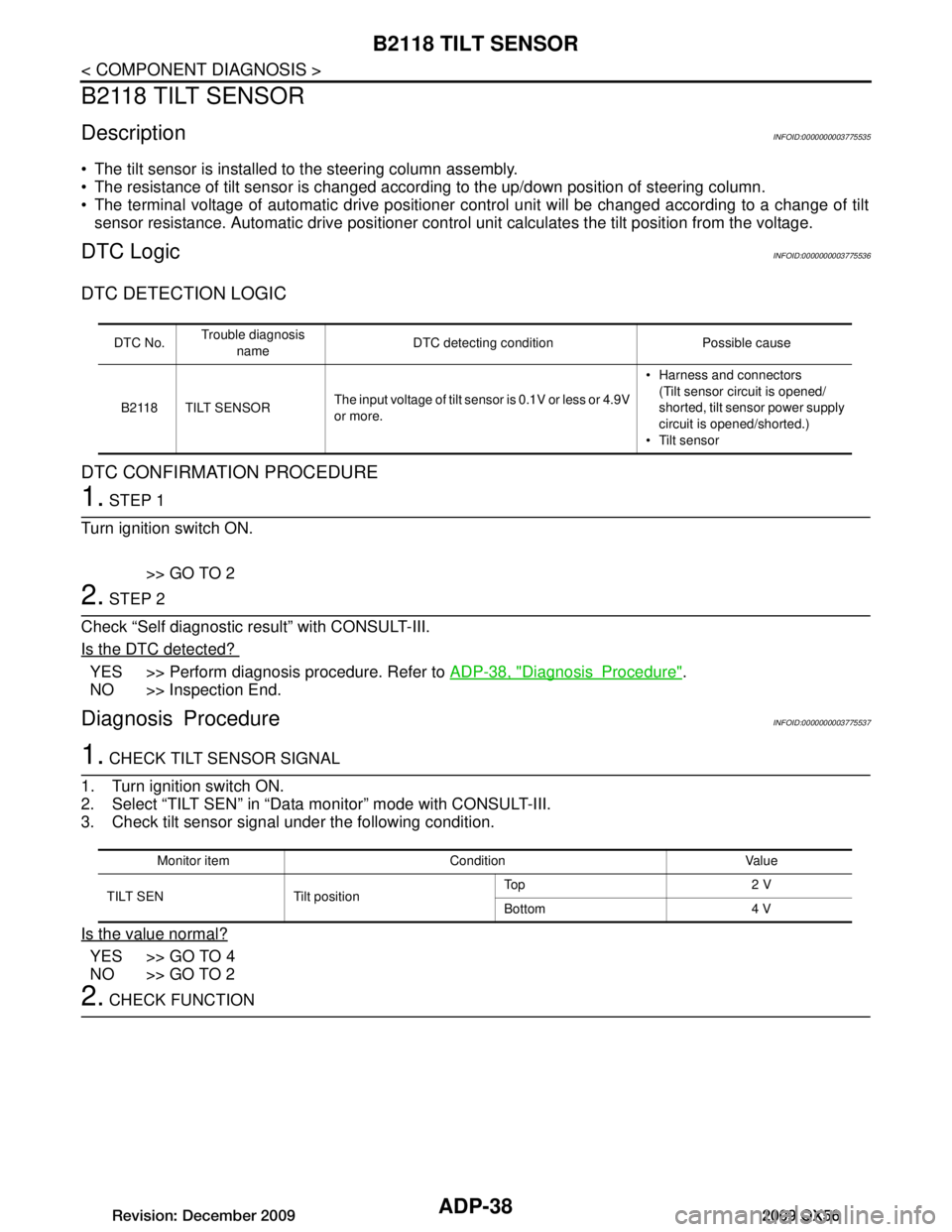

1. CHECK TILT SENSOR SIGNAL

1. Turn ignition switch ON.

2. Select “TILT SEN” in “Data m onitor” mode with CONSULT-III.

3. Check tilt sensor signal under the following condition.

Is the value normal?

YES >> GO TO 4

NO >> GO TO 2

2. CHECK FUNCTION

DTC No. Trouble diagnosis

name DTC detecting condition Possible cause

B2118 TILT SENSOR The input voltage of tilt sensor is 0.1V or less or 4.9V

or more. Harness and connectors

(Tilt sensor circuit is opened/

shorted, tilt sensor power supply

circuit is opened/shorted.)

Tilt sensor

Monitor item Condition Value

TILT SEN Tilt position To p 2 V

Bottom 4 V

Revision: December 20092009 QX56

Page 53 of 4171

B2118 TILT SENSORADP-39

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

1. Turn ignition switch OFF.

2. Check voltage between automatic drive positioner connector

and ground.

Is the inspection result normal?

YES >> Tilt sensor circuit is OK.

NO >> GO TO 3

3. CHECK HARNESS CONTINUITY

1. Disconnect automatic drive positi oner control unit and tilt motor

assembly.

2. Check continuity between autom atic drive positioner connector

M33 (A), M34 (B) terminals 7, 33, 41 and tilt motor assembly

connector M85 (C) terminals 2, 3, 4.

3. Check continuity between automat ic drive positioner control unit

connectors M33 (A), M34 (B ) terminals 7, 33, 41 and ground.

Is the inspection result normal?

YES >> Replace tilt motor assembly. Refer to ST-19, "Removal

and Installation".

NO >> Repair or replace harness.

4. CHECK DOOR MIRROR OPERATION

1. Connect automatic drive positioner c ontrol unit and tilt motor assembly.

2. Turn ignition switch ON.

3. Check door mirror operation with memory function.

Is the operation normal?

YES >> Replace tilt motor assembly. Refer to ST-19, "Removal and Installation".

NO >> GO TO 5

5. CHECK INTERMITTENT INCIDENT

Refer to GI-38, "Intermittent Incident"

.

Is the inspection result normal?

YES >> Replace automatic drive posit ioner control unit. Refer to ADP-166, "Removal and Installation".

NO >> Repair or replace the malfunctioning part.

Connector Te r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

M33 7 Ground Tilt top position 2

Tilt bottom position 4

LIIA0485E

7 - 3 : Continuity should exist.

33 - 2 : Continuity should exist.

41 - 4 : Continuity should exist.

7 - Ground : Continuity should not exist.

33 - Ground : Continuity should not exist.

41 - Ground : Continuity should not exist.

ALJIA0291ZZ

Revision: December 20092009 QX56

Page 54 of 4171

ADP-40

< COMPONENT DIAGNOSIS >

B2120 ADJ PEDAL SENSOR

B2120 ADJ PEDAL SENSOR

DescriptionINFOID:0000000003775538

The pedal adjusting sensor is installed in the pedal assembly.

The resistance of pedal adjusting sensor is changed according to the forward/backward position of pedalassembly.

The terminal voltage of automatic drive positioner control unit will be changed according to a change of

pedal adjusting sensor resistance. Automatic drive pos itioner control unit calculates the pedal assembly

position from the voltage.

DTC LogicINFOID:0000000003775539

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. STEP 1

Turn ignition switch ON.

>> GO TO 2

2. STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC is detected?

YES >> Perform diagnosis procedure. Refer to ADP-40, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000003775540

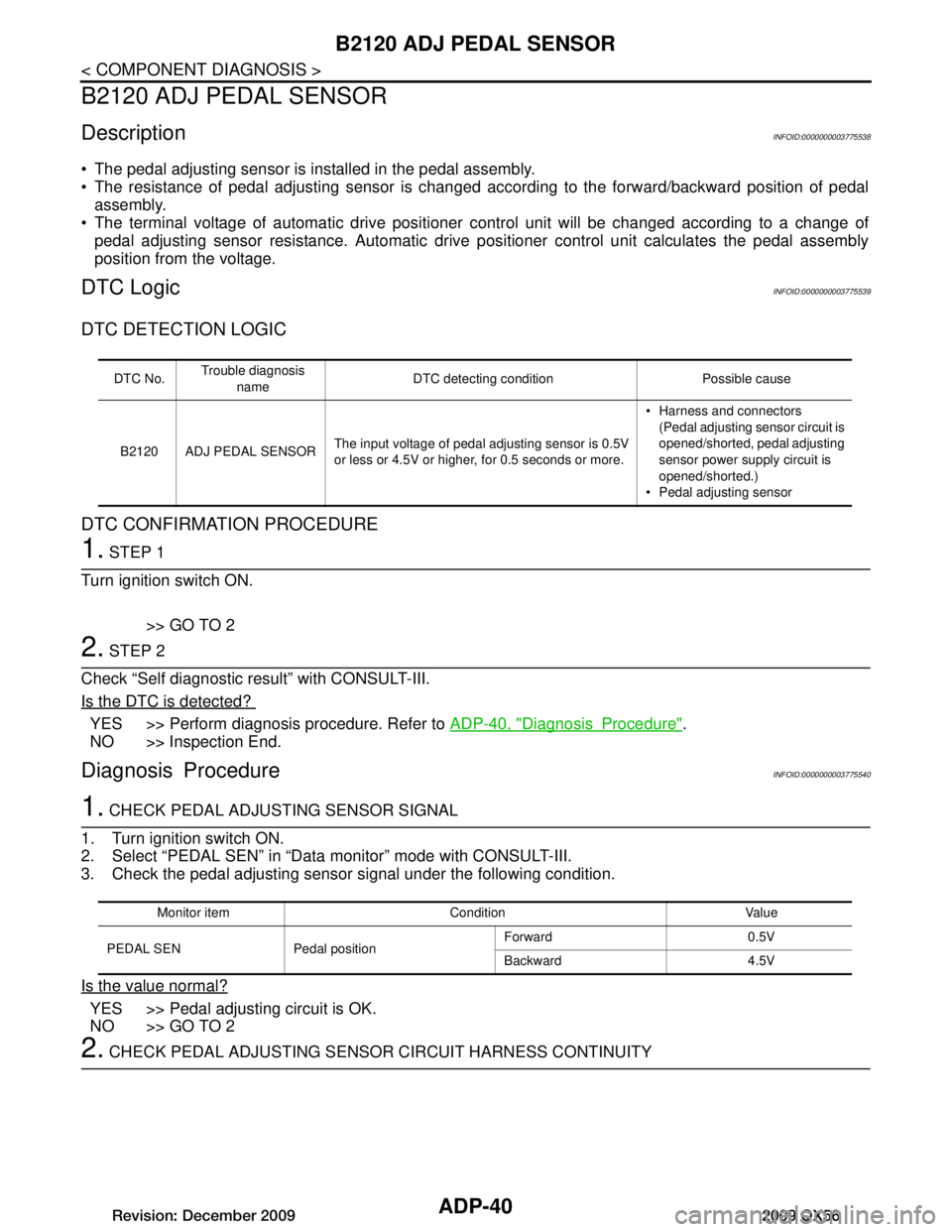

1. CHECK PEDAL ADJUSTING SENSOR SIGNAL

1. Turn ignition switch ON.

2. Select “PEDAL SEN” in “Dat a monitor” mode with CONSULT-III.

3. Check the pedal adjusting sensor signal under the following condition.

Is the value normal?

YES >> Pedal adjusting circuit is OK.

NO >> GO TO 2

2. CHECK PEDAL ADJUSTING SENSO R CIRCUIT HARNESS CONTINUITY

DTC No.Trouble diagnosis

name DTC detecting condition Possible cause

B2120 ADJ PEDAL SENSOR The input voltage of pedal adjusting sensor is 0.5V

or less or 4.5V or higher, for 0.5 seconds or more. Harness and connectors

(Pedal adjusting sensor circuit is

opened/shorted, pedal adjusting

sensor power supply circuit is

opened/shorted.)

Pedal adjusting sensor

Monitor item Condition Value

PEDAL SEN Pedal position Forward 0.5V

Backward 4.5V

Revision: December 20092009 QX56

Page 55 of 4171

B2120 ADJ PEDAL SENSORADP-41

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

1. Disconnect automatic drive positioner control unit and pedal adjusting motor assembly.

2. Check continuity between autom atic drive positioner connector

M33 (A), M34 (C) terminals 8, 33, 41 and pedal adjusting motor

assembly connector E110 (B) terminals 3, 4, 5.

3. Check continuity between automat ic drive positioner control unit

connector M33 (A), M34 (C) terminals 8, 33, 41 and ground.

Is the inspection result normal?

YES >> Replace pedal adjusting motor assembly. Refer to ADP-

169, "Removal and Installation".

NO >> Repair or replace harness. 8 - 4 : Continuity should exist.

33 - 3 : Continuity should exist.

41 - 5 : Continuity should exist.

8 - Ground : Continuity should not exist.

33 - Ground : Continuity should not exist.

41 - Ground : Continuity should not exist.

ALJIA0327ZZ

Revision: December 20092009 QX56

Page 56 of 4171

ADP-42

< COMPONENT DIAGNOSIS >

B2126 DETENT SW

B2126 DETENT SW

DescriptionINFOID:0000000003775541

Park position switch is installed on A/T shift selector. It is turned OFF when the A/T selector lever is in P

position.

The driver seat control unit judges that the A/T selector le ver is in P position if continuity does not exist in this

circuit.

DTC LogicINFOID:0000000003775542

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. STEP 1

Drive the vehicle at 7 ±4km/h or more.

>> GO TO 2

2. STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-42, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000003775543

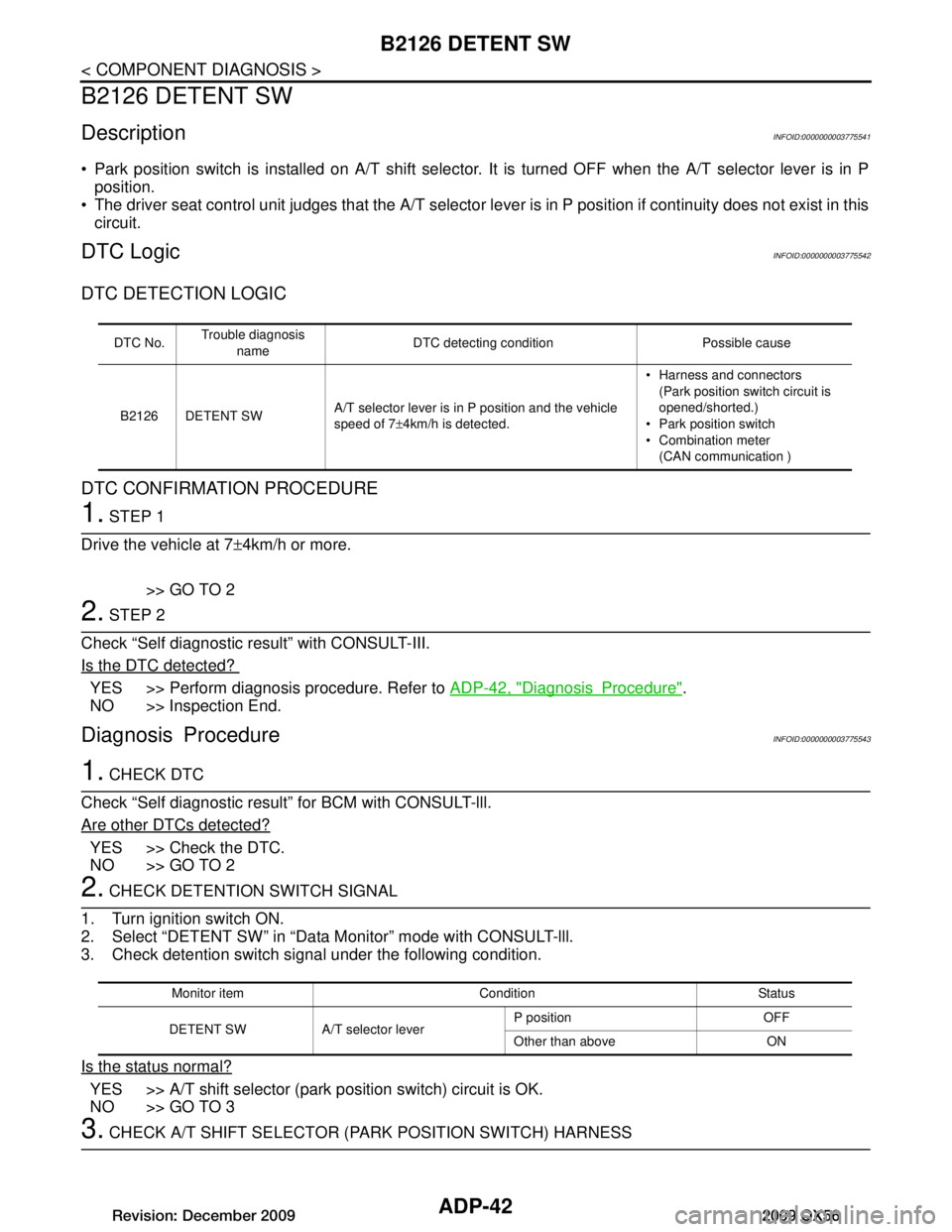

1. CHECK DTC

Check “Self diagnostic result” for BCM with CONSULT-lll.

Are other DTCs detected?

YES >> Check the DTC.

NO >> GO TO 2

2. CHECK DETENTION SWITCH SIGNAL

1. Turn ignition switch ON.

2. Select “DETENT SW” in “Data Monitor” mode with CONSULT-lll.

3. Check detention switch signal under the following condition.

Is the status normal?

YES >> A/T shift selector (park position switch) circuit is OK.

NO >> GO TO 3

3. CHECK A/T SHIFT SELECTOR (PARK POSITION SWITCH) HARNESS

DTC No. Trouble diagnosis

name DTC detecting condition Possible cause

B2126 DETENT SW A/T selector lever is in P position and the vehicle

speed of 7

±4km/h is detected. Harness and connectors

(Park position switch circuit is

opened/shorted.)

Park position switch

Combination meter (CAN communication )

Monitor item Condition Status

DETENT SW A/T selector lever P position OFF

Other than above ON

Revision: December 20092009 QX56

Page 57 of 4171

B2126 DETENT SWADP-43

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

1. Turn ignition switch OFF.

2. Disconnect A/T shift selector and driver seat control unit.

3. Check continuity between A/T shift selector connector M203 (B)

terminal 6 and driver seat control unit connector B203 (A) termi-

nal 21.

4. Check continuity between A/T shift selector connector M203 (B) terminal 6 and ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair or replace harness.

4. CHECK PARK POSITION SWITCH

Check continuity between A/T shift selector (park position switch)

terminals as follows.

Is the inspection result normal?

YES >> GO TO 5

NO >> Replace A/T shift selector. Refer to TM-196, "A/T Shift

Selector Removal and Installation".

5. CHECK INTERMITTENT INCIDENT

Refer to GI-38, "Intermittent Incident"

.

Is the inspection result normal?

YES >> Replace driver seat control unit. Refer to ADP-165, "Removal and Installation".

NO >> Repair or replace the malfunctioning part. 6 - 21 : Continuity should exist.

6 - Ground : Continuity should not exist.

ALJIA0194ZZ

Terminals Condition Continuity

56 P position Yes

Other than P position No

ALJIA0486ZZ

Revision: December 20092009 QX56

Page 58 of 4171

ADP-44

< COMPONENT DIAGNOSIS >

B2128 UART COMMUNICATION LINE

B2128 UART COMMUNICATION LINE

DescriptionINFOID:0000000003775544

Driver seat control unit performs UART communication with the automatic drive positioner control unit using 2

communication lines, TX and RX line. Driver seat cont rol unit receives the operation signals of pedal adjusting

switch, door mirror remote control switch, set switch and memory switch and the position signals of adjustable

pedal sensor and door mirror sensor from the automatic drive positioner control unit and transmits the opera-

tion request signal.

DTC LogicINFOID:0000000003775545

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. STEP 1

Turn ignition switch ON.

>> GO TO 2

2. STEP 2

Operate pedal adjusting switch for more than 2 seconds.

>> GO TO 3

3. PROCEDURE 3

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-44, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000003775546

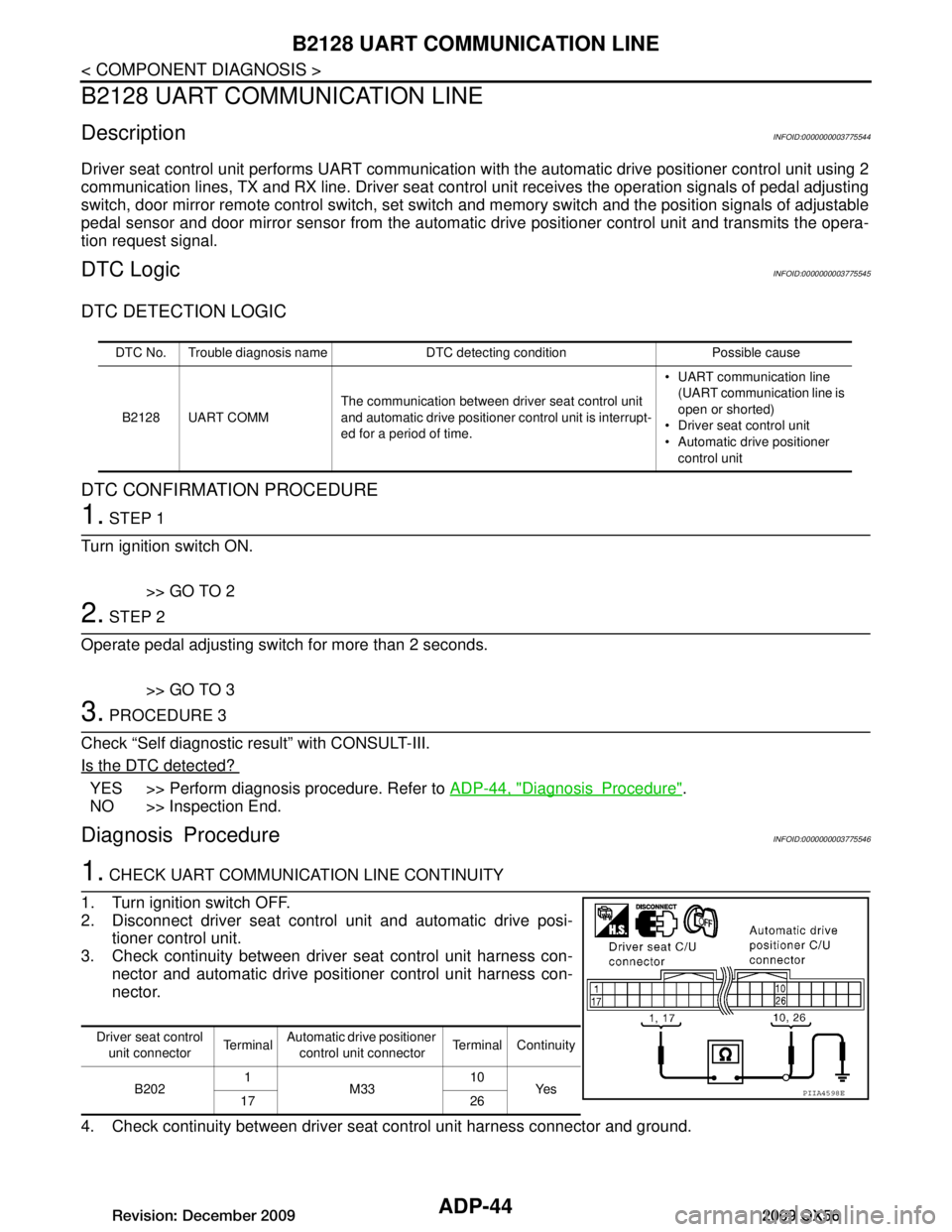

1. CHECK UART COMMUNICA TION LINE CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect driver seat contro l unit and automatic drive posi-

tioner control unit.

3. Check continuity between driver seat control unit harness con- nector and automatic drive positi oner control unit harness con-

nector.

4. Check continuity between driver seat control unit harness connector and ground.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause B2128 UART COMM The communication between driver seat control unit

and automatic drive positioner control unit is interrupt-

ed for a period of time. UART communication line

(UART communication line is

open or shorted)

Driver seat control unit

Automatic drive positioner control unit

Driver seat control unit connector Te r m i n a lAutomatic drive positioner

control unit connector Terminal Continuity

B202 1

M33 10

Ye s

17 26

PIIA4598E

Revision: December 20092009 QX56

Page 59 of 4171

B2128 UART COMMUNICATION LINEADP-45

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-38, "Intermittent Incident".

NO >> Repair or replace harness.

Driver seat control unit con-

nector Te r m i n a l

GroundContinuity

B202 1

No

17

Revision: December 20092009 QX56

Page 60 of 4171

ADP-46

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000004055989

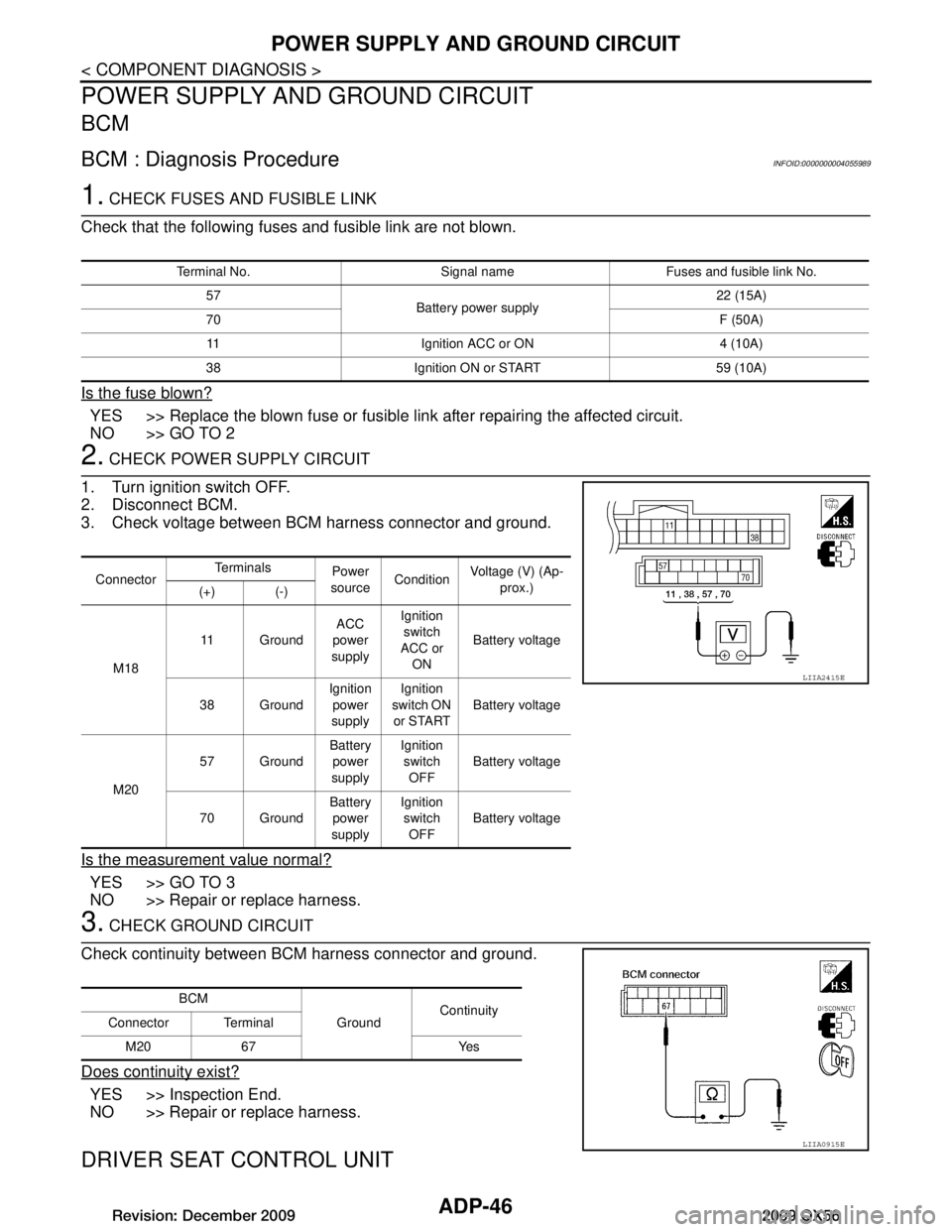

1. CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> Inspection End.

NO >> Repair or replace harness.

DRIVER SEAT CONTROL UNIT

Terminal No. Signal name Fuses and fusible link No.

57 Battery power supply 22 (15A)

70 F (50A)

11 Ignition ACC or ON 4 (10A)

38 Ignition ON or START 59 (10A)

Connector Te r m i n a l s

Power

source Condition

Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch

OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch OFF Battery voltage

LIIA2415E

BCM

GroundContinuity

Connector Terminal

M20 67 Yes

LIIA0915E

Revision: December 20092009 QX56