engine oil capacity INFINITI QX56 2010 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2726 of 4210

MA-22

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE

8. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to the specification.Use Genuine RTV Silicone Seal ant or equivalent. Refer to GI-15, "

Recommended Chemical Prod-

ucts and Sealants".

c. After warming up engine, make sure there is no leakage of engine oil with engine running.

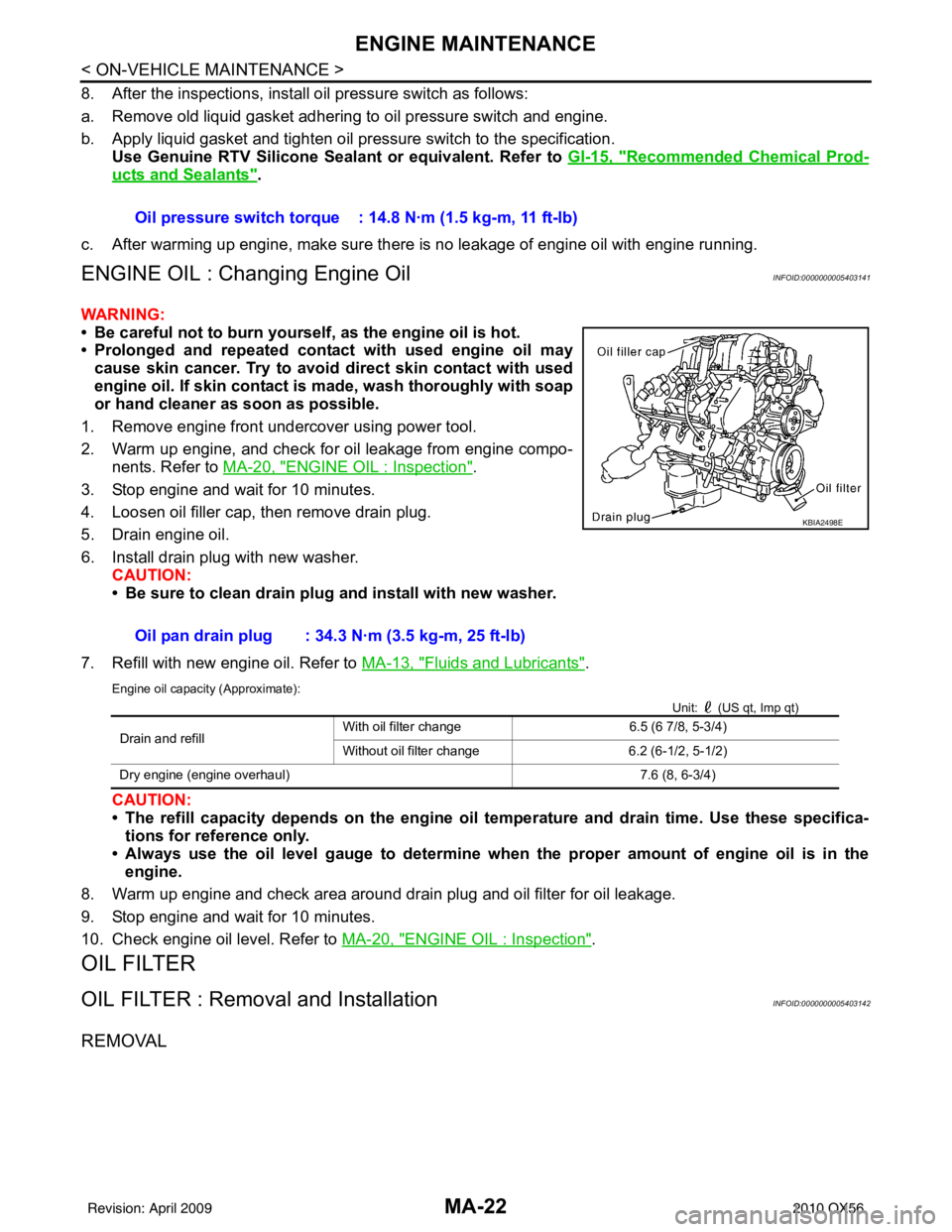

ENGINE OIL : Changing Engine OilINFOID:0000000005403141

WARNING:

• Be careful not to burn yoursel f, as the engine oil is hot.

• Prolonged and repeated contact with used engine oil may

cause skin cancer. Try to avoid di rect skin contact with used

engine oil. If skin contact is made, wash thoroughly with soap

or hand cleaner as soon as possible.

1. Remove engine front undercover using power tool.

2. Warm up engine, and check for oil leakage from engine compo- nents. Refer to MA-20, "

ENGINE OIL : Inspection".

3. Stop engine and wait for 10 minutes.

4. Loosen oil filler cap, then remove drain plug.

5. Drain engine oil.

6. Install drain plug with new washer. CAUTION:

• Be sure to clean drain plug and install with new washer.

7. Refill with new engine oil. Refer to MA-13, "

Fluids and Lubricants".

Engine oil capacity (Approximate):

Unit: (US qt, Imp qt)

CAUTION:

• The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

• Always use the oil level gauge to determine when the proper amount of engine oil is in the engine.

8. Warm up engine and check area around drain plug and oil filter for oil leakage.

9. Stop engine and wait for 10 minutes.

10. Check engine oil level. Refer to MA-20, "

ENGINE OIL : Inspection".

OIL FILTER

OIL FILTER : Removal and InstallationINFOID:0000000005403142

REMOVAL

Oil pressure switch torque : 14.8 N·m (1.5 kg-m, 11 ft-lb)

Oil pan drain plug : 34.3 N·m (3.5 kg-m, 25 ft-lb)

KBIA2498E

Drain and refill With oil filter change

6.5 (6 7/8, 5-3/4)

Without oil filter change 6.2 (6-1/2, 5-1/2)

Dry engine (engine overhaul) 7.6 (8, 6-3/4)

Revision: April 20092010 QX56

Page 2733 of 4210

CHASSIS AND BODY MAINTENANCEMA-29

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

A/T FLUID : Changing the A/T Fluid (ATF)INFOID:0000000005403152

CAUTION:

If using the vehicle for towing, the A/T fluid must be replaced as specified. Refer to

MA-9, "

Introduc-

tion of Periodic Maintenance".

1. Drive the vehicle to warm up the A/T fluid to approximately 80 ° C (176 ° F).

2. Stop the engine.

3. Remove the A/T fluid level gauge.

4. Drain the A/T fluid from the drain plug hole, then install the drain plug with a new gasket. Refill the transmission with new A/T

fluid. Always refill with the same volume as the drained A/T fluid.

Use the A/T fluid level gauge to check the A/T fluid level as

shown. Add A/T fluid as necessary.

• To flush out the old A/T fluid from the transmission o il coolers, pour new A/T fluid into the A/T fluid charg-

ing pipe with the engine idling and at the same time drain the old A/T fluid from the auxiliary transmis-

sion oil cooler hose return line.

• When the color of the A/T fluid coming out of the aux iliary transmission oil cooler hose return line is

about the same as the color of the new A/T fluid, flushing out the old A/T fluid is complete. The amount

of new A/T fluid used for flushing should be 30% to 50% increase of the specified capacity.

CAUTION:

• If Genuine NISSAN Matic S ATF is not available, Genuine NISSAN Matic J ATF may also be used.

• Using ATF fluid other than Genuine NISSAN Matic S ATF or Matic J ATF will cause deterioration

in driveability and A/T durability, and may damage the A/T, which is not covered by the warranty.

• When filling the transmission with A/T fluid, do not spill the A/T fluid on any heat generating

parts such as the exhaust parts.

• Do not reuse the drain plug gasket.

5. Install the A/T fluid level gauge and tighten t he A/T fluid level gauge bolt to specification.

6. Drive the vehicle to warm up the A/T fluid to approximately 80 ° C (176 ° F).

7. Check the fluid level and condition. If the A/T fluid is still dirty, repeat steps 2 through 6.

8. Install the A/T fluid level gauge in the A/T fluid charging pipe and install the A/T fluid level gauge bolt.

9. Tighten the A/T fluid level gauge bolt to specification. Drain plug : Refer to

TM-192, "

Component".

LLIA0071E

A/T fluid grade and capacity : Refer to MA-13, "Fluids and Lubricants".

A/T fluid level

gauge bolt : Refer to

TM-186, "

Removal and Installation (2WD)" or TM-188, "Removal and

Installation (4WD)".

LLIA0071E

Revision: April 20092010 QX56

Page 2735 of 4210

CHASSIS AND BODY MAINTENANCEMA-31

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

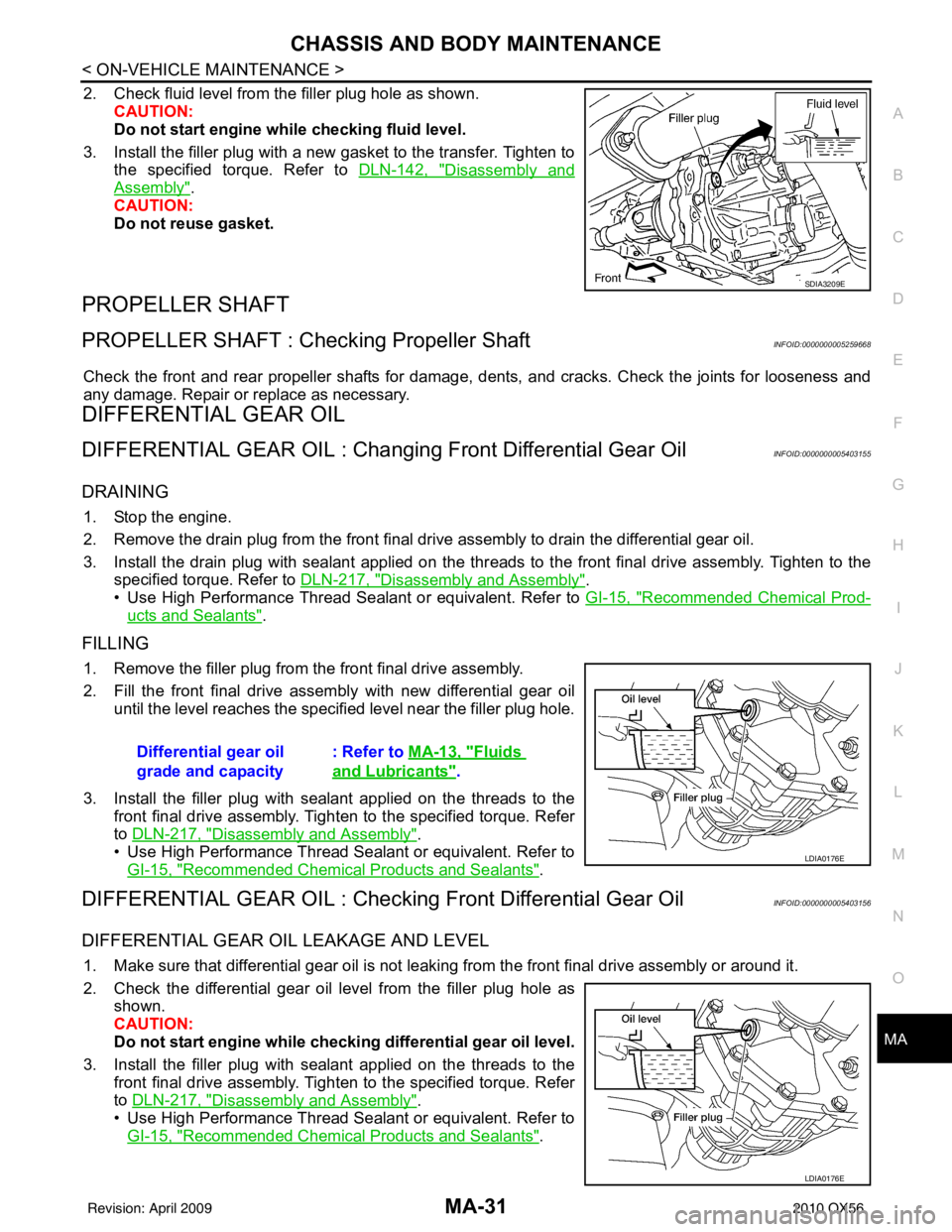

2. Check fluid level from the filler plug hole as shown.

CAUTION:

Do not start engine while checking fluid level.

3. Install the filler plug with a new gasket to the transfer. Tighten to the specified torque. Refer to DLN-142, "

Disassembly and

Assembly".

CAUTION:

Do not reuse gasket.

PROPELLER SHAFT

PROPELLER SHAFT : Checking Propeller ShaftINFOID:0000000005259668

Check the front and rear propeller shafts for damage, dents, and cracks. Check the joints for looseness and

any damage. Repair or replace as necessary.

DIFFERENTIAL GEAR OIL

DIFFERENTIAL GEAR OIL : Changing Front Differential Gear OilINFOID:0000000005403155

DRAINING

1. Stop the engine.

2. Remove the drain plug from the front final drive assembly to drain the differential gear oil.

3. Install the drain plug with sealant applied on the thr eads to the front final drive assembly. Tighten to the

specified torque. Refer to DLN-217, "

Disassembly and Assembly".

• Use High Performance Thread Sealant or equivalent. Refer to GI-15, "

Recommended Chemical Prod-

ucts and Sealants".

FILLING

1. Remove the filler plug from the front final drive assembly.

2. Fill the front final drive assembly with new differential gear oil

until the level reaches the specified level near the filler plug hole.

3. Install the filler plug with sealant applied on the threads to the front final drive assembly. Tighten to the specified torque. Refer

to DLN-217, "

Disassembly and Assembly".

• Use High Performance Thread Sealant or equivalent. Refer to GI-15, "

Recommended Chemical Products and Sealants".

DIFFERENTIAL GEAR OIL : Checking Front Differential Gear OilINFOID:0000000005403156

DIFFERENTIAL GEAR OIL LEAKAGE AND LEVEL

1. Make sure that differential gear oil is not leaking from the front final drive assembly or around it.

2. Check the differential gear oil level from the filler plug hole as

shown.

CAUTION:

Do not start engine while checki ng differential gear oil level.

3. Install the filler plug with sealant applied on the threads to the front final drive assembly. Tighten to the specified torque. Refer

to DLN-217, "

Disassembly and Assembly".

• Use High Performance Thread Sealant or equivalent. Refer to GI-15, "

Recommended Chemical Products and Sealants".

SDIA3209E

Differential gear oil

grade and capacity : Refer to

MA-13, "Fluids

and Lubricants".

LDIA0176E

LDIA0176E

Revision: April 20092010 QX56

Page 2736 of 4210

MA-32

< ON-VEHICLE MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

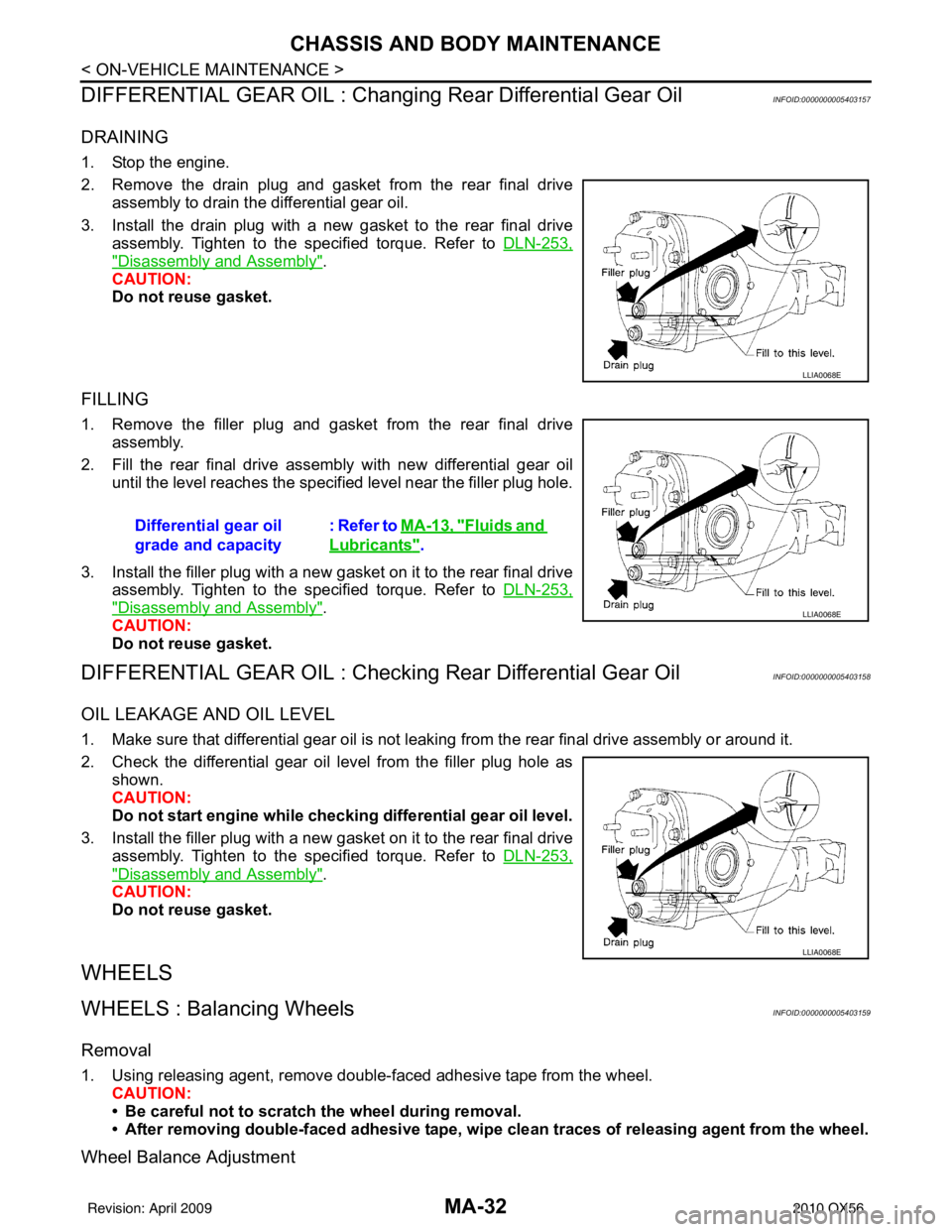

DIFFERENTIAL GEAR OIL : Changi ng Rear Differential Gear Oil

INFOID:0000000005403157

DRAINING

1. Stop the engine.

2. Remove the drain plug and gasket from the rear final drive

assembly to drain the differential gear oil.

3. Install the drain plug with a new gasket to the rear final drive assembly. Tighten to the specified torque. Refer to DLN-253,

"Disassembly and Assembly".

CAUTION:

Do not reuse gasket.

FILLING

1. Remove the filler plug and gasket from the rear final drive assembly.

2. Fill the rear final drive assembly with new differential gear oil until the level reaches the specified level near the filler plug hole.

3. Install the filler plug with a new gasket on it to the rear final drive assembly. Tighten to the specified torque. Refer to DLN-253,

"Disassembly and Assembly".

CAUTION:

Do not reuse gasket.

DIFFERENTIAL GEAR OIL : Checking Rear Differential Gear OilINFOID:0000000005403158

OIL LEAKAGE AND OIL LEVEL

1. Make sure that differential gear oil is not leaki ng from the rear final drive assembly or around it.

2. Check the differential gear oil level from the filler plug hole as shown.

CAUTION:

Do not start engine while checki ng differential gear oil level.

3. Install the filler plug with a new gasket on it to the rear final drive assembly. Tighten to the specified torque. Refer to DLN-253,

"Disassembly and Assembly".

CAUTION:

Do not reuse gasket.

WHEELS

WHEELS : Balancing WheelsINFOID:0000000005403159

Removal

1. Using releasing agent, remove double-faced adhesive tape from the wheel. CAUTION:

• Be careful not to scratch the wheel during removal.

• After removing double-faced adh esive tape, wipe clean traces of releasing agent from the wheel.

Wheel Balance Adjustment

LLIA0068E

Differential gear oil

grade and capacity: Refer to MA-13, "Fluids and

Lubricants".

LLIA0068E

LLIA0068E

Revision: April 20092010 QX56

Page 3722 of 4210

A/T CONTROL SYSTEMTM-27

< FUNCTION DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

FUNCTION OF PRESSURE SWITCH

Pilot valve A Adjusts the line pressure and produces the constant pressure (pilot pressure) required

for line pressure control, shift change control, and lock-up control.

Pilot valve B Adjusts the line pressure and produces the constant pressure (pilot pressure) required

for shift change control.

Low coast brake switching valve During engine braking, supplies the line pressure to the low coast brake reducing valve.

Low coast brake reducing valve When the low coast brake is coupled, adjusts the line pressure to the optimum pressure

(low coast brake pressure) and supplies it to the low coast brake.

N-R accumulator Produces the stabilizing pressure for when N-R is selected.

Direct clutch piston switching valve Operates in 4GR and switches the direct clutch coupling capacity.

High and low reverse clutch control valve When the high and low reverse clutch is coupled, adjusts the line pressure to the opti-

mum pressure (high and low reverse clutch pressure) and supplies it to the high and low

reverse clutch. (In 1GR, 3GR, 4GR and 5GR, adjusts the clutch pressure.)

Input clutch control valve When the input clutch is coupled, adjusts the line pressure to the optimum pressure (in-

put clutch pressure) and supplies it to the input clutch. (In 4GR and 5GR, adjusts the

clutch pressure.)

Direct clutch control valve When the direct clutch is coupled, adjusts the line pressure to the optimum pressure (di-

rect clutch pressure) and supplies it to the direct clutch. (In 2GR, 3GR, and 4GR, adjusts

the clutch pressure.)

TCC control valve

TCC control plug

TCC control sleeve Switches the lock-up to operating or released. Also, by performing the lock-up operation

transiently, lock-up smoothly.

Torque converter lubrication valve Operates during lock-up to switch the torque converter, cooling, and lubrication system

oil path.

Cool bypass valve Allows excess oil to bypass cooler circuit without being fed into it.

Line pressure relief valve Discharges excess oil from line pressure circuit.

N-D accumulator Produces the stabilizing pressure for when N-D is selected.

Manual valve Sends line pressure to each circuit according to the select position. The circuits to which

the line pressure is not sent drain.

Name

Function

Name Function

Pressure switch 2 (LC/B) Detects any malfunction in the low coast brake hydraulic pressure. When it detects any

malfunction, it puts the system into fail-safe mode.

Revision: April 20092010 QX56

Page 3845 of 4210

TM-150

< ON-VEHICLE MAINTENANCE >

A/T FLUID

Changing the A/T Fluid (ATF)

INFOID:0000000005148723

CAUTION:

If using the vehicle for towing, the A/T fl uid must be replaced as specified. Refer to MA-9, "

Introduc-

tion of Periodic Maintenance".

1. Drive the vehicle to warm up the A/T fluid to approximately 80 ° C (176 ° F).

2. Stop the engine.

3. Remove the A/T fluid level gauge.

4. Drain the A/T fluid from the drain plug hole, then install the drain plug with a new gasket. Refill the transmission with new A/T

fluid. Always refill with the same volume as the drained A/T fluid.

Use the A/T fluid level gauge to check the A/T fluid level as

shown. Add A/T fluid as necessary.

• To flush out the old A/T fluid from the transmission oil coolers, pour new A/T fluid into the A/T fluid charg-

ing pipe with the engine idling and at the same time drain the old A/T fluid from the auxiliary transmis-

sion oil cooler hose return line.

• When the color of the A/T fluid coming out of the auxiliary transmission oil cooler hose return line is

about the same as the color of the new A/T fluid, flushing out the old A/T fluid is complete. The amount

of new A/T fluid used for flushing should be 30% to 50% increase of the specified capacity.

CAUTION:

• If Genuine NISSAN Matic S ATF is not available, Genuine NISSAN Matic J ATF may also be used.

• Using ATF fluid other than Genuine NISSAN Matic S ATF or Matic J ATF will cause deterioration in driveability and A/T durability, and may damage the A/T, which is not covered by the warranty.

• When filling the transmission with A/T fluid, do not spill the A/T fluid on any heat generating

parts such as the exhaust parts.

• Do not reuse the drain plug gasket.

5. Install the A/T fluid level gauge and tighten the A/T fluid level gauge bolt to specification.

6. Drive the vehicle to warm up the A/T fluid to approximately 80 ° C (176 ° F).

7. Check the fluid level and condition. If the A/T fluid is still dirty, repeat steps 2 through 6.

8. Install the A/T fluid level gauge in the A/T fluid charging pipe and install the A/T fluid level gauge bolt.

9. Tighten the A/T fluid level gauge bolt to specification. Drain plug : Refer to

TM-192, "

Component".

LLIA0071E

A/T fluid grade and capacity : Refer to MA-13, "Fluids and Lubricants".

A/T fluid level

gauge bolt : Refer to TM-186, "

Removal and Installation (2WD)" or TM-188, "Removal and

Installation (4WD)".

LLIA0071E

Revision: April 20092010 QX56