low beam INFINITI QX56 2010 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 725 of 4210

CCS-56

< ECU DIAGNOSIS >

ICC UNIT

Diagnostic Trouble Code (DTC) Chart

INFOID:0000000005146007

× :Applicable

DTC

No. CONSULT-III screen terms ICC sys-

tem

warning lamp Fail-safe

Malfunctions detected where... Refer-

ence

page

Vehicle-

to-vehi-cle dis-

tance

control mode Conven-

tional

(fixed

speed) cruise

control mode Brake as-

sist (with

preview

function)

11 CONTROL UNIT ×××× • ICC unit internal malfunctionCCS-22

12 VDC CONTROL UNIT ×××× • VDC malfunction

• Brake booster signal harness is

open or shorted CCS-23

20 CAN COMM CIRCUIT

×××× • ICC unit detected

CAN communi-

cation malfunction CCS-24

31 POWER SUPPLY CIR1

×××× • ICC unit power supply voltage is

excessively low (less than 8V) CCS-25

34 POWER SUPPLY CIR2

×××× • ICC unit power supply voltage is

excessively high. CCS-25

41 VHCL SPEED SE CIRC

×××× • Wheel sensor malfunction

• ABS actuator and electric unit

(control unit) malfunction

• A/T vehicle speed sensor mal-

function

•TCM malfunction CCS-26

43 VDC/TCS/ABS CIRC

×××× • VDC/TCS/ABS system malfunc-

tion CCS-27

45 BRAKE SW/ STOP L SW

×××× • ICC brake switch or stop lamp

switch harness is open or shorted

• ICC brake switch or stop lamp switch is stuck to OFF

• ICC brake switch or stop lamp switch is stuck to ON CCS-28

46 OPERATION SW CIRC

××× • ICC steering switch harness or

spiral cable is open or shorted

• ICC steering switch malfunction CCS-30

74 LASER BEAM OFF CNTR

××ו Laser beam of ICC sensor is off

the aiming point CCS-32

90 STOP LAMP RLY FIX

××ו Normally open terminal of stop

lamp relay is stuck CCS-33

92 ECM CIRCUIT

×××× •ECM malfunction

• Accelerator pedal position sensor

malfunction

• ICC unit malfunction CCS-38

96 NP RANGE

××× • Transmission range switch har-

ness is open or shorted

• Transmission range switch mal- function

•TCM malfunction CCS-39

97 AT CIRCUIT

××× •TCM malfunctionCCS-40

98 GEAR POSITION ××× •TCM malfunction

• A/T input speed sensor malfunc-

tion

• A/T vehicle speed sensor mal- function CCS-41

Revision: April 20092010 QX56

Page 734 of 4210

CCS

ICC SYSTEM FREQUENTLY CANNOT DETECT THE VEHICLE AHEAD/ DETEC-

TION ZONE IS SHORT

CCS-65

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B

N P A

ICC SYSTEM FREQUENTLY CANNOT DETECT THE VEHICLE AHEAD/

DETECTION ZONE IS SHORT

Diagnosis ProcedureINFOID:0000000005146015

The detection function may become disrupted in the following cases:

• When the reflector of the vehicle ahead is small or not clean enough to reflect the laser.

• When driving a road with extremely sharp corners.

• When the laser cannot detect the reflector of the vehicle ahead as the vehicle ahead is passing a hill or

passing the peak.

1.VISUAL CHECK

1. Check ICC sensor body window for contamination and foreign materials.

Is the ICC sensor window clean and free of obstruction?

YES >> GO TO 2

NO >> If any contamination or foreign materials are found, remove them. Then perform ICC system run-

ning test. Refer to CCS-8, "

ACTION TEST : ICC System Running Test".

2.CHECK FUNCTION

1. After performing laser beam aiming adjustment, perform ICC system running test. Refer to CCS-8,

"ACTION TEST : ICC System Running Test". Check that preceding vehicle detection performance has

been improved.

Is the ICC system operating normally?

YES >> INSPECTION END.

NO >> • Replace ICC sensor and perform laser beam aiming adjustment. Refer to CCS-72, "

ICC Sen-

sor".

• Perform ICC system running test. Refer to CCS-8, "

ACTION TEST : ICC System Running Test".

Revision: April 20092010 QX56

Page 738 of 4210

CCS

PRECAUTIONSCCS-69

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

N P A

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005146018

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

ICC System ServiceINFOID:0000000005146019

• Do not look straight into the laser beam discharger when adjusting laser beam aiming.

• Turn the MAIN switch OFF in conditions similar to dr iving, such as free rollers or a chassis dynamometer.

• Do not use the ICC sensor integrated unit removing from vehicle. Never disassemble and remodel.

• Erase DTC when replacing parts of ICC system, then c heck the operation of ICC system after adjusting laser

beam aiming if necessary.

Revision: April 20092010 QX56

Page 1984 of 4210

EXL-8

< FUNCTION DIAGNOSIS >

HEADLAMP

A Xenon type headlamp is adapted to the low beam headlamps. Xenon bulbs do not use a filament. Instead,

they produce light when a high voltage current is pa ssed between two tungsten electrodes through a mixture

of Xenon (an inert gas) and certain other metal halides. In addition to added lighting power, electronic control

of the power supply gives the headlamps stable quality and tone color. Following are some of the advantages

of the Xenon type headlamp.

• The light produced by the headlamps is a white color comparable to sunlight that is easy on the eyes.

• Light output is nearly double that of halogen headlamps, affording increased area of illumination.

• The light features a high relative spectral distribution at wavelengths to which the human eye is most sensi- tive. This means that even in the rain, more light is reflected back from the road surface toward the vehicle,

for added visibility.

• Power consumption is approximately 25 percent less than halogen headlamps, reducing battery load.

HIGH BEAM OPERATION/FLASH-TO-PASS OPERATION

With the combination switch (lighting and turn signal switch) in the 2ND position and placed in HIGH position,

the BCM receives input requesting the headlamp high beams to illuminate. The flash to pass feature can be

used any time and also sends a signal to the BCM. This input is communicated to the IPDM E/R via the CAN

communication lines. The CPU of the combination meter c ontrols the ON/OFF status off the HIGH BEAM indi-

cator. The CPU of the IPDM E/R controls the headlamp high relay coil which supplies power to the high beam

headlamps.

The combination meter receives a high beam request signal (ON) via the CAN communication lines and turns

the high beam indicator lamp ON.

EXTERIOR LAMP BATTERY SAVER CONTROL

With the combination switch (lighting and turn signal switch) in the 2nd position and the ignition switch is

turned from ON or ACC to OFF, the battery saver feature is activated.

Under this condition, the headlamps remain illuminated for 5 minutes unless the lighting switch position is

changed. If the lighting switch position is changed, then the headlamps are turned off.

This setting can be changed by CONSULT-III. Refer to BCS-22, "

HEADLAMP : CONSULT-III Function (BCM -

HEAD LAMP)".

Revision: April 20092010 QX56

Page 1986 of 4210

EXL-10

< FUNCTION DIAGNOSIS >

DAYTIME LIGHT SYSTEM

Component Description

INFOID:0000000005369870

After starting the engine with the parking brake releas ed and the combination switch (lighting and turn signal

switch) in the OFF or 1ST position, the headlamp high beam automatically turns on at a reduced intensity.

With the combination switch (lighting and turn signal switch) in the 2nd position or with autolamps ON, the

headlamps function the same as conventional light systems.

OPERATION

The BCM monitors inputs from the parking brake swit ch and the combination switch (lighting and turn signal

switch) to determine when to activate the daytime light system. The BCM sends a daytime light request to the

IPDM E/R via the CAN communication lines. The IPDM E/ R grounds the daytime light relay which in turn, pro-

vides power to the ground side of the LH high beam lamp. Power flows backward through the LH high beam

lamp to the IPDM E/R, through the high beam fuses, through the RH high beam lamp circuit to the RH high

beam lamp and on to ground. The high beam lamps are wired in series which causes them to illuminate at a

reduced intensity.

1. IPDM E/R E119, E122, E123, E124 2. BCM M18, M20 (view with instrument

panel removed)3. Daytime light relay E103

4. Combination switch (lighting and turn signal switch) M28 5. Combination meter M23, M24 6. Parking brake switch M11

Revision: April 20092010 QX56

Page 1988 of 4210

EXL-12

< FUNCTION DIAGNOSIS >

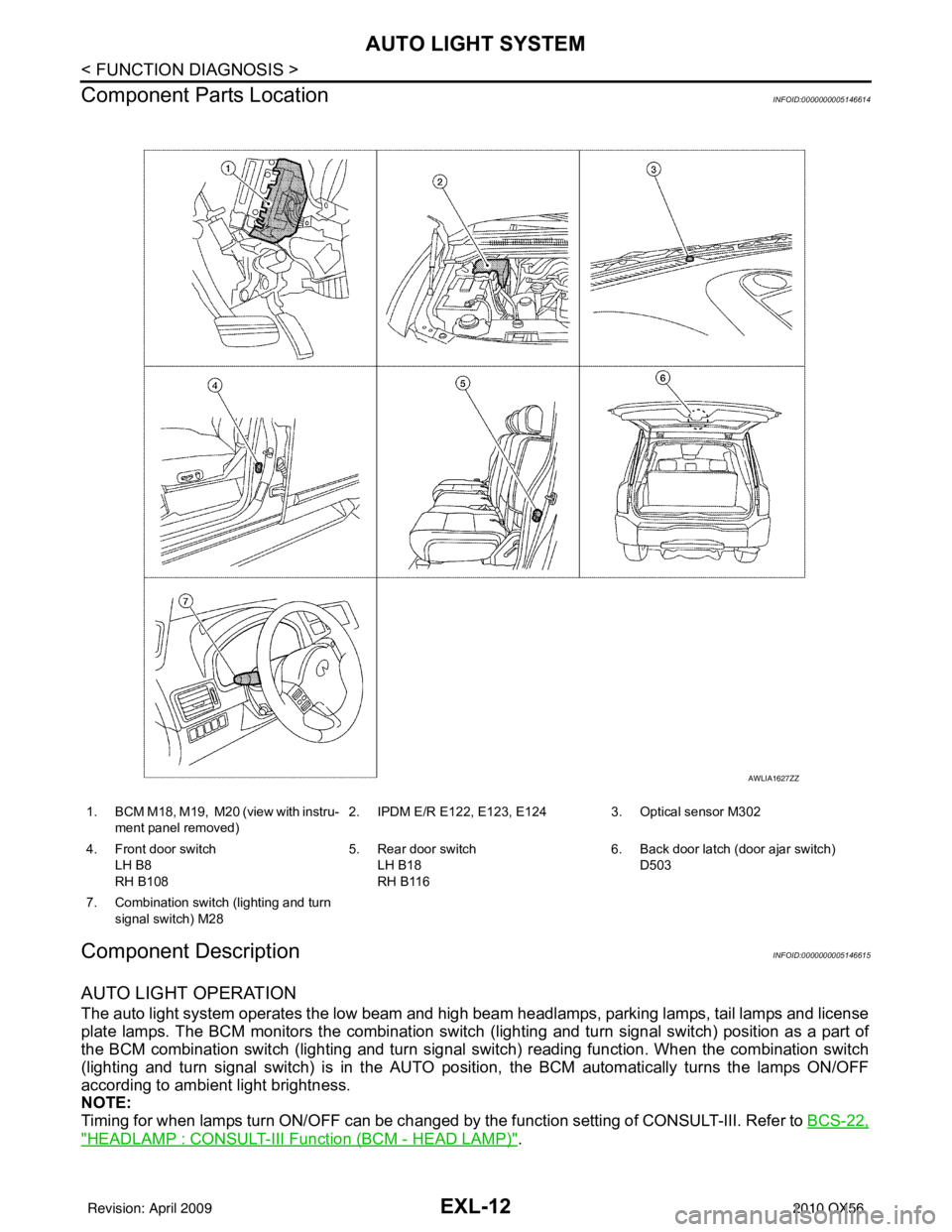

AUTO LIGHT SYSTEM

Component Parts Location

INFOID:0000000005146614

Component DescriptionINFOID:0000000005146615

AUTO LIGHT OPERATION

The auto light system operates t he low beam and high beam headlamps, parking lamps, tail lamps and license

plate lamps. The BCM monitors the combination switch (lighting and turn signal switch) position as a part of

the BCM combination switch (lighting and turn signal switch) reading function. When the combination switch

(lighting and turn signal switch) is in the AUTO position, the BCM automatically turns the lamps ON/OFF

according to ambient light brightness.

NOTE:

Timing for when lamps turn ON/OFF can be changed by the function setting of CONSULT-III. Refer to BCS-22,

"HEADLAMP : CONSULT-III Function (BCM - HEAD LAMP)".

1. BCM M18, M19, M20 (view with instru-

ment panel removed) 2. IPDM E/R E122, E123, E124 3. Optical sensor M302

4. Front door switch LH B8

RH B108 5. Rear door switch

LH B18

RH B116 6. Back door latch (door ajar switch)

D503

7. Combination switch (lighting and turn signal switch) M28

AWLIA1627ZZ

Revision: April 20092010 QX56

Page 1996 of 4210

EXL-20

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

FLASHER

FLASHER : CONSULT-III Function (BCM - FLASHER)INFOID:0000000005369884

DATA MONITOR

ACTIVE TEST

COMB SW

COMB SW : CONSULT-III Function (BCM - COMB SW)INFOID:0000000005369885

DATA MONITOR

Test ItemOperation Description

TA I L L A M P ON

Transmits the position light reques

t signal to IPDM E/R with CAN com-

munication to turn the tail lamp ON.

OFF Stops the tail lamp request signal transmission.

HEAD LAMP HI

Transmits the high beam request signal with CAN communication to turn

the headlamp (HI).

LO Transmits the low beam request signal with CAN communication to turn

the headlamp (LO).

OFF Stops the high & low beam request signal transmission.

FR FOG LAMP ON

Transmits the front fog lights request signal to IPDM E/R with CAN com-

munication to turn the front fog lamp ON.

OFF Stops the front fog lights request signal transmission.

CARGO LAMP ON

Transmits the cargo lamp request signal with CAN communication to

turn the lamp ON.

OFF Stops the cargo lamp request signal transmission.

CORNERING LAMP LH

Transmits the LH cornering lamp request signal with CAN communica-

tion to turn the lamp ON.

RH Transmits the RH cornering lamp request signal with CAN communica-

tion to turn the lamp ON.

OFF Stops the day time running light request signal transmission.

Monitor Item [Unit] Description

IGN ON SW [ON/OFF] Ignition switch (ON) status judged from IGN signal (ignition power supply)

HAZARD SW [ON/OFF] The switch status input from the hazard switch

TURN SIGNAL R [ON/OFF] Each switch condition that BCM judges from the combination switch reading function

TURN SIGNAL L [ON/OFF]

BRAKE SW [ON/OFF] The switch status input from the brake switch

Test ItemOperation Description

FLASHER RH Outputs the voltage to turn the right side turn signal lamps ON.

LH Outputs the voltage to turn the left side turn signal lamps ON.

OFF Stops the voltage to turn the turn signal lamps OFF.

Revision: April 20092010 QX56

Page 1997 of 4210

![INFINITI QX56 2010 Factory User Guide DIAGNOSIS SYSTEM (BCM)EXL-21

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Monitor Item [Unit] Description

TURN SIGNAL R

[OFF/ON] Displays the status of the TURN RH switch in combination sw INFINITI QX56 2010 Factory User Guide DIAGNOSIS SYSTEM (BCM)EXL-21

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Monitor Item [Unit] Description

TURN SIGNAL R

[OFF/ON] Displays the status of the TURN RH switch in combination sw](/img/42/57032/w960_57032-1996.png)

DIAGNOSIS SYSTEM (BCM)EXL-21

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Monitor Item [Unit] Description

TURN SIGNAL R

[OFF/ON] Displays the status of the TURN RH switch in combination switch judged by BCM with the combination switch

reading function

TURN SIGNAL L

[OFF/ON] Displays the status

of the TURN LH switch in co mbination switch judged by BCM with the combination switch

reading function

HI BEAM SW

[OFF/ON] Displays the status of the HI BEAM sw

itch in combination switch judged by BCM with the combination switch

reading function

HEAD LAMP SW1

[OFF/ON] Displays the status of the HEADLAMP switch in combination switch judged by BCM with the combination

switch reading function

HEAD LAMP SW2

[OFF/ON] Displays the status of the HEADLAMP switch in combination switch judged by BCM with the combination

switch reading function

LIGHT SW 1ST

[OFF/ON] Displays the status of the HEADLAMP switch in combination switch judged by BCM with the combination

switch reading function

PA S S I N G S W

[OFF/ON] Displays the status of the PASSING sw

itch in combination switch judged by BCM with the combination switch

reading function

AUTO LIGHT SW

[OFF/ON] Displays the status of the AUTO LIGHT switch in combination switch judged by BCM with the combination

switch reading function

FR FOG SW

[OFF/ON] Displays the status of the FR FOG switch in combination switch judged by BCM with the combination switch

reading function

FR WIPER HI

[OFF/ON] Displays the status of the FR WIPER HI switch in combination switch judged by BCM with the combination

switch reading function

FR WIPER LOW

[OFF/ON] Displays the status of the FR WIPER LOW switch in combination switch judged by BCM with the combination

switch reading function

FR WIPER INT

[OFF/ON] Displays the status of the FR WIPER INT switch in combination switch judged by BCM with the combination

switch reading function

FR WASHER SW

[OFF/ON] Displays the status of the FR WASHER switch in combination switch judged by BCM with the combination

switch reading function

INT VOLUME

[1 - 7] Displays the status of wiper intermittent dial position judged by BCM with the combination switch reading

function

RR WIPER ON

[OFF/ON] Displays the status of the RR WIPER switch in combination switch judged by BCM with the combination

switch reading function

RR WIPER INT

[OFF/ON] Displays the status of the RR WIPER INT switch in combination switch judged by BCM with the combination

switch reading function

RR WASHER SW

[OFF/ON] Displays the status of the RR WASHER switch in combination switch judged by BCM with the combination

switch reading function

Revision: April 20092010 QX56

Page 2001 of 4210

![INFINITI QX56 2010 Factory User Guide DIAGNOSIS SYSTEM (IPDM E/R)EXL-25

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

ACTIVE TEST

Te s t i t e m

TAIL&CLR REQ

[OFF/ON] ×Displays the status of the position light request signal r INFINITI QX56 2010 Factory User Guide DIAGNOSIS SYSTEM (IPDM E/R)EXL-25

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

ACTIVE TEST

Te s t i t e m

TAIL&CLR REQ

[OFF/ON] ×Displays the status of the position light request signal r](/img/42/57032/w960_57032-2000.png)

DIAGNOSIS SYSTEM (IPDM E/R)EXL-25

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

ACTIVE TEST

Te s t i t e m

TAIL&CLR REQ

[OFF/ON] ×Displays the status of the position light request signal received from BCM via CAN

communication.

HL LO REQ

[OFF/ON] ×

Displays the status of the low beam request signal received from BCM via CAN

communication.

HL HI REQ

[OFF/ON] ×Displays the status of the high beam request signal received from BCM via CAN

communication.

FR FOG REQ

[OFF/ON] ×Displays the status of the front fog lamp request signal received from BCM via

CAN communication.

FR WIP REQ

[STOP/1LOW/LOW/HI] ×

Displays the status of the front wiper request signal received from BCM via CAN

communication.

WIP AUTO STOP

[STOP P/ACT P] ×

Displays the status of the front wiper auto stop signal judged by IPDM E/R.

WIP PROT

[OFF/Block] ×

Displays the status of the front wiper fail-safe operation judged by IPDM E/R.

ST RLY REQ

[OFF/ON] Displays the status of the starter request signal received from ECM via CAN com-

munication.

IGN RLY

[OFF/ON] ×

Displays the status of the ignition relay judged by IPDM E/R.

RR DEF REQ

[OFF/ON] ×Displays the status of the rear defogger request signal received from AV control

unit via CAN communication.

OIL P SW

[OPEN/CLOSE] Displays the status of the oil pressure switch judged by IPDM E/R.

DTRL REQ

[OFF] Displays the status of the daytime light request signal received from BCM via CAN

communication.

HOOD SW

[OPEN/CLOSE] Displays the status of the hood switch judged by IPDM E/R.

THFT HRN REQ

[OFF/ON] Displays the status of the theft warning horn request signal received from BCM

via CAN communication.

HORN CHIRP

[OFF/ON] Displays the status of the horn reminder signal received from BCM via CAN com-

munication.

Monitor Item

[Unit] MAIN SIG-

NALS Description

Test item

Operation Description

REAR DEFOGGER OFF

OFF

ON Operates rear window defogger relay.

FRONT WIPER OFF

OFF

LO Operates the front wiper relay.

HI Operates the front wiper relay and front wiper high relay.

MOTOR FAN 1O

FF

2O FF

3 Operates the cooling fan relay.

4 Operates the cooling fan relay.

Revision: April 20092010 QX56

Page 2006 of 4210

EXL-30

< COMPONENT DIAGNOSIS >

HEADLAMP (HI) CIRCUIT

HEADLAMP (HI) CIRCUIT

DescriptionINFOID:0000000005370270

The IPDM E/R (intelligent power distribution module engine room) controls the headlamp LH high and head-

lamp RH high relays based on inputs from the BCM via the CAN communication lines. When the headlamp LH

high and headlamp RH high relays are energized, power flows through fuse\

s 34 and 35, located in the IPDM

E/R. Power then flows to the front combination lamps to the headlamp high beam.

Component Function CheckINFOID:0000000005146640

1.CHECK HEADLAMP (HI) OPERATION

WITHOUT CONSULT-III

1. Start IPDM E/R auto active test. Refer to PCS-12, "

Diagnosis Description".

2. Check that the headlamp switches to the high beam. NOTE:

HI/LO is repeated 1 second each when usi ng the IPDM E/R auto active test.

CONSULT-III

1. Select "EXTERNAL LAMPS" of IPDM E/R active test item.

2. With the test item operating, check that the headlamp switches to high beam.

Does the headlamp switch to high beam?

YES >> Headlamp (HI) circuit is normal.

NO >> Refer to EXL-30, "

Diagnosis Procedure - Without Daytime Light System", EXL-31, "Diagnosis

Procedure - With Daytime Light System".

Diagnosis Procedure - Wit hout Daytime Light SystemINFOID:0000000005146641

Regarding Wiring Diagram information, refer to EXL-52, "Wiring Diagram".

1.CHECK HEADLAMP (HI) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not open.

Is the fuse open?

YES >> Repair the harness and replace the fuse.

NO >> GO TO 2.

2.CHECK HEADLAMP (HI) OUTPUT VOLTAGE Hi : Headlamp switches to the high beam.

Off : Headlamp OFF

Unit

LocationFuse No.Capacity

Headlamp HI (LH) IPDM E/R3510A

Headlamp HI (RH) IPDM E/R3410A

Revision: April 20092010 QX56