wheel INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2218 of 4210

KNUCKLEFSU-19

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

KNUCKLE

Removal and InstallationINFOID:0000000005148118

REMOVAL

1. Remove wheel hub and bearing assembly. Refer to FAX-7, "Removal and Installation" .

• Disconnect wheel sensor harness connector. Do not remove wheel sensor from wheel hub and bearing

assembly for this procedure.

2. Remove steering outer socket from steering knuckle using Tool. CAUTION:

• Be careful not to damage ball joint boot.

• Temporarily tighten nut to prevent damage to threads andto prevent Tool from coming off.

3. Remove the coil spring and shock absorber assembly using power tool. Refer to FSU-14, "

Removal and

Installation" .

4. Support lower link using a suitable jack.

5. Remove cotter pin and nut from upper link ball joint and discard the cotter pin.

6. Separate upper link ball joint from steering knuckle using Tool.

1. Disc rotor 2. Wheel hub and bearing assembly 3. Wheel stud

4. Splash guard 5. Steering knuckle Front

AWDIA0423GB

Tool number : HT72520000 (J-25730-A)

WGIA0130E

Tool number : ST29020001 (J-24319-01)

LEIA0095E

Revision: April 20092010 QX56

Page 2219 of 4210

FSU-20

< REMOVAL AND INSTALLATION >

KNUCKLE

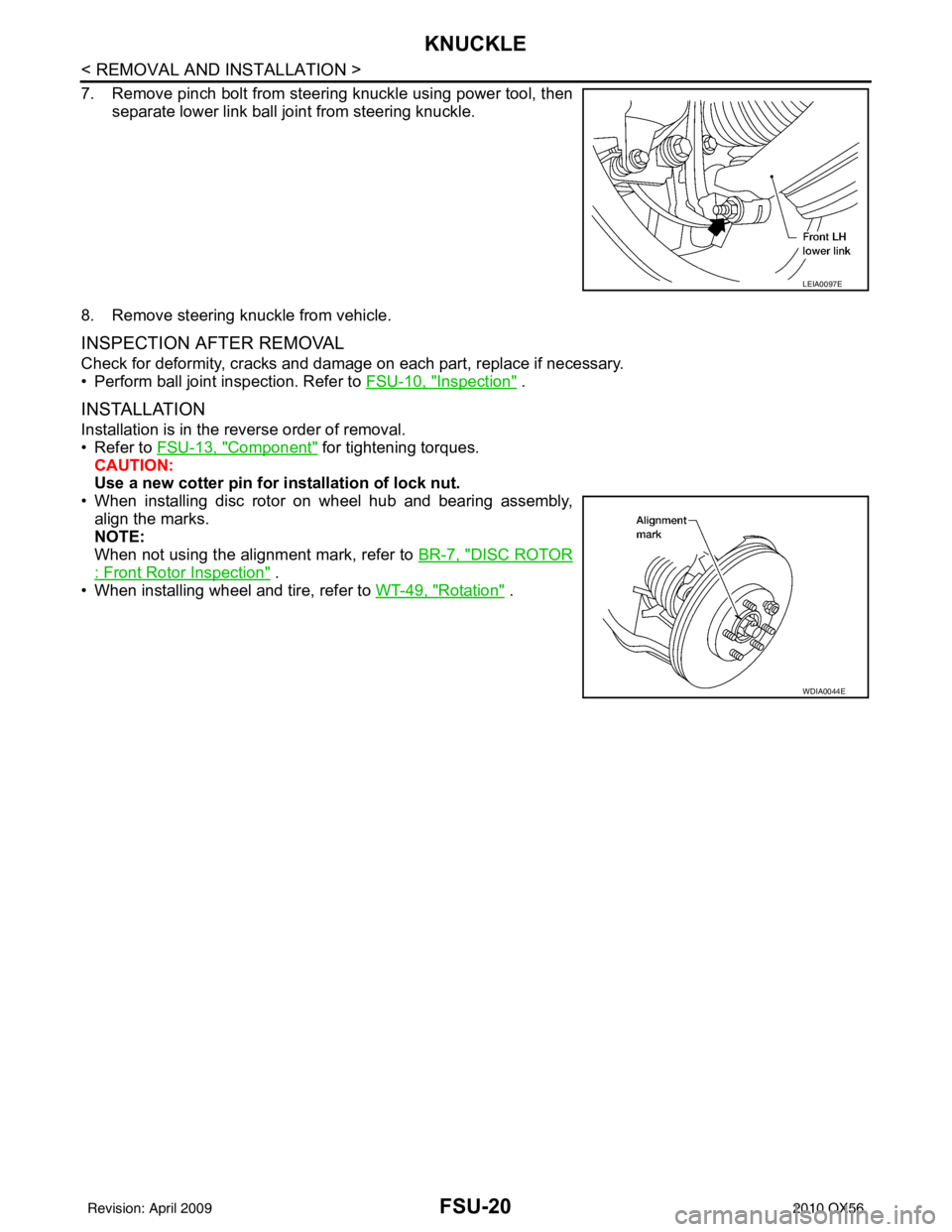

7. Remove pinch bolt from steering knuckle using power tool, thenseparate lower link ball joint from steering knuckle.

8. Remove steering knuckle from vehicle.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each part, replace if necessary.

• Perform ball joint inspection. Refer to FSU-10, "

Inspection" .

INSTALLATION

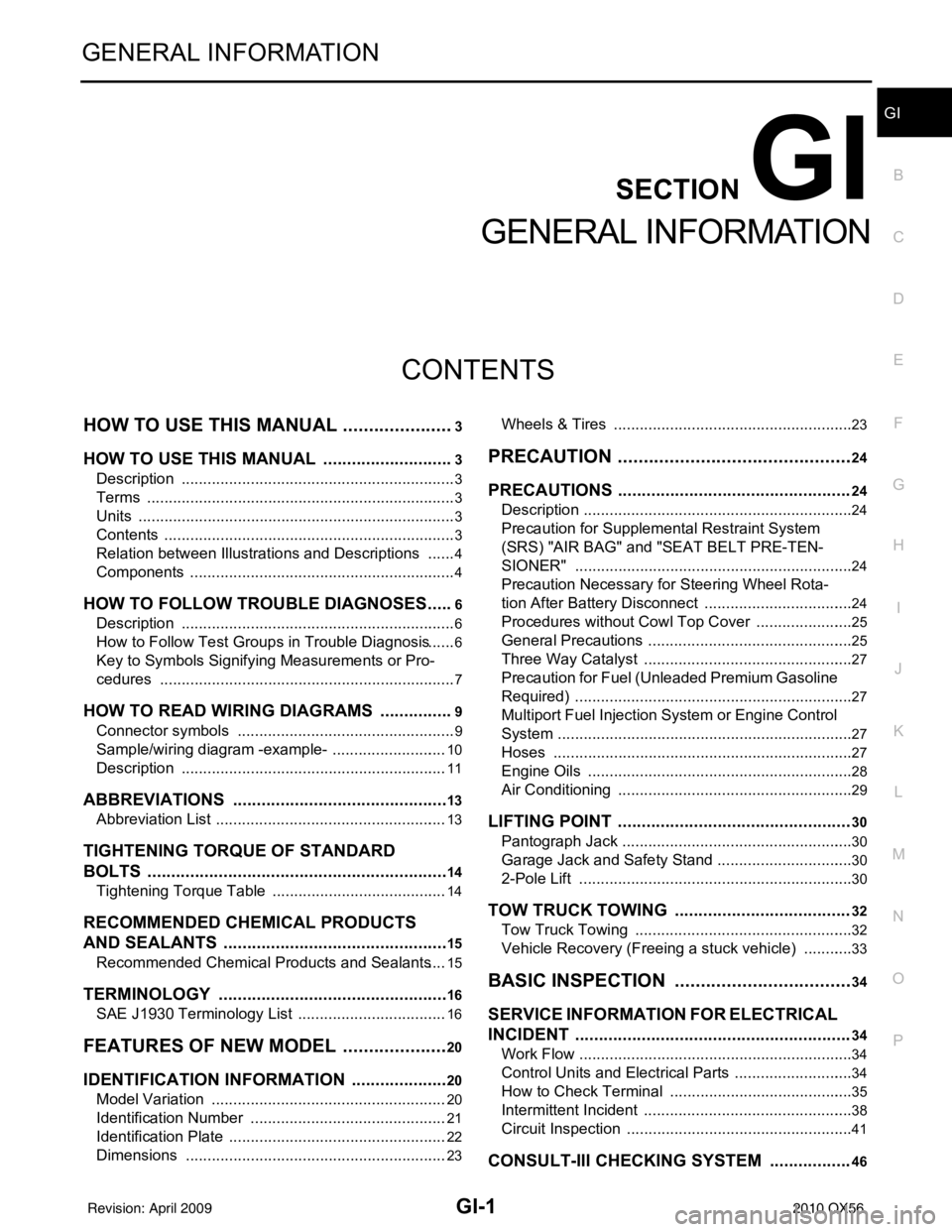

Installation is in the reverse order of removal.

• Refer to FSU-13, "

Component" for tightening torques.

CAUTION:

Use a new cotter pin for installation of lock nut.

• When installing disc rotor on wheel hub and bearing assembly, align the marks.

NOTE:

When not using the alignment mark, refer to BR-7, "

DISC ROTOR

: Front Rotor Inspection" .

• When installing wheel and tire, refer to WT-49, "

Rotation" .

LEIA0097E

WDIA0044E

Revision: April 20092010 QX56

Page 2222 of 4210

SERVICE DATA AND SPECIFICATIONS (SDS)FSU-23

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005148120

Spring Free HeightINFOID:0000000005148121

Wheel Alignment (Unladen*1)INFOID:0000000005148122

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions. Suspension type

Independent double wishbone coil over shock

Shock absorber type Double-acting hydraulic

Stabilizer Standard equipment

2WD325.5 ± 3 mm (12.8 ± 0.1 in)

4WD 335.0 ± 3 mm (13.2 ± 0.1 in)

Drive type 2WD 4WD

Camber

Degree minute (decimal degree) Minimum

-0° 51 ′ (-0.85 °)- 0° 33 ′ (-0.55 °)

Nominal -0° 6 ′ (-0.10 °)0 ° 12 ′ (0.20 °)

Maximum 0° 39 ′ (0.65 °)0 ° 57 ′ (0.95 °)

Cross camber 0° 45 ′ (0.75 °) or less 0 ° 45′ (0.75 °) or less

Caster

Degree minute (decimal degree) Minimum

3° 15 ′ (3.25 °)2 °45 ′ (2.75 °)

Nominal 4° 0 ′ (4.00 °)3 ° 30 ′ (3.50 °)

Maximum 4° 45 ′ (4.75 °)4 ° 15 ′ (4.25 °)

Cross caster 0° 45 ′ (0.75 °) or less 0

° 45 ′ (0

.75°) or less

Kingpin inclination

Degree minute (decimal degree) 13

° 32 ′ (13.53 °)1 3°13 ′ (13.22 °)

Total toe-in Distance (A

− B) Minimum

1.8 mm (0.07 in) 1.8 mm (0.07 in)

Nominal 2.8 mm (0.11 in) 2.8 mm (0.11 in)

Maximum 3.8 mm (0.15 in) 3.8 mm (0.15 in)

Angle (left side or right side)

Degree minute (decimal degree) Minimum

0° 3 ′ (0.05 °)0 ° 3 ′ (0.05 °)

Nominal 0° 5 ′ (0.08 °)0 ° 5 ′ (0.08 °)

Maximum 0° 7 ′ (0.12 °)0 ° 7 ′ (0.12 °)

Wheel turning angle

(full turn) Inside

Degree minute (decimal degree)

34

° 31 ′ – 38 ° 31 ′ *2

(34.52 ° – 38.52 °) 34

° 44 ′ – 38 ° 44 ′ *4

(34.73 ° – 38.73 °)

Ou t

side

Degree minute (decimal degree) 30

° 59 ′ – 34 ° 59 ′ *3

(30.98 ° – 34.98 °) 30

° 29 ′ – 34 ° 29 ′ *5

(30.48 ° – 34.48 °)

SFA234AC

Revision: April 20092010 QX56

Page 2223 of 4210

FSU-24

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

*2: Target value 37° 31 ′ (37.52 °)

*3: Target value 33 ° 59 ′ (33.98 °)

*4: Target value 37 ° 44 ′ (37.73 °)

*5: Target value 33 ° 29 ′ (33.48 °)

Ball JointINFOID:0000000005148123

*1 Measure at cotter pin hole

*2 Measure at groove

Wheelarch Height (Unladen*1)INFOID:0000000005148124

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Verify the vehicle height. If vehicle height is not within ± 10 mm (0.39 in) of the specification, perform the control unit initialization pro-

cedure. Refer to SCS-7, "

CONSULT-III Function".

Swinging force (A)

Upper ball joint

8.1 – 103.2 N (0.8 – 10.5 kg-f, 1.8 – 23.2 lb-f) *1

Lower ball joint 11.4 – 145.5 N (1.1 – 14.8 kg-f, 2.5 – 32.7 lb-f) *2

Turning torque (B) 0.5 - 6.4 N·m (0.05 - 0.65 kg-m, 4 - 57 in-lb)

Vertical end play (C) 0 mm (0 in)

SFA858AWEIA0076E

Suspension type

Air leveling*2

Applied model2WD4WD

Front wheelarch height (Hf) 920

(36.22) 937

(36.89)

Rear wheelarch height (Hr) 917

(36.10) 937

(36.89)

LEIA0085E

Revision: April 20092010 QX56

Page 2224 of 4210

GI-1

GENERAL INFORMATION

C

DE

F

G H

I

J

K L

M B

GI

SECTION GI

N

O P

CONTENTS

GENERAL INFORMATION

HOW TO USE THIS MANU AL ......................3

HOW TO USE THIS MANUAL ....................... .....3

Description .......................................................... ......3

Terms ........................................................................3

Units ..........................................................................3

Contents ....................................................................3

Relation between Illustrations and Descriptions .......4

Components ..............................................................4

HOW TO FOLLOW TROUBLE DIAGNOSES .....6

Description ................................................................6

How to Follow Test Groups in Trouble Diagnosis ......6

Key to Symbols Signifying Measurements or Pro-

cedures ............................................................... ......

7

HOW TO READ WIRING DIAGRAMS ................9

Connector symbols ............................................. ......9

Sample/wiring diagram -example- ...........................10

Description ..............................................................11

ABBREVIATIONS .......................................... ....13

Abbreviation List .................................................. ....13

TIGHTENING TORQUE OF STANDARD

BOLTS ................................................................

14

Tightening Torque Table .........................................14

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ............................................ ....

15

Recommended Chemical Products and Sealants ....15

TERMINOLOGY .................................................16

SAE J1930 Terminology List ............................... ....16

FEATURES OF NEW MODEL .....................20

IDENTIFICATION INFORMATION .....................20

Model Variation ................................................... ....20

Identification Number ..............................................21

Identification Plate ...................................................22

Dimensions .............................................................23

Wheels & Tires .................................................... ....23

PRECAUTION ..............................................24

PRECAUTIONS .................................................24

Description ........................................................... ....24

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

24

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

24

Procedures without Cowl Top Cover .......................25

General Precautions ................................................25

Three Way Catalyst .................................................27

Precaution for Fuel (Unleaded Premium Gasoline

Required) .................................................................

27

Multiport Fuel Injection System or Engine Control

System .....................................................................

27

Hoses ......................................................................27

Engine Oils ..............................................................28

Air Conditioning .......................................................29

LIFTING POINT .................................................30

Pantograph Jack ......................................................30

Garage Jack and Safety Stand ................................30

2-Pole Lift ................................................................30

TOW TRUCK TOWING .....................................32

Tow Truck Towing ...................................................32

Vehicle Recovery (Freeing a stuck vehicle) ............33

BASIC INSPECTION ...................................34

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ..........................................................

34

Work Flow ............................................................ ....34

Control Units and Electrical Parts ............................34

How to Check Terminal ...........................................35

Intermittent Incident ............................................. ....38

Circuit Inspection .....................................................41

CONSULT-III CHECKING SYSTEM .................46

Revision: April 20092010 QX56

Page 2236 of 4210

ABBREVIATIONSGI-13

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O PABBREVIATIONS

Abbreviation ListINFOID:0000000005149579

The following ABBREVIATIONS are used:

ABBREVIATION DESCRIPTION

A/C Air Conditioner

A/T Automatic Transaxle/Transmission

ATF Automatic Transmission Fluid

D

1Drive range 1st gear

D

2Drive range 2nd gear

D

3Drive range 3rd gear

D

4Drive range 4th gear

D5 Drive range 5th gear

FR, RR Front, Rear LH, RH Left-Hand, Right-Hand M/T Manual Transaxle/Transmission

OD Overdrive

P/S Power Steering

SAE Society of Automotive Engineers, Inc.

SDS Service Data and Specifications

SST Special Service Tools

2WD 2-Wheel Drive

4WD 4-Wheel Drive

2

22nd range 2nd gear

2

12nd range 1st gear

1

21st range 2nd gear

1

11st range 1st gear

Revision: April 20092010 QX56

Page 2244 of 4210

IDENTIFICATION INFORMATIONGI-21

< FEATURES OF NEW MODEL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

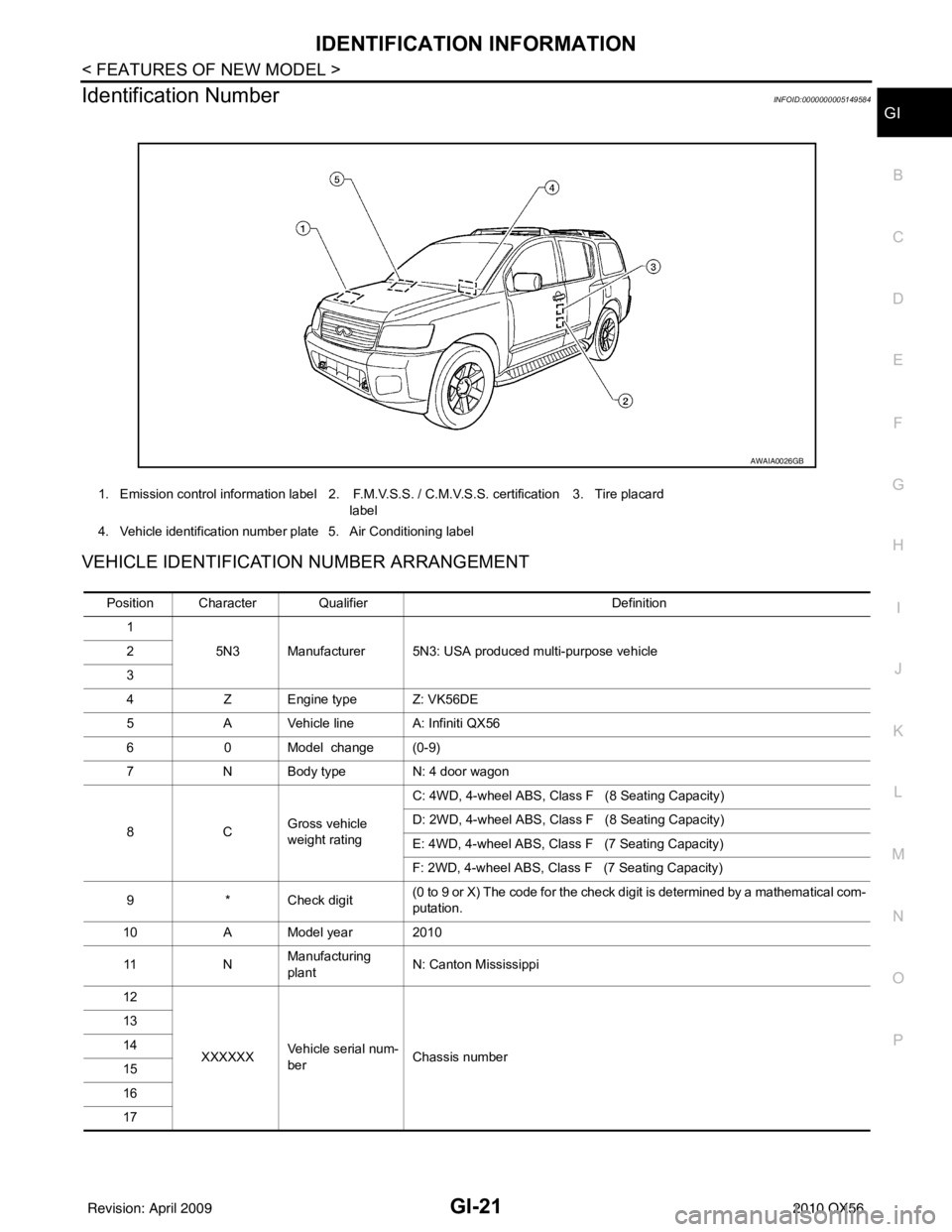

Identification NumberINFOID:0000000005149584

VEHICLE IDENTIFICATION NUMBER ARRANGEMENT

1. Emission control information label 2. F.M.V.S.S. / C.M.V.S.S. certification label3. Tire placard

4. Vehicle identification number plate 5. Air Conditioning label

AWAIA0026GB

Position Character Qualifier Definition

1 5N3 Manufacturer 5N3: USA produced multi-purpose vehicle

2

3

4 Z Engine type Z: VK56DE

5 A Vehicle line A: Infiniti QX56

6 0 Model change (0-9)

7 N Body type N: 4 door wagon

8C Gross vehicle

weight ratingC: 4WD, 4-wheel ABS, Class F (8 Seating Capacity)

D: 2WD, 4-wheel ABS, Class F (8 Seating Capacity)

E: 4WD, 4-wheel ABS, Class F (7 Seating Capacity)

F: 2WD, 4-wheel ABS, Class F (7 Seating Capacity)

9 * Check digit (0 to 9 or X) The code for the check digit is determined by a mathematical com-

putation.

10 A Model year 2010

11 NManufacturing

plant

N: Canton Mississippi

12

XXXXXX Vehicle serial num-

ber Chassis number

13

14

15

16

17

Revision: April 20092010 QX56

Page 2246 of 4210

IDENTIFICATION INFORMATIONGI-23

< FEATURES OF NEW MODEL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

DimensionsINFOID:0000000005149586

Unit: mm (in)

Wheels & TiresINFOID:0000000005149587

* With Steel Wheel Drive type

2WD4WD

Overall length 5254 (206.9)5254 (206.9)

Overall width 2021 (79.6)2021 (79.6)

Overall height (with roof rack) 1948 (76.7)1968 (77.5)

Front tread width 1729 (68.1)1729 (68.1)

Rear tread width 1729 (68.1)1729 (68.1)

Wheelbase 3130 (123.2)3130 (123.2)

Minimum Running Ground Clearance (at front suspension) 211.2 (8.3)232 (9.1)

Drive Type Grade Road wheelTireSpare tire size *

All QX56 20x8JJ Chromium Aluminum Alloy

P275/60R20P275/60R20

20X8J Steel P275/60R20P275/60R20

Revision: April 20092010 QX56

Page 2247 of 4210

GI-24

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

DescriptionINFOID:0000000005149588

Observe the following precautions to ensure safe and proper servicing. These precautions are not

described in each individual section.

Precaution for Supplemental Restraint Syst em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005402047

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005259102

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

Revision: April 20092010 QX56

Page 2248 of 4210

PRECAUTIONSGI-25

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Procedures without Cowl Top CoverINFOID:0000000005149591

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

General PrecautionsINFOID:0000000005149592

• Do not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any inflam-

mable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or ot her enclosed area, be sure to prop-

erly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

• Before jacking up the vehicle, apply wheel chocks or other tire blocks to the wheels to prevent t he vehicle from moving. After jack-

ing up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehi-

cle.

These operations should be done on a level surface.

• When removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

PIIB3706J

SGI285

SGI231

Revision: April 20092010 QX56