parking brake INFINITI QX56 2010 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 1090 of 4210

![INFINITI QX56 2010 Factory Owners Guide DLN-8

< BASIC INSPECTION >[ATX14B]

DIAGNOSIS AND REPAIR WORKFLOW

Does 4WD warning lamp turn ON?

YES >> GO TO CHECK AT IDLE.

NO >> GO TO

DLN-105, "

Diagnosis Procedure".

CHECK AT IDLE

1.CHECK 4WD SHIF INFINITI QX56 2010 Factory Owners Guide DLN-8

< BASIC INSPECTION >[ATX14B]

DIAGNOSIS AND REPAIR WORKFLOW

Does 4WD warning lamp turn ON?

YES >> GO TO CHECK AT IDLE.

NO >> GO TO

DLN-105, "

Diagnosis Procedure".

CHECK AT IDLE

1.CHECK 4WD SHIF](/img/42/57032/w960_57032-1089.png)

DLN-8

< BASIC INSPECTION >[ATX14B]

DIAGNOSIS AND REPAIR WORKFLOW

Does 4WD warning lamp turn ON?

YES >> GO TO CHECK AT IDLE.

NO >> GO TO

DLN-105, "

Diagnosis Procedure".

CHECK AT IDLE

1.CHECK 4WD SHIFT INDICATOR LAMP

1. Park vehicle on flat surface and engage the parking brake.

2. Turn ignition switch to OFF position.

3. Move A/T selector lever to P position.

4. Set 4WD shift switch to 2WD position.

5. Start engine.

Does 4WD shift indicator lamp turn ON?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK 4WD WARNING LAMP

Check 4WD warning lamp state.

Is 4WD warning lamp turned ON?

YES >> Perform the self-diagnosis. Refer to DLN-18, "CONSULT-III Function (ALL MODE AWD/4WD)".

NO >> Refer to DLN-107, "

Diagnosis Procedure".

3.CHECK 4WD SHIFT INDICATOR AND 4LO INDICATOR OPERATION

1. Brake pedal depressed.

2. Move A/T selector lever to N position.

3. Set 4WD shift switch to 2WD, AUTO, 4H, 4LO, 4H, AUTO and 2WD in order. (Stay at each switch position for at least 1 sec-

ond.)

Do 4WD shift indicator and 4LO indicator lamps change properly?

Does buzzer sound?

YES >> GO TO CRUISE TEST.

NO >> GO TO DLN-107, "

Diagnosis Procedure".

CRUISE TEST

1.CHECK INPUT SIGNAL

1. Warm up engine to normal operating temperature.

2. Park vehicle on flat surface.

3. Move A/T selector lever to P position.

4. Set 4WD shift switch to AUTO position.

5. Start engine.

6. Drive vehicle for at least 30 seconds at a speed higher than 20 km/h (12 MPH).

Is 4WD warning lamp turned ON?

On steady>>Perform the self-diagnosis. Refer to DLN-18, "CONSULT-III Function (ALL MODE AWD/4WD)".

WDIA0136E

Revision: April 20092010 QX56

Page 1279 of 4210

![INFINITI QX56 2010 Factory Owners Guide PROPELLER SHAFTDLN-197

< REMOVAL AND INSTALLATION > [PROPELLER SHAFT: 2S1410]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4WD

REMOVAL

1. Move the A/T select lever to the N position and release the parking brake. INFINITI QX56 2010 Factory Owners Guide PROPELLER SHAFTDLN-197

< REMOVAL AND INSTALLATION > [PROPELLER SHAFT: 2S1410]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4WD

REMOVAL

1. Move the A/T select lever to the N position and release the parking brake.](/img/42/57032/w960_57032-1278.png)

PROPELLER SHAFTDLN-197

< REMOVAL AND INSTALLATION > [PROPELLER SHAFT: 2S1410]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4WD

REMOVAL

1. Move the A/T select lever to the N position and release the parking brake.

2. Put matching marks on the rear propeller shaft flange yoke and the rear final drive companion flange as shown.

CAUTION:

For matching marks, use paint. Never damage the rear pro-

peller shaft flange yoke or the companion flange.

3. Remove the bolts, then remove the propeller shaft from the rear final drive and A/T or transfer.

INSPECTION

• Inspect the propeller shaft runout. If runout exceeds the limit, replace the propeller shaft assembly.

AWDIA0699GB

1. Propeller shaft tube 2. Snap ring3. Journal bearing

4. Sleeve yoke 5. Journal6. Flange yoke

Front

WDIA0049E

Limit

Propeller shaft run out : Refer to DLN-270, "

In-

spection and Adjustment"

LDIA0121E

Revision: April 20092010 QX56

Page 1334 of 4210

![INFINITI QX56 2010 Factory Owners Guide DLN-252

< REMOVAL AND INSTALLATION >[REAR FINAL DRIVE: R230]

REAR FINAL DRIVE

REAR FINAL DRIVE BREATHER

• Fill the rear final drive assembl

y with differential gear oil after installation. Refer to INFINITI QX56 2010 Factory Owners Guide DLN-252

< REMOVAL AND INSTALLATION >[REAR FINAL DRIVE: R230]

REAR FINAL DRIVE

REAR FINAL DRIVE BREATHER

• Fill the rear final drive assembl

y with differential gear oil after installation. Refer to](/img/42/57032/w960_57032-1333.png)

DLN-252

< REMOVAL AND INSTALLATION >[REAR FINAL DRIVE: R230]

REAR FINAL DRIVE

REAR FINAL DRIVE BREATHER

• Fill the rear final drive assembl

y with differential gear oil after installation. Refer to DLN-244.

ALDIA0210GB

1. Rear final drive breather hose connector 2. Plastic clip 3. Rear final drive breather tube

4. Rear final drive assembly 5. Rear suspension member 6. Rear final drive breather hose

7. Parking brake cable 8. Exhaust pipe9. Frame (LH)

10. Rear final drive breather hose frame connector A. Close-up view

Front

Revision: April 20092010 QX56

Page 1371 of 4210

![INFINITI QX56 2010 Factory Owners Guide EC-18

< BASIC INSPECTION >[VK56DE]

INSPECTION AND ADJUSTMENT

With CONSULT-III

1. Check the VIN of the vehicle and note it. Refer to

GI-20, "Model Variation".

2. Turn ignition switch ON and engine st INFINITI QX56 2010 Factory Owners Guide EC-18

< BASIC INSPECTION >[VK56DE]

INSPECTION AND ADJUSTMENT

With CONSULT-III

1. Check the VIN of the vehicle and note it. Refer to

GI-20, "Model Variation".

2. Turn ignition switch ON and engine st](/img/42/57032/w960_57032-1370.png)

EC-18

< BASIC INSPECTION >[VK56DE]

INSPECTION AND ADJUSTMENT

With CONSULT-III

1. Check the VIN of the vehicle and note it. Refer to

GI-20, "Model Variation".

2. Turn ignition switch ON and engine stopped.

3. Select “VIN REGISTRATION ” in “WORK SUPPORT” mode.

4. Follow the instruction of CONSULT-III display.

Accelerator Pedal Released Position LearningINFOID:0000000005149059

DESCRIPTION

Accelerator Pedal Released Position Learning is an operation to learn the fully released position of the accel-

erator pedal by monitoring the accelerator pedal positi on sensor output signal. It must be performed each time

harness connector of accelerator pedal pos ition sensor or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON and wait at least 2 seconds.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON and wait at least 2 seconds.

5. Turn ignition switch OFF and wait at least 10 seconds.

Throttle Valve Closed Position LearningINFOID:0000000005149060

DESCRIPTION

Throttle Valve Closed Position Learning is an operation to l earn the fully closed position of the throttle valve by

monitoring the throttle position sensor output signal . It must be performed each time harness connector of

electric throttle control actuator or ECM is disconnected.

OPERATION PROCEDURE

1. Make sure that accelerator pedal is fully released.

2. Turn ignition switch ON.

3. Turn ignition switch OFF wait at least 10 seconds. Make sure that throttle valve moves during above 10 seconds by confirming the operating sound.

Idle Air Volume LearningINFOID:0000000005149061

DESCRIPTION

Idle Air Volume Learning is an operation to learn the idle air volume that keeps each engine within the specific

range. It must be performed under any of the following conditions:

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

PREPARATION

Before performing Idle Air Volume Learning, make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the follo wing conditions are missed for even a moment.

• Battery voltage: More than 12.9V (At idle)

• Engine coolant temperature: 70 - 100 °C (158 - 212° F)

• Select lever: P or N

• Electric load switch: OFF (Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

start the headlamp will not be illuminated.

• Steering wheel: Neutral (Straight-ahead position)

• Vehicle speed: Stopped

• Transmission: Warmed-up

- With CONSULT-III: Drive vehicle until “ATF TEMP SE 1” in “DATA MONITOR” mode of “A/T” system indi- cates less than 0.9V.

- Without CONSULT-III: Drive vehicle for 10 minutes.

OPERATION PROCEDURE

Revision: April 20092010 QX56

Page 1985 of 4210

DAYTIME LIGHT SYSTEMEXL-9

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

DAYTIME LIGHT SYSTEM

System DiagramINFOID:0000000005369869

System DescriptionINFOID:0000000005146609

The headlamp system for Canada vehicles is equipped with a daytime light relay that activates the high beam

headlamps at approximately half illumination whenever the engine is operating. If the parking brake is applied

before the engine is started the daytime lights will not be illuminated. The daytime lights will illuminate once the

parking brake is released. Thereafter, the daytime lights will continue to operate when the parking brake is

applied.

Component Parts LocationINFOID:0000000005146610

AWLIA1751GB

AWLIA1626ZZ

Revision: April 20092010 QX56

Page 1986 of 4210

EXL-10

< FUNCTION DIAGNOSIS >

DAYTIME LIGHT SYSTEM

Component Description

INFOID:0000000005369870

After starting the engine with the parking brake releas ed and the combination switch (lighting and turn signal

switch) in the OFF or 1ST position, the headlamp high beam automatically turns on at a reduced intensity.

With the combination switch (lighting and turn signal switch) in the 2nd position or with autolamps ON, the

headlamps function the same as conventional light systems.

OPERATION

The BCM monitors inputs from the parking brake swit ch and the combination switch (lighting and turn signal

switch) to determine when to activate the daytime light system. The BCM sends a daytime light request to the

IPDM E/R via the CAN communication lines. The IPDM E/ R grounds the daytime light relay which in turn, pro-

vides power to the ground side of the LH high beam lamp. Power flows backward through the LH high beam

lamp to the IPDM E/R, through the high beam fuses, through the RH high beam lamp circuit to the RH high

beam lamp and on to ground. The high beam lamps are wired in series which causes them to illuminate at a

reduced intensity.

1. IPDM E/R E119, E122, E123, E124 2. BCM M18, M20 (view with instrument

panel removed)3. Daytime light relay E103

4. Combination switch (lighting and turn signal switch) M28 5. Combination meter M23, M24 6. Parking brake switch M11

Revision: April 20092010 QX56

Page 2113 of 4210

EXTERIOR LIGHTING SYSTEM SYMPTOMSEXL-137

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Daytime light system does not activate. • Either high beam bulb

• Parking brake switch

• Combination switch (lighting

and turn signal switch)

•BCM

• IPDM E/R

• Daytime light relay

• Harness between IPDM E/R

and daytime light relay. Daytime light system description.

Refer to

EXL-9, "System Descrip-

tion".

Front fog lamp is not

turned ON. One side

• Front fog lamp bulb

• Harness between IPDM E/R

and the front combination lamp

• Front combination lamp

• IPDM E/R Front fog lamp circuit

Refer to

EXL-36

.

Both sides Symptom diagnosis

"BOTH SIDE FRONT FOG LAMPS ARE NOT TURNED ON"

Refer to EXL-142

.

Parking lamp is not turned

ON. One side•Fuse

• Parking lamp bulb

• Harness between IPDM E/R

and the front/rear combination

lamp

• Front/rear combination lamp

• IPDM E/R Parking lamp circuit

Refer to

EXL-38

.

Both sides Symptom diagnosis

"PARKING, LICENSE PLATE AND TAIL LAMPS ARE NOT TURNED

ON"

Refer to EXL-141

.

Turn signal lamp does not

blink. Indicator lamp is nor-

mal.

(The applicable side

performs the high flash-

er activation).• Harness between BCM and

each turn signal lamp

• Turn signal lamp bulb

• Door mirror Turn signal lamp circuit

Refer to

EXL-44

.

Turn signal indicator lamp

does not blink. One side

Combination meter —

Both sides

(Always) • Turn signal indicator lamp sig-

nal

• Combination meter

•BCM • Combination meter.

Data monitor "TURN IND".

• BCM (FLASHER) Active test "FLASHER".

Both sides

(Does blink when acti-

vating the hazard warn-

ing lamp with the

ignition switch OFF) • The combination meter power

supply and the ground circuit

• Combination meter Combination meter

Power supply and the ground circuit

Refer to

MWI-28

.

Symptom

Possible causeInspection item

Revision: April 20092010 QX56

Page 2235 of 4210

GI-12

< HOW TO USE THIS MANUAL >

HOW TO READ WIRING DIAGRAMS

• ignition switch is “OFF”,

• doors, hood and trunk lid/back door are closed,

• pedals are not depressed, and

• parking brake is released.

MULTIPLE SWITCH

The continuity of multiple switch is described in two ways as shown below.

• The switch chart is used in schematic diagrams.

• The switch diagram is used in wiring diagrams.

SGI860

JSAIA0017GB

Revision: April 20092010 QX56

Page 2644 of 4210

![INFINITI QX56 2010 Factory Owners Guide LAN-46

< FUNCTION DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

NOTE:

CAN data of the air bag diagnosis sensor unit is not us

ed by usual service work, thus it is omitted.

Tire pressure data signal R T

T INFINITI QX56 2010 Factory Owners Guide LAN-46

< FUNCTION DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

NOTE:

CAN data of the air bag diagnosis sensor unit is not us

ed by usual service work, thus it is omitted.

Tire pressure data signal R T

T](/img/42/57032/w960_57032-2643.png)

LAN-46

< FUNCTION DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

NOTE:

CAN data of the air bag diagnosis sensor unit is not us

ed by usual service work, thus it is omitted.

Tire pressure data signal R T

Tire pressure signal R TR

Turn indicator signal TR

Buzzer output signal TR

Door lock/unlock request signal RT

Hazard request signal RT

Hazard warning lamp request signal RT

Ignition knob switch signal RT

KEY warning signal TR

LOCK warning signal TR

Panic alarm request signal RT

Power window open request signal RT

1st position switch signal R T

4th position switch signal R T

Distance to empty signal RT

Fuel level low warning signal RT

Fuel level sensor signal R T

Parking brake switch signal RT

Seat belt buckle switch signal RT

Stop lamp switch signal R T

Tow mode switch signal R T

Vehicle speed signal RRR RRR R T

RRRT

Steering angle sensor signal TR

ABS malfunction signal RT

ABS warning lamp signal RT

Brake pressure sensor signal RT

Brake warning lamp signal RT

SLIP indicator lamp signal RT

TCS malfunction signal RT

VDC malfunction signal RT

VDC OFF indicator lamp signal RRT

VDC operation signal RT

Front wiper stop position signal RT

High beam status signal R T

Hood switch signal RT

Low beam status signal R T

Rear window defogger control signal R RT

Signal name/Connecting unit

ECM

TCM

LASER ICC

ADP

AV

BCM

HVAC I-KEY M&A

STRG 4WDABS

IPDM-E

Revision: April 20092010 QX56

Page 2711 of 4210

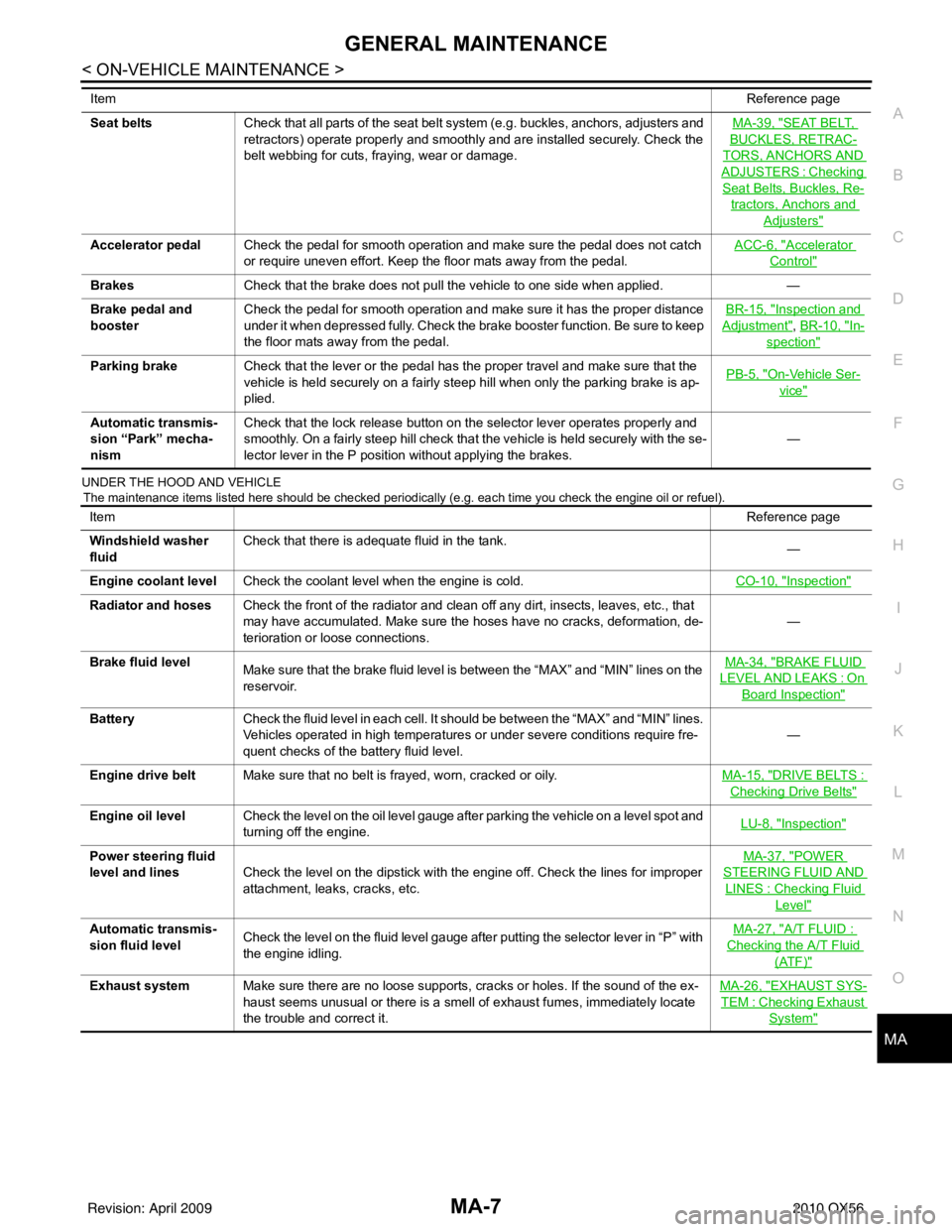

GENERAL MAINTENANCEMA-7

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage. MA-39, "SEAT BELT,

BUCKLES, RETRAC-

TORS, ANCHORS AND

ADJUSTERS : Checking

Seat Belts, Buckles, Re-

tractors, Anchors and

Adjusters"

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. ACC-6, "Accelerator

Control"

Brakes

Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to keep

the floor mats away from the pedal. BR-15, "

Inspection and

Adjustment", BR-10, "In-

spection"

Parking brake

Check that the lever or the pedal has the proper travel and make sure that the

vehicle is held securely on a fairly steep hill when only the parking brake is ap-

plied. PB-5, "On-Vehicle Ser-

vice"

Automatic transmis-

sion “Park” mecha-

nismCheck that the lock release button on the selector lever operates properly and

smoothly. On a fairly steep hill check that the vehicle is held securely with the se-

lector lever in the P position without applying the brakes.

—

Item

Reference page

Item Reference page

Windshield washer

fluid Check that there is adequate fluid in the tank.

—

Engine coolant level Check the coolant level when the engine is cold. CO-10, "

Inspection"

Radiator and hosesCheck the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the hoses have no cracks, deformation, de-

terioration or loose connections. —

Brake fluid level Make sure that the brake fluid level is between the “MAX” and “MIN” lines on the

reservoir. MA-34, "

BRAKE FLUID

LEVEL AND LEAKS : On

Board Inspection"

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require fre-

quent checks of the battery fluid level. —

Engine drive belt Make sure that no belt is frayed, worn, cracked or oily. MA-15, "

DRIVE BELTS :

Checking Drive Belts"

Engine oil levelCheck the level on the oil level gauge after parking the vehicle on a level spot and

turning off the engine. LU-8, "Inspection"

Power steering fluid

level and lines

Check the level on the dipstick with the engine off. Check the lines for improper

attachment, leaks, cracks, etc. MA-37, "POWER

STEERING FLUID AND

LINES : Checking Fluid

Level"

Automatic transmis-

sion fluid level

Check the level on the fluid level gauge after putting the selector lever in “P” with

the engine idling. MA-27, "A/T FLUID :

Checking the A/T Fluid

(ATF)"

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate

the trouble and correct it. MA-26, "EXHAUST SYS-

TEM : Checking Exhaust

System"

Revision: April 20092010 QX56