belt INFINITI QX56 2010 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 1904 of 4210

CAMSHAFTEM-53

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

CAMSHAFT

Exploded ViewINFOID:0000000005149001

Removal and InstallationINFOID:0000000005149002

NOTE:

Do not remove the engine assembly to perform this procedure.

REMOVAL

1. Remove the power steering fluid reservoir tank bolts and position the power steering fluid reservoir tank

aside.

2. Remove the RH bank and LH bank rocker covers. Refer to EM-38, "

Removal and Installation".

3. Remove the spark plugs. Refer to EM-16, "

Removal and Installation".

4. Remove the drive belt. Refer to EM-13, "

Removal and Installation".

AWBIA0819GB

1. Cylinder head RH bank 2. Camshaft bracket (No. 2, 3, 4, 5) 3. Valve lifter

4. Camshaft bracket (No. 1) 5. Seal washer6. Camshaft RH bank EXH

7. Camshaft RH bank INT 8. Camshaft LH bank INT9. Camshaft LH bank EXH

10. Camshaft sprocket RH bank EXH 11. Camshaft sprocket RH bank INT (VTC)12. Camshaft sprocket LH bank INT

(VTC)

13. Camshaft sprocket LH bank EXH 14. Camshaft position sensor (PHASE) 15. O-ring

16. Cylinder head LH bank A. Refer to EM-53

Revision: April 20092010 QX56

Page 1914 of 4210

CAMSHAFTEM-63

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

• Perform this inspection only when

DTC P0011 is detected in self-diagnostic results of CONSULT III

and it is directed according to inspecti on procedure of EC section. Refer to EC-88, "

On Board Diag-

nosis Logic".

1. Check engine oil level. Refer to LU-8, "

Inspection".

2. Perform the following procedure so as to prevent the engine from being unintentionally started while checking.

a. Release fuel pressure. Refer to EC-489, "

Fuel Pressure Check".

b. Disconnect ignition coil and injector harness connectors if practical.

3. Remove IVT control solenoid valve.

4. Crank engine, and then make sure that engine oil comes out from IVT control cover oil hole. End cranking after checking.

WARNING:

Be careful not to touch rotating parts (drive be lts, idler pulley, and crankshaft pulley, etc.).

CAUTION:

• Engine oil may squirt from IVT control solenoid valve installation hole during cranking. Use a

shop cloth to prevent engine oil from splash ing on worker, engine components and vehicle.

• Do not allow engine oil to get on rubber components such as drive belts or engine mount insula- tors. Immediately wipe off any splashed engine oil.

5. Clean oil groove between oil strainer and IVT control solenoid valve if engine oil does not come out from IVT control valve cover oil hole. Refer to LU-7, "

Schematic".

6. Remove components between IVT control solenoid valve and camshaft sprocket (INT), and then check each oil groove for clogging.

• Clean oil groove if necessary.

7. After inspection, installation of the remaining components is in the reverse order of removal.

Revision: April 20092010 QX56

Page 1915 of 4210

EM-64

< ON-VEHICLE REPAIR >

OIL SEAL

OIL SEAL

Removal and Installation of Valve Oil SealINFOID:0000000005149004

REMOVAL

1. Remove the camshaft relating to the valve oil seal to be removed. Refer to EM-53, "Removal and Installa-

tion".

2. Remove the valve lifters. Refer to EM-53, "

Exploded View".

• Correctly identify the location where each part is removed from. Keep parts organized to avoid mixing

them up.

3. Turn the crankshaft until the cylinder requiring new oil seals is at TDC. This will prevent the valve from

dropping into the cylinder.

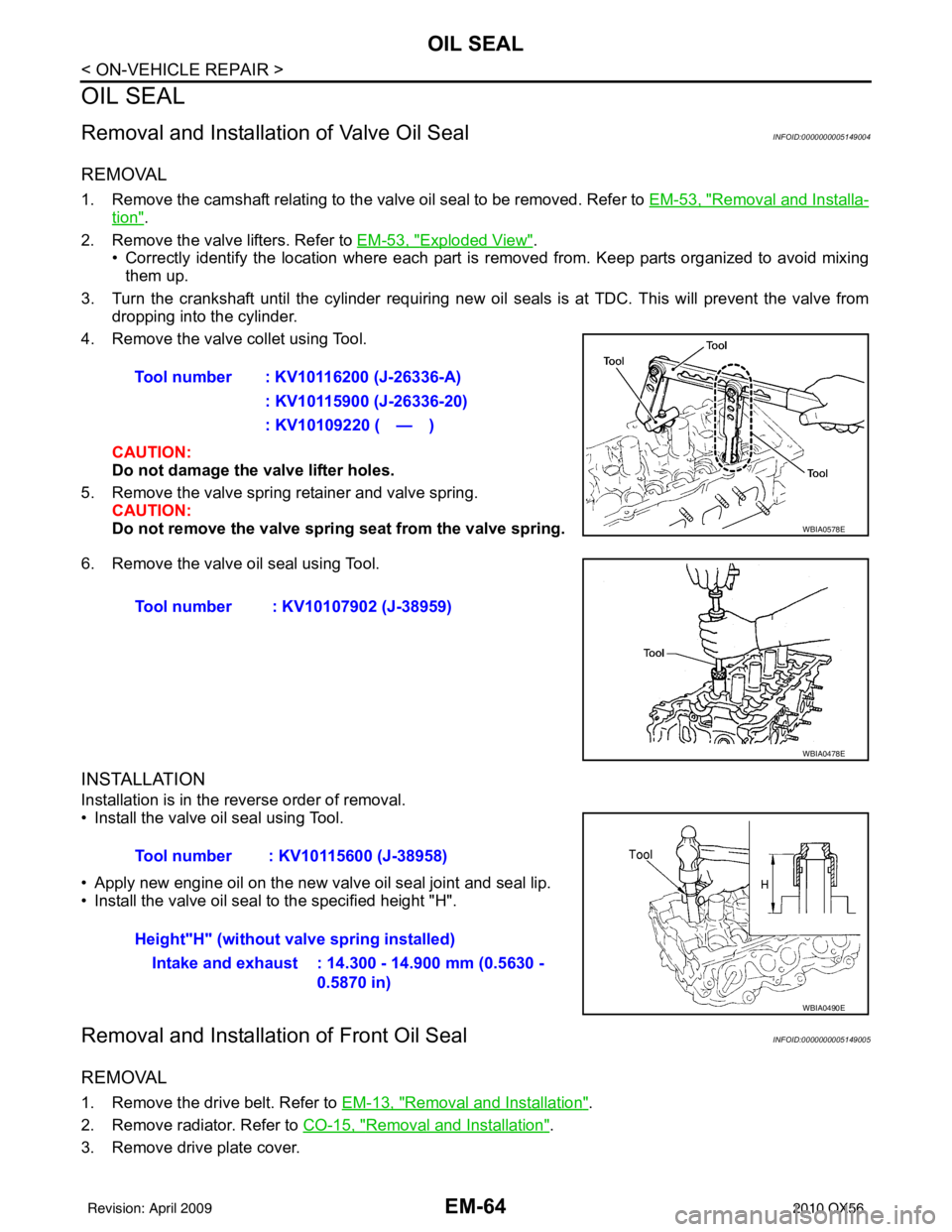

4. Remove the valve collet using Tool.

CAUTION:

Do not damage the valve lifter holes.

5. Remove the valve spring retainer and valve spring. CAUTION:

Do not remove the valve spring seat from the valve spring.

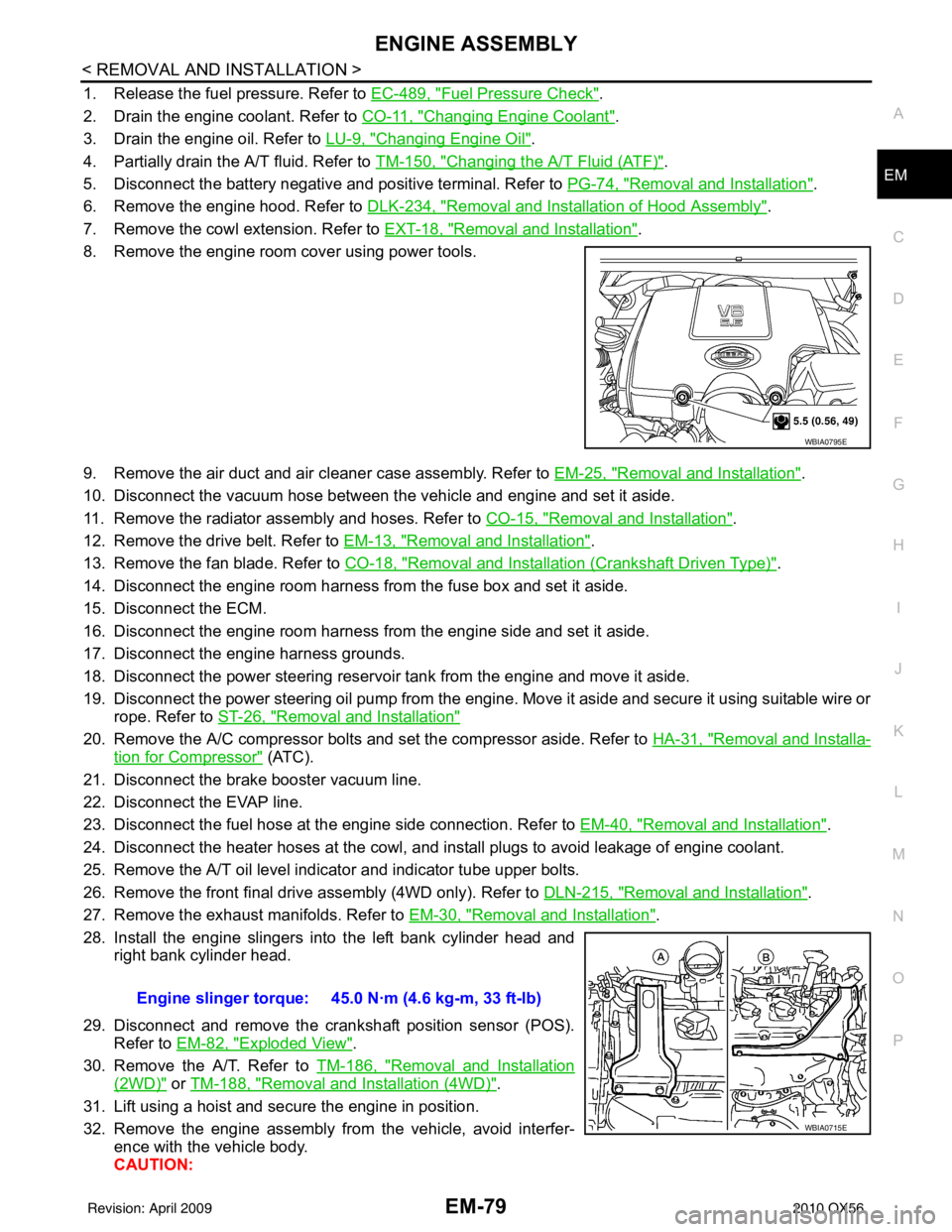

6. Remove the valve oil seal using Tool.

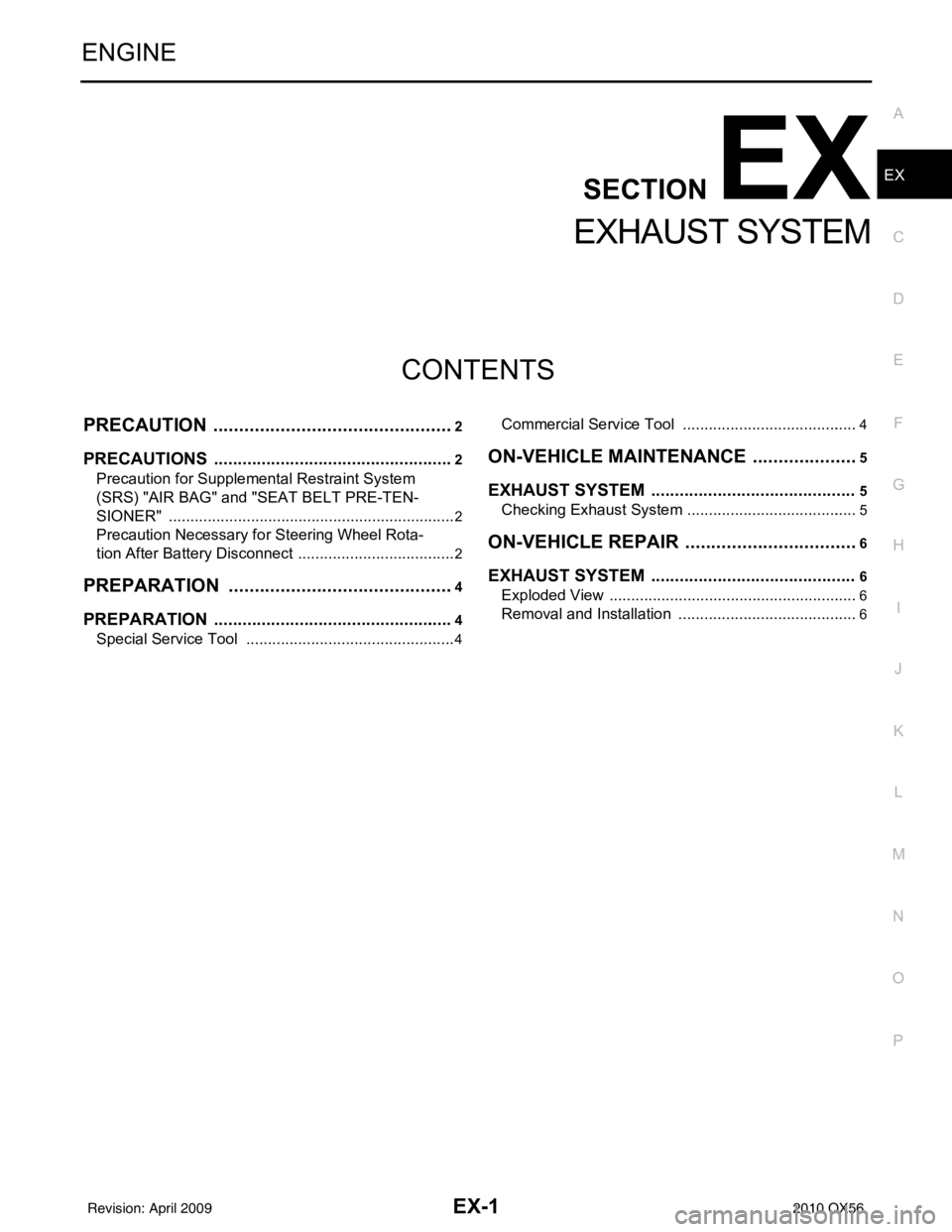

INSTALLATION

Installation is in the reverse order of removal.

• Install the valve oil seal using Tool.

• Apply new engine oil on the new valve oil seal joint and seal lip.

• Install the valve oil seal to the specified height "H".

Removal and Installation of Front Oil SealINFOID:0000000005149005

REMOVAL

1. Remove the drive belt. Refer to EM-13, "Removal and Installation".

2. Remove radiator. Refer to CO-15, "

Removal and Installation".

3. Remove drive plate cover. Tool number : KV10116200 (J-26336-A)

: KV10115900 (J-26336-20)

: KV10109220 ( — )

WBIA0578E

Tool number : KV10107902 (J-38959)

WBIA0478E

Tool number : KV10115600 (J-38958)

Height"H" (without valve spring installed)Intake and exhaust : 14.300 - 14.900 mm (0.5630 - 0.5870 in)

WBIA0490E

Revision: April 20092010 QX56

Page 1919 of 4210

EM-68

< ON-VEHICLE REPAIR >

CYLINDER HEAD

CYLINDER HEAD

Exploded ViewINFOID:0000000005149007

Removal and InstallationINFOID:0000000005149008

REMOVAL

1. Remove the engine assembly from the vehicle. Refer to EM-78, "Removal and Installation".

2. Remove the following components and related parts: • Drive belt auto tensioner drive belts and idler pulley. Refer to EM-14, "

Drive Belt Auto Tensioner and

Idler Pulley".

• Thermostat housing and hose. Refer to CO-22, "

Removal and Installation".

• Oil pan and oil strainer. Refer to EM-33, "

Removal and Installation".

• Fuel tube and fuel injector assembly. Refer to EM-40, "

Removal and Installation".

• Intake manifold. Refer to EM-26, "

Removal and Installation".

• Rocker cover. Refer to EM-38, "

Removal and Installation".

3. Remove the crankshaft pulley, front cover, oil pump, and timing chain. Refer to EM-45, "

Removal and

Installation".

4. Remove the camshaft sprockets and camshafts. Refer to EM-53, "

Removal and Installation".

5. Remove the cylinder head bolts in reverse of order shown.

6. Remove the cylinder heads.

INSPECTION AFTER REMOVAL

Cylinder Head Bolts Diameter

1. Harness bracket 2. Engine coolant temperature sensor 3. Washer

4. Cylinder head gasket (LH) 5. Cylinder head (RH) 6. Cylinder head bolt

7. Cylinder head gasket (RH) 8. Cylinder head (LH)

KBIA2528E

PBIC0068E

Revision: April 20092010 QX56

Page 1930 of 4210

ENGINE ASSEMBLYEM-79

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

1. Release the fuel pressure. Refer to

EC-489, "Fuel Pressure Check".

2. Drain the engine coolant. Refer to CO-11, "

Changing Engine Coolant".

3. Drain the engine oil. Refer to LU-9, "

Changing Engine Oil".

4. Partially drain the A/T fluid. Refer to TM-150, "

Changing the A/T Fluid (ATF)".

5. Disconnect the battery negative and positive terminal. Refer to PG-74, "

Removal and Installation".

6. Remove the engine hood. Refer to DLK-234, "

Removal and Installation of Hood Assembly".

7. Remove the cowl extension. Refer to EXT-18, "

Removal and Installation".

8. Remove the engine room cover using power tools.

9. Remove the air duct and air cleaner case assembly. Refer to EM-25, "

Removal and Installation".

10. Disconnect the vacuum hose between the vehicle and engine and set it aside.

11. Remove the radiator assembly and hoses. Refer to CO-15, "

Removal and Installation".

12. Remove the drive belt. Refer to EM-13, "

Removal and Installation".

13. Remove the fan blade. Refer to CO-18, "

Removal and Installation (Crankshaft Driven Type)".

14. Disconnect the engine room harness from the fuse box and set it aside.

15. Disconnect the ECM.

16. Disconnect the engine room harness from the engine side and set it aside.

17. Disconnect the engine harness grounds.

18. Disconnect the power steering reservoir t ank from the engine and move it aside.

19. Disconnect the power steering oil pump from the engine. Move it aside and secure it using suitable wire or rope. Refer to ST-26, "

Removal and Installation"

20. Remove the A/C compressor bolts and set the compressor aside. Refer to HA-31, "Removal and Installa-

tion for Compressor" (ATC).

21. Disconnect the brake booster vacuum line.

22. Disconnect the EVAP line.

23. Disconnect the fuel hose at the engine side connection. Refer to EM-40, "

Removal and Installation".

24. Disconnect the heater hoses at the cowl, and in stall plugs to avoid leakage of engine coolant.

25. Remove the A/T oil level indicator and indicator tube upper bolts.

26. Remove the front final drive assembly (4WD only). Refer to DLN-215, "

Removal and Installation".

27. Remove the exhaust manifolds. Refer to EM-30, "

Removal and Installation".

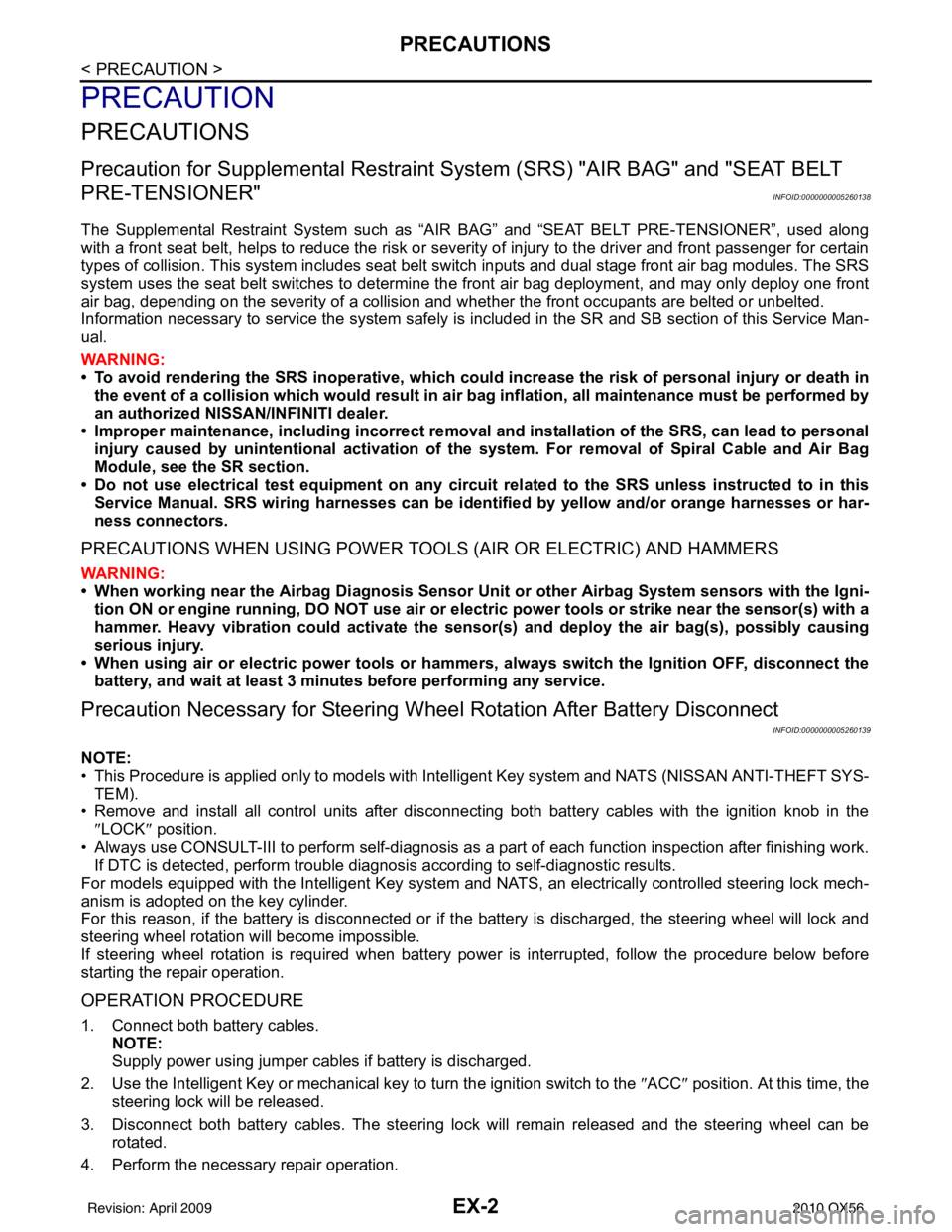

28. Install the engine slingers into the left bank cylinder head and right bank cylinder head.

29. Disconnect and remove the crankshaft position sensor (POS). Refer to EM-82, "

Exploded View".

30. Remove the A/T. Refer to TM-186, "

Removal and Installation

(2WD)" or TM-188, "Removal and Installation (4WD)".

31. Lift using a hoist and secure the engine in position.

32. Remove the engine assembly from the vehicle, avoid interfer- ence with the vehicle body.

CAUTION:

WBIA0795E

Engine slinger torque: 45.0 N·m (4.6 kg-m, 33 ft-lb)

WBIA0715E

Revision: April 20092010 QX56

Page 1959 of 4210

EM-108

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000005149018

GENERAL SPECIFICATIONS

DRIVE BELTS

EXHAUST MANIFOLD

Cylinder arrangementV- 8

Displacement cm

3(in3) 5,552 (338.80)

Bore and stroke mm (in) 98 x 92 (3.86 x 3.62)

Valve arrangement DOHC

Firing order 1-8-7-3-6-5-4-2

Number of piston rings Compression

2

Oil 1

Number of main bearings 5

Compression ratio 9.8:1

Compression pressure

kPa (kg/cm

2, psi)/rpm Standard 1,520 (15.5, 220)/200

Minimum

1,324 (13.5, 192)/200

Differential limit between cylinders 98 (1.0, 14)/200

Cylinder number

Valve timing Unit: degree

abcde f

244 ° 232° -8° 60° 10° 54°

SEM957C

PBIC0187E

Tension of drive belts Auto adjustment by auto tensioner

Revision: April 20092010 QX56

Page 1970 of 4210

EX-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EX

A

EX

N

O P

CONTENTS

EXHAUST SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool .................................... .....4

ON-VEHICLE MAINTENANCE .....................5

EXHAUST SYSTEM ...........................................5

Checking Exhaust System ................................... .....5

ON-VEHICLE REPAIR ..................................6

EXHAUST SYSTEM ...........................................6

Exploded View ..................................................... .....6

Removal and Installation ..........................................6

Revision: April 20092010 QX56

Page 1971 of 4210

EX-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005260138

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005260139

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 1979 of 4210

EXL-3

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

PRECAUTION ....... .....................................143

PRECAUTIONS .............................................. ..143

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

143

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

143

General precautions for service operations ..........144

ON-VEHICLE REPAIR .... ...........................145

ADJUSTMENT AND INSPECTION ................ ..145

HEADLAMP ........................................................... ..145

HEADLAMP : Aiming Adjustment .........................145

FRONT FOG LAMP ............................................... ..146

FRONT FOG LAMP : Aiming Adjustment .............146

REMOVAL AND INSTALLATION .............148

HEADLAMP .................................................... ..148

Bulb Replacement .................................................148

Removal and Installation .......................................149

Disassembly and Assembly ................................ ..149

AUTO LIGHT SYSTEM ....................................151

Removal and Installation .......................................151

FRONT FOG LAMP ........................................152

Bulb Replacement ............................................... ..152

Removal and Installation .......................................152

LIGHTING & TURN SIGNAL SWITCH ...........154

Removal and Installation .......................................154

HAZARD SWITCH ..........................................155

Removal and Installation .......................................155

LICENSE PLATE LAMP .................................156

Bulb Replacement .................................................156

Removal and Installation .......................................156

STOP LAMP ....................................................157

Bulb Replacement .................................................157

Removal and Installation .......................................157

REAR COMBINATION LAMP .........................158

Bulb Replacement .................................................158

Removal and Installation .......................................158

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... .

159

BULB SPECIFICATIONS ................................159

Headlamp ............................................................ ..159

Exterior Lamp ........................................................159

Revision: April 20092010 QX56

Page 2119 of 4210

PRECAUTIONSEXL-143

< PRECAUTION >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005369809

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005369810

NOTE:

• Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

• After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnect ed or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Carry the Intelligent Key or insert it to the key slot and turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon- nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56