fuse INFINITI QX56 2010 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 1874 of 4210

COMPRESSION PRESSUREEM-23

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

COMPRESSION PRESSURE

Checking Compression PressureINFOID:0000000005148983

1. Warm up the engine thoroughly. Then stop the engine.

2. Release the fuel pressure. Refer to EC-489, "

Fuel Pressure Check".

CAUTION:

If CONSULT-III is not used to release fuel pressure leave the fuel pump fuse disconnected until

step 7.

3. Remove the spark plug from each cylinder. Refer to EM-16, "

Removal and Installation".

4. Connect the engine tachometer (not required in use of CONSULT-III).

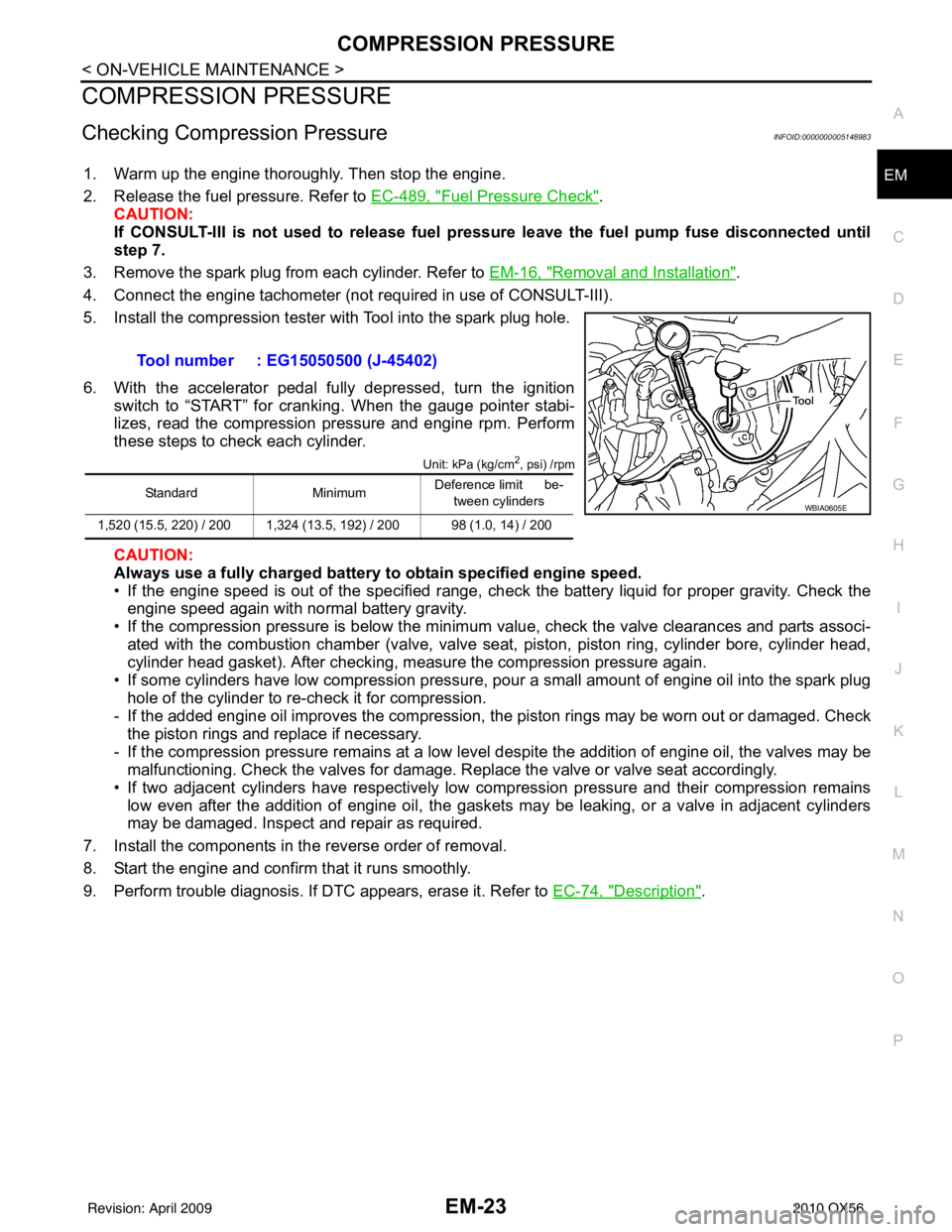

5. Install the compression tester with Tool into the spark plug hole.

6. With the accelerator pedal fully depressed, turn the ignition switch to “START” for cranking. When the gauge pointer stabi-

lizes, read the compression pressure and engine rpm. Perform

these steps to check each cylinder.

Unit: kPa (kg/cm2, psi) /rpm

CAUTION:

Always use a fully charged battery to obtain specified engine speed.

• If the engine speed is out of the specified range, check the battery liquid for proper gravity. Check the engine speed again with normal battery gravity.

• If the compression pressure is below the minimum value, check the valve clearances and parts associ-

ated with the combustion chamber (valve, valve seat , piston, piston ring, cylinder bore, cylinder head,

cylinder head gasket). After checking, measure the compression pressure again.

• If some cylinders have low compression pressure, pour a small amount of engine oil into the spark plug hole of the cylinder to re-check it for compression.

- If the added engine oil improves the compression, t he piston rings may be worn out or damaged. Check

the piston rings and replace if necessary.

- If the compression pressure remains at a low level despite the addition of engine oil, the valves may be malfunctioning. Check the valves for damage. Replace the valve or valve seat accordingly.

• If two adjacent cylinders have respectively low compression pressure and their compression remains low even after the addition of engine oil, the gaskets may be leaking, or a valve in adjacent cylinders

may be damaged. Inspect and repair as required.

7. Install the components in the reverse order of removal.

8. Start the engine and confirm that it runs smoothly.

9. Perform trouble diagnosis. If DTC appears, erase it. Refer to EC-74, "

Description".

Tool number : EG15050500 (J-45402)

Standard

MinimumDeference limit be-

tween cylinders

1,520 (15.5, 220) / 200 1,324 (13.5, 192) / 200 98 (1.0, 14) / 200WBIA0605E

Revision: April 20092010 QX56

Page 1930 of 4210

ENGINE ASSEMBLYEM-79

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

1. Release the fuel pressure. Refer to

EC-489, "Fuel Pressure Check".

2. Drain the engine coolant. Refer to CO-11, "

Changing Engine Coolant".

3. Drain the engine oil. Refer to LU-9, "

Changing Engine Oil".

4. Partially drain the A/T fluid. Refer to TM-150, "

Changing the A/T Fluid (ATF)".

5. Disconnect the battery negative and positive terminal. Refer to PG-74, "

Removal and Installation".

6. Remove the engine hood. Refer to DLK-234, "

Removal and Installation of Hood Assembly".

7. Remove the cowl extension. Refer to EXT-18, "

Removal and Installation".

8. Remove the engine room cover using power tools.

9. Remove the air duct and air cleaner case assembly. Refer to EM-25, "

Removal and Installation".

10. Disconnect the vacuum hose between the vehicle and engine and set it aside.

11. Remove the radiator assembly and hoses. Refer to CO-15, "

Removal and Installation".

12. Remove the drive belt. Refer to EM-13, "

Removal and Installation".

13. Remove the fan blade. Refer to CO-18, "

Removal and Installation (Crankshaft Driven Type)".

14. Disconnect the engine room harness from the fuse box and set it aside.

15. Disconnect the ECM.

16. Disconnect the engine room harness from the engine side and set it aside.

17. Disconnect the engine harness grounds.

18. Disconnect the power steering reservoir t ank from the engine and move it aside.

19. Disconnect the power steering oil pump from the engine. Move it aside and secure it using suitable wire or rope. Refer to ST-26, "

Removal and Installation"

20. Remove the A/C compressor bolts and set the compressor aside. Refer to HA-31, "Removal and Installa-

tion for Compressor" (ATC).

21. Disconnect the brake booster vacuum line.

22. Disconnect the EVAP line.

23. Disconnect the fuel hose at the engine side connection. Refer to EM-40, "

Removal and Installation".

24. Disconnect the heater hoses at the cowl, and in stall plugs to avoid leakage of engine coolant.

25. Remove the A/T oil level indicator and indicator tube upper bolts.

26. Remove the front final drive assembly (4WD only). Refer to DLN-215, "

Removal and Installation".

27. Remove the exhaust manifolds. Refer to EM-30, "

Removal and Installation".

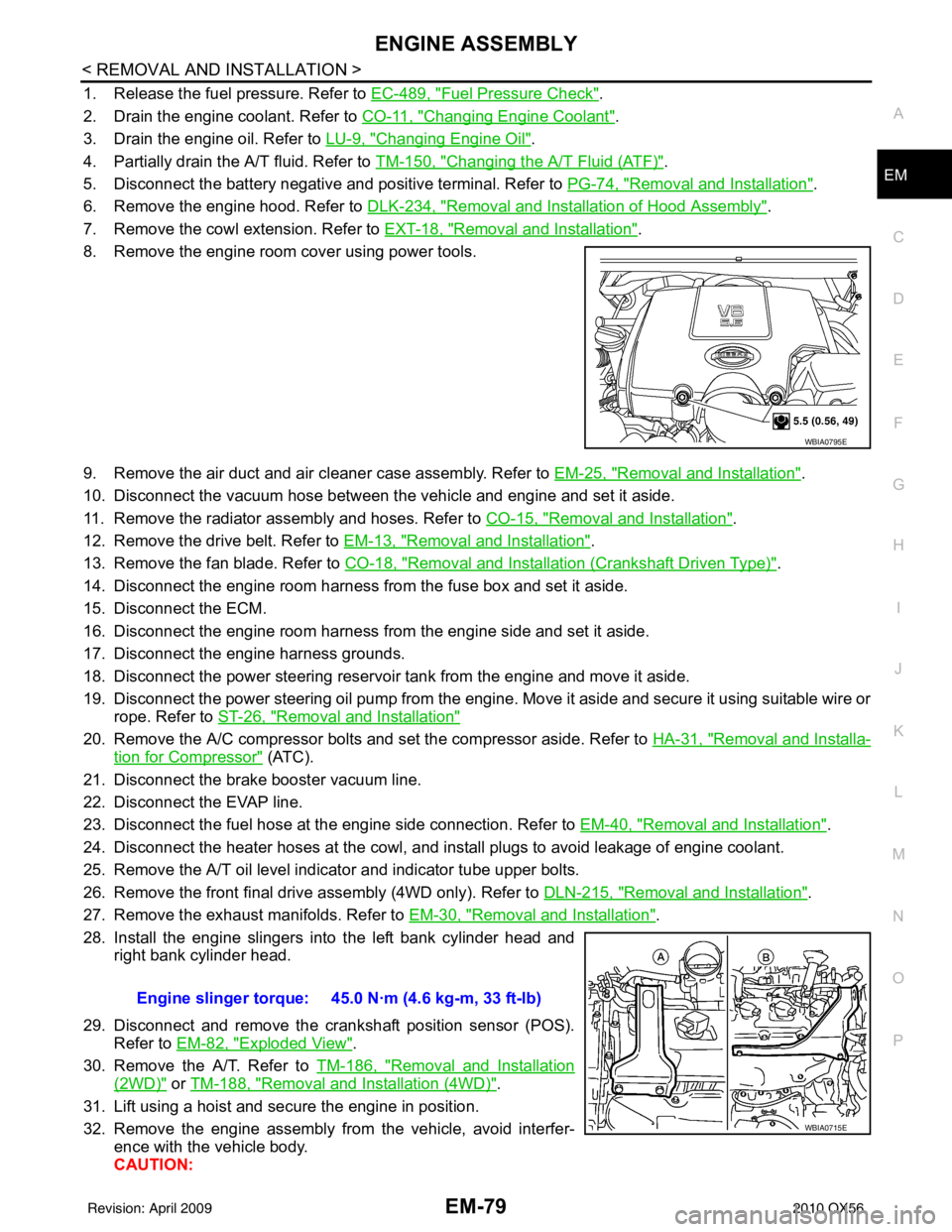

28. Install the engine slingers into the left bank cylinder head and right bank cylinder head.

29. Disconnect and remove the crankshaft position sensor (POS). Refer to EM-82, "

Exploded View".

30. Remove the A/T. Refer to TM-186, "

Removal and Installation

(2WD)" or TM-188, "Removal and Installation (4WD)".

31. Lift using a hoist and secure the engine in position.

32. Remove the engine assembly from the vehicle, avoid interfer- ence with the vehicle body.

CAUTION:

WBIA0795E

Engine slinger torque: 45.0 N·m (4.6 kg-m, 33 ft-lb)

WBIA0715E

Revision: April 20092010 QX56

Page 1955 of 4210

EM-104

< DISASSEMBLY AND ASSEMBLY >

HOW TO SELECT PISTON AND BEARING

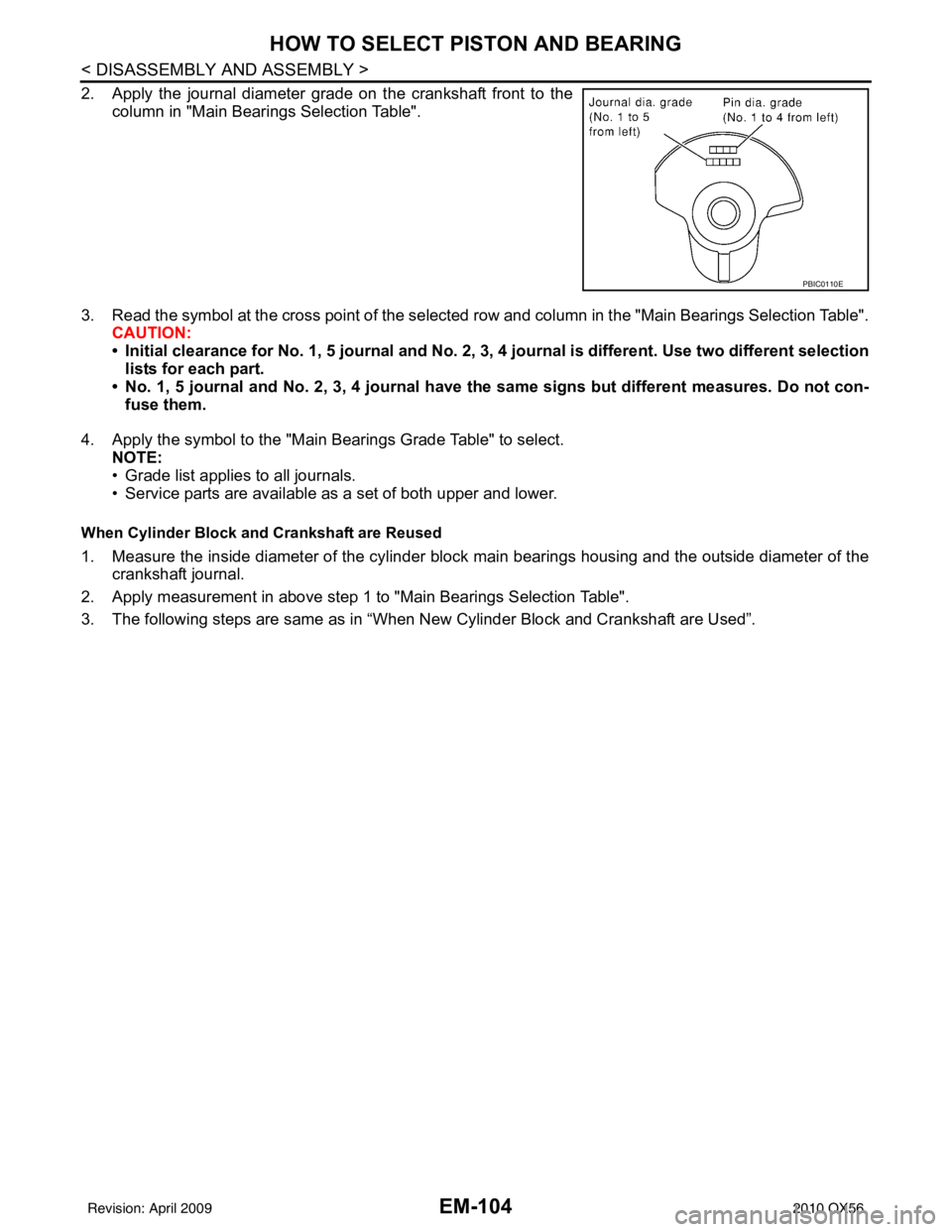

2. Apply the journal diameter grade on the crankshaft front to thecolumn in "Main Bearings Selection Table".

3. Read the symbol at the cross point of the selected row and column in the "Main Bearings Selection Table".

CAUTION:

• Initial clearance for No. 1, 5 journal and No. 2, 3, 4 journal is different. Use two different selection

lists for each part.

• No. 1, 5 journal and No. 2, 3, 4 journal have the same signs but different measures. Do not con-

fuse them.

4. Apply the symbol to the "Main Bearings Grade Table" to select. NOTE:

• Grade list applies to all journals.

• Service parts are available as a set of both upper and lower.

When Cylinder Block and Crankshaft are Reused

1. Measure the inside diameter of the cylinder block main bearings housing and the outside diameter of the

crankshaft journal.

2. Apply measurement in above step 1 to "Main Bearings Selection Table".

3. The following steps are same as in “When New Cylinder Block and Crankshaft are Used”.

PBIC0110E

Revision: April 20092010 QX56

Page 1986 of 4210

EXL-10

< FUNCTION DIAGNOSIS >

DAYTIME LIGHT SYSTEM

Component Description

INFOID:0000000005369870

After starting the engine with the parking brake releas ed and the combination switch (lighting and turn signal

switch) in the OFF or 1ST position, the headlamp high beam automatically turns on at a reduced intensity.

With the combination switch (lighting and turn signal switch) in the 2nd position or with autolamps ON, the

headlamps function the same as conventional light systems.

OPERATION

The BCM monitors inputs from the parking brake swit ch and the combination switch (lighting and turn signal

switch) to determine when to activate the daytime light system. The BCM sends a daytime light request to the

IPDM E/R via the CAN communication lines. The IPDM E/ R grounds the daytime light relay which in turn, pro-

vides power to the ground side of the LH high beam lamp. Power flows backward through the LH high beam

lamp to the IPDM E/R, through the high beam fuses, through the RH high beam lamp circuit to the RH high

beam lamp and on to ground. The high beam lamps are wired in series which causes them to illuminate at a

reduced intensity.

1. IPDM E/R E119, E122, E123, E124 2. BCM M18, M20 (view with instrument

panel removed)3. Daytime light relay E103

4. Combination switch (lighting and turn signal switch) M28 5. Combination meter M23, M24 6. Parking brake switch M11

Revision: April 20092010 QX56

Page 2003 of 4210

POWER SUPPLY AND GROUND CIRCUITEXL-27

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

COMPONENT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

BCM (BODY CONTROL MODULE)

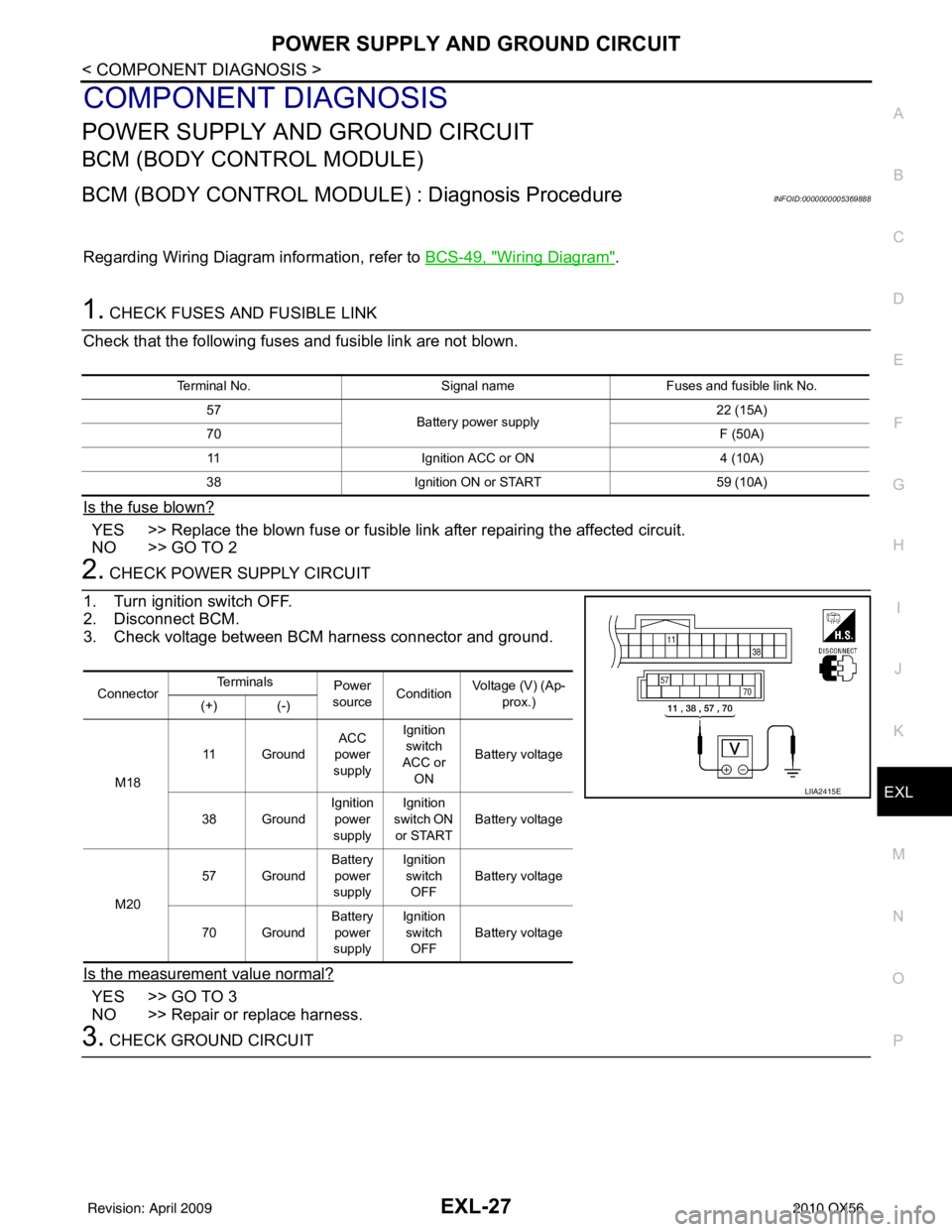

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000005369888

Regarding Wiring Diagram information, refer to BCS-49, "Wiring Diagram".

1. CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

Terminal No. Signal nameFuses and fusible link No.

57 Battery power supply 22 (15A)

70 F (50A)

11 Ignition ACC or ON 4 (10A)

38 Ignition ON or START 59 (10A)

ConnectorTe r m i n a l s

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON

or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch OFF Battery voltage

LIIA2415E

Revision: April 20092010 QX56

Page 2004 of 4210

EXL-28

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> Inspection End.

NO >> Repair or replace harness.

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DIST RIBUTION MODULE ENGINE ROOM) : Di-

agnosis Procedure

INFOID:0000000005369889

Regarding Wiring Diagram information, refer to PCS-27, "Wiring Diagram".

1. CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK BATTERY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R.

3. Check voltage between IPDM E/R harness connectors and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

BCM

GroundContinuity

Connector Terminal

M20 67 Yes

LIIA0915E

Terminal No. Signal nameFuses and fusible link No.

1 Battery A, D

2 Battery C

12 Ignition switch ON or START 59

TerminalsIgnition switch position

(+) (−) OFF ON START

Connector Terminal

E118 (A) 1

Ground Battery

voltage Battery

voltage Battery

voltage

2 Battery

voltage Battery

voltage Battery

voltage

E119 (B) 12 0VBattery

voltage Battery

voltage

AWMIA0023ZZ

Revision: April 20092010 QX56

Page 2006 of 4210

EXL-30

< COMPONENT DIAGNOSIS >

HEADLAMP (HI) CIRCUIT

HEADLAMP (HI) CIRCUIT

DescriptionINFOID:0000000005370270

The IPDM E/R (intelligent power distribution module engine room) controls the headlamp LH high and head-

lamp RH high relays based on inputs from the BCM via the CAN communication lines. When the headlamp LH

high and headlamp RH high relays are energized, power flows through fuse\

s 34 and 35, located in the IPDM

E/R. Power then flows to the front combination lamps to the headlamp high beam.

Component Function CheckINFOID:0000000005146640

1.CHECK HEADLAMP (HI) OPERATION

WITHOUT CONSULT-III

1. Start IPDM E/R auto active test. Refer to PCS-12, "

Diagnosis Description".

2. Check that the headlamp switches to the high beam. NOTE:

HI/LO is repeated 1 second each when usi ng the IPDM E/R auto active test.

CONSULT-III

1. Select "EXTERNAL LAMPS" of IPDM E/R active test item.

2. With the test item operating, check that the headlamp switches to high beam.

Does the headlamp switch to high beam?

YES >> Headlamp (HI) circuit is normal.

NO >> Refer to EXL-30, "

Diagnosis Procedure - Without Daytime Light System", EXL-31, "Diagnosis

Procedure - With Daytime Light System".

Diagnosis Procedure - Wit hout Daytime Light SystemINFOID:0000000005146641

Regarding Wiring Diagram information, refer to EXL-52, "Wiring Diagram".

1.CHECK HEADLAMP (HI) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not open.

Is the fuse open?

YES >> Repair the harness and replace the fuse.

NO >> GO TO 2.

2.CHECK HEADLAMP (HI) OUTPUT VOLTAGE Hi : Headlamp switches to the high beam.

Off : Headlamp OFF

Unit

LocationFuse No.Capacity

Headlamp HI (LH) IPDM E/R3510A

Headlamp HI (RH) IPDM E/R3410A

Revision: April 20092010 QX56

Page 2007 of 4210

HEADLAMP (HI) CIRCUITEXL-31

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector E11 or E107.

3. Turn the ignition switch ON.

4. Turn the high beam headlamps ON.

5. With the high beam headlamps ON, check the voltage between the combination lamp connector and ground.

Are the voltage readings as specified?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK HEADLAMP (HI) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E123.

3. Check continuity between the IPDM E/R harness connector (A) and the front combination lamp harness connector (B).

Does continuity exist?

YES >> GO TO 4.

NO >> Repair the harnesses or connectors.

4.CHECK FRONT COMBINATION LAMP (HI) GROUND CIRCUIT

Check continuity between the front combination lamp harness con-

nector terminal and ground.

Does continuity exist?

YES >> Inspect the headlamp bulb.

NO >> Repair the harness.

Diagnosis Procedure - With Daytime Light SystemINFOID:0000000005146642

Regarding Wiring Diagram information, refer to EXL-56, "Wiring Diagram".

1.CHECK HEADLAMP (HI) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not open.

(+) (−)Voltage

Connector Terminal

LH E11 6 Ground Battery voltage

RH E107 6

ALLIA0852ZZ

AB Continuity

Connector Terminal Connector Terminal

LH E123 55

E11 6

Ye s

RH 56E107 6

AWLIA1371ZZ

Connector Terminal —Continuity

LH E11 2

Ground Yes

RH E107 2

ALLIA0854ZZ

Revision: April 20092010 QX56

Page 2008 of 4210

EXL-32

< COMPONENT DIAGNOSIS >

HEADLAMP (HI) CIRCUIT

Is the fuse open?

YES >> Repair the harness and replace the fuse.

NO >> GO TO 2.

2.CHECK HEADLAMP (HI) OUTPUT VOLTAGE

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector E6 or E108.

3. Turn the ignition switch ON.

4. Turn the high beam headlamps ON.

5. With the high beam headlamps ON, check the voltage between the combination lamp connector and ground.

Are the voltage readings as specified?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK HEADLAMP (HI) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E123.

3. Check continuity between the IPDM E/R harness connector (A) and the front combination lamp harness connector (B).

Does continuity exist?

YES >> GO TO 4.

NO >> Repair the harnesses or connectors.

4.CHECK FRONT COMBINATION LAMP (HI) GROUND CIRCUIT

Check continuity between the front combination lamp harness con-

nector terminal and ground.

Does continuity exist?

YES >> Inspect the headlamp bulb.

NO - RH>>Repair the harness.

NO - LH >>Inspect daytime light rela y. If OK, repair harness. If NG,

replace the daytime light relay.

Unit LocationFuse No.Capacity

Headlamp HI (LH) IPDM E/R3510A

Headlamp HI (RH) IPDM E/R3410A

(+)

(−)Voltage

Connector Terminal

LH E6 6 GroundBattery voltage

RH E108 6

ALLIA0852ZZ

AB

Continuity

Connector Terminal Connector Terminal

LH E123 55

E66

Ye s

RH 56E108 6

AWLIA1371ZZ

Connector Terminal —Continuity

LH E6 2

Ground Yes

RH E108 2

ALLIA0854ZZ

Revision: April 20092010 QX56

Page 2009 of 4210

HEADLAMP (LO) CIRCUITEXL-33

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

HEADLAMP (LO) CIRCUIT

DescriptionINFOID:0000000005146643

The IPDM E/R (intelligent power distribution modul e engine room) controls the headlamp low relay based on

inputs from the BCM via the CAN communication li nes. When the headlamp low relay is energized, power

flows through fuses 40 and 41, located in the IPDM E/R. Power then flows to the front combination lamps to

the headlamp low beam.

Component Function CheckINFOID:0000000005146644

1.CHECK HEADLAMP (LO) OPERATION

WITHOUT CONSULT-III

1. Start IPDM E/R auto active test. Refer to PCS-12, "

Diagnosis Description".

2. Check that the headlamp is turned ON. NOTE:

HI/LO is repeated 1 second each when using the IPDM E/R auto active test.

CONSULT-III

1. Select "EXTERNAL LAMPS" of IPDM E/R active test item.

2. With the test items operating, c heck that the headlamp is turned ON.

Is the headlamp turned ON?

YES >> Headlamp (LO) is normal.

NO >> Refer to EXL-33, "

Diagnosis Procedure - Without Daytime Light System", EXL-34, "Diagnosis

Procedure - With Daytime Light System".

Diagnosis Procedure - Without Daytime Light SystemINFOID:0000000005146645

Regarding Wiring Diagram information, refer to EXL-52, "Wiring Diagram".

1.CHECK HEADLAMP (LO) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not open.

Is the fuse open?

YES >> Repair the harness and replace the fuse.

NO >> GO TO 2.

2.CHECK HEADLAMP (LO) OUTPUT VOLTAGE Lo : Headlamp ON

Off : Headlamp OFF

Unit

LocationFuse No.Capacity

Headlamp LO (LH) IPDM E/R4015A

Headlamp LO (RH) IPDM E/R4115A

Revision: April 20092010 QX56