INFINITI QX56 2010 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 751 of 4210

CHG

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM OPERATION

INSPECTION

CHG-9

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

POWER GENERATION VOLTAGE VARI

ABLE CONTROL SYSTEM OPER-

ATION INSPECTION

Diagnosis ProcedureINFOID:0000000005146558

Regarding Wiring Diagram information, refer to CHG-14, "Wiring Diagram".

CAUTION:

When performing this inspection, always use a charged battery that has completed the battery inspec-

tion. (When the charging rate of the battery is low, the response speed of the voltage change will

become slow. This can cause an incorrect inspection.)

1.CHECK ECM (CONSULT-III)

Perform ECM self-diagnosis with CONSULT-III. Refer to EC-63, "

CONSULT-III Function (ENGINE)".

Self

-diagnostic results content

No malfunction detected>> GO TO 2.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

2.CHECK OPERATION OF POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

1. Connect CONSULT-III and start the engine.

2. The selector lever is in “P” or “N” position and a ll of the electric loads and A/C, etc. are turned OFF.

3. Select “ALTERNATOR DUTY” in “Active Test” of “ENGINE”, and then check the value of “BATTERY

VOLT” monitor when DUTY value of “ALTERNATOR DUTY” is set to 40.0 %.

4. Check the value of “BATTERY VOLT” monitor when DUTY value of “ALTERNATOR DUTY” is set to 80.0%.

Is the measurement val ue within specification?

YES >> Inspection End.

NO >> GO TO 3.

3.CHECK IPDM E/R (CONSULT-III)

Perform IPDM E/R self-diagnosis with CONSULT-III. Refer to PCS-14, "

CONSULT - III Function (IPDM E/R)".

Self

-diagnostic results content

No malfunction detected>> GO TO 4.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

4.CHECK HARNESS BETWEEN GE NERATOR AND IPDM E/R

“BATTERY VOLT”

2 seconds after setting the

DUTY value of “ALTERNA-

TOR DUTY” to 40.0 %

: 12 - 13.6 V

“BATTERY VOLT”

20 seconds after setting

the DUTY value of “ALTER-

NATOR DUTY” to 80.0 % : +0.5 V or more against

the value of “BATTERY

VOLT” monitor when

DUTY value is 40.0 %

Revision: April 20092010 QX56

Page 752 of 4210

CHG-10

< COMPONENT DIAGNOSIS >

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM OPERATION

INSPECTION

1. Turn ignition switch OFF.

2. Disconnect generator connector E205 and IPDM E/R connector

E122.

3. Check continuity between generator harness connector E205 (A) terminal 4 and IPDM E/R harness connector E122 (B) termi-

nal 37.

4. Check continuity between generator harness connector E122 (A) terminal 4 and ground.

Are the continuity test results as specified?

YES >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation of IPDM E/R".

NO >> Repair harness or connector between IPDM E/R and generator.

AB Continuity

Connector Terminal Connector Terminal

E205 4E122 37Yes

A —Contin u it y

Connector Terminal

E205 4Ground No

ALMIA0196ZZ

Revision: April 20092010 QX56

Page 753 of 4210

CHG

B TERMINAL CIRCUITCHG-11

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

B TERMINAL CIRCUIT

DescriptionINFOID:0000000005146559

The terminal “1” circuit supplies power to charge the battery and operate the vehicles electrical system.

Diagnosis ProcedureINFOID:0000000005146560

Regarding Wiring Diagram information, refer to

CHG-14, "Wiring Diagram".

1.CHECK TERMINAL “1” CONNECTION

1. Turn ignition switch OFF.

2. Verify terminal “1” is clean and tight.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair terminal “1” connection. Confirm repa ir by performing complete Starting/Charging system

test. Refer to diagnostic station instruction manual.

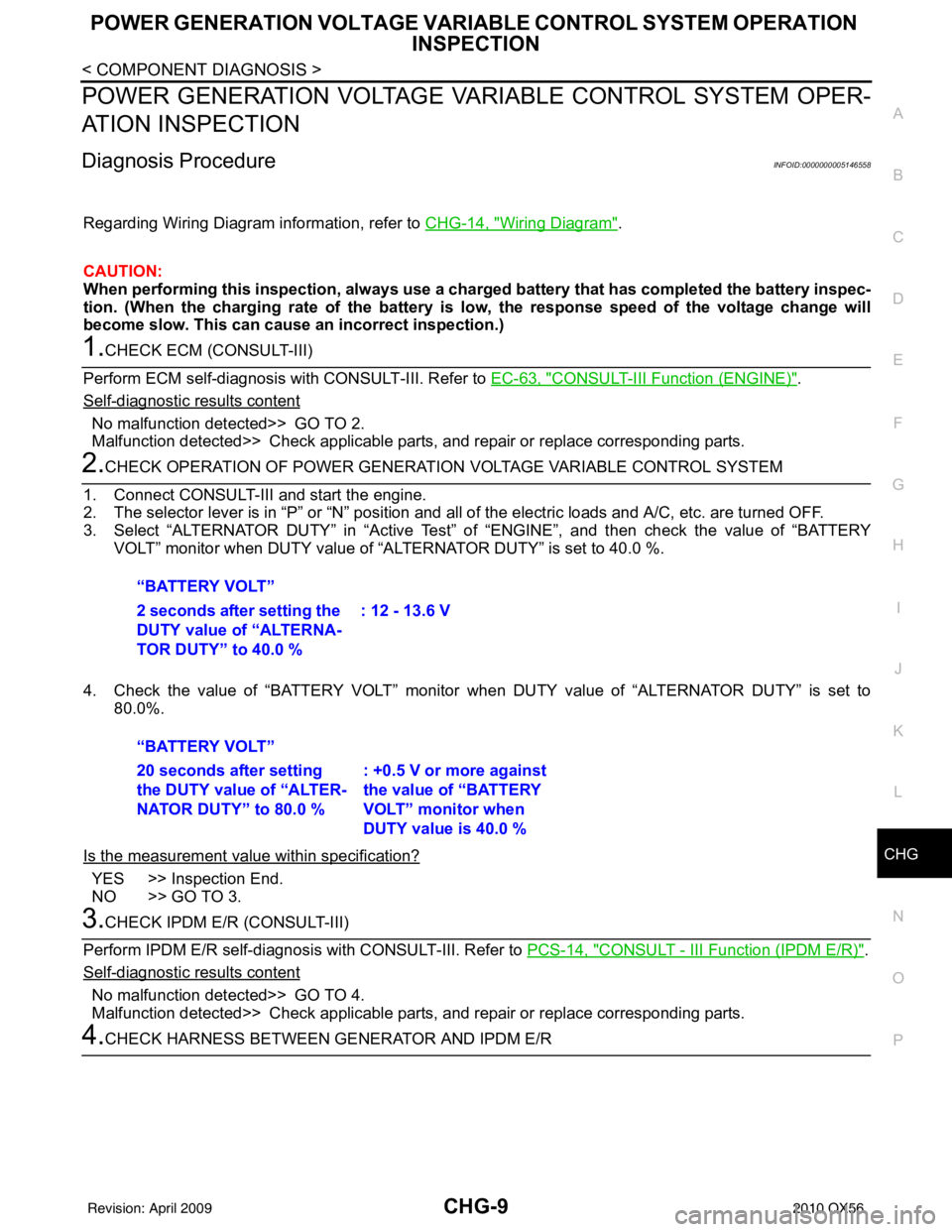

2.CHECK TERMINAL “1” CIRCUIT

Check voltage between generator connector E204 terminal 1 and

ground.

Is voltage reading as specified?

YES >> GO TO 3.

NO >> Check harness for open between generator and fusible link.

3.CHECK TERMINAL “1” CONNECTION (VOLTAGE DROP TEST)

1. Start engine, then engine running at idle and warm.

2. Check voltage between battery positive terminal and generator connector E204 terminal 1.

Is the voltage reading as specified?

YES >> Terminal “1” circuit is normal. Refer to CHG-5, "Work

Flow".

NO >> Check harness between battery and generator for high resistance.

(+) (-) Voltage

Connector Terminal

E204 1Ground Battery voltage

ALMIA0197ZZ

(+)

(-)Voltage

Connector Terminal

E204 1 Battery positive terminal Less than 0.2V

ALMIA0198ZZ

Revision: April 20092010 QX56

Page 754 of 4210

CHG-12

< COMPONENT DIAGNOSIS >

L TERMINAL CIRCUIT

L TERMINAL CIRCUIT

DescriptionINFOID:0000000005146561

The terminal “2” (L) circuit controls the charge warning lamp. The charge warning lamp illuminates when the

ignition switch is set to ON or START. When the generator is providing sufficient voltage with the engine run-

ning, the charge warning lamp will go off. If the c harge warning lamp illuminates with the engine running, a

malfunction is indicated.

Diagnosis ProcedureINFOID:0000000005146562

Regarding Wiring Diagram information, refer to CHG-14, "Wiring Diagram".

1.CHECK CHARGE WARNING LAMP CIRCUIT CONNECTION

Verify generator connector E205 terminal 2 is clean and tight.

Is the connection secure?

YES >> GO TO 2.

NO >> Repair the connection. Confirm repair by per forming complete Starting/Charging system test.

Refer to diagnostic station instruction manual.

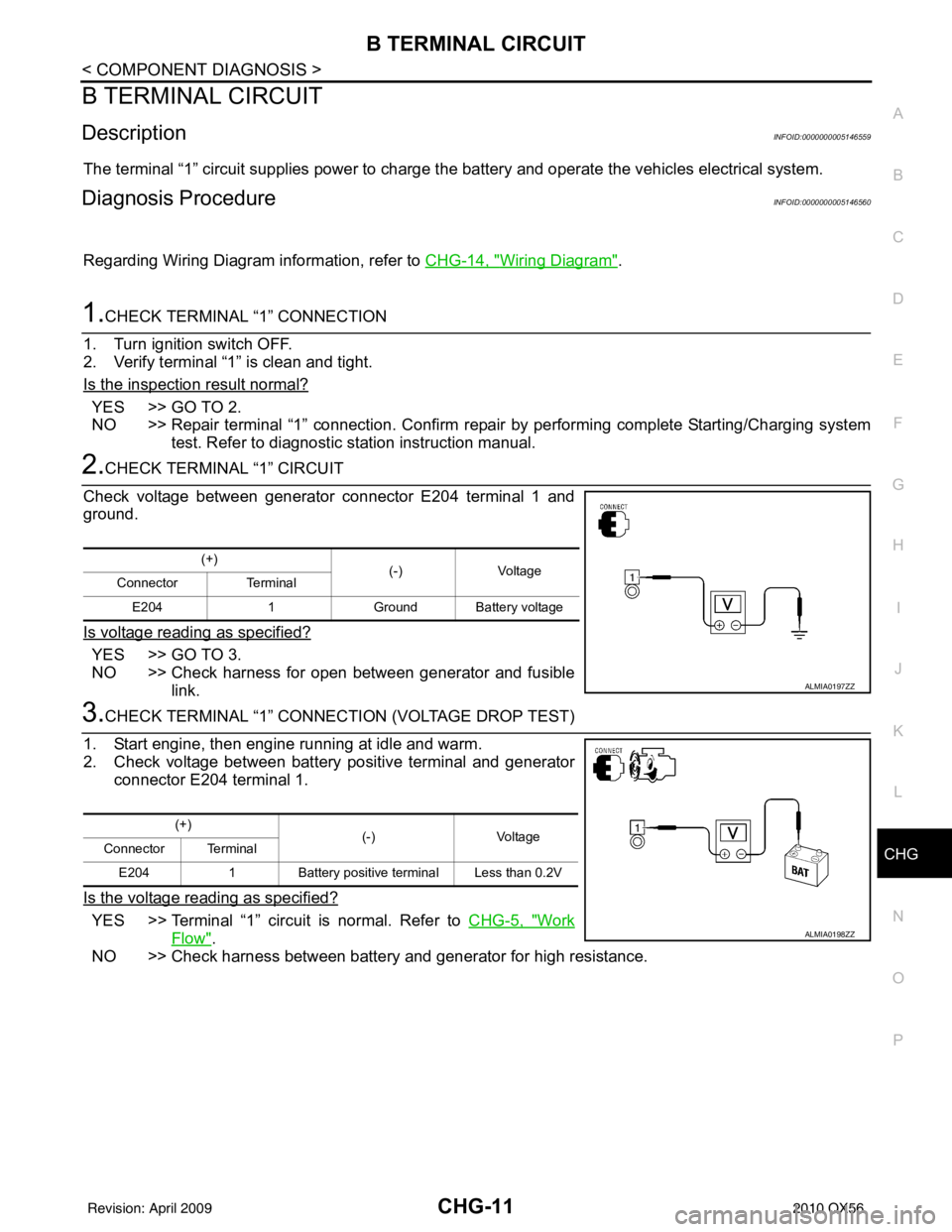

2.CHECK CHARGE WARNING LAMP CIRCUIT

1. Disconnect generator connector E205.

2. Apply ground to generator harness connector E205 terminal 2 with the ignition switch in the ON position.

Does the charge lamp illuminate?

YES >> Check generator function. Refer to CHG-5, "Work Flow".

NO >> GO TO 3.

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect the generator connector E205 and combination meter connector M24.

3. Check continuity between generator harness connector E205 (A) terminal 2 and combination meter harness connector M24

(B) terminal 6.

4. Check continuity between generator harness connector E205 (A) terminal 2 and ground.

Are the continuity results as specified?

YES >> Replace the combination meter. Refer to MWI-100, "Removal and Installation".

NO >> Repair the harness or connector. Charge lamp should illuminate

ALMIA0200ZZ

AB

Continuity

Connector Terminal Connector Terminal

E205 2M24 6Yes

A —

Continuity

Connector Terminal

E205 2Ground No

AWMIA1099ZZ

Revision: April 20092010 QX56

Page 755 of 4210

CHG

S TERMINAL CIRCUITCHG-13

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

S TERMINAL CIRCUIT

DescriptionINFOID:0000000005146563

The output voltage of the generator is controlled by the IC

regulator at terminal “3” (S) detecting the input volt-

age. Terminal “3” circuit detects the battery voltage to adjust the generator output voltage with the IC regulator.

Diagnosis ProcedureINFOID:0000000005146564

Regarding Wiring Diagram information, refer to CHG-14, "Wiring Diagram".

1.CHECK VOLTAGE REGULATOR CIRCUIT CONNECTION

Check to see if connector E205 terminal 3 is clean and tight.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair terminal connection. Confirm repair by performing complete Starting/Charging system test.

Refer to diagnostic station instruction manual.

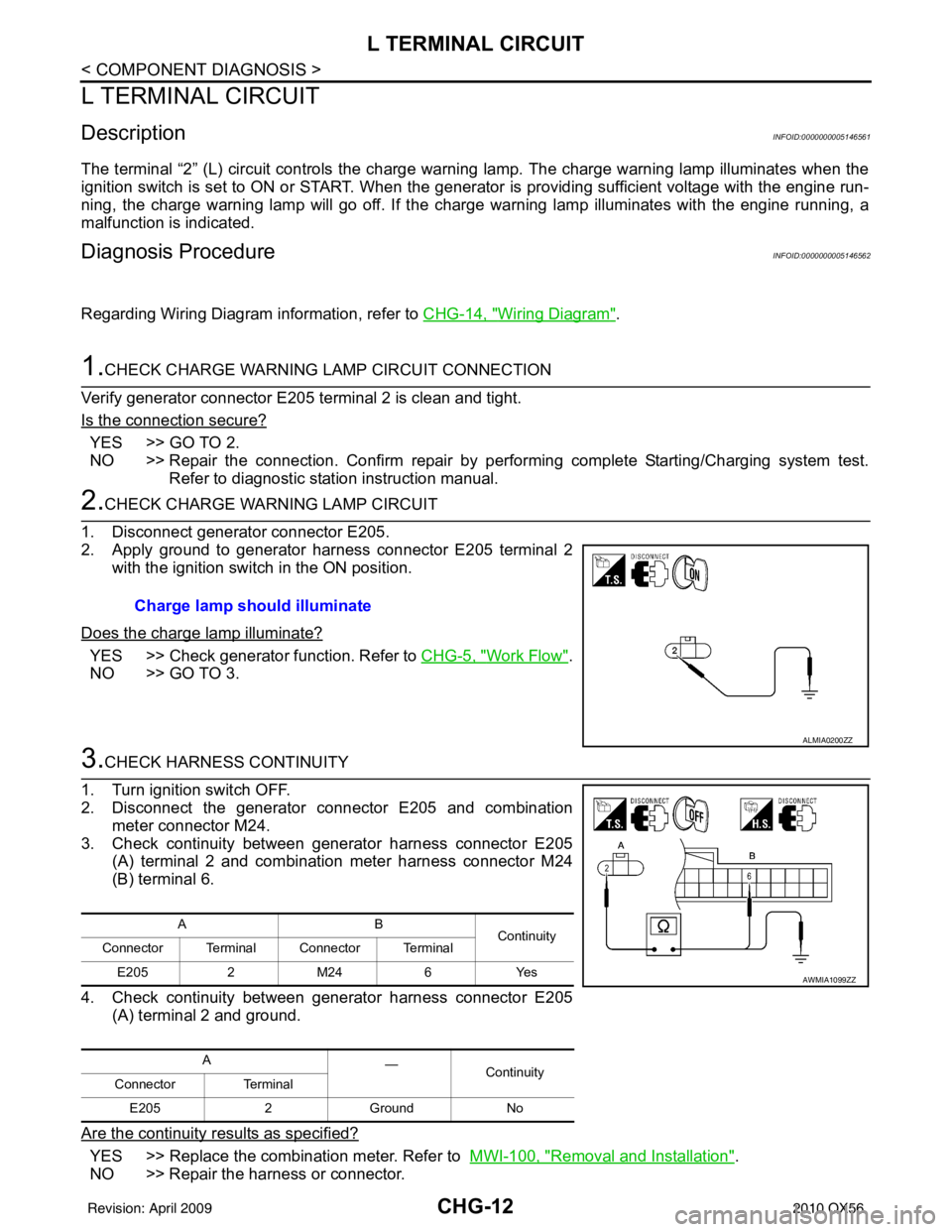

2.CHECK VOLTAGE REGULATOR CIRCUIT

Check voltage between generator harness connector E205 terminal

3 and ground.

Does battery voltage exist?

YES >> Refer to CHG-5, "Work Flow".

NO >> Check harness for open between generator and fuse. 3 - ground

Battery voltage

ALMIA0201ZZ

Revision: April 20092010 QX56

Page 756 of 4210

CHG-14

< COMPONENT DIAGNOSIS >

CHARGING SYSTEM

CHARGING SYSTEM

Wiring DiagramINFOID:0000000005146565

ABMWA0376GB

Revision: April 20092010 QX56

Page 757 of 4210

CHG

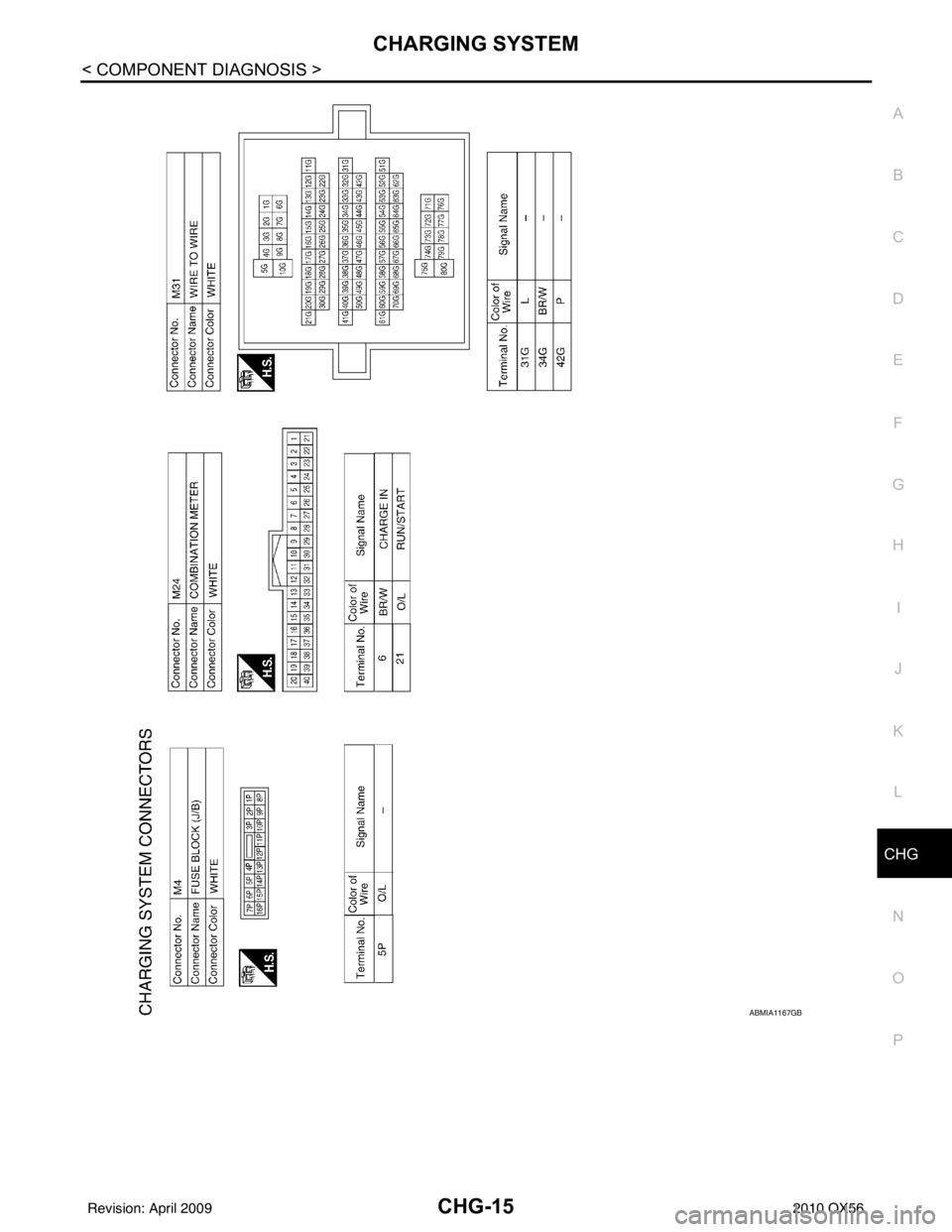

CHARGING SYSTEMCHG-15

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

ABMIA1167GB

Revision: April 20092010 QX56

Page 758 of 4210

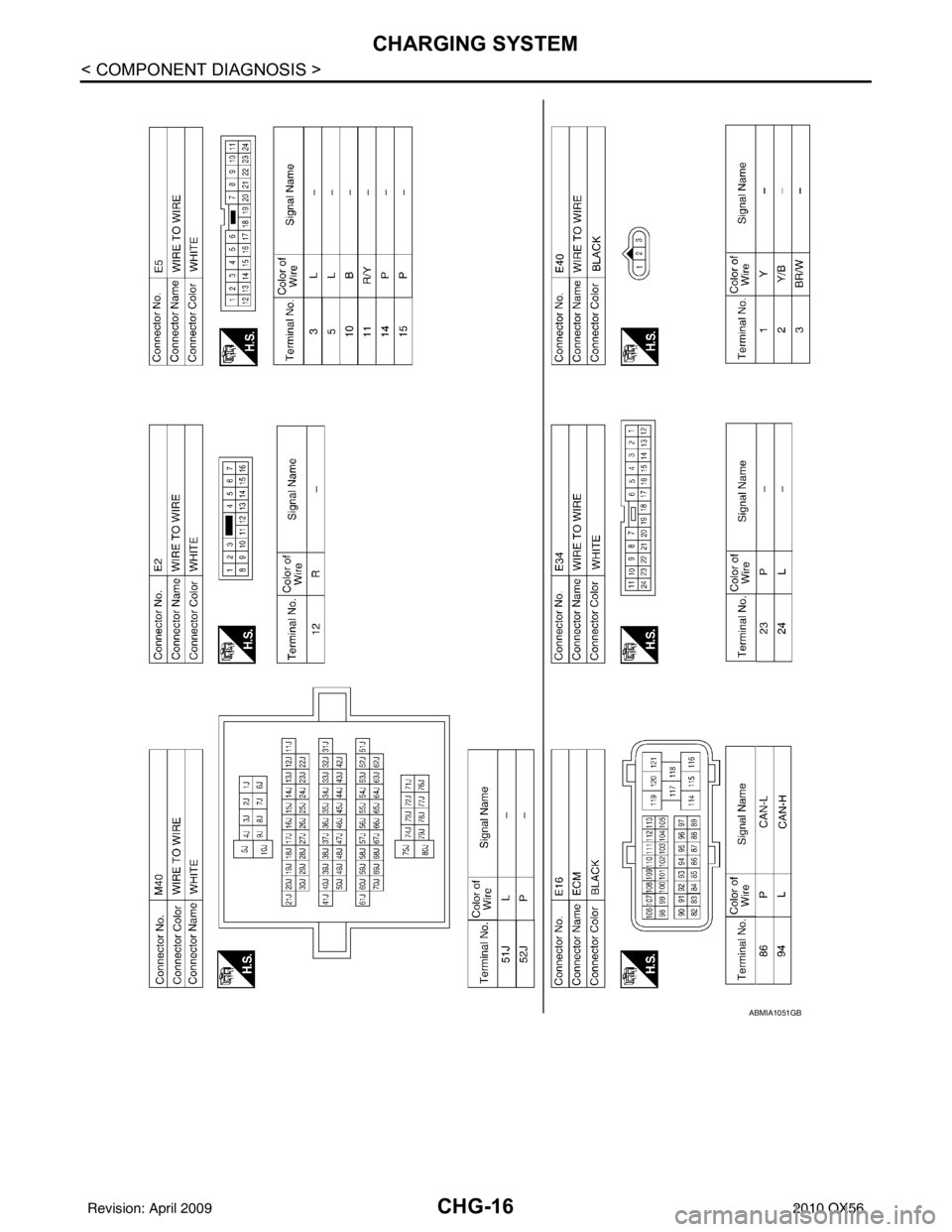

CHG-16

< COMPONENT DIAGNOSIS >

CHARGING SYSTEM

ABMIA1051GB

Revision: April 20092010 QX56

Page 759 of 4210

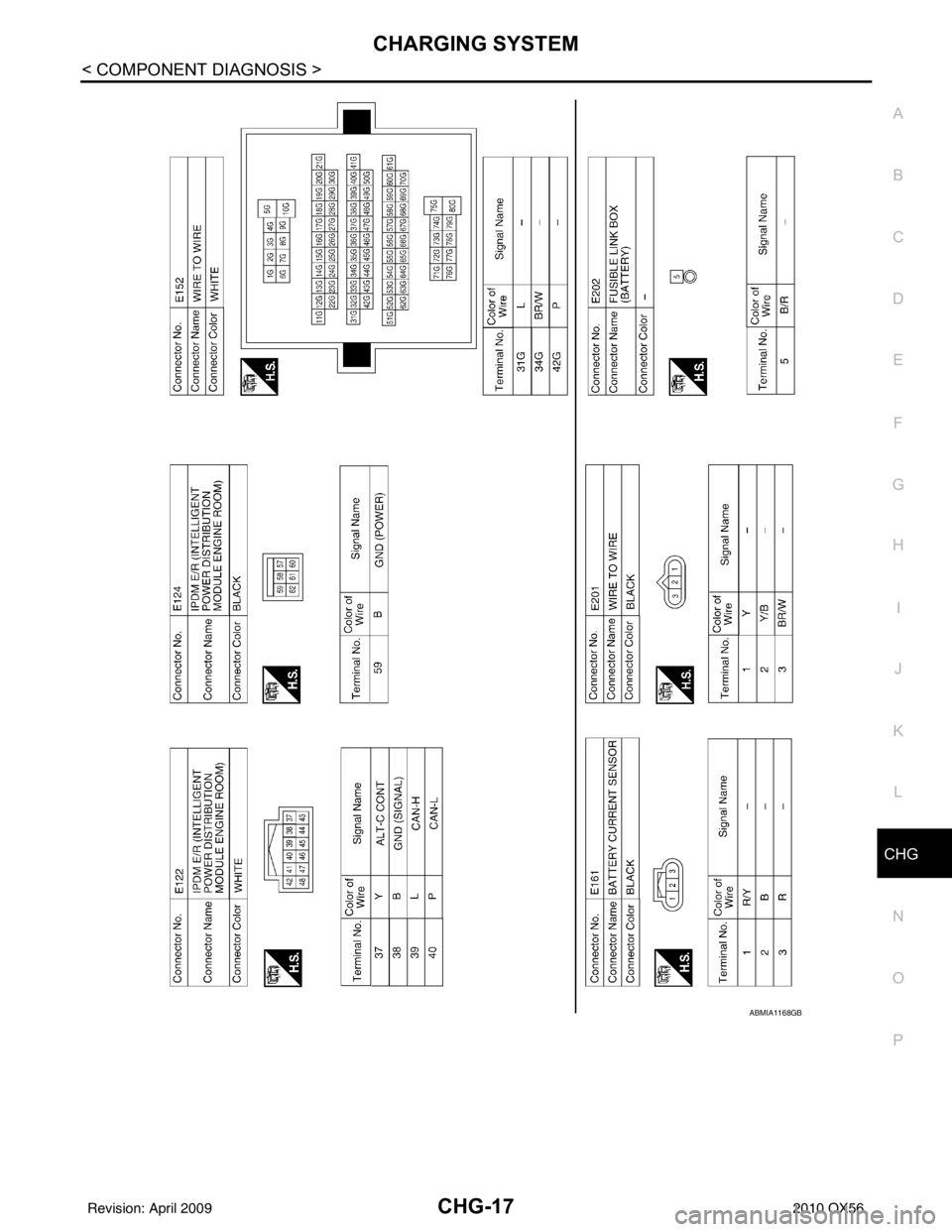

CHG

CHARGING SYSTEMCHG-17

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

ABMIA1168GB

Revision: April 20092010 QX56

Page 760 of 4210

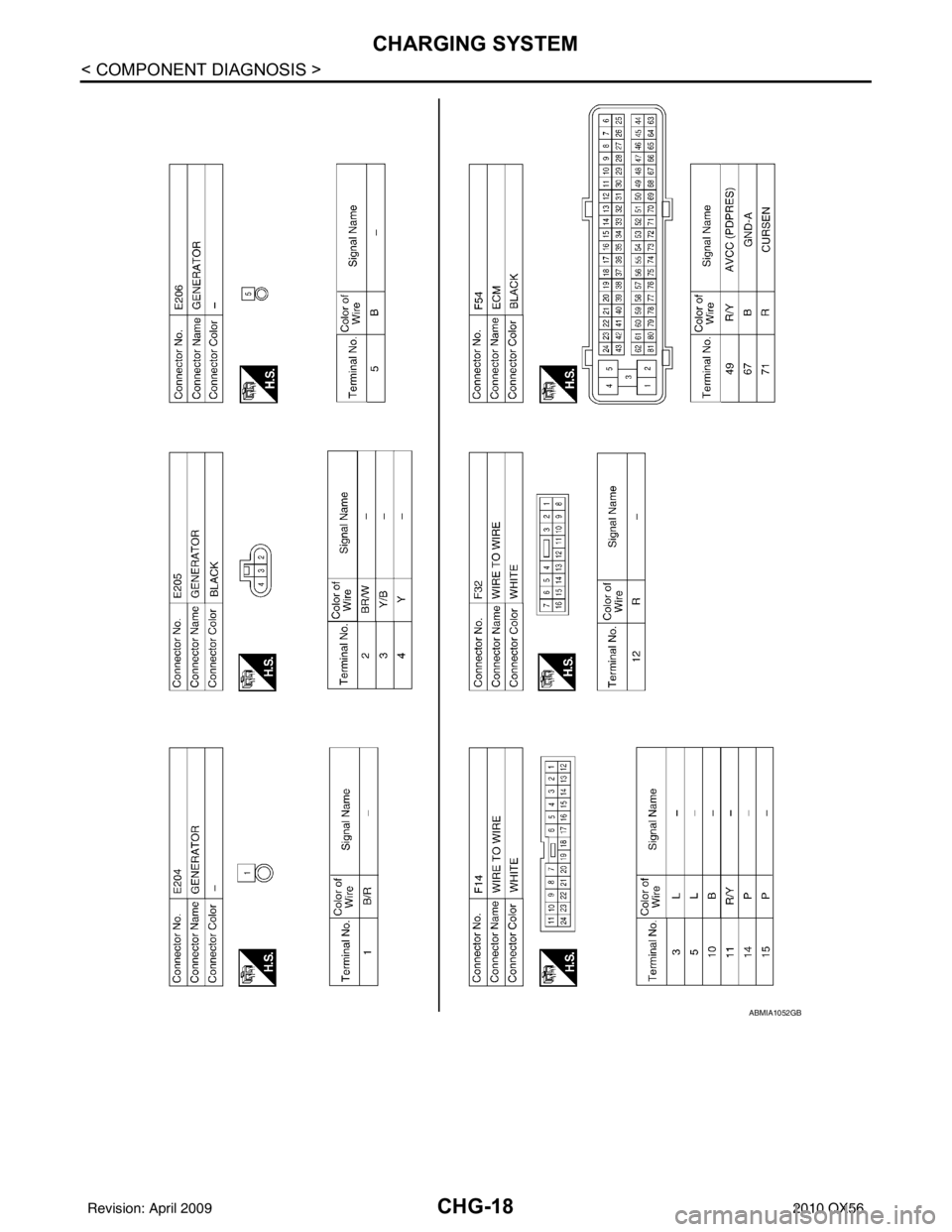

CHG-18

< COMPONENT DIAGNOSIS >

CHARGING SYSTEM

ABMIA1052GB

Revision: April 20092010 QX56