ESP INFINITI QX56 2011 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3243 of 5598

![INFINITI QX56 2011 Factory Owners Manual

ACCS (ADVANCE CLIMATE CONTROL SYSTEM)HAC-137

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

ACCS (ADVANCE CLIMATE CONTROL SYSTEM)

Symptom TableINFOID:00000000062 INFINITI QX56 2011 Factory Owners Manual

ACCS (ADVANCE CLIMATE CONTROL SYSTEM)HAC-137

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

ACCS (ADVANCE CLIMATE CONTROL SYSTEM)

Symptom TableINFOID:00000000062](/img/42/57033/w960_57033-3242.png)

ACCS (ADVANCE CLIMATE CONTROL SYSTEM)HAC-137

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

ACCS (ADVANCE CLIMATE CONTROL SYSTEM)

Symptom TableINFOID:0000000006275982

NOTE:

Perform the self-diagnoses with CONSULT-III before performing the symptom diagnosis. If DTC is detected,

perform the corresponding diagnosis.

The following table is based on the condition that fr ont automatic air conditioning system operates normally.

Symptom Corresponding malfunction part Reference

Auto intake switch cannot be operated. [Automatic

intake control (exhaust gas / outside odor detecting

mechanism) does not operate] Multi AV system

AV- 1 9 9 , "

Symptom Table"

Plasmacluster™ control does not operate.

NOTE:

Plasmacluster

™ ion technology developed by

Sharp Corporation is installed in this item.

Plasmacluster

™ is a trademark of Sharp Corpora-

tion. Power supply system of ionizer

The circuit between ionizer and A/C

auto amp.

Ionizer

A/C auto amp. HAC-124, "

Diagnosis Procedure"

Operation status of Plasmacluster™ control does not

switch according to air flow.

NOTE:

Plasmacluster

™ ion technology developed by

Sharp Corporation is installed in this item.

Plasmacluster

™ is a trademark of Sharp Corpora-

tion. A/C auto amp.

Replace A/C auto amp.. Refer to

HAC-146, "

Removal and Installa-

tion".

Revision: 2010 May2011 QX56

Page 3244 of 5598

![INFINITI QX56 2011 Factory Owners Manual

HAC-138

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONING]

INSUFFICIENT COOLING

INSUFFICIENT COOLING

FRONT AIR CONDITIONER

FRONT AIR CONDITIONER : DescriptionINFOID:0000000006275984

Symptom Insuffici INFINITI QX56 2011 Factory Owners Manual

HAC-138

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONING]

INSUFFICIENT COOLING

INSUFFICIENT COOLING

FRONT AIR CONDITIONER

FRONT AIR CONDITIONER : DescriptionINFOID:0000000006275984

Symptom Insuffici](/img/42/57033/w960_57033-3243.png)

HAC-138

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONING]

INSUFFICIENT COOLING

INSUFFICIENT COOLING

FRONT AIR CONDITIONER

FRONT AIR CONDITIONER : DescriptionINFOID:0000000006275984

Symptom Insufficient cooling

No cool air comes out. (Air flow volume is normal.)

FRONT AIR CONDITIONER

: Diagnosis ProcedureINFOID:0000000006275985

NOTE:

Perform self-diagnoses with CONSULT-III before perform ing symptom diagnosis. If any DTC is detected, per-

form the corresponding diagnosis.

1.CHECK MAGNET CLUTCH OPERATION

1. Turn ignition switch ON.

2. Operate fan switch.

3. Press A/C switch.

4. Check that A/C indicator turns ON. Check visually and by sound that compressor operates.

5. Press A/C switch again.

6. Check that A/C indicator turns OFF. Check that compressor stops.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Perform diagnosis of “COMPRESSOR DOSE NOT OPERATE” in “SYMPTOM DIAGNOSIS”.

Refer to HAC-142, "

Diagnosis Procedure".

2.CHECK DRIVE BELT

Check tension of drive belt. Refer to EM-20, "

Checking".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Adjust or replace drive belt depending on the inspection results.

3.CHECK REFRIGERANT CYCLE

Connect recovery/recycling recharging equipment to the vehicle and perform pressure inspection with gauge.

Refer to HA-27, "

Symptom Table".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace parts depending on the inspection results.

4.CHECK AIR LEAKAGE FROM EACH DUCT

Check duct and nozzle, etc. of the fr ont air conditioning system for leakage.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace parts depending on the inspection results.

5.CHECK AMBIENT TEMPERATURE DISPLAY

Check that there is not much diference between act ual ambient temperature and indicated temperature on

information display in combination meter.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Perform diagnosis for the A/C auto amp. connection recognition signal circuit. Refer to MWI-74,

"DiagnosisProcedure".

6.CHECK SETTING OF TEMPERATURE SETTING TRIMMER (FRONT)

1. Check setting value of temperature setting trimmer (front). Refer to HAC-68, "

FRONT AUTOMATIC AIR

CONDITIONING SYSTEM : Temperature Setting Trimmer (Front)".

2. Check that temperature setting trimme r (front) is set to “+ direction”.

Revision: 2010 May2011 QX56

Page 3245 of 5598

![INFINITI QX56 2011 Factory Owners Manual

INSUFFICIENT COOLINGHAC-139

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

NOTE:

The control temperature can be set with the setti ng of the temperature setting INFINITI QX56 2011 Factory Owners Manual

INSUFFICIENT COOLINGHAC-139

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

NOTE:

The control temperature can be set with the setti ng of the temperature setting](/img/42/57033/w960_57033-3244.png)

INSUFFICIENT COOLINGHAC-139

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

NOTE:

The control temperature can be set with the setti ng of the temperature setting trimmer (front).

3. Set difference between set temperature and control temperature to “0”.

Is inspection result normal?

YES >> INSPECTION END

NO >> Replace A/C auto amp.. Refer to HAC-146, "

Removal and Installation".

REAR AIR CONDITIONER

REAR AIR CONDITIONER : DescriptionINFOID:0000000006275986

Symptom Insufficient cooling

No cool air comes out. (Air flow volume is normal.)

REAR AIR CONDITIONER : Diagnosis ProcedureINFOID:0000000006275987

NOTE:

Perform self-diagnoses with CONSULT-III before performi ng symptom diagnosis. If any DTC is detected, per-

form the corresponding diagnosis.

1.CHECK REAR A/C SOLENOID VALVE

Check rear A/C solenoid valve. Refer to HAC-128, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace malfunctioning parts.

2.CHECK REFRIGERANT CYCLE

Connect recovery/recycling recharging equipment to t he vehicle and perform pressure inspection with gauge.

Refer to HA-27, "

Symptom Table".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace parts depending on the inspection results.

3.CHECK AIR LEAKAGE FROM EACH DUCT

Check duct and nozzle, etc. of the rear air conditioning system for leakage.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace parts depending on the inspection results.

4.CHECK SETTING OF TEMPERATURE SETTING TRIMMER (REAR)

1. Check setting value of temperature setting trimmer (rear). Refer to HAC-69, "

REAR AUTOMATIC AIR

CONDITIONING SYSTEM : Temperature Setting Trimmer (Rear)".

2. Check that temperature setting trimmer (rear) is set to “+ direction”. NOTE:

The control temperature can be set with the sett ing of the temperature setting trimmer (rear).

3. Set difference between set temperature and control temperature to “0”.

Is inspection result normal?

YES >> INSPECTION END

NO >> Replace A/C auto amp.. Refer to HAC-146, "

Removal and Installation".

Revision: 2010 May2011 QX56

Page 3246 of 5598

![INFINITI QX56 2011 Factory Owners Manual

HAC-140

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONING]

INSUFFICIENT HEATING

INSUFFICIENT HEATING

FRONT AIR CONDITIONER

FRONT AIR CONDITIONER : DescriptionINFOID:0000000006275990

Symptom Insuffici INFINITI QX56 2011 Factory Owners Manual

HAC-140

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONING]

INSUFFICIENT HEATING

INSUFFICIENT HEATING

FRONT AIR CONDITIONER

FRONT AIR CONDITIONER : DescriptionINFOID:0000000006275990

Symptom Insuffici](/img/42/57033/w960_57033-3245.png)

HAC-140

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONING]

INSUFFICIENT HEATING

INSUFFICIENT HEATING

FRONT AIR CONDITIONER

FRONT AIR CONDITIONER : DescriptionINFOID:0000000006275990

Symptom Insufficient heating

No warm air comes out. (Air flow volume is normal.)

FRONT AIR CONDITIONER

: Diagnosis ProcedureINFOID:0000000006275991

NOTE:

Perform self-diagnoses with on board diagnosis and CO NSULT-III before performing symptom diagnosis. If

DTC is detected, perform the corresponding diagnosis.

1.CHECK COOLING SYSTEM

1. Check engine coolant level and check leakage. Refer to CO-8, "

Inspection".

2. Check reservoir tank cap. Refer to CO-11, "

RESERVOIR TANK CAP : Inspection".

3. Check water flow sounds of the engine coolant. Refer to CO-9, "

Refilling".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Refill engine coolant and repair or repl ace parts depending on the inspection results.

2.CHECK HEATER HOSE

Check installation of heater hose by visually or touching.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace parts depending on the inspection results.

3.CHECK FRONT HEATER CORE

1. Check temperature of inlet hose and outlet hose of front heater core.

2. Check that inlet side of front heater core is hot and t he outlet side is slightly lower than/almost equal to the

inlet side.

CAUTION:

Always perform the temperature in spection in a short period of time because the engine coolant

temperature is very hot.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace front heater core. Refer to HA-44, "

HEATER CORE : Removal and Installation".

4.CHECK AIR LEAKAGE FROM EACH DUCT

Check duct and nozzle, etc. of front air conditioning system for air leakage.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace parts depending on the inspection results.

5.CHECK SETTING OF TEMPERATURE SETTING TRIMMER (FRONT)

1. Check setting value of temperature setting trimmer (front). Refer to HAC-68, "

FRONT AUTOMATIC AIR

CONDITIONING SYSTEM : Temperature Setting Trimmer (Front)".

2. Check that temperature setting trimmer (front) is set to “ − direction”.

NOTE:

The control temperature can be set by t he temperature setting trimmer (front).

3. Set difference between the set temperature and control temperature to “0”.

Are the symptoms solved?

YES >> INSPECTION END

NO >> Replace A/C auto amp.. Refer to HAC-146, "

Removal and Installation".

REAR AIR CONDITIONER

Revision: 2010 May2011 QX56

Page 3247 of 5598

![INFINITI QX56 2011 Factory Owners Manual

INSUFFICIENT HEATINGHAC-141

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REAR AIR CONDITIONER : DescriptionINFOID:0000000006275992

Symptom

Insufficient heati INFINITI QX56 2011 Factory Owners Manual

INSUFFICIENT HEATINGHAC-141

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REAR AIR CONDITIONER : DescriptionINFOID:0000000006275992

Symptom

Insufficient heati](/img/42/57033/w960_57033-3246.png)

INSUFFICIENT HEATINGHAC-141

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REAR AIR CONDITIONER : DescriptionINFOID:0000000006275992

Symptom

Insufficient heating

No warm air comes out. (Air flow volume is normal.)

REAR AIR CONDITIONER : Diagnosis ProcedureINFOID:0000000006275993

CAUTION:

Perform the self-diagnoses with on board diagnosi s and CONSULT-III before performing symptom

diagnosis. If any malfunction result or DTC is detected, perform the corresponding diagnosis.

1.CHECK COOLING SYSTEM

1. Check engine coolant level and check leakage. Refer to CO-8, "

Inspection".

2. Check reservoir tank cap. Refer to CO-11, "

RESERVOIR TANK CAP : Inspection".

3. Check water flow sounds of the engine coolant. Refer to CO-9, "

Refilling".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Refill the engine coolant and repair or replace the parts depending on the inspection results.

2.CHECK HEATER HOSE

Check installation of heater hose by visually or touching.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace parts depending on the inspection results.

3.CHECK REAR HEATER CORE

1. Check temperature of inlet hose and outlet hose of rear heater core.

2. Check that the inlet side of rear heater core is hot and the outlet side is slightly lower than/almost equal to

the inlet side.

CAUTION:

Always perform the temperature inspection in a sh ort period of time because the engine coolant

temperature is very hot.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace rear heater core. Refer to HA-48, "

HEATER CORE : Removal and Installation".

4.CHECK AIR LEAKAGE FROM EACH DUCT

Check duct and nozzle, etc. of the rear air conditioning system for air leakage.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace parts depending on the inspection results.

5.CHECK SETTING OF TEMPERATURE SETTING TRIMMER (REAR)

1. Check setting value of temperature setting trimmer (rear). Refer to HAC-69, "

REAR AUTOMATIC AIR

CONDITIONING SYSTEM : Temperature Setting Trimmer (Rear)".

2. Check that the temperature setting trimmer is set to “ − direction”.

NOTE:

The control temperature can be set by the temperature setting trimmer (rear).

3. Set the difference between the set temperature (rear) and control temperature to “0”.

Are the symptoms solved?

YES >> INSPECTION END

NO >> Replace A/C auto amp.. Refer to HAC-146, "

Removal and Installation".

Revision: 2010 May2011 QX56

Page 3248 of 5598

![INFINITI QX56 2011 Factory Owners Manual

HAC-142

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONING]

COMPRESSOR DOSE DOT OPERATE

COMPRESSOR DOSE DOT OPERATE

DescriptionINFOID:0000000006275994

Symptom: Compressor dose not operate.

Diagnosis Pr INFINITI QX56 2011 Factory Owners Manual

HAC-142

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONING]

COMPRESSOR DOSE DOT OPERATE

COMPRESSOR DOSE DOT OPERATE

DescriptionINFOID:0000000006275994

Symptom: Compressor dose not operate.

Diagnosis Pr](/img/42/57033/w960_57033-3247.png)

HAC-142

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONING]

COMPRESSOR DOSE DOT OPERATE

COMPRESSOR DOSE DOT OPERATE

DescriptionINFOID:0000000006275994

Symptom: Compressor dose not operate.

Diagnosis ProcedureINFOID:0000000006275995

NOTE:

Perform self-diagnoses with CONSULT-III before perfo

rming symptom diagnosis. If DTC is detected, per-

form the corresponding diagnosis.

Check that refrigerant is enclosed in cooler cycle normally. If refrigerant amount is shortage from proper

amount, perform inspection of refrigerant leakage.

1.CHECK MAGNET CLUTCH OPERATION

Check magnet clutch. Refer to HAC-126, "

Component Function Check".

Does it operate normally?

YES >> GO TO 2.

NO >> Repair or replace malfunctioning parts.

2.CHECK REFRIGERANT PRESSURE SENSOR

Check refrigerant pressure sensor. Refer to EC-520, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace malfunctioning parts.

3.CHECK A/C AUTO AMP. OUTPUT SIGNAL

With CONSULT-III

Check “COMP REQ SIG” and “FAN REQ SIG” in “DAT A MONITOR” mode of “HVAC” using CONSULT-III.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace A/C auto amp.. Refer to HAC-146, "

Removal and Installation".

4.CHECK ECM INPUT SIGNAL

With CONSULT-III

Check “AIR COND SIG” and “HEATER FAN SW” in “D ATA MONITOR” mode of “ECM” using CONSULT-III.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Check CAN communication system. Refer to LAN-18, "

Trouble Diagnosis Flow Chart".

5.CHECK IPDM E/R INPUT SIGNAL

With CONSULT-III

1. Start engine.

Monitor item Condition Status

COMP REQ SIG A/C switch ON On

OFF Off

FAN REQ SIG Front blower motor ON On

OFF Off

Monitor item Condition Status

COMP REQ SIG A/C switch ON On

OFF Off

HEATER FAN SW Front blower motor ON On

OFF Off

Revision: 2010 May2011 QX56

Page 3356 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESINT-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

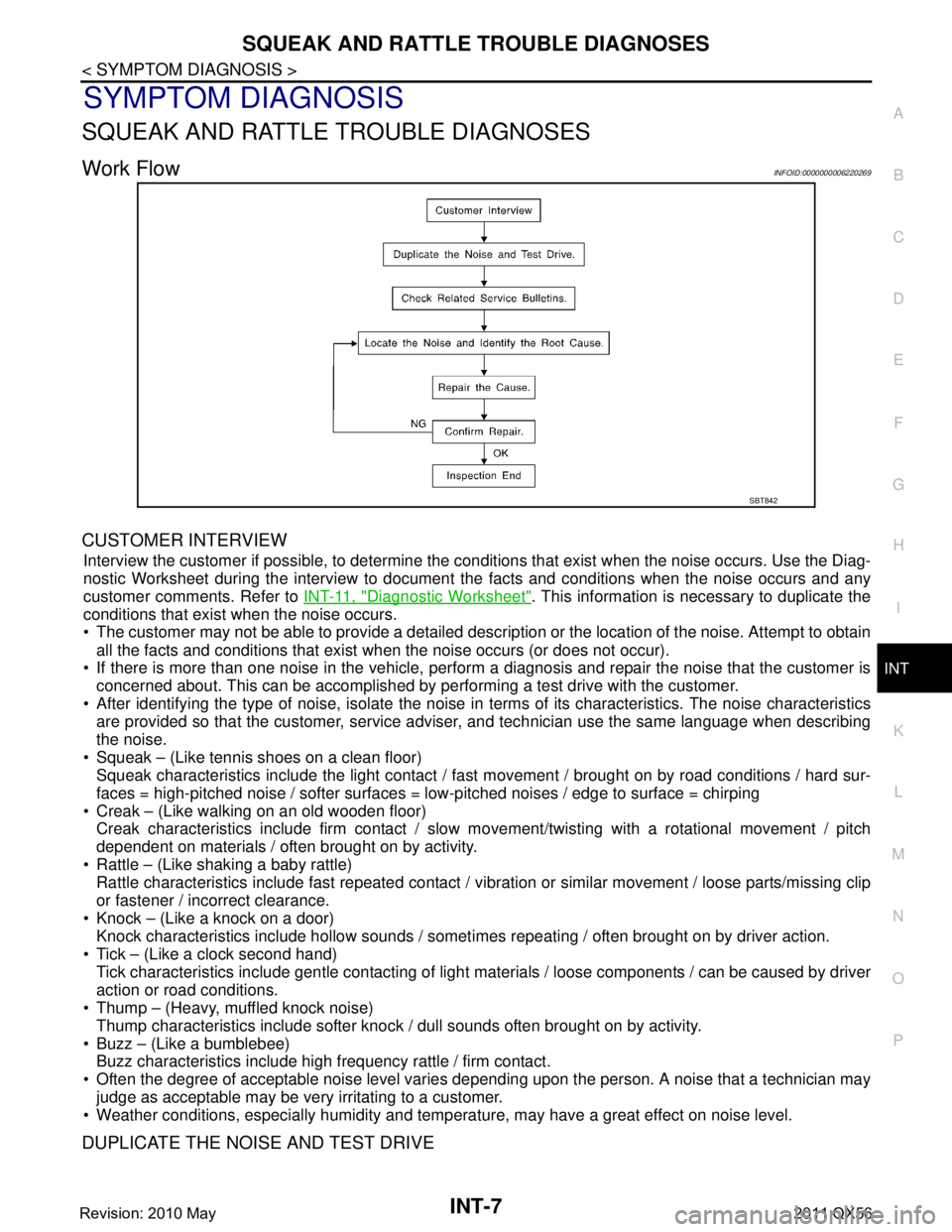

Work FlowINFOID:0000000006220269

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer comments. Refer to INT-11, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

If there is more than one noise in the vehicle, perform a diagnosis and repair the noise that the customer is

concerned about. This can be accomplished by performing a test drive with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so that the customer, service advis er, and technician use the same language when describing

the noise.

Squeak – (Like tennis shoes on a clean floor) Squeak characteristics include the light contact / fast movement / brought on by road conditions / hard sur-

faces = high-pitched noise / softer surfaces = low-pitched noises / edge to surface = chirping

Creak – (Like walking on an old wooden floor) Creak characteristics include firm contact / slow mo vement/twisting with a rotational movement / pitch

dependent on materials / often brought on by activity.

Rattle – (Like shaking a baby rattle) Rattle characteristics include fast repeated contact / vi bration or similar movement / loose parts/missing clip

or fastener / incorrect clearance.

Knock – (Like a knock on a door) Knock characteristics include hollow sounds / someti mes repeating / often brought on by driver action.

Tick – (Like a clock second hand) Tick characteristics include gentle contacting of light materials / loose components / can be caused by driver

action or road conditions.

Thump – (Heavy, muffled knock noise)

Thump characteristics include softer knock / dull sounds often brought on by activity.

Buzz – (Like a bumblebee) Buzz characteristics include high frequency rattle / firm contact.

Often the degree of acceptable noise level varies depending upon the person. A noise that a technician may

judge as acceptable may be very irritating to a customer.

Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: 2010 May2011 QX56

Page 3397 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESIP-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

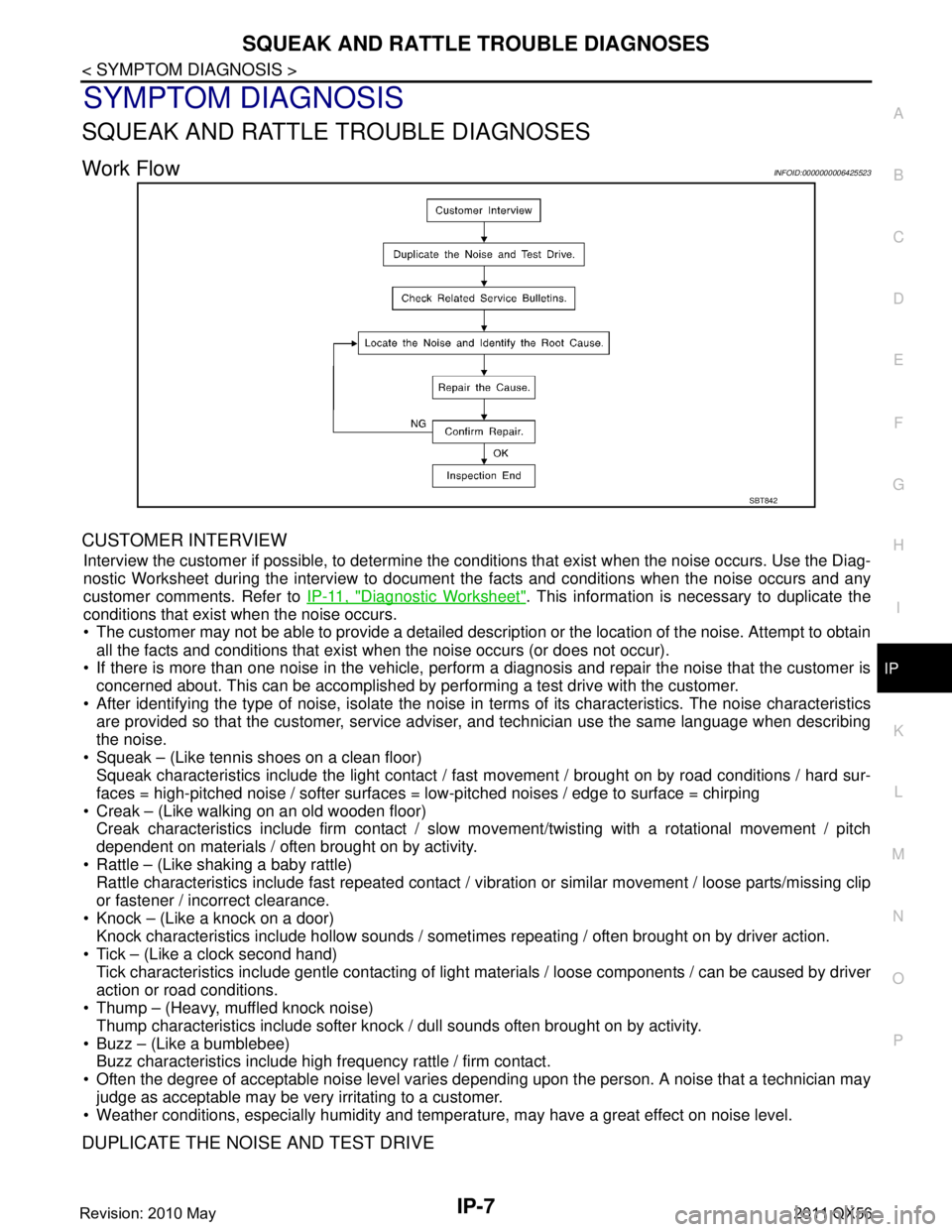

Work FlowINFOID:0000000006425523

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer comments. Refer to IP-11, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

If there is more than one noise in the vehicle, perform a diagnosis and repair the noise that the customer is

concerned about. This can be accomplished by performing a test drive with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so that the customer, service advis er, and technician use the same language when describing

the noise.

Squeak – (Like tennis shoes on a clean floor) Squeak characteristics include the light contact / fast movement / brought on by road conditions / hard sur-

faces = high-pitched noise / softer surfaces = low-pitched noises / edge to surface = chirping

Creak – (Like walking on an old wooden floor) Creak characteristics include firm contact / slow mo vement/twisting with a rotational movement / pitch

dependent on materials / often brought on by activity.

Rattle – (Like shaking a baby rattle) Rattle characteristics include fast repeated contact / vi bration or similar movement / loose parts/missing clip

or fastener / incorrect clearance.

Knock – (Like a knock on a door) Knock characteristics include hollow sounds / someti mes repeating / often brought on by driver action.

Tick – (Like a clock second hand) Tick characteristics include gentle contacting of light materials / loose components / can be caused by driver

action or road conditions.

Thump – (Heavy, muffled knock noise)

Thump characteristics include softer knock / dull sounds often brought on by activity.

Buzz – (Like a bumblebee) Buzz characteristics include high frequency rattle / firm contact.

Often the degree of acceptable noise level varies depending upon the person. A noise that a technician may

judge as acceptable may be very irritating to a customer.

Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: 2010 May2011 QX56

Page 3434 of 5598

![INFINITI QX56 2011 Factory Owners Manual

LAN-14

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000006220519

CAN diagnosis on CONSULT-III extract INFINITI QX56 2011 Factory Owners Manual

LAN-14

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000006220519

CAN diagnosis on CONSULT-III extract](/img/42/57033/w960_57033-3433.png)

LAN-14

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000006220519

CAN diagnosis on CONSULT-III extracts the root

cause by receiving the following information.

Response to the system call

Control unit diagnosis information

Self-diagnosis

CAN diagnostic support monitor

SKIB8741E

Unit name Major symptom

ECM Engine torque limiting is affected, and shift harshness increases.

Engine speed drops.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front

wiper switch being in the intermittent position.

The room lamp does not turn ON.

The engine does not start (if an error or malfunction occurs while turning the igni- tion switch OFF.)

The steering lock does not release (if an error or malfunction occurs while turning the ignition switch OFF.)

EPS control unit The steeri ng effort increases.

Combination meter The tachometer and the speedometer do not move.

Warning lamps turn ON.

Indicator lamps do not turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R When the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

Revision: 2010 May2011 QX56

Page 3684 of 5598

MA-14

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-107, "Disassem-

bly and Assembly".

2. Check that each hose clamp is firmly tightened.

3. Remove air relief plug (1) on heater hose.

4. Fill radiator, and reservoir tank, to specified level. Pour engine coolant through engine coolant filler neck

slowly of less than 3 (2-5/8 lmp qt) a minute to allow air

in system to escape.

Use Genuine NISSAN Long Life Antifreeze/Coolant or

equivalent mixed with water (d istilled or demineralized).

Refer to MA-10, "

Fluids and Lubricants".

5. When engine coolant overflows air relief hole on heater hose, install air relief plug with clamp. Then refill

radiator with engine coolant.

6. Install radiator cap.

7. Install reservoir tank cap.

8. Warm up engine until opening thermostat less than 3,000 rpm. Check thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat engine.

9. Stop the engine and cool down to less than approximately 50 °C (122 °F).

Cool down using fan to reduce the time.

If necessary, refill radiator up to filler neck with engine coolant.

10. Refill reservoir tank to “MAX” level line with engine coolant if necessary.

11. Repeat steps 6 through 10 two or more times with reservoir tank cap installed until engine coolant level no longer drops. : 1.96 N·m (0.2 kg-m, 17 in-lb)

2. Engine cover

: Vehicle front

JPBIA3429ZZ

Engine coolant capacity : Refer to CO-23,

"PeriodicalMaintenanceS

pecification".

(With reservoir tank at

“MAX” level)JPBIA0412ZZ

Reservoir tank engine

coolant capacity :Refer to

CO-23,

"PeriodicalMaintenanceSp

ecification".

(At “MAX” level)

A : MAX

B: MIN

JPBIA0102ZZ

Revision: 2010 May2011 QX56