ESP INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3729 of 5598

MIR-24

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000006257247

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document t he facts and conditions when the noise occurs and any of

customer's comments; refer to MIR-28, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain all the facts and conditions that exist w hen the noise occurs (or does not occur).

If there is more than one noise in the vehicle, perform a diagnosis and repair the noise that the customer is

concerned about. This can be accomplished by performing a cruise test on the vehicle with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

Squeak – (Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping

Creak – (Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

Rattle – (Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

Knock – (Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

Tick – (Like a clock second hand) Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

Thump – (Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

Buzz – (Like a bumblebee)

Buzz characteristics include hi gh frequency rattle/firm contact.

Often the degree of acceptable noise level will vary depending up on the person. A noise that you may judge as acceptable may be very irritating to the customer.

Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

SBT842

Revision: 2010 May2011 QX56

Page 3770 of 5598

MWI

SYSTEMMWI-27

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

Settings-reject Indication

Regarding settings-reject indications, “SETTING CA

N BE OPERATED WHEN STOPPED” is shown on the

information display when indication conditions are satisfied.

When reaching 5 km/h (3.1 MPH) after accelerating from a stopping condition, a settings-reject indication is

displayed.

When reaching less than 1 km/h (0.6 MPH) after decelerat ing from 5 km/h (3.1 MPH), a settings-reject indi-

cation is cancelled to allow settings.

The combination meter judges a vehicle condition based on the following signals and displays a settings-

reject indication on the information display.

Setting item

Options Language

English

Francais

Espanol

Unit Miles,MPG,

°F

km, l/100 km,

°C

Effects ON/OFF

Signal name Signal path

Ignition signal —

Vehicle speed signal ABS actuator and electric unit (control unit) Combination meter

JSNIA2408GB

Revision: 2010 May2011 QX56

Page 3897 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS-56

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B2614 ACC RELAY CIRCUIT

DTC/CIRCUIT DIAGNOSIS

B2614 ACC RELAY CIRCUIT

DTC LogicINFOID:0000000006220203

DTC DETECTION LOGIC

DTC CONFIRMATION INFINITI QX56 2011 Factory Service Manual

PCS-56

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B2614 ACC RELAY CIRCUIT

DTC/CIRCUIT DIAGNOSIS

B2614 ACC RELAY CIRCUIT

DTC LogicINFOID:0000000006220203

DTC DETECTION LOGIC

DTC CONFIRMATION](/img/42/57033/w960_57033-3896.png)

PCS-56

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B2614 ACC RELAY CIRCUIT

DTC/CIRCUIT DIAGNOSIS

B2614 ACC RELAY CIRCUIT

DTC LogicINFOID:0000000006220203

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn the power supply position to ACC under the following conditions, and wait for 2 second or more.

- Selector lever is in the P position

- Do not depress brake pedal

2. Check “Self-diagnosis result” of BCM with CONSULT-III.

Is DTC detected?

YES >> Go to PCS-56, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006220204

1.CHECK ACCESSORY RELAY POWER SUPPLY-1

1. Turn ignition switch OFF.

2. Disconnect accessory relay.

3. Check voltage between accessory relay harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK ACCESSORY RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between accessory relay harness connector and BCM harness connector.

4. Check continuity between accessory relay harness connector and ground.

DTC No. Trouble diagnosis

name DTC detecting condition Possible cause

B2614 BCM An immediate operation of accessory relay is re-

quested by BCM, but there is no response for more

than 2 second. Harness or connectors

(Accessory relay ci rcuit is open or

shorted)

BCM

Accessory relay

(+)

(–) Condition Voltage (V)

(Approx.)

Accessory relay

Te r m i n a l

1 Ground Ignition switch OFF 0

ACC or ON 12

Accessory relay BCM Continuity

Terminal Connector Terminal

1 M71 96 Existed

Revision: 2010 May2011 QX56

Page 3902 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS

B2616 IGNITION RELAY CIRCUITPCS-61

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

B2616 IGNITION RELAY CIRCUIT

DTC LogicINFOID:0000000006220209

DTC DETECTION INFINITI QX56 2011 Factory Service Manual

PCS

B2616 IGNITION RELAY CIRCUITPCS-61

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

B2616 IGNITION RELAY CIRCUIT

DTC LogicINFOID:0000000006220209

DTC DETECTION](/img/42/57033/w960_57033-3901.png)

PCS

B2616 IGNITION RELAY CIRCUITPCS-61

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

B2616 IGNITION RELAY CIRCUIT

DTC LogicINFOID:0000000006220209

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON under the following conditions, and wait for 1 second or more.

- Selector lever is in the P position

- Do not depress brake pedal

2. Check “Self-diagnosis result” of BCM with CONSULT-III.

Is DTC detected?

YES >> Go to PCS-61, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006220210

1.CHECK IGNITION RELAY-1 POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect ignition relay-1.

3. Check voltage between ignition relay-1 harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK IGNITION RELAY-1 POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between ignition relay-1 harness connector and BCM harness connector.

4. Check continuity between ignition relay-1 harness connector and ground.

Is the inspection result normal?

DTC No. Trouble diagnosis

name DTC detecting condition Possible cause

B2616 BCM An immediate operation of ignition relay-1 is re-

quested by BCM, but there is no response for more

than 1 second Harness or connectors

(Ignition relay-1 circuit is open or

shorted)

BCM

Ignition relay-1

(+)

(–) Condition Voltage (V)

(Approx.)

Ignition relay-1

Te r m i n a l

2 Ground Ignition switch OFF or ACC 0

ON 12

Ignition relay-1 BCM Continuity

Terminal Connector Terminal

2 M71 99 Existed

Ignition relay-1 GroundContinuity

Te r m i n a l

2 Not existed

Revision: 2010 May2011 QX56

Page 3904 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS

B2618 BCMPCS-63

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

B2618 BCM

DTC LogicINFOID:0000000006220212

DTC DETECTION LOGIC

NOTE:

If DTC B2618 is displaye INFINITI QX56 2011 Factory Service Manual

PCS

B2618 BCMPCS-63

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

B2618 BCM

DTC LogicINFOID:0000000006220212

DTC DETECTION LOGIC

NOTE:

If DTC B2618 is displaye](/img/42/57033/w960_57033-3903.png)

PCS

B2618 BCMPCS-63

< DTC/CIRCUIT DIAGNOSIS > [POWER DISTRIBUTION SYSTEM]

C

D

E

F

G H

I

J

K L

B A

O P

N

B2618 BCM

DTC LogicINFOID:0000000006220212

DTC DETECTION LOGIC

NOTE:

If DTC B2618 is displayed with DTC U1000, first per

form the trouble diagnosis for DTC U1000. Refer to

BCS-70, "

DTC Logic".

If DTC B2618 is displayed with DTC U1010, first per form the trouble diagnosis for DTC U1010. Refer to

BCS-71, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON under the following conditions, and wait for 1 second or more.

- Selector lever is in the P or N position

- Do not depress brake pedal

2. Check “Self-diagnosis result” of BCM with CONSULT-III.

Is DTC detected?

YES >> Go to PCS-63, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006220213

1.INSPECTION START

1. Turn ignition switch ON.

2. Select “Self-diagnosis resu lt” of BCM with CONSULT-III.

3. Touch “ERASE”.

4. Perform DTC Confirmation Procedure. See PCS-63, "

DTC Logic".

Is the 1st trip DTC B2618 displayed again?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation"

NO >> INSPECTION END

DTC No.Trouble diagnosis

name DTC detecting condition Possible cause

B2618 BCM An immediate operation of ignition relay (IPDM E/R) is re-

quested by BCM, but there is no response for more than

1 second BCM

Revision: 2010 May2011 QX56

Page 3924 of 5598

PG

COMPONENT PARTSPG-5

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

B A

O P

N

SYSTEM DESCRIPTION

COMPONENT PARTS

Circuit BreakerINFOID:0000000006275745

The PTC thermistor generates heat in response to current flow. The

temperature (and resistance) of t

he thermistor element varies with

current flow. Excessive current flow will cause the element's temper-

ature to rise. When the temperature reaches a specified level, the

electrical resistance will rise shar ply to control the circuit current.

Reduced current flow will cause the element to cool. Resistance falls

accordingly and normal circuit current flow is allowed to resume.

BatteryINFOID:0000000006275746

Harness ConnectorINFOID:0000000006275747

HARNESS CONNECTOR (TAB-LOCKING TYPE)

The tab-locking type connectors help prevent accidental looseness or disconnection.

The tab-locking type connectors are disconnected by pushi ng or lifting the locking tab(s). Refer to the figure

below.

CAUTION:

Never pull the harness or wires when disconnecting the connector.

SEL109W

Ty pe 115D31R

20 hour rate capacity [V – Ah] 12 – 82

Cold cranking current (For reference value) [A] 782

Revision: 2010 May2011 QX56

Page 3925 of 5598

![INFINITI QX56 2011 Factory Service Manual

PG-6

< SYSTEM DESCRIPTION >

COMPONENT PARTS

[Example]

HARNESS CONNECTOR (SLIDE-LOCKING TYPE)

A new style slide-locking type connector is used on certain systems and components, especially those

rel INFINITI QX56 2011 Factory Service Manual

PG-6

< SYSTEM DESCRIPTION >

COMPONENT PARTS

[Example]

HARNESS CONNECTOR (SLIDE-LOCKING TYPE)

A new style slide-locking type connector is used on certain systems and components, especially those

rel](/img/42/57033/w960_57033-3924.png)

PG-6

< SYSTEM DESCRIPTION >

COMPONENT PARTS

[Example]

HARNESS CONNECTOR (SLIDE-LOCKING TYPE)

A new style slide-locking type connector is used on certain systems and components, especially those

related to OBD.

The slide-locking type connectors help prevent incomplete locking and accidental looseness or disconnec-

tion.

The slide-locking type connectors are disconnected by pushing or pulling the slider. Refer to the figure below.

CAUTION:

Never pull the harness or wires when disconnecting the connector.

Be careful not to damage the connector su pport bracket when disconnecting the connector.

SEL769DA

Revision: 2010 May2011 QX56

Page 4093 of 5598

PWC-8

< SYSTEM DESCRIPTION >

SYSTEM

SYSTEM

System DiagramINFOID:0000000006217266

System DescriptionINFOID:0000000006217267

POWER WINDOW OPERATION

Power window system is activated by power window switch operation when ignition switch turns ON, or dur-

ing the retained power operation after ignition switch turns OFF.

Power window main switch can open/close door glass.

Front and rear power window switch can open/close the corresponding door glass.

Power window lock switch can lock all power windows other than driver seat.

All power windows close when pressing Intelligent Ke y lock button or unlock button for 3 seconds.

If door glass receives resistance that is the specifi ed value or more while power window of each seat is in

AUTO-UP operation, power window operates in the reverse direction.

Power window serial link transmits the signals from power window main switch to each power window switch.

AUTO-UP/DOWN operation can be performed when front power window switch turns to AUTO.

POWER WINDOW AUTO-OPERATION

AUTO-UP/DOWN operation can be performed when each power window motor turns to AUTO.

Encoder continues detecting the movement of power window motor and output the encoder pulse signal to

power window switch while power window motor is operating.

Power window switch reads the changes of encoder signal and stops AUTO operation when door glass is at

fully opened/closed position.

Power window motor is operable in case encoder is malfunctioning.

AUTO function does not operate if encoder is malfunctioning.

POWER WINDOW SERIAL LINK

Power window main switch, front power window switch (passenger side), rear power window switch LH/RH

and BCM transmit and receive the signal by power window serial link.

JMKIA5147GB

Revision: 2010 May2011 QX56

Page 4240 of 5598

RF-26

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

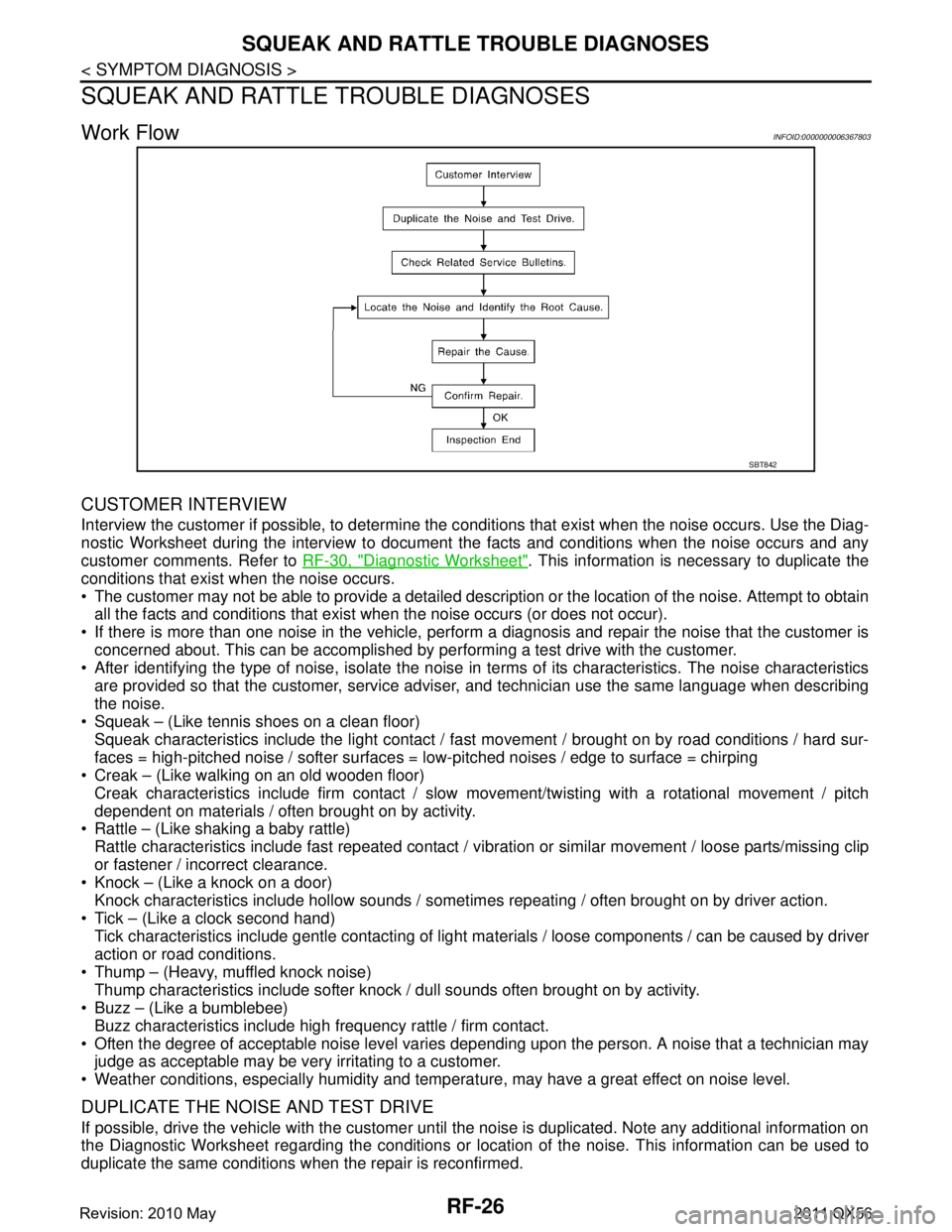

Work FlowINFOID:0000000006367803

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer comments. Refer to RF-30, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain all the facts and conditions that exist w hen the noise occurs (or does not occur).

If there is more than one noise in the vehicle, perform a diagnosis and repair the noise that the customer is

concerned about. This can be accomplished by per forming a test drive with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so that the customer, service advis er, and technician use the same language when describing

the noise.

Squeak – (Like tennis shoes on a clean floor)

Squeak characteristics include the light contact / fast movement / brought on by road conditions / hard sur-

faces = high-pitched noise / softer surfaces = low-pitched noises / edge to surface = chirping

Creak – (Like walking on an old wooden floor)

Creak characteristics include firm contact / slow movement/twisting with a rotational movement / pitch

dependent on materials / often brought on by activity.

Rattle – (Like shaking a baby rattle)

Rattle characteristics include fast repeated contact / vibr ation or similar movement / loose parts/missing clip

or fastener / incorrect clearance.

Knock – (Like a knock on a door)

Knock characteristics include hollow sounds / someti mes repeating / often brought on by driver action.

Tick – (Like a clock second hand) Tick characteristics include gentle contacting of light materials / loose components / can be caused by driver

action or road conditions.

Thump – (Heavy, muffled knock noise) Thump characteristics include softer knock / dull sounds often brought on by activity.

Buzz – (Like a bumblebee)

Buzz characteristics include high frequency rattle / firm contact.

Often the degree of acceptable noise level varies depending upon the person. A noise that a technician may

judge as acceptable may be very irritating to a customer.

Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when the repair is reconfirmed.

SBT842

Revision: 2010 May2011 QX56

Page 4308 of 5598

DIAGNOSIS SYSTEM (PRE-CRASH SEAT BELT)SBC-11

< SYSTEM DESCRIPTION >

C

DE

F

G

I

J

K L

M A

B

SBC

N

O P

DIAGNOSIS SYSTEM (P RE-CRASH SEAT BELT)

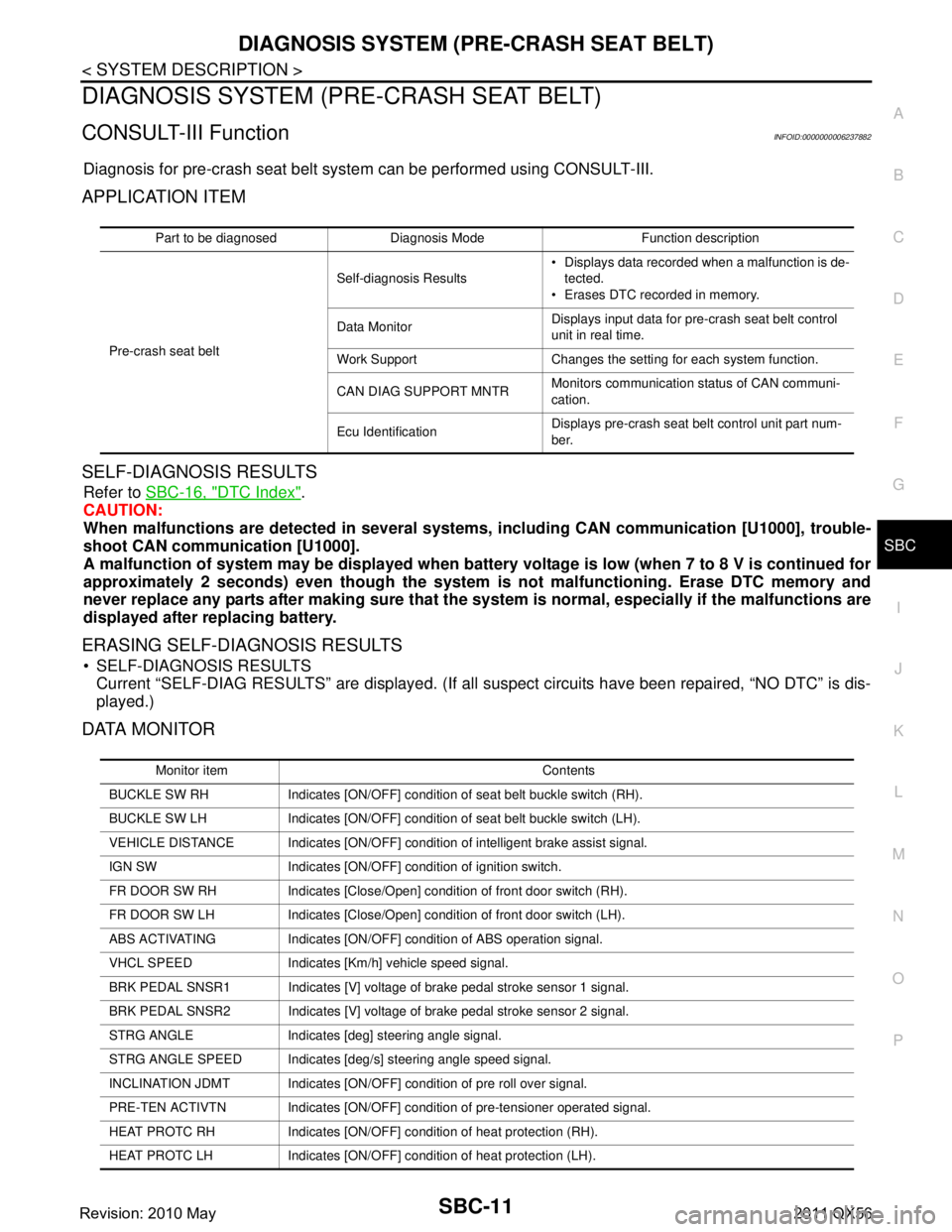

CONSULT-III FunctionINFOID:0000000006237882

Diagnosis for pre-crash seat belt syst em can be performed using CONSULT-III.

APPLICATION ITEM

SELF-DIAGNOSIS RESULTS

Refer to SBC-16, "DTC Index".

CAUTION:

When malfunctions are detect ed in several systems, includin g CAN communication [U1000], trouble-

shoot CAN communication [U1000].

A malfunction of system may be disp layed when battery voltage is low (when 7 to 8 V is continued for

approximately 2 seconds) even though the system is not malfunctioning. Erase DTC memory and

never replace any parts after making sure that the syst em is normal, especially if the malfunctions are

displayed after replacing battery.

ERASING SELF-DIAGNOSIS RESULTS

SELF-DIAGNOSIS RESULTS Current “SELF-DIAG RESULTS” are displayed. (If all suspect circuits have been repaired, “NO DTC” is dis-

played.)

DATA MONITOR

Part to be diagnosed Diagnosis Mode Function description

Pre-crash seat belt Self-diagnosis Results

Displays data recorded when a malfunction is de-

tected.

Erases DTC recorded in memory.

Data Monitor Displays input data for pre-crash seat belt control

unit in real time.

Work Support Changes the setting for each system function.

CAN DIAG SUPPORT MNTR Monitors communication status of CAN communi-

cation.

Ecu Identification Displays pre-crash seat belt control unit part num-

ber.

Monitor item Contents

BUCKLE SW RH Indicates [ON/OFF] condition of seat belt buckle switch (RH).

BUCKLE SW LH Indicates [ON/OFF] condition of seat belt buckle switch (LH).

VEHICLE DISTANCE Indicates [ON/OFF] condit ion of intelligent brake assist signal.

IGN SW Indicates [ON/OFF] condition of ignition switch.

FR DOOR SW RH Indicates [Close/Open] condition of front door switch (RH).

FR DOOR SW LH Indicates [Close/Open] condition of front door switch (LH).

ABS ACTIVATING Indicates [ON/OFF] co ndition of ABS operation signal.

VHCL SPEED Indicates [Km/h] vehicle speed signal.

BRK PEDAL SNSR1 Indicates [V] voltage of brake pedal stroke sensor 1 signal.

BRK PEDAL SNSR2 Indicates [V] voltage of brake pedal stroke sensor 2 signal.

STRG ANGLE Indicates [deg] steering angle signal.

STRG ANGLE SPEED Indicates [deg/s] steering angle speed signal.

INCLINATION JDMT Indicates [ON/OFF] condition of pre roll over signal.

PRE-TEN ACTIVTN Indicates [ON/OFF] condition of pre-tensioner operated signal.

HEAT PROTC RH Indicates [ON/OFF] condition of heat protection (RH).

HEAT PROTC LH Indicates [ON/OFF] condition of heat protection (LH).

Revision: 2010 May2011 QX56