water pump INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 943 of 5598

CO-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION CO

A

CO

N

O P

CONTENTS

ENGINE COOLING SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Commercial Service Tools ................................. ......3

SYSTEM DESCRIPTION ..............................4

DESCRIPTION ............................................... .....4

Engine Cooling System ..................................... ......4

Engine Cooling System Schematic .........................5

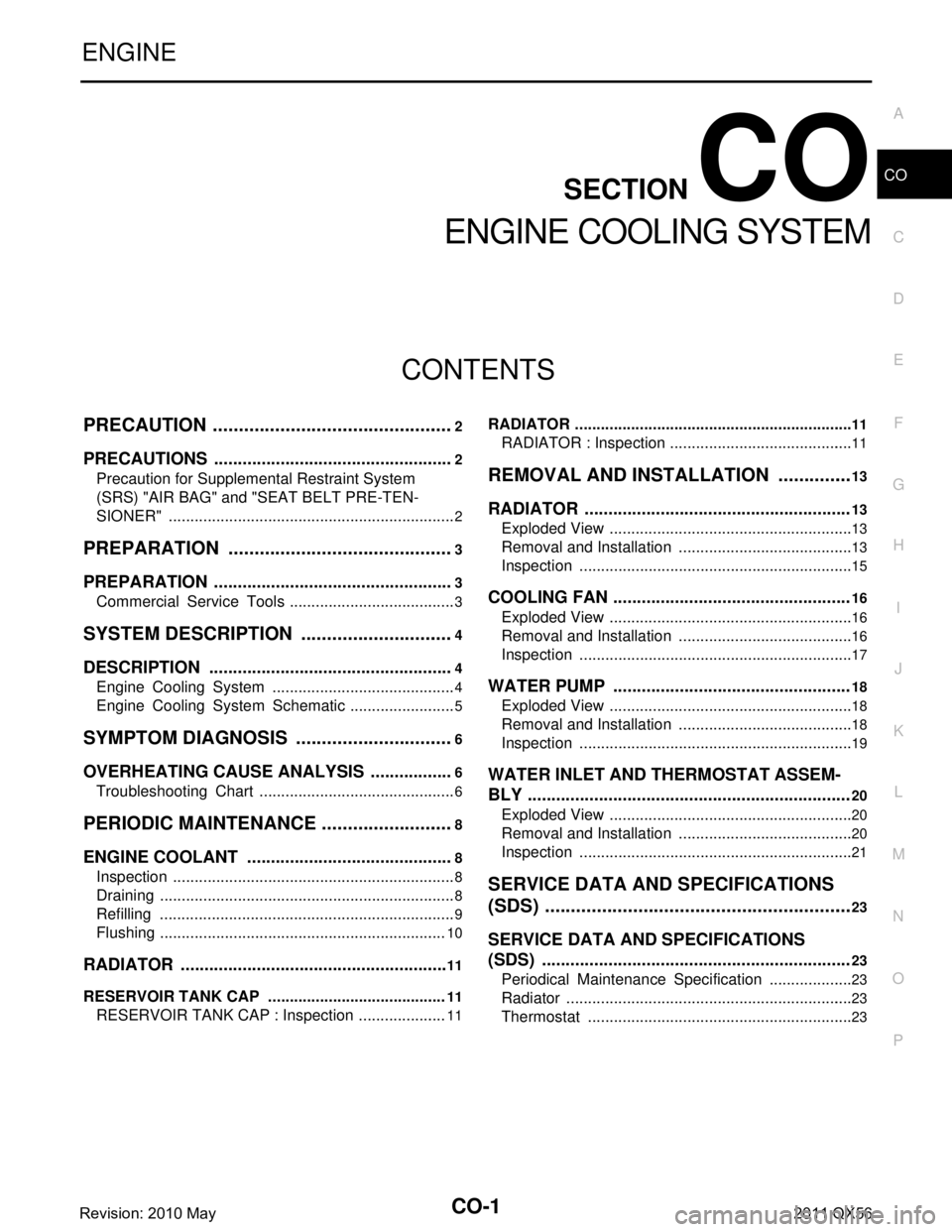

SYMPTOM DIAGNOSIS ...............................6

OVERHEATING CAUSE ANALYSIS ............. .....6

Troubleshooting Chart ........................................ ......6

PERIODIC MAINTENANCE ..........................8

ENGINE COOLANT ....................................... .....8

Inspection ............................................................ ......8

Draining .....................................................................8

Refilling .....................................................................9

Flushing ...................................................................10

RADIATOR .........................................................11

RESERVOIR TANK CAP ..........................................11

RESERVOIR TANK CAP : Inspection ................. ....11

RADIATOR ............................................................. ....11

RADIATOR : Inspection ...........................................11

REMOVAL AND INSTALLATION ...............13

RADIATOR ....................................... .................13

Exploded View ..................................................... ....13

Removal and Installation .........................................13

Inspection ................................................................15

COOLING FAN ..................................................16

Exploded View .........................................................16

Removal and Installation .........................................16

Inspection ................................................................17

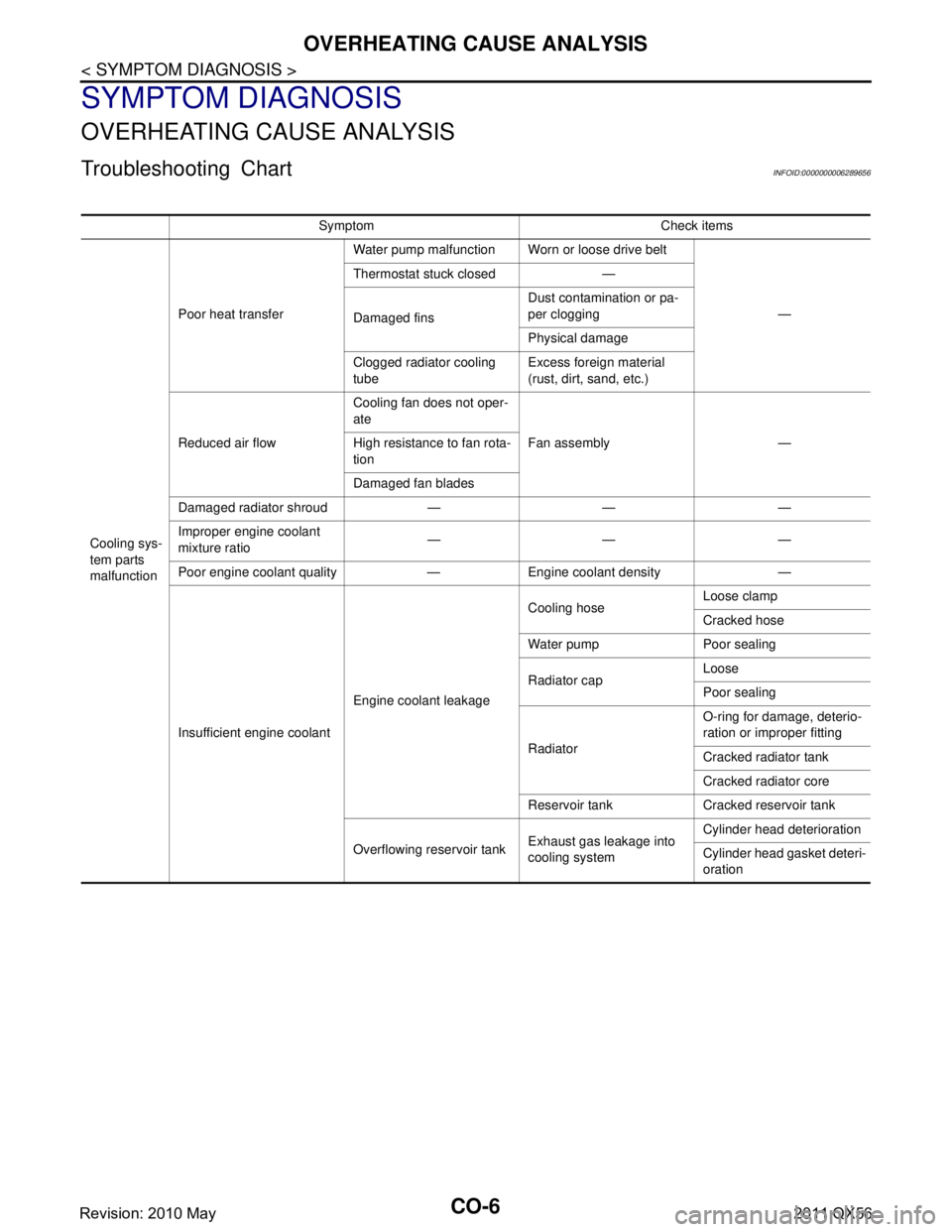

WATER PUMP ..................................................18

Exploded View .........................................................18

Removal and Installation .........................................18

Inspection ................................................................19

WATER INLET AND THERMOSTAT ASSEM-

BLY ....................................................................

20

Exploded View .........................................................20

Removal and Installation .........................................20

Inspection ................................................................21

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

23

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

23

Periodical Maintenance Specification ................ ....23

Radiator ...................................................................23

Thermostat ..............................................................23

Revision: 2010 May2011 QX56

Page 948 of 5598

CO-6

< SYMPTOM DIAGNOSIS >

OVERHEATING CAUSE ANALYSIS

SYMPTOM DIAGNOSIS

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000006289656

Symptom Check items

Cooling sys-

tem parts

malfunction Poor heat transfer

Water pump malfunction Worn or loose drive belt

—

Thermostat stuck closed —

Damaged fins

Dust contamination or pa-

per clogging

Physical damage

Clogged radiator cooling

tube Excess foreign material

(rust, dirt, sand, etc.)

Reduced air flow Cooling fan does not oper-

ate

Fan assembly —

High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud — — —

Improper engine coolant

mixture ratio ———

Poor engine coolant quality — Engine coolant density —

Insufficient engine coolant Engine coolant leakageCooling hose

Loose clamp

Cracked hose

Water pump Poor sealing

Radiator cap Loose

Poor sealing

Radiator O-ring for da

mage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tank Exhaust gas leakage into

cooling system Cylinder head deterioration

Cylinder head gasket deteri-

oration

Revision: 2010 May2011 QX56

Page 960 of 5598

CO-18

< REMOVAL AND INSTALLATION >

WATER PUMP

WATER PUMP

Exploded ViewINFOID:0000000006289669

Removal and InstallationINFOID:0000000006289670

CAUTION:

When removing water pump assembly, be careful not to get engine coolant on drive belts.

Water pump cannot be disassembled and should be replaced as a unit.

After installing water pump, co nnect hose and clamp securely, then check for leakage using the radi-

ator cap tester (commercial service tool) and the radiator cap tester adapter (commercial service

tool).

REMOVAL

1. Drain engine coolant from drain plugs on radiator and cylinder block. Refer to CO-8, "Draining" and EM-

103, "Setting".

CAUTION:

Perform this step when engine is cold.

Never spill engine coolant on drive belt.

2. Remove front under cover with power tool. Refer to EXT-25, "

Exploded View".

3. Remove fan shroud (lower). Refer to CO-13, "

Exploded View".

4. Move reservoir tank to the position with out the hindrance for work. Refer to CO-13, "

Exploded View".

5. Remove radiator core support cover. Refer to DLK-220, "

Exploded View".

6. Remove fan shroud (upper). Refer to CO-13, "

Exploded View".

7. Remove drive belt. Refer to EM-20, "

Exploded View".

8. Remove cooling fan, fan coupling, cooling fan pulley and bracket. Refer to CO-16, "

Exploded View"

9. Remove radiator hose (upper). Refer to CO-13, "Exploded View".

10. Remove water pump pulley.

1. Water pump pulley 2. Water pump 3. Gasket

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA2316GB

Revision: 2010 May2011 QX56

Page 961 of 5598

WATER PUMPCO-19

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

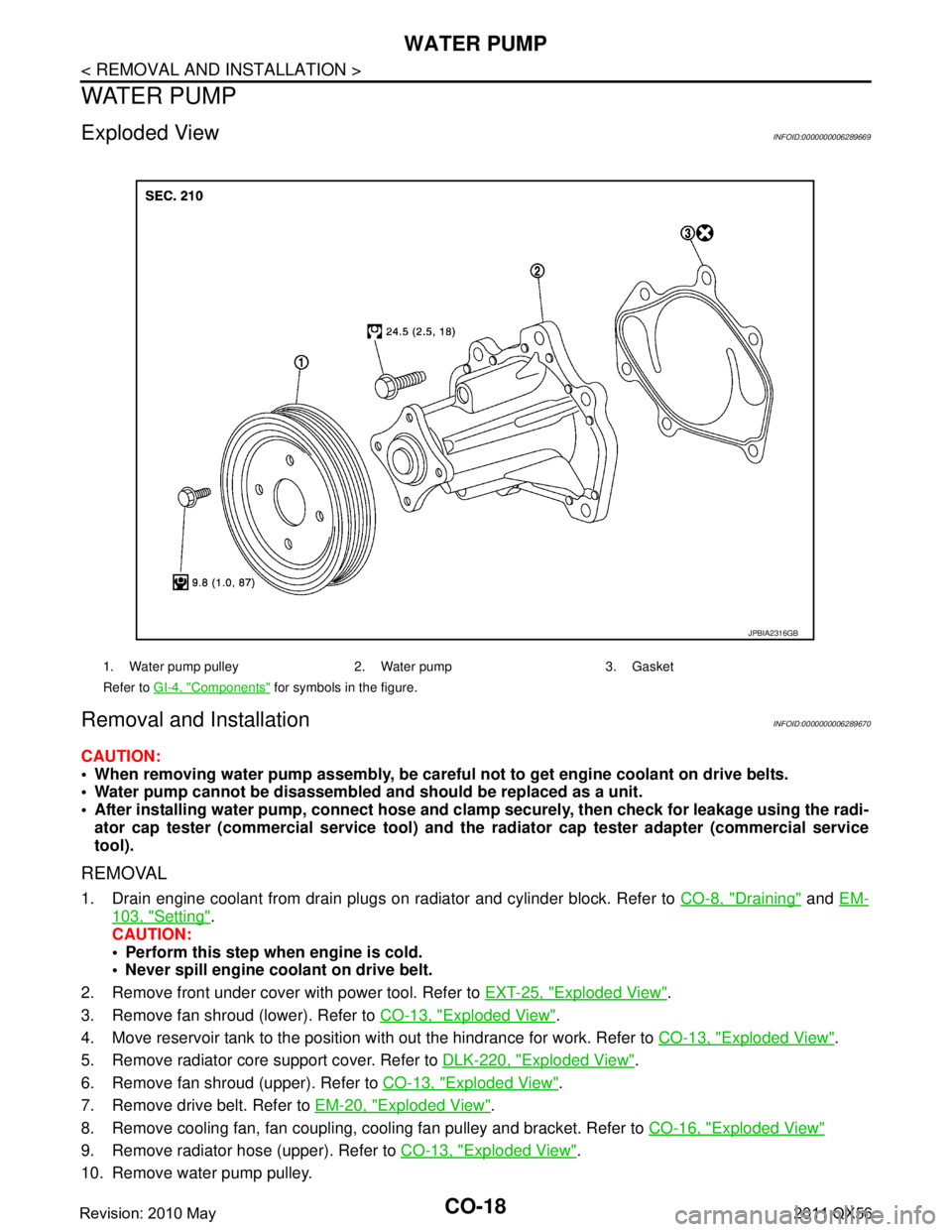

11. Remove water pump. Refer to

CO-18, "Exploded View".

Engine coolant will leak from cylinder block, so have a receptacle ready under vehicle.

CAUTION:

Handle the water pump vane so that it does not contact any other parts.

Never disassemble water pump.

INSTALLATION

Install in the reverse order of removal.

InspectionINFOID:0000000006289671

INSPECTION AFTER REMOVAL

Visually check that there is no significant dirt or rusting on water pump body and vane (A).

Check there is no slack in vane shaft, and that it turns smoothly when rotated by hand.

If anything is found, replace water pump.

INSPECTION AFTER INSTALLATION

Check that the reservoir tank cap is tightened.

Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-8, "

Inspection".

Start and warm up the engine. Visually check that there is no leakage of engine coolant.

JPBIA2315ZZ

Revision: 2010 May2011 QX56

Page 2100 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-76

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

EVAP DIAG READY Ignition switch: ON Indicates the ready condi-

tion of EVAP leak diagnosis.

VVEL LEARN Ignition switch: OFF

→ ON

(After warming INFINITI QX56 2011 Factory Service Manual

EC-76

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

EVAP DIAG READY Ignition switch: ON Indicates the ready condi-

tion of EVAP leak diagnosis.

VVEL LEARN Ignition switch: OFF

→ ON

(After warming](/img/42/57033/w960_57033-2099.png)

EC-76

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

EVAP DIAG READY Ignition switch: ON Indicates the ready condi-

tion of EVAP leak diagnosis.

VVEL LEARN Ignition switch: OFF

→ ON

(After warming up) VVEL learning has no

t been performed

yet. YET

VVEL learning has already been per-

formed successfully. DONE

VVEL SEN LEARN-B1 VVEL learning has already been performed successfully Approx. 0.30 - 0.80 V

VVEL SEN LEARN-B2 VVEL learning has already been performed successfully Approx. 0.30 - 0.80 V

VVEL POSITION SEN-

B1 Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle Approx. 0.25 - 1.50 V

When revving engine up to 2,000 rpm

quickly

Approx. 0.25 - 4.75 V

VVEL POSITION SEN-

B2 Engine: After warming up

Selector lever: P or N position

Air conditioner switch: OFF

No load Idle Approx. 0.25 - 1.50 V

When revving engine up to 2,000 rpm

quickly

Approx. 0.25 - 4.75 V

VVEL TIM-B1 Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle Approx. 0 - 23 deg

When revving engine up to 2,000 rpm

quickly

Approx. 0 - 90 deg

VVEL TIM-B2 Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle Approx. 0 - 23 deg

When revving engine up to 2,000 rpm

quickly

Approx. 0 - 90 deg

FPCM Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Engine: Cranking HI

Revving engine from idle to 4,000 rpm

quickly MID

Engine: Idle

Engine coolant temperature: More than 10 °C (50 °F) LOW

BAT TEMP SEN Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle

Indicates the temperature

around the battery.

COOLING FAN SPD Engine speed: Idle

Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Water temp: Less than 98

°C Approx. 100 – 200 rpm

Water temp: More than 98 °C Approx. 600 – 700 rpm

THRTL STK CNT B1 NOTE:

The item is indicated, but not used. —

HO2 S2 DIAG2(B1) NOTE:

The item is indicated, but not used.

—

HO2 S2 DIAG2(B2) NOTE:

The item is indicated, but not used. —

FUEL INJ TIMG Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle Approx. 16 deg

2,000 rpm Approx.

−170 deg

H/P FUEL PUMP DEG Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle Approx. 211.0 deg

2,000 rpm Approx. 206.0 deg

Monitor Item Condition Values/Status

Revision: 2010 May2011 QX56

Page 2219 of 5598

![INFINITI QX56 2011 Factory Service Manual

P0087, P0088, P0090 FRP CONTROL SYSTEM

EC-195

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0087, P0088, P0090 FRP CONTROL SYSTEM

DTC LogicINFOID:0000000006217784

DTC DETECTION INFINITI QX56 2011 Factory Service Manual

P0087, P0088, P0090 FRP CONTROL SYSTEM

EC-195

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0087, P0088, P0090 FRP CONTROL SYSTEM

DTC LogicINFOID:0000000006217784

DTC DETECTION](/img/42/57033/w960_57033-2218.png)

P0087, P0088, P0090 FRP CONTROL SYSTEM

EC-195

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0087, P0088, P0090 FRP CONTROL SYSTEM

DTC LogicINFOID:0000000006217784

DTC DETECTION LOGIC

NOTE:

If DTC P0087 or P0090 is displayed with DTC P1197, first perform the trouble diagnosis for DTC

P1197.

DTC P0087 or P0090 may be displayed when running out of gas.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is 11 V or more at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE-I

1. Check that the fuel tank is 1/8 full of fuel.

2. Warm up the engine to the normal operating temperature and keep the engine speed at idle for 60 sec- onds.

NOTE:

Warm up the engine until “COOLAN TEMP/S” on “DATA MONITOR” of CONSULT-III reaches at least

70 °C (158 °F).

3. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Proceed to EC-196, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-II

1. Cool the engine until the engine coolant temperature reaches 60 °C (140 °F) or less.

2. Start the engine and wait at least 60 seconds.

3. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Proceed to EC-196, "Diagnosis Procedure".

NO >> INSPECTION END

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0087 High fuel pressure too low The following condition continues for 5

seconds or more after engine start (re-

gardless of water temperature): Target

fuel pressure

− Actual fuel pressure ≥

2.7 MPa (27 bar, 27.5 kg/cm

2, 392 psi)

Harness or connectors(The fuel pump circuit is open or shorted.)

Fuel system

P0088 high fuel pressure too high The following condition continues for 5

seconds or more after engine start (re-

gardless of water temperature):Actual

fuel pressure

− Target fuel pressure ≥

2.7 MPa (27 bar, 27.5 kg/cm

2, 392 psi)

P0090 High pressure fuel pump per-

formance Fuel rail pressure remains at 1.5 MPa

(15 bar, 15.3 kg/ cm

2, 217.5 psi) or less

for 3 seconds or more during engine rev.

Revision: 2010 May2011 QX56

Page 2297 of 5598

![INFINITI QX56 2011 Factory Service Manual

P0181 FTT SENSOREC-273

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component Inspection (Fuel

Tank Temperature Sensor)INFOID:0000000006288291

1.CHECK FUEL TANK TEMPERATURE SEN INFINITI QX56 2011 Factory Service Manual

P0181 FTT SENSOREC-273

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component Inspection (Fuel

Tank Temperature Sensor)INFOID:0000000006288291

1.CHECK FUEL TANK TEMPERATURE SEN](/img/42/57033/w960_57033-2296.png)

P0181 FTT SENSOREC-273

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component Inspection (Fuel

Tank Temperature Sensor)INFOID:0000000006288291

1.CHECK FUEL TANK TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect “fuel level sensor unit and fuel pump” harness connector.

3. Remove fuel level sensor unit.

4. Check resistance between “fuel level sensor unit and fuel pump ” terminals by heating with hot water as shown in the figure.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace “fuel level sensor unit and fuel pump”.

Terminals Condition Resistance (k Ω)

4 and 5 Temperature [ °C ( °F)] 20 (68) 2.3 - 2.7

50 (122) 0.79 - 0.90

JMBIA0167ZZ

Revision: 2010 May2011 QX56

Page 2299 of 5598

![INFINITI QX56 2011 Factory Service Manual

P0182, P0183 FTT SENSOREC-275

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Loose or poor connection for each connector and harness

>> Repair open circuit, short to ground or s INFINITI QX56 2011 Factory Service Manual

P0182, P0183 FTT SENSOREC-275

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Loose or poor connection for each connector and harness

>> Repair open circuit, short to ground or s](/img/42/57033/w960_57033-2298.png)

P0182, P0183 FTT SENSOREC-275

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Loose or poor connection for each connector and harness

>> Repair open circuit, short to ground or short to power in harness or connector.

4.CHECK FUEL TANK TEMPERATURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect combination meter harness connector.

3. Check the continuity between “fuel level sensor unit and fuel pump” harness connector and “combination

meter” harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

Harness for open or short between “fuel level s ensor unit and fuel pump” and “combination meter”

Loose or poor connection for each connector and harness

>> Repair open circuit, short to ground or short to power in harness or connector.

6.CHECK FUEL TANK TEMPERATURE SENSOR

Refer to EC-275, "

Component Inspection (Fuel Tank Temperature Sensor)".

Is the inspection result normal?

YES >> GO TO 7.

NO >> Replace “fuel level sensor unit and fuel pump”. Refer to FL-5, "

Removal and Installation".

7.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component Inspection (Fuel Tank Temperature Sensor)INFOID:0000000006288294

1.CHECK FUEL TANK TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect “fuel level sensor unit and fuel pump” harness connector.

3. Remove fuel level sensor unit.

4. Check resistance between “fuel level sensor unit and fuel pump ” terminals by heating with hot water as shown in the figure.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace “fuel level sensor unit and fuel pump”.

Fuel level sensor unit and fuel pump Combination meter

Continuity

Connector Terminal Connector Terminal

C5 5 M34 24 Existed

Terminals Condition Resistance (k Ω)

4 and 5 Temperature [ °C ( °F)] 20 (68) 2.3 - 2.7

50 (122) 0.79 - 0.90

JMBIA0167ZZ

Revision: 2010 May2011 QX56

Page 2369 of 5598

![INFINITI QX56 2011 Factory Service Manual

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOREC-345

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Check if water will drain from the EVAP canister (1).

- EVAP canister vent contro INFINITI QX56 2011 Factory Service Manual

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOREC-345

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Check if water will drain from the EVAP canister (1).

- EVAP canister vent contro](/img/42/57033/w960_57033-2368.png)

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOREC-345

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Check if water will drain from the EVAP canister (1).

- EVAP canister vent control valve (2)

Does water drain from EVAP canister?

YES >> GO TO 17.

NO >> GO TO 19.

17.CHECK EVAP CANISTER

Weigh the EVAP canister with the EV AP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 2.5 kg (5.5 lb).

Is the inspection result normal?

YES >> GO TO 19.

NO >> GO TO 18.

18.DETECT MALFUNCTIONING PART

Check the following.

EVAP canister for damage

EVAP hose between EVAP canister and vehi cle frame for clogging or poor connection

>> Repair hose or replace EVAP canister. Refer to FL-10, "

Hydraulic Layout".

19.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component Inspection (EVAP Cont rol System Pressure Sensor)INFOID:0000000006288365

1.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

1. Turn ignition switch OFF.

2. Remove EVAP control system pressure sensor with its harness connector. Always replace O-ring with a new one.

3. Install a vacuum pump to EVAP control system pressure sensor.

4. Turn ignition switch ON and check output voltage between ECM harness connector terminals under the following conditions.

CAUTION:

Always calibrate the vacuum pu mp gauge when using it.

Never apply below -93.3 kPa (-0.952 kg/cm

2, -13.53 psi) or pressure over 101.3 kPa (1.033 kg/cm2,

14.69 psi).

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace EVAP control system pressure sensor.

JSBIA0692ZZ

ECM Condition

[Applied vacuum kPa (kg/cm

2, psi)] Voltage (V)

Connector +–

Terminal Terminal

E80 143 150 Not applied 1.8 - 4.8

-26.7 (-0.272, -3.87) 2.1 to 2.5 lower than above value

Revision: 2010 May2011 QX56

Page 2424 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-400

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P1217 ENGINE OVER TEMPERATURE

P1217 ENGINE OVER TEMPERATURE

DTC LogicINFOID:0000000006217909

DTC DETECTION LOGIC

NOTE:

If DTC P1217 is displayed with DTC UX INFINITI QX56 2011 Factory Service Manual

EC-400

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P1217 ENGINE OVER TEMPERATURE

P1217 ENGINE OVER TEMPERATURE

DTC LogicINFOID:0000000006217909

DTC DETECTION LOGIC

NOTE:

If DTC P1217 is displayed with DTC UX](/img/42/57033/w960_57033-2423.png)

EC-400

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P1217 ENGINE OVER TEMPERATURE

P1217 ENGINE OVER TEMPERATURE

DTC LogicINFOID:0000000006217909

DTC DETECTION LOGIC

NOTE:

If DTC P1217 is displayed with DTC UXXXX, perform the trouble diagnosis for DTC UXXXX.

If DTC P1217 is displayed with DTC P0607, perfo rm the trouble diagnosis for DTC P0607. Refer to

EC-378, "

DTC Logic".

If DTC P1217 is displayed with DTC P0527, perfo rm the trouble diagnosis for DTC P0527. Refer to

EC-367, "

DTC Logic".

If the cooling fan or any of other components in the cooling system has a malfunction, engine coolant temper-

ature increases.

When the engine coolant temperature reaches an abnorma lly high temperature condition, a malfunction is

indicated.

CAUTION:

When a malfunction is indicated, al ways replace the coolant. Refer to CO-8, "

Draining" and CO-9,

"Refilling". Also, replace the engine oil. Refer to LU-8, "Draining" and LU-8, "Refilling".

1. Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Always use

coolant with the proper mixture ratio. Refer to MA-11, "

Anti-Freeze Coolant Mixture Ratio".

2. After refilling coolant, run engine to en sure that no water-flow noise is emitted.

DTC CONFIRMATION PROCEDURE

1.PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to EC-400, "

Component Function Check".

NOTE:

Use component function check to check the overall functi on of the cooling fan. During this check, a DTC might

not be confirmed.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-401, "

Diagnosis Procedure".

Component Function CheckINFOID:0000000006217910

1.PERFORM COMPONENT FUNCTION CHECK-I

WARNING:

Never remove the reservoir tank cap when the engi ne is hot. Serious burns could be caused by high

pressure fluid escaping from the radiator.

Wrap a thick cloth around cap. Carefully remove the cap by turning it a quarter turn to allow built-up

pressure to escape. Then turn the cap all the way off.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1217 Engine over temperature

(Overheat) Cooling fan does not operate properly

(Overheat).

Cooling fan system does not operate properly (Overheat).

Engine coolant is not within the specified quantity. Harness or connectors

(The cooling fan circuit is open or shorted.)

IPDM E/R

Electrically-controlled cooling fan coupling

Cooling fan speed sensor

Radiator hose

Radiator

Reservoir tank cap

Water pump

Thermostat

Revision: 2010 May2011 QX56