brake fluid INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3754 of 5598

MWI

SYSTEMMWI-11

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

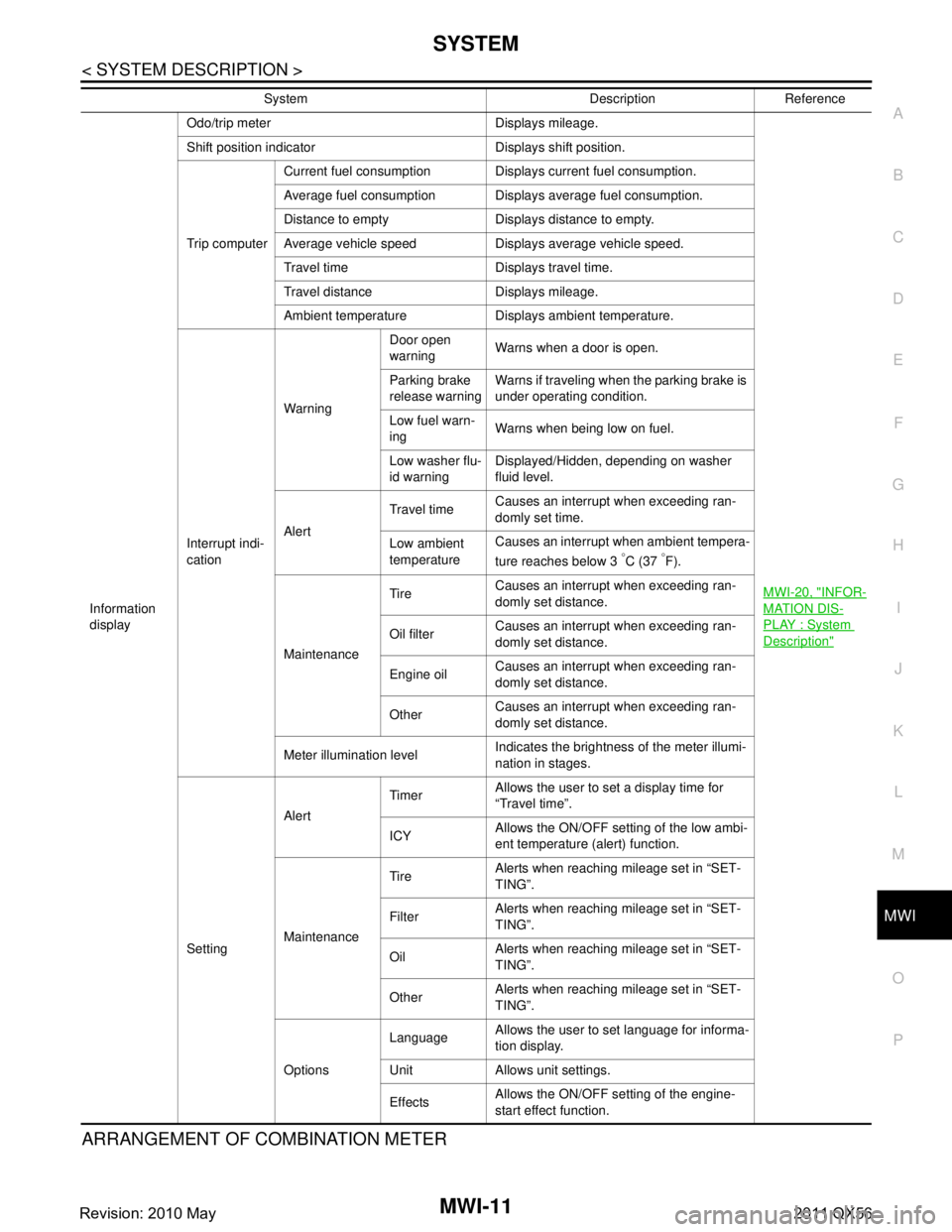

ARRANGEMENT OF COMBINATION METER

Information

display Odo/trip meter Displays mileage.

MWI-20, "

INFOR-

MATION DIS-

PLAY : System

Description"

Shift position indicator Displays shift position.

Trip computerCurrent fuel consumption Displays current fuel consumption.

Average fuel consumption Displays average fuel consumption.

Distance to empty Displays distance to empty.

Average vehicle speed Displays average vehicle speed.

Travel time Displays travel time.

Travel distance Displays mileage.

Ambient temperature Displays ambient temperature.

Interrupt indi-

cation Warning

Door open

warning

Warns when a door is open.

Parking brake

release warning Warns if traveling when the parking brake is

under operating condition.

Low fuel warn-

ing Warns when being low on fuel.

Low washer flu-

id warning Displayed/Hidden, depending on washer

fluid level.

Alert Travel time

Causes an interrupt when exceeding ran-

domly set time.

Low ambient

temperature Causes an interrupt when ambient tempera-

ture reaches below 3

°C (37 °F).

Maintenance Tire

Causes an interrupt when exceeding ran-

domly set distance.

Oil filter Causes an interrupt when exceeding ran-

domly set distance.

Engine oil Causes an interrupt when exceeding ran-

domly set distance.

Other Causes an interrupt when exceeding ran-

domly set distance.

Meter illumination level Indicates the brightness of the meter illumi-

nation in stages.

Setting Alert

Timer

Allows the user to set a display time for

“Travel time”.

ICY Allows the ON/OFF setting of the low ambi-

ent temperature (alert) function.

Maintenance Tire

Alerts when reaching mileage set in “SET-

TING”.

Filter Alerts when reaching mileage set in “SET-

TING”.

Oil Alerts when reaching mileage set in “SET-

TING”.

Other Alerts when reaching mileage set in “SET-

TING”.

Options Language

Allows the user to set language for informa-

tion display.

Unit Allows unit settings.

Effects Allows the ON/OFF setting of the engine-

start effect function.

System Description Reference

Revision: 2010 May2011 QX56

Page 3759 of 5598

MWI-16

< SYSTEM DESCRIPTION >

SYSTEM

OIL PRESSURE WARNING LAMP : System Description

INFOID:0000000006221709

IPDM E/R reads the ON/OFF signals fr om the oil pressure switch and transmits the oil pressure switch sig-

nal to the combination meter via BCM with the CAN communication.

The combination meter turns the oil pressure warning lamp ON (at the time of a reduction in hydraulic pres-

sure)/OFF (except at the time of a reduction in hydraulic pressure) according to the oil pressure switch signal

received via CAN communication.

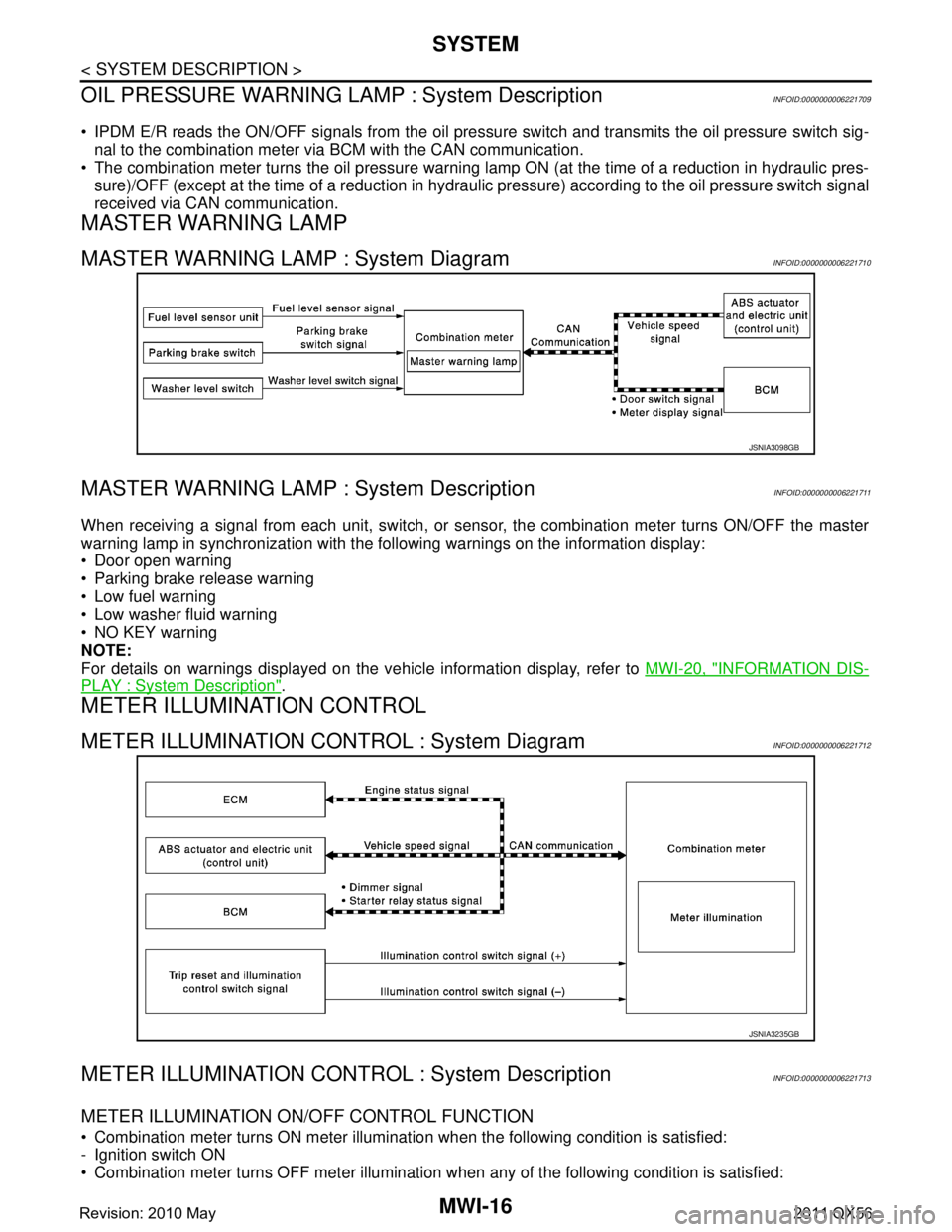

MASTER WARNING LAMP

MASTER WARNING LAMP : System DiagramINFOID:0000000006221710

MASTER WARNING LAMP : System DescriptionINFOID:0000000006221711

When receiving a signal from each unit, switch, or s ensor, the combination meter turns ON/OFF the master

warning lamp in synchronization with the following warnings on the information display:

Door open warning

Parking brake release warning

Low fuel warning

Low washer fluid warning

NO KEY warning

NOTE:

For details on warnings displayed on the vehicle information display, refer to MWI-20, "

INFORMATION DIS-

PLAY : System Description".

METER ILLUMINATION CONTROL

METER ILLUMINATION CONTROL : System DiagramINFOID:0000000006221712

METER ILLUMINATION CONTRO L : System DescriptionINFOID:0000000006221713

METER ILLUMINATION ON/OFF CONTROL FUNCTION

Combination meter turns ON meter illumination when the following condition is satisfied:

- Ignition switch ON

Combination meter turns OFF meter illumination when any of the following condition is satisfied:

JSNIA3098GB

JSNIA3235GB

Revision: 2010 May2011 QX56

Page 3774 of 5598

![INFINITI QX56 2011 Factory Service Manual

MWI

DIAGNOSIS SYSTEM (COMBINATION METER)

MWI-31

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K L

M B A

O P

W TEMP METER

[ ° C] XValue of engine coolant temperature signal is received from ECM via CAN com INFINITI QX56 2011 Factory Service Manual

MWI

DIAGNOSIS SYSTEM (COMBINATION METER)

MWI-31

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K L

M B A

O P

W TEMP METER

[ ° C] XValue of engine coolant temperature signal is received from ECM via CAN com](/img/42/57033/w960_57033-3773.png)

MWI

DIAGNOSIS SYSTEM (COMBINATION METER)

MWI-31

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K L

M B A

O P

W TEMP METER

[ ° C] XValue of engine coolant temperature signal is received from ECM via CAN com-

munication.

NOTE:

215 is displayed when the malfunction signal is input.

ABS W/L

[On/Off] Status of ABS warning lamp detected fr

om ABS warning lamp signal is received

from ABS actuator and electric unit (control unit) via CAN communication.

VDC/TCS IND

[On/Off] Status of VDC OFF indicator lamp detected from VDC OFF indicator lamp signal

is received from ABS actuator

and electric unit (control unit) via CAN communica-

tion.

SLIP IND

[On/Off] Status of VDC warning lamp detected from VDC warning lamp signal received

from ABS actuator and electric unit (control unit) via CAN communication.

BRAKE W/L

[On/Off] Status of brake warning lamp detected from brake warning lamp signal is received

from ABS actuator and electric unit (control unit) via CAN communication.

NOTE:

Displays “Off” if the brake warning lamp is illuminated when the valve check starts,

the parking brake switch is turned ON or the brake fluid level switch is turned ON.

DOOR W/L

[On/Off] Status of door open warning detected from door switch signal received from BCM

via CAN communication.

HI-BEAM IND

[On/Off] Status of high beam indicator lamp detected from high beam request signal is re-

ceived from BCM via CAN communication.

TURN IND

[On/Off] Status of turn indicator lamp detected from turn indicator signal is received from

BCM via CAN communication.

FR FOG IND

[Off] This item is displayed, but cannot be monitored.

RR FOG IND

[Off] This item is displayed, but cannot be monitored.

LIGHT IND

[On/Off] Status of light indicator lamp detected from position light request signal is received

from BCM via CAN communication.

OIL W/L

[On/Off] Status of oil pressure warning lamp detected from oil pressure switch signal is re-

ceived from BCM via CAN communication.

MIL

[On/Off] Status of malfunction indicator lamp detected from malfunctioning indicator lamp

signal is received from ECM via CAN communication.

GLOW IND

[Off] This item is displayed, but cannot be monitored.

CRUISE IND

[On/Off] Status of CRUISE indicator detected from ASCD status signal is received from

ECM via CAN communicat ion. (ASCD models)

Status of CRUISE indicator de tected from meter display signal is received from

ADAS control unit via CAN communication. (ICC models)

SET IND

[On/Off] Status of SET indicator detected from meter display signal is received from ADAS

control unit via CAN communication.

CRUISE W/L

[On/Off] Status of CRUISE warning lamp

judged from ICC warning lamp signal received

from ADAS control unit with CAN communication line.

BA W/L

[On/Off] Status of IBA OFF indicator lamp judged from IBA OFF indicator lamp signal re-

ceived from ADAS control unit with CAN communication line.

ATC/T-AMT W/L

[On/Off] Status of A/T CHECK warning lamp judged

from A/T CHECK indicator lamp signal

received from TCM with CAN communication line.

ATF TEMP W/L

[Off] This item is displayed, but cannot be monitored.

4WD W/L

[On/Off] Status of 4WD warning lamp judged from 4WD warning lamp signal received from

4WD control unit with

CAN communication line.

FUEL W/L

[On/Off] Low-fuel warning lamp status detected by the identified fuel level.

WASHER W/L

[On/Off] Status of low washer fluid warning judged from washer level switch input to com-

bination meter.

Display item [Unit]

MAIN

SIGNALS Description

Revision: 2010 May2011 QX56

Page 3776 of 5598

MWI

DIAGNOSIS SYSTEM (COMBINATION METER)

MWI-33

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K L

M B A

O P

*: DDS (hill descent control) NOTE:

Some items are not available according to vehicle specification.

SPECIAL FUNCTION

Special menu

W/L ON HISTORY

Stores histories when warning/indicator lamp is turned on.

“W/L ON HISTORY” indicates the “TIME” when the warning/ indicator lamp is turned on.

The “TIME” above is:

- 0: The condition that the warning/indicator lamp has been turned on 1 or more times after starting the engine and waiting for 30 seconds.

- 1 - 39: The number of times the engine was restarted after the 0 condition.

- NO W/L ON HISTORY: Stores NO (0) turning on history of warning/indicator lamp.

NOTE:

W/L ON HISTORY is not stored for approximately 30 seconds after the engine starts.

Brake warning lamp does not store any history when the parking brake is applied or the brake fluid level gets

low.

Display Item

AT SFT DWN SW

[On/Off] Status of manual mode shift down switch.

PKB SW

[On/Off] Status of parking brake switch.

BUCKLE SW

[On/Off] Status of seat belt buckle switch (driver side).

BRAKE OIL SW

[On/Off] Status of brake fluid level switch.

A/C AMP CONN

[Off] This item is displayed, but cannot be monitored.

ENTER SW

[On/Off] Status of (ENTER) switch.

SELECT SW

[On/Off] Status of (SELECT) switch.

DISTANCE

[km] Value of distance to empty calculated by combination meter.

OUTSIDE TEMP

[ ° C or °F] Ambient temperature value converted from ambient sensor signal received from

ambient sensor.

NOTE:

This may not match with the temperature value indicated on the information dis-

play. (Because the information display value is a corrected value from the ambient

sensor input value.)

FUEL LOW SIG

[On/Off] Status of fuel level low warning signal to output to AV control unit via CAN com-

munication.

TOW MODE IND

[On/Off] Status of TOW mode indicator lamp judged from TOW mode indicator lamp signal

received from TCM with CAN communication line.

BUZZER

[On/Off] XBuzzer status (in the combination meter) is detected from the buzzer output signal

received from each unit via CAN communication and the warning output condition

of the combination meter.

Display item [Unit]

MAIN

SIGNALS Description

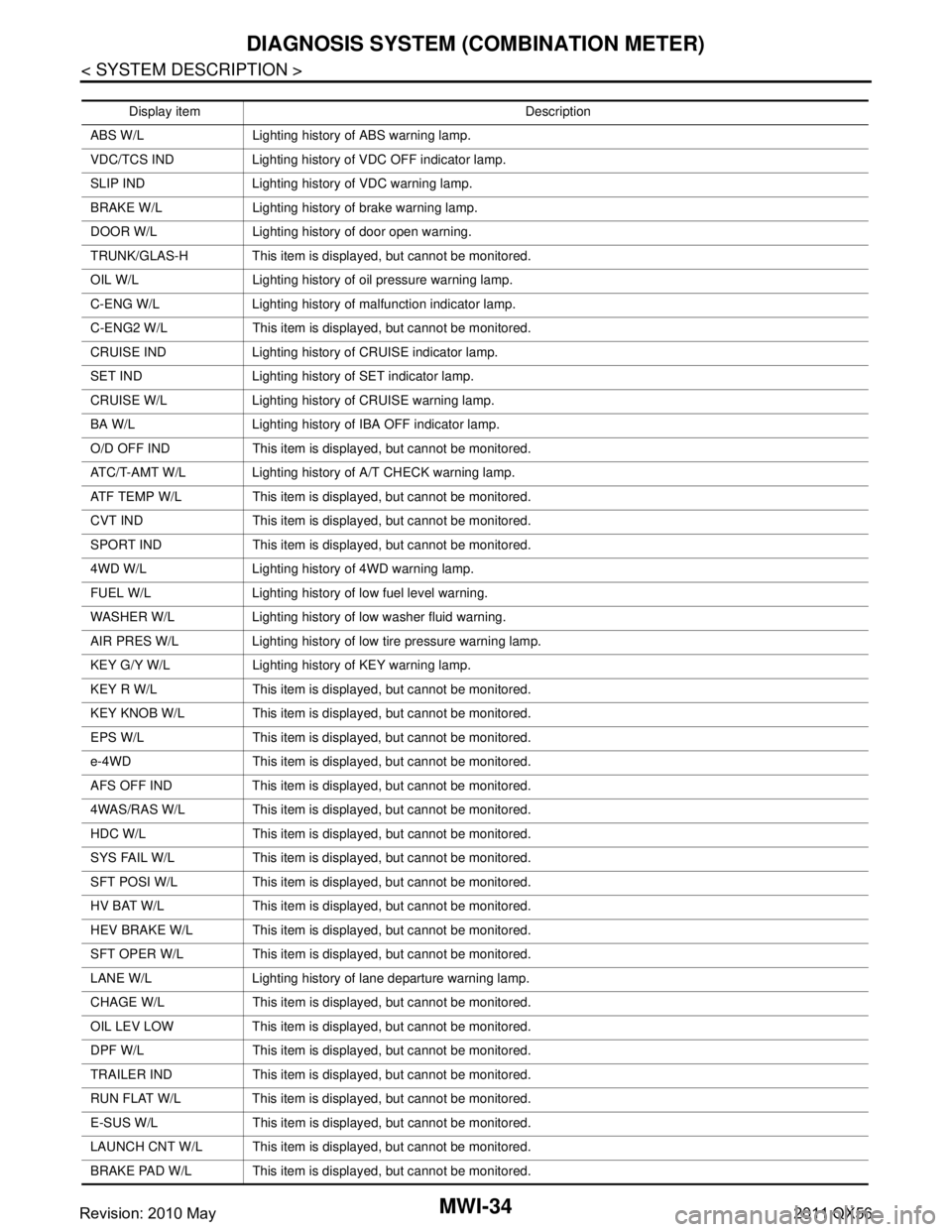

Display item Description

W/L ON HISTORY Lighting history of warning lamp and indicator lamp can be checked.

Revision: 2010 May2011 QX56

Page 3777 of 5598

MWI-34

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (COMBINATION METER)

Display item Description

ABS W/L Lighting history of ABS warning lamp.

VDC/TCS IND Lighting history of VDC OFF indicator lamp.

SLIP IND Lighting history of VDC warning lamp.

BRAKE W/L Lighting history of brake warning lamp.

DOOR W/L Lighting history of door open warning.

TRUNK/GLAS-H This item is displa yed, but cannot be monitored.

OIL W/L Lighting history of oil pressure warning lamp.

C-ENG W/L Lighting history of malfunction indicator lamp.

C-ENG2 W/L This item is displayed, but cannot be monitored.

CRUISE IND Lighting history of CRUISE indicator lamp.

SET IND Lighting history of SET indicator lamp.

CRUISE W/L Lighting history of CRUISE warning lamp.

BA W/L Lighting history of IBA OFF indicator lamp.

O/D OFF IND This item is displayed, but cannot be monitored.

ATC/T-AMT W/L Lighting history of A/T CHECK warning lamp.

ATF TEMP W/L This item is displayed, but cannot be monitored.

CVT IND This item is displayed, but cannot be monitored.

SPORT IND This item is displayed, but cannot be monitored.

4WD W/L Lighting history of 4WD warning lamp.

FUEL W/L Lighting history of low fuel level warning.

WASHER W/L Lighting history of low washer fluid warning.

AIR PRES W/L Lighting history of low tire pressure warning lamp.

KEY G/Y W/L Lighting history of KEY warning lamp.

KEY R W/L This item is displaye d, but cannot be monitored.

KEY KNOB W/L This item is displa yed, but cannot be monitored.

EPS W/L This item is displayed, but cannot be monitored.

e-4WD This item is displayed, but cannot be monitored.

AFS OFF IND This item is displayed, but cannot be monitored.

4WAS/RAS W/L This item is displayed, but cannot be monitored.

HDC W/L This item is displayed, but cannot be monitored.

SYS FAIL W/L This item is displa yed, but cannot be monitored.

SFT POSI W/L This item is displayed, but cannot be monitored.

HV BAT W/L This item is displayed, but cannot be monitored.

HEV BRAKE W/L This item is displayed, but cannot be monitored.

SFT OPER W/L This item is displayed, but cannot be monitored.

LANE W/L Lighting history of lane departure warning lamp.

CHAGE W/L This item is displayed, but cannot be monitored.

OIL LEV LOW This item is displayed, but cannot be monitored.

DPF W/L This item is displayed, but cannot be monitored.

TRAILER IND This item is displayed, but cannot be monitored.

RUN FLAT W/L This item is displa yed, but cannot be monitored.

E-SUS W/L This item is displayed, but cannot be monitored.

LAUNCH CNT W/L This item is displayed, but cannot be monitored.

BRAKE PAD W/L This item is displa yed, but cannot be monitored.

Revision: 2010 May2011 QX56

Page 3781 of 5598

MWI-38

< ECU DIAGNOSIS INFORMATION >

COMBINATION METER

SHIFT INDIgnition switch

ONDuring the indication of “P” by shift position

indicator

P

During the indication of “R” by shift position

indicator R

During the indication of “N” by shift position

indicator N

During the indication of “D” by shift position

indicator D

During the indication of “M1” by shift posi-

tion indicator M1

During the indication of “M2” by shift posi-

tion indicator M2

During the indication of “M3” by shift posi-

tion indicator M3

During the indication of “M4” by shift posi-

tion indicator M4

During the indication of “M5” by shift posi-

tion indicator M5

During the indication of “M6” by shift posi-

tion indicator M6

During the indication of “M7” by shift posi-

tion indicator M7

4WD IND Ignition switch

ON4WD shift switch in AUTO position AUTO

4WD shift switch in 4H position LOCK

4WD shift switch in 4L position LOCK/4Lo

BSW IND Ignition switch

ONNOTE:

This item is displayed, but cannot be moni-

tored.

Off

BSW W/L Ignition switch

ONBSW warning lamp ON On

BSW warning lamp OFF Off

AT S MODE SW Ignition switch

ONSnow mode switch ON On

Snow mode switch OFF Off

M RANGE SW Ignition switch

ONSelector lever in manual mode position On

Other than the above Off

NM RANGE SW Ignition switch

ONSelector lever in manual mode position Off

Other than the above On

AT SFT UP SW Ignition switch

ONSelector lever in + position On

Other than the above Off

AT SFT DWN SW Ignition switch

ONSelector lever in – position On

Other than the above Off

PKB SW Ignition switch

ONParking brake switch ON On

Parking brake switch OFF Off

BUCKLE SW Ignition switch

ONDriver seat belt not fastened On

Driver seat belt fastened Off

BRAKE OIL SW Ignition switch

ONBrake fluid level switch ON On

Brake fluid level switch OFF Off

A/C AMP CONN Ignition switch

ONNOTE:

This item is displayed, but cannot be moni-

tored.

Off

Monitor Item Condition Value/Status

Revision: 2010 May2011 QX56

Page 4273 of 5598

RSU-18

< UNIT REMOVAL AND INSTALLATION >

REAR SUSPENSION MEMBER

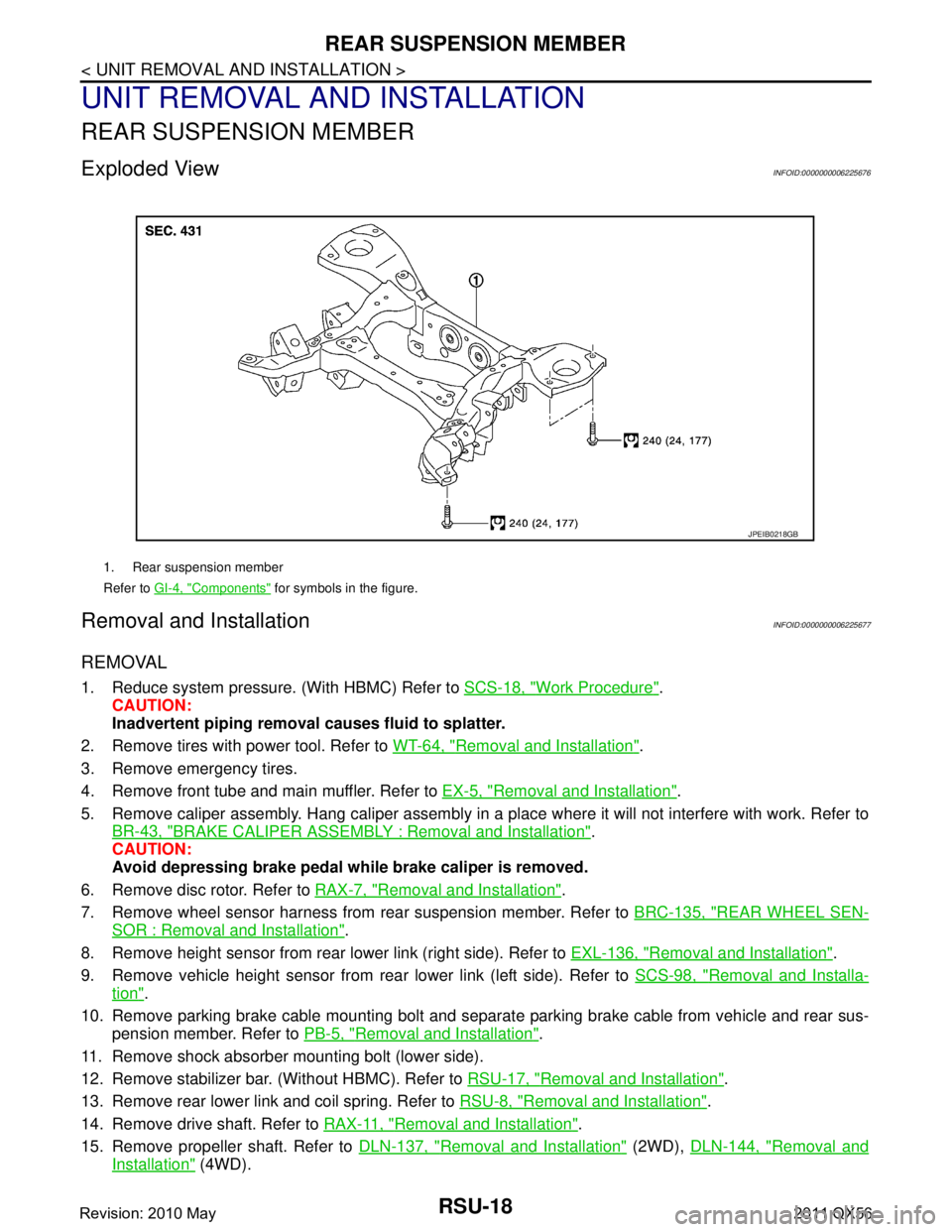

UNIT REMOVAL AND INSTALLATION

REAR SUSPENSION MEMBER

Exploded ViewINFOID:0000000006225676

Removal and InstallationINFOID:0000000006225677

REMOVAL

1. Reduce system pressure. (With HBMC) Refer to SCS-18, "Work Procedure".

CAUTION:

Inadvertent piping removal causes fluid to splatter.

2. Remove tires with power tool. Refer to WT-64, "

Removal and Installation".

3. Remove emergency tires.

4. Remove front tube and main muffler. Refer to EX-5, "

Removal and Installation".

5. Remove caliper assembly. Hang caliper assembly in a place where it will not interfere with work. Refer to BR-43, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

CAUTION:

Avoid depressing brake pedal wh ile brake caliper is removed.

6. Remove disc rotor. Refer to RAX-7, "

Removal and Installation".

7. Remove wheel sensor harness from rear suspension member. Refer to BRC-135, "

REAR WHEEL SEN-

SOR : Removal and Installation".

8. Remove height sensor from rear lower link (right side). Refer to EXL-136, "

Removal and Installation".

9. Remove vehicle height sensor from rear lower link (left side). Refer to SCS-98, "

Removal and Installa-

tion".

10. Remove parking brake cable mounting bolt and separa te parking brake cable from vehicle and rear sus-

pension member. Refer to PB-5, "

Removal and Installation".

11. Remove shock absorber mounting bolt (lower side).

12. Remove stabilizer bar. (Without HBMC). Refer to RSU-17, "

Removal and Installation".

13. Remove rear lower link and coil spring. Refer to RSU-8, "

Removal and Installation".

14. Remove drive shaft. Refer to RAX-11, "

Removal and Installation".

15. Remove propeller shaft. Refer to DLN-137, "

Removal and Installation" (2WD), DLN-144, "Removal and

Installation" (4WD).

1. Rear suspension member

Refer to GI-4, "

Components" for symbols in the figure.

JPEIB0218GB

Revision: 2010 May2011 QX56

Page 4365 of 5598

![INFINITI QX56 2011 Factory Service Manual

PRECAUTIONSSCS-5

< PRECAUTION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ign INFINITI QX56 2011 Factory Service Manual

PRECAUTIONSSCS-5

< PRECAUTION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ign](/img/42/57033/w960_57033-4364.png)

PRECAUTIONSSCS-5

< PRECAUTION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006256138

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Hydraulic Body-Motion Control SystemINFOID:0000000006255996

WARNING:

Always check the piping for loose co nnections, damage, or twists before starting operation, since

pressure in hydraulic circuit becom es high during air bleeding operation.

When repairing or replacing a malfunctioning pa rt, always release pressure from hydraulic circuit,

since dangerous conditions may be created when oil leakage occurs during air bleeding operation.

Clean surrounding areas of oil inlet and air bleeder usi ng steam before starting operation, since there may

be mud on it.

Always decrease pressure when removing a system related part, since system pressure is high.

Seal the removed part using vinyl tape for preventi ng dirt from getting on or entering the removed part.

Check system pressure again 1 day or more after bleeding operation is complete, since system pressure may decrease when air bleeding is insufficient.

Use Genuine NISSAN Hydraulic Suspension Fluid for suspension fluid.

Never reuse drained suspension fluid.

Check for suspension fluid leakage after removing a system-related part.

PIIB3706J

Revision: 2010 May2011 QX56

Page 4406 of 5598

![INFINITI QX56 2011 Factory Service Manual

SCS-46

< REMOVAL AND INSTALLATION >[HBMC]

HYDRAULIC BODY-MOTION CONTROL SYSTEM

3. Remove lower side pipe (A) of rear shock absorber RH.

4. Remove pipe (A) from left side rear joint (B).

5. Remove mou INFINITI QX56 2011 Factory Service Manual

SCS-46

< REMOVAL AND INSTALLATION >[HBMC]

HYDRAULIC BODY-MOTION CONTROL SYSTEM

3. Remove lower side pipe (A) of rear shock absorber RH.

4. Remove pipe (A) from left side rear joint (B).

5. Remove mou](/img/42/57033/w960_57033-4405.png)

SCS-46

< REMOVAL AND INSTALLATION >[HBMC]

HYDRAULIC BODY-MOTION CONTROL SYSTEM

3. Remove lower side pipe (A) of rear shock absorber RH.

4. Remove pipe (A) from left side rear joint (B).

5. Remove mounting bolts of bracket of rear tube assembly B.

6. Remove mounting bolts of bracket of rear left brake hose, and

then free hose.

7. Remove rear tube assembly B from the vehicle.

8. Perform inspection after removal. Refer to SCS-46, "

REAR

TUBE ASSEMBLY : Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

Apply genuine NISSAN hydraulic suspension fluid to O-ring.

Check connection portion of each piping for dirt or dust.

REAR TUBE ASSEMBLY : InspectionINFOID:0000000006256034

INSPECTION AFTER REMOVAL

O-ring must be free of scratches and damage.

Pipe and tube must be free of scratches and damage.

INSPECTION AFTER INSTALLATION

Check oil leakage, twists, deformation, contact with other parts, and loose connections.

ADJUSTMENT AFTER INSTALLATION

Perform air bleeding. Refer to SCS-18, "Work Procedure".

JSEIA0212ZZ

JSEIA0204ZZ

Revision: 2010 May2011 QX56

Page 5001 of 5598

ST-14

< BASIC INSPECTION >

STEERING WHEEL

STEERING WHEEL

InspectionINFOID:0000000006225584

NEUTRAL POSITION STEERING WHEEL

1. Check that steering gear assembly, steering column assembly and steering wheel are installed in the cor-

rect position.

2. Perform neutral position inspection after wheel alignment. Refer to FSU-7, "

Inspection".

3. Set vehicle to the straight-ahead position and c onfirm steering wheel is in the neutral position.

4. Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if steering wheel is not in the neutral position.

STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Tires need to be inflated the specified pressure. Refer to WT-69, "

Tire Air Pressure".

3. Start the engine.

4. Bring power steering fluid up to adequate operating temperature.

5. Check steering wheel turning force when steering wheel has been turned 540 ° from neutral position.

NOTE:

Multiply the distance (L) from the hook of spring balance to the

center of steering wheel by the measurement value with a spring

balance.

6. If steering wheel turning force is out of the specification, check

rack sliding force and relief hydraulic pressure of oil pump.

Regarding relief hydraulic pressure of oil pump, refer to ST-52, "

Inspection".

RACK SLIDING FORCE

1. Disconnect lower joint and steering knuckle from steering gear assembly. Refer to ST-41, "Exploded

View".

2. Start and run engine at idle to make sure steer ing fluid has reached normal operating temperature.

3. While pulling outer socket slowly in ±11.5 mm ( ±0.453 in) range

from neutral position, make sure rack sliding force is within

specification.

4. If rack sliding force is not within specification, overhaul steering gear assembly.

FRONT WHEEL TURNING ANGLE

1. Check front wheel turning angle after toe-in inspection. Refer to FSU-7, "Inspection".

Fluid temperature : 50 – 80

°C (122 – 176 °F)

Steering wheel turning

force : Refer to

ST-57, "

Steering

Wheel Turning Force".

JSGIA0027ZZ

Fluid temperature : 50 – 80 °C (122 – 176 °F)

Rack sliding force : Refer to ST-58, "

Rack

Sliding Force".

SST090B

Revision: 2010 May2011 QX56