warning light INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1 of 5598

A

B

D

E

F

G

H

I

J

K

L

M

N

P

O

C

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

STRStarting System

ACCAccelerator Control System

CHYBRIDHBCHybrid Control System

HBBHybrid Battery System

HBRHybrid Brake System

DTRANSMISSION & DRIVE-

LINECLClutch

TMTransaxle & Transmission

DLNDriveline

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

SCSSuspension Control System

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGSTSteering System

STCSteering Control System

HRESTRAINTSSBSeat Belt

SBCSeat Belt Control System

SRSRS Airbag

SRCSRS Airbag Control System

IVENTILATION, HEATER &

AIR CONDITIONERVTLVentilation System

HAHeater & Air Conditioning System

HACHeater & Air Conditioning Control System

JBODY INTERIORINTInterior

IPInstrument Panel

SESeat

ADPAutomatic Drive Positioner

KBODY EXTERIOR,

DOORS, ROOF & VEHICLE

SECURITYDLKDoor & Lock

SECSecurity Control System

GWGlass & Window System

PWCPower Window Control System

RFRoof

HDHood

EXTExterior

BRMBody Repair

LDRIVER CONTROLSMIRMirrors

EXLExterior Lighting System

INLInterior Lighting System

WWWiper & Washer

DEFDefogger

HRNHorn

MELECTRICAL & POWER

CONTROLPWOPower Outlet

BCSBody Control System

LANLAN System

PCSPower Control System

CHGCharging System

PGPower Supply, Ground & Circuit Elements

NDRIVER INFORMATION &

MULTIMEDIAMWIMeter, Warning Lamp & Indicator

WCSWarning Chime System

SNSonar System

AVAudio, Visual & Navigation System

OCRUISE CONTROL &

DRIVER ASSISTANCECCSCruise Control System

DASDriver Assistance System

DMSDrive Mode System

PMAINTENANCEMAMaintenance

All rights reserved. No part

of this Service Manual may

be reproduced or stored in a

retrieval system, or transmit-

ted in any form, or by any

means, electronic, mechani-

cal, recording or otherwise,

without the prior written per-

mission of NISSAN MOTOR

CO., LTD.

Edition: May 2010

Publication No. SM1E-1Z62U0

Page 160 of 5598

AV-12

< SYSTEM DESCRIPTION >

COMPONENT PARTS

*1: Image signals cannot be received from iPod®.

Side camera RH It inputs the power supply from around view monitor control unit and outputs the

image of the vehicle RH to around view monitor control unit.

It performs the reception/transmission of the communication signal with around view monitor control unit.

Infrared LED

(Auxiliary lighting) It illuminates around the front RH wheel by the power supply from around view

monitor control unit to improve nighttime visibility of front-side view.

The infrared LED is an invisible light ray.

Sonar control unit It is connected with around view monitor control unit via AV communication and

receives the sonar operation signal from around view monitor control unit.

It transmits the sonar detection status to around view monitor control unit via AV

communication.

It judges the warning level according to the signal from corner sensor.

Corner sensor The obstacle distance is detected. The signal is transmitted to sonar control unit.

Steering angle sensor It is connected to the AV control unit and transmits the steering angle sensor signal

via CAN communication.

Microphone Used for hands-free phone operation.

Microphone signal is transmitted to AV control unit.

Power (Microphone VCC) is supplied from AV control unit.

GPS antenna GPS signal is received and transmitted to AV control unit.

Satellite radio antenna Receives the satellite radio waves and outputs it to AV control unit.

Antenna amp. Radio signal received by glass antenna (main) is amplified and transmitted to AV

control unit.

Power (antenna amp. ON signal) is supplied from AV control unit.

USB connector Image signal

*1 and sound signal of USB input is transmitted to AV control unit.

Part name Description

Revision: 2010 May2011 QX56

Page 175 of 5598

AV

SYSTEMAV-27

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

When the light switch is in the 1st or 2nd position, the dimming of the display is judged according to a dimming

signal transmitted from BCM to the AV control unit. Dis play illuminance is independent of vehicle exterior illu-

minance detected by the auto light detecting sensor ev en when the light switch is in 1st or 2nd position.

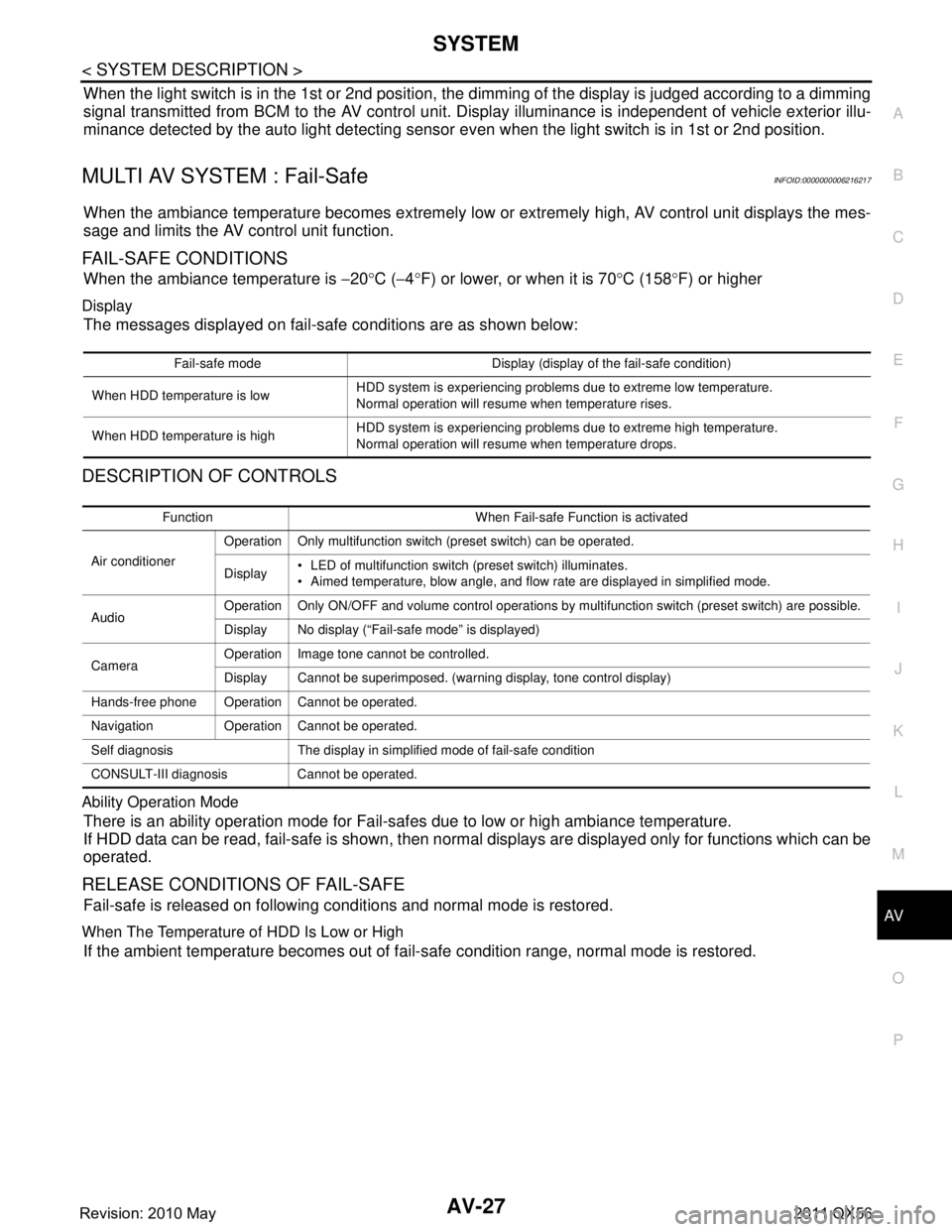

MULTI AV SYSTEM : Fail-SafeINFOID:0000000006216217

When the ambiance temperature becomes extremely low or extremely high, AV control unit displays the mes-

sage and limits the AV control unit function.

FAIL-SAFE CONDITIONS

When the ambiance temperature is −20 °C ( −4 °F) or lower, or when it is 70 °C (158 °F) or higher

Display

The messages displayed on fail-safe conditions are as shown below:

DESCRIPTION OF CONTROLS

Ability Operation Mode

There is an ability operation mode for Fail-safes due to low or high ambiance temperature.

If HDD data can be read, fail-safe is shown, then normal displays are displayed only for functions which can be

operated.

RELEASE CONDITIONS OF FAIL-SAFE

Fail-safe is released on following conditions and normal mode is restored.

When The Temperature of HDD Is Low or High

If the ambient temperature becomes out of fa il-safe condition range, normal mode is restored.

Fail-safe mode Display (display of the fail-safe condition)

When HDD temperature is low HDD system is experienci

ng problems due to extreme low temperature.

Normal operation will resume when temperature rises.

When HDD temperature is high HDD system is experienci

ng problems due to extreme high temperature.

Normal operation will resume when temperature drops.

Function When Fail-safe Function is activated

Air conditioner Operation Only multifunction switch (preset switch) can be operated.

Display

LED of multifunction switch (preset switch) illuminates.

Aimed temperature, blow angle, and flow rate are displayed in simplified mode.

Audio Operation Only ON/OFF and volume control operations by multifunction switch (preset switch) are possible.

Display No display (“Fail-safe mode” is displayed)

Camera Operation Image tone cannot be controlled.

Display Cannot be superimposed. (warning display, tone control display)

Hands-free phone Operation Cannot be operated.

Navigation Operation Cannot be operated.

Self diagnosis The display in simplified mode of fail-safe condition

CONSULT-III diagnosis Cannot be operated.

Revision: 2010 May2011 QX56

Page 394 of 5598

BCS-6

< SYSTEM DESCRIPTION >

SYSTEM

SYSTEM

BODY CONTROL SYSTEM

BODY CONTROL SYSTEM : System DescriptionINFOID:0000000006274789

OUTLINE

BCM (Body Control Module) controls the various electrical components. It inputs the information required to

the control from CAN communication and the signal received from each switch and sensor.

BCM has combination switch reading function for reading the operation status of combination switches (light,

turn signal, wiper and washer) in addition to a function fo r controlling the operation of various electrical com-

ponents. It also has the signal transmission function as the passed point of signal and the power saving con-

trol function that reduces the power c onsumption with the ignition switch OFF.

BCM is equipped with the diagnosis function that perfo rms the diagnosis with CONSULT-III and various set-

tings.

BCM CONTROL FUNCTION LIST

System Reference

Combination switch reading system BCS-7, "

COMBINATION SWITCH READING SYSTEM : System

Diagram"

Signal buffer system

BCS-10, "SIGNAL BUFFER SYSTEM : System Diagram"

Power consumption control systemBCS-11, "POWER CONSUMPTION CONTROL SYSTEM : Sys-

tem Diagram"

Auto light system

EXL-11, "AUTO LIGHT SYSTEM : System Diagram"

Turn signal and hazard warning lamp systemEXL-18, "TURN SIGNAL AND HAZARD WARNING LAMP SYS-

TEM : System Diagram"

Headlamp system

EXL-10, "HEADLAMP SYSTEM : System Diagram"

Daytime running light systemEXL-14, "DAYTIME RUNNING LIGHT SYSTEM : System Dia-

gram"

Parking, license plate, side maker and tail lamps system

EXL-18, "PARKING, LICENSE PLATE, SIDE MARKER AND

TAIL LAMP SYSTEM : System Diagram"

Front fog lamp system

EXL-20, "FRONT FOG LAMP SYSTEM : System Diagram"

Exterior lamp battery saver systemEXL-20, "EXTERIOR LAMP BATTERY SAVER SYSTEM : Sys-

tem Diagram"

Interior room la

mp control system INL-6, "INTERIOR ROOM LAMP CONTROL SYSTEM : System

Diagram"

Interior room lamp battery saver system

INL-9, "INTERIOR ROOM LAMP BATTERY SAVER SYSTEM :

System Diagram"

Front wiper and washer systemWW-7, "FRONT WIPER AND WASHER SYSTEM : System Dia-

gram"

Rear wiper and washer systemWW-10, "REAR WIPER AND WASHER SYSTEM : System Dia-

gram"

Headlamp washer system

WW-13, "HEADLAMP WASHER SYSTEM : System Diagram"

Warning chime systemWCS-6, "WARNING CHIME SYSTEM : System Diagram"

Power door lock systemDLK-16, "System Diagram"

Infiniti Vehicle immobilizer System (IVIS)SEC-15, "INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS :

System Diagram"

Vehicle security systemTheft warning alarm

SEC-17, "VEHICLE SECURITY SYSTEM : System Diagram"Panic alarm

Rear window defogger system DEF-6, "

System Diagram"

Intelligent Key system/engine start systemDLK-18, "INTELLIGENT KEY SYSTEM : System Diagram"

Power window system PWC-8, "SystemDiagram"

Retained accessory power (RAP) systemPWC-8, "System Description"

Revision: 2010 May2011 QX56

Page 405 of 5598

BCS

DIAGNOSIS SYSTEM (BCM)BCS-17

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

B A

O P

N

REAR WINDOW DEFOGGER : CONSULT-III

Function (BCM - REAR DEFOGGER)

INFOID:0000000006376460

Data monitor

ACTIVE TEST

BUZZER

BUZZER : CONSULT-III Function (BCM - BUZZER)INFOID:0000000006376483

CONSULT-III APPLICATION ITEMS

DATA MONITOR

ACTIVE TEST

INT LAMP

Monitor Item Description

REAR DEF SW Displays “Press (ON)/other (OFF)” status determined with the rear window defogger switch.

PUSH SW Indicates [ON/OFF] condition of push switch.

Test Item Description

REAR DEFOGGER Give a drive signal to the re ar window defogger relay to activate it.

Test item Diagnosis mode Description

BUZZER Data Monitor Displays BCM input data in real time.

Active Test Operation of electrical loads can be checked by sending driving signal to them.

Display item

[Unit] Description

PUSH SW

[On/Off] Status of push-button ignition switch judged by BCM.

UNLK SEN-DR

[On/Off] Status of unlock sensor judged by BCM.

VEH SPEED 1

[km/h] Value of vehicle speed signal received from combination meter with CAN communication line.

TAIL LAMP SW

[On/Off] Status of lighting switch judged by BCM using the combination switch readout function.

FR FOG SW

[On/Off] Status of front fog lamp switch judged by BCM using the combination switch readout function.

DOOR SW-DR

[On/Off] Status of driver side door switch judged by BCM.

CDL LOCK SW

[On/Off] Status of door lock unlock switch judged by BCM.

Display item

[Unit] Description

SEAT BELT WARN TEST The seat belt warning chime operation can be checked by operating the relevant function (On/Off).

LIGHT WARN ALM The light warning chime operation can be checked by operating the relevant function (On/Off).

Revision: 2010 May2011 QX56

Page 474 of 5598

BR-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

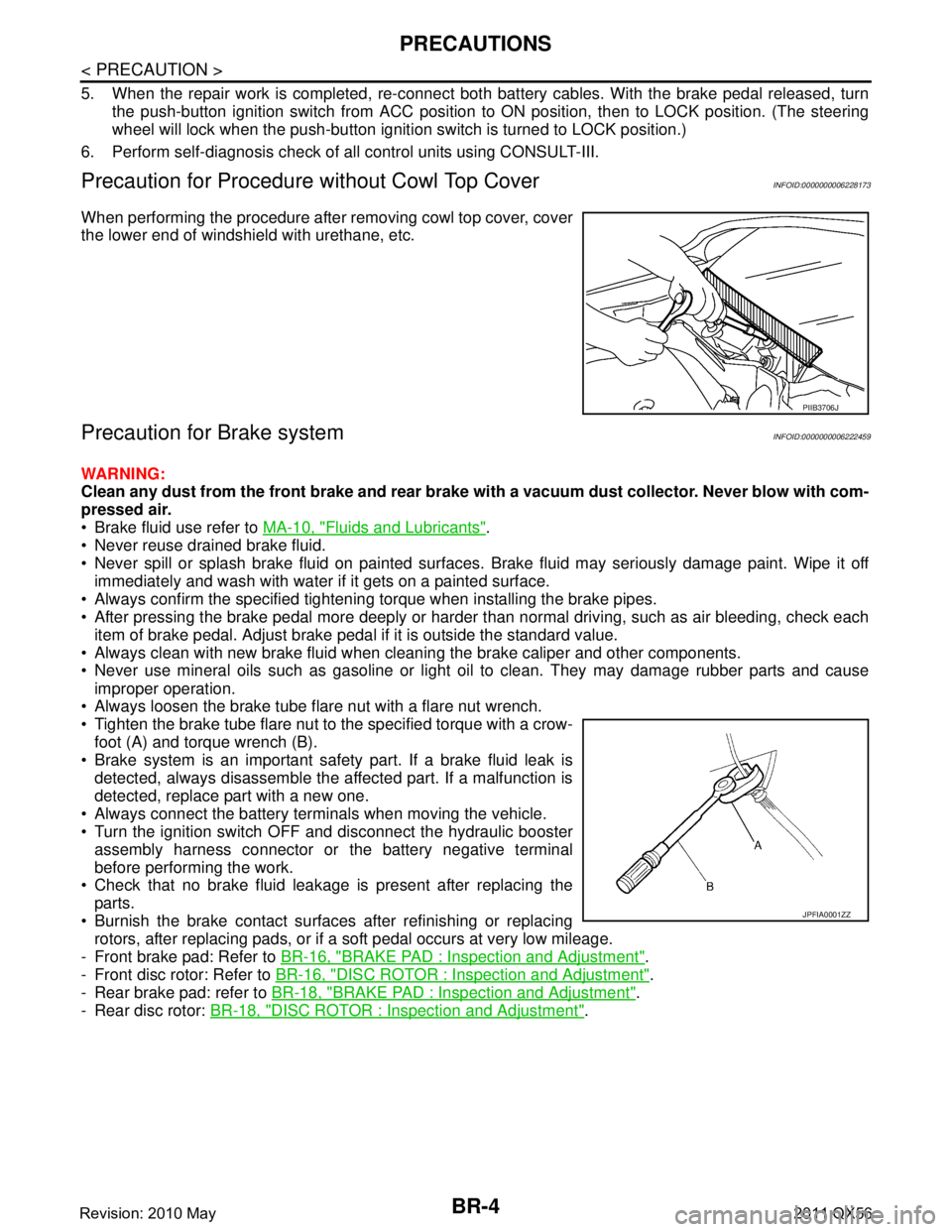

Precaution for Procedure without Cowl Top CoverINFOID:0000000006228173

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake systemINFOID:0000000006222459

WARNING:

Clean any dust from the front brake and rear brake wi th a vacuum dust collector. Never blow with com-

pressed air.

Brake fluid use refer to MA-10, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

Always confirm the specified tightening torque when installing the brake pipes.

After pressing the brake pedal more deeply or harder t han normal driving, such as air bleeding, check each

item of brake pedal. Adjust brake pedal if it is outside the standard value.

Always clean with new brake fluid when cleaning the brake caliper and other components.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause

improper operation.

Always loosen the brake tube flar e nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

Brake system is an important safety part. If a brake fluid leak is detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

Always connect the battery terminals when moving the vehicle.

Turn the ignition switch OFF and disconnect the hydraulic booster assembly harness connector or the battery negative terminal

before performing the work.

Check that no brake fluid leakage is present after replacing the

parts.

Burnish the brake contact surfaces after refinishing or replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

- Front brake pad: Refer to BR-16, "

BRAKE PAD : Inspection and Adjustment".

- Front disc rotor: Refer to BR-16, "

DISC ROTOR : Inspection and Adjustment".

- Rear brake pad: refer to BR-18, "

BRAKE PAD : Inspection and Adjustment".

- Rear disc rotor: BR-18, "

DISC ROTOR : Inspection and Adjustment".

PIIB3706J

JPFIA0001ZZ

Revision: 2010 May2011 QX56

Page 482 of 5598

BR-12

< PERIODIC MAINTENANCE >

BRAKE FLUID

warning lamp, ABS warning lamp, and brake warning lamp turn OFF. After these steps, erase self-

diagnosis results for “ABS” with CONSULT-III.

- DTC other than “C118E” is detected: Refer to BRC-51, "

DTC Index".

NOTE:

When the ignition switch is ON, the brake warning la mp may turns ON even when the parking brake pedal is

released with the brake fluid within the specified level. This indicates the decrease in accumulator fluid pres-

sure.

MOTOR/ACCUMULATOR ASSEMBLY

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never operate the brake pedal with the reservoir cap removed. Failure to do this may cause the scat-

tering of brake fluid.

Never operate the brake pedal excessively during the work procedure.

Monitor the fluid level in the reservoir tank while performing the air bleeding.

Bleed air in the following order: motor/accumulator assembly → front right brake → front left brake

→ rear left brake → and rear right brake.

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more.

3. Check that there is no foreign material in the reservoir tank, and refill with new brake fluid. CAUTION:

Never reuse drained brake fluid.

Never allow oils other than brake fluid to enter the reservoir tank.

4. Turn the ignition switch ON. NOTE:

The motor is activated and automatically stops.

5. Turn the ignition switch OFF.

6. Depress the brake pedal 20 times or more. NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

7. Repeat steps 4 to 6 for 5 times.

8. Turn the ignition switch ON to check that the time between motor activation and automatic stop is less

than 18 seconds. If the time is 18 seconds or more, repeat from Step 4 to 8.

FRONT BRAKE

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never operate the brake pedal with the reservoir cap removed. Failure to do this may cause the scat- tering of brake fluid.

Never operate the brake pedal excessively during the work procedure.

Monitor the fluid level in the reservoir tank while performing the air bleeding.

Bleed air in the following order: motor/accumulator assembly → front right brake → front left brake

→ rear left brake → and rear right brake.

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more. NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Check that there is no foreign material in the reservoir tank, and refill with new brake fluid. CAUTION:

Never reuse drained brake fluid.

Never allow oils other than brake fluid to enter the reservoir tank.

4. Turn the ignition switch ON.

Revision: 2010 May2011 QX56

Page 485 of 5598

HYDRAULIC BOOSTER ASSEMBLYBR-15

< PERIODIC MAINTENANCE >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

HYDRAULIC BOOSTER ASSEMBLY

InspectionINFOID:0000000006222467

OPERATION CHECK

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more. NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Check that the fluid level in the reservoir tank is MAX line.

4. Position the selector lever in P range to release the parking brake.

5. Turn the ignition switch ON to check the time between motor activation and motor stop.

6. After the motor is stopped, check that the ABS warning lamp and the VDC warning lamp in the combina- tion meter are OFF when the engine is started.

7. Stop the engine (ignition switch OFF).

8. Turn the ignition switch ON and depress the brake pedal 4 to 5 times to check the time between motor activation and motor stop.

9. Turn the ignition switch OFF. Turn the ignition switch ON again. Check that the VDC warning lamp turns ON when the brake pedal is depressed 15 to 20 times.

10. Check that the VDC warning lamp turns ON when the brake pedal is depressed 15 to 20 times after the lapse of 120 seconds or more after the ignition switch is turned ON again.

11. Perform the self-diagnosis for “ABS” with CONSULT-III and erase self-diagnosis results.

FUNCTION CHECK

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more.

NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Turn the ignition switch ON with the brake pedal depr essed to check that the clearance between the brake

pedal and the dash lower panel decreases. Motor operating time : 18 seconds or less

Motor operating time : 2

− 11 seconds

Revision: 2010 May2011 QX56

Page 502 of 5598

BR-32

< REMOVAL AND INSTALLATION >

HYDRAULIC BOOSTER ASSEMBLY

Apply new brake fluid to grommet of between reservoir tank and grommet and ABS actuator and electric unit

(control unit).

Inspection and AdjustmentINFOID:0000000006222486

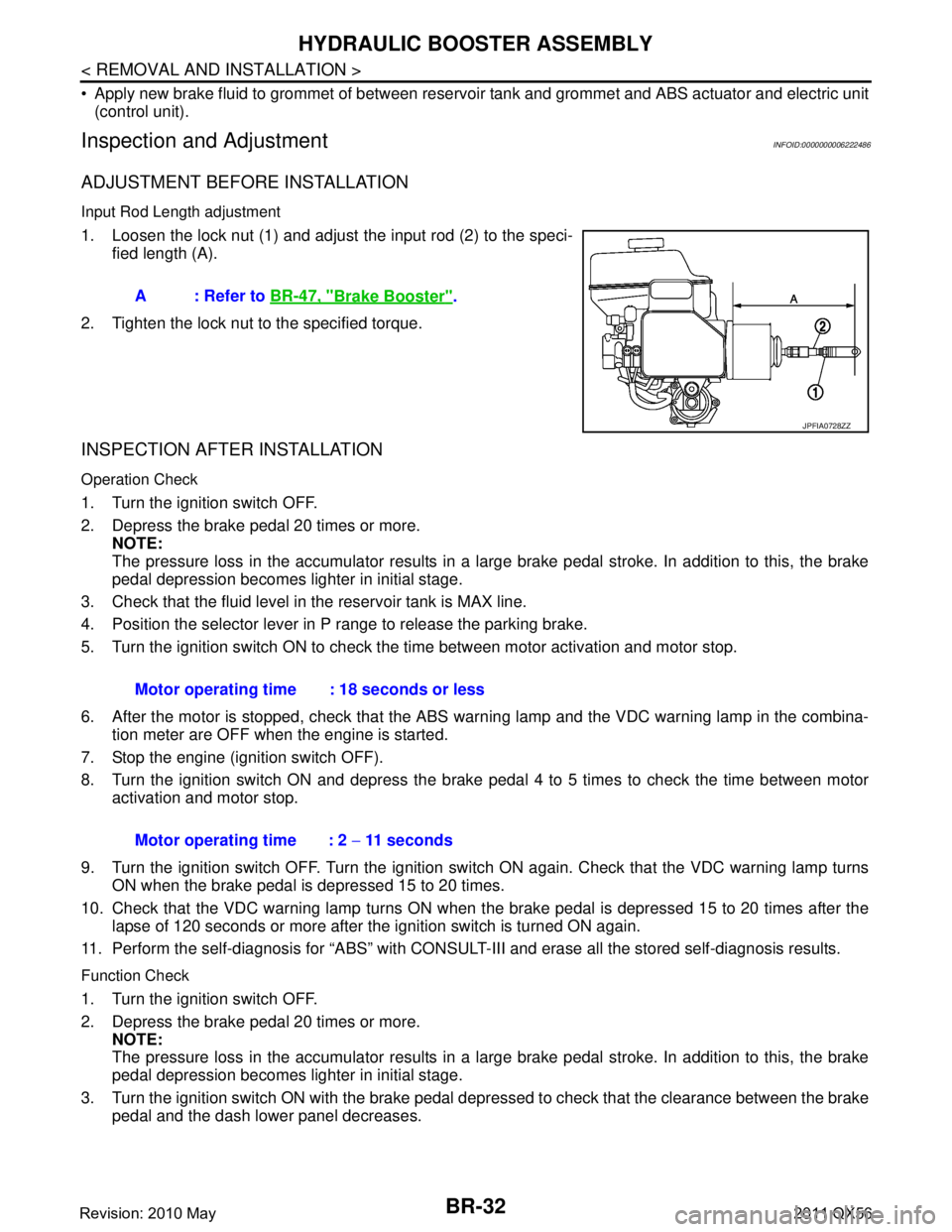

ADJUSTMENT BEFORE INSTALLATION

Input Rod Length adjustment

1. Loosen the lock nut (1) and adjust the input rod (2) to the speci-

fied length (A).

2. Tighten the lock nut to the specified torque.

INSPECTION AFTER INSTALLATION

Operation Check

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more. NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Check that the fluid level in the reservoir tank is MAX line.

4. Position the selector lever in P range to release the parking brake.

5. Turn the ignition switch ON to check the time between motor activation and motor stop.

6. After the motor is stopped, check that the ABS warn ing lamp and the VDC warning lamp in the combina-

tion meter are OFF when the engine is started.

7. Stop the engine (ignition switch OFF).

8. Turn the ignition switch ON and depress the brake pedal 4 to 5 times to check the time between motor activation and motor stop.

9. Turn the ignition switch OFF. Turn the ignition swit ch ON again. Check that the VDC warning lamp turns

ON when the brake pedal is depressed 15 to 20 times.

10. Check that the VDC warning lamp turns ON when the brake pedal is depressed 15 to 20 times after the lapse of 120 seconds or more after the ignition switch is turned ON again.

11. Perform the self-diagnosis for “ABS” with CONSULT- III and erase all the stored self-diagnosis results.

Function Check

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more.

NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Turn the ignition switch ON with the brake pedal depr essed to check that the clearance between the brake

pedal and the dash lower panel decreases. A : Refer to

BR-47, "

Brake Booster".

JPFIA0728ZZ

Motor operating time : 18 seconds or less

Motor operating time : 2 − 11 seconds

Revision: 2010 May2011 QX56

Page 523 of 5598

![INFINITI QX56 2011 Factory Service Manual

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position INFINITI QX56 2011 Factory Service Manual

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position](/img/42/57033/w960_57033-522.png)

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006228176

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000006222556

WARNING:

Clean any dust from the front brake and rear brake using a vacuum dust collector. Never blow by com-

pressed air.

Brake fluid use refer to MA-10, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

Always confirm the specified tightening torque when installing the brake pipes.

After pressing the brake pedal more deeply or harder t han normal driving, such as air bleeding, check each

item of brake pedal. Adjust brake pedal if it is outside the standard value.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause

improper operation.

Always loosen the brake tube flar e nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

Always connect the battery terminal when moving the vehicle.

Turn the ignition switch OFF and disconnect the ABS actuator and

electric unit (control unit) harness connector or the battery negative

terminal before performing the work.

Check that no brake fluid leakage is present after replacing the parts.

Precaution for Brak e Control SystemINFOID:0000000006222557

Slight vibrations are felt on the brake pedal and the operation noises occur, when VDC function, TCS func-

tion, ABS function, EBD function, hill start assist function or brake limited slip differential (BLSD) function

operates. This is not a malfunction because it is caus ed by VDC function, TCS function, ABS function, EBD

function, hill start assist function or brake limited sl ip differential (BLSD) function that is normally operated.

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate or motor

operating noise may be heard from engine compartment. This is normal condition.

Brake stopping distance may become longer than models without ABS function depending on the road con-

ditions, when ABS function is operated on slippery r oad like rough road, gravel road or snowy road.

When a malfunction is indicated, always collect info rmation from the customer about conditions of occur-

rence, estimate cause and perform operation. Check brake booster operation, brake fluid level and brake

fluid leakage, as well as electrical system.

The optimum performance is achieved by control for V DC function, TCS function, ABS function, EBD func-

tion, hill start assist function or brake limited slip di fferential (BLSD) function when all of brakes, suspensions

PIIB3706J

JPFIA0001ZZ

Revision: 2010 May2011 QX56