ECU INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 790 of 5598

![INFINITI QX56 2011 Factory Service Manual

CCS

ICC SENSORCCS-55

< ECU DIAGNOSIS INFORMATION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

Fail-safeINFOID:0000000006224286

If a malfunction occurs in the ICC sensor, ADAS cont rol unit cancels control, INFINITI QX56 2011 Factory Service Manual

CCS

ICC SENSORCCS-55

< ECU DIAGNOSIS INFORMATION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

Fail-safeINFOID:0000000006224286

If a malfunction occurs in the ICC sensor, ADAS cont rol unit cancels control,](/img/42/57033/w960_57033-789.png)

CCS

ICC SENSORCCS-55

< ECU DIAGNOSIS INFORMATION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

Fail-safeINFOID:0000000006224286

If a malfunction occurs in the ICC sensor, ADAS cont rol unit cancels control, sounds a beep, and turns ON the

ICC system warning lamp in the combination meter.

DTC Inspection Priority ChartINFOID:0000000006224287

If multiple DTCs are detected simultaneously, che ck them one by one depending on the following DTC inspec-

tion priority chart.

DTC IndexINFOID:0000000006224288

NOTE:

The details of time display are as per the following.

- 0: The malfunctions that are detected now

CAN communication system (U1000, U1010)

- 1 - 39: It increases like 0 → 1 → 2 ··· 38 → 39 after returning to the normal condition whenever the ignition

switch OFF → ON. It returns to 0 when a malfunc tion is detected again in the process.

- If it is over 39, it is fixed to 39 unt il the self-diagnosis results are erased.

Other than CAN communication s ystem (Other than U1000, U1010)

- 1 - 49: It increases like 0 → 1 → 2 ··· 38 → 49 after returning to the normal condition whenever the ignition

switch OFF → ON. It returns to 0 when a malfunc tion is detected again in the process.

- If it is over 49, it is fixed to 49 unt il the self-diagnosis results are erased.

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

Output

1

(W/G)

GroundIgnition power supply Input Ignition switch ON Battery voltage

3

(L) ITS communication-H — — —

4

(B) Ground — Ignition switch ON 0 V

6

(Y) ITS communication-L — — —

Priority Detected items (DTC)

1 U1000: CAN COMM CIRCUIT

U1010: CONTROL UNIT (CAN)

2 C1A50: ADAS MALFUNCTION

3 C1A01: POWER SUPPLY CIR

C1A02: POWER SUPPLY CIR 2

C1A12: LASER BEAM OFFCNTR

C1A16: RADAR STAIN

C1A18: LASER AIMING INCMP

C1A21: UNIT HIGH TEMP

C1A39: STRG SEN CIR

U0104: ADAS CAN CIR1

U0121: VDC CAN CIR2

U0126: STRG SEN CAN CIR1

U0405: ADAS CAN CIR2

U0415: VDC CAN CIR1

U0428: STRG SEN CAN CIR2

4 C1A00: CONTROL UNIT

Revision: 2010 May2011 QX56

Page 791 of 5598

![INFINITI QX56 2011 Factory Service Manual

CCS-56

< ECU DIAGNOSIS INFORMATION >[ICC]

ICC SENSOR

×

: Applicable

DTC

CONSULT-III display

ICC system warning lamp

Fail-safe function Reference

CONSULT-III

Vehicle-to-vehicle distance control mode

INFINITI QX56 2011 Factory Service Manual

CCS-56

< ECU DIAGNOSIS INFORMATION >[ICC]

ICC SENSOR

×

: Applicable

DTC

CONSULT-III display

ICC system warning lamp

Fail-safe function Reference

CONSULT-III

Vehicle-to-vehicle distance control mode](/img/42/57033/w960_57033-790.png)

CCS-56

< ECU DIAGNOSIS INFORMATION >[ICC]

ICC SENSOR

×

: Applicable

DTC

CONSULT-III display

ICC system warning lamp

Fail-safe function Reference

CONSULT-III

Vehicle-to-vehicle distance control mode

Conventional (fixed speed) cruise control mode

Distance Control Assist (DCA)

Forward Collision Warning (FCW) Intelligent Brake Assist (IBA)

Brake Assist (with preview function)

C1A00 CONTROL UNIT ON ××××××CCS-83

C1A01 POWER SUPPLY CIR ON ××××××CCS-85

C1A02 POWER SUPPLY CIR2 ON ××××××CCS-85

C1A12 LASER BEAM OFFCNTR ON ×××××CCS-96

C1A16 RADAR STAIN ON ×××××CCS-106

C1A18 LASER AIMING INCMP ON ×××××CCS-109

C1A21 UNIT HIGH TEMP ON ××××××CCS-111

C1A39 STRG SEN CIR ON ××××××CCS-124

C1A50 ADAS MALFUNCTION ON ××××××CCS-128

U0104 ADAS CAN CIR1 ON ××××××CCS-132

U0121 VDC CAN CIR2 ON ××××××CCS-133

U0126 STRG SEN CAN CIR1 ON ××××××CCS-135

U0405 ADAS CAN CIR2 ON ××××××CCS-140

U0415 VDC CAN CIR1 ON ××××××CCS-141

U0428 STRG SEN CAN CIR2 ON ××××××CCS-143

U1000 CAN COMM CIRCUIT ON ××××××CCS-145

U1010 CONTROL UNIT (CAN) ON ××××××CCS-147

Revision: 2010 May2011 QX56

Page 810 of 5598

![INFINITI QX56 2011 Factory Service Manual

CCS

LASER BEAM AIMING ADJUSTMENTCCS-75

< BASIC INSPECTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

5.CHECK THE ICC TARGET BOARD INSTALLATION AREA

Do not place anything other than ICC target board in th INFINITI QX56 2011 Factory Service Manual

CCS

LASER BEAM AIMING ADJUSTMENTCCS-75

< BASIC INSPECTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

5.CHECK THE ICC TARGET BOARD INSTALLATION AREA

Do not place anything other than ICC target board in th](/img/42/57033/w960_57033-809.png)

CCS

LASER BEAM AIMING ADJUSTMENTCCS-75

< BASIC INSPECTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

5.CHECK THE ICC TARGET BOARD INSTALLATION AREA

Do not place anything other than ICC target board in the space shown in the figure (view from top).

NOTE:

In case the space shown in the figure is not avail able, cover the side of the ICC target board with a 1400

mm(4.6 ft)-size frosted black board or black cloth.

>> Go to CCS-75, "

Work Procedure (Laser Beam Aiming Adjustment)".

Work Procedure (Laser B eam Aiming Adjustment)INFOID:0000000006224296

DESCRIPTION

Adjust the laser beam aiming in a vertical di rection with CONSULT-III as per the following.

The laser beam aiming adjustment in a horizontal dire ction is performed automatically with CONSULT-III.

CAUTION:

Never look directly into the laser beam source (ICC sensor body window) during laser beam aiming

adjustment.

Perform all necessary work for laser beam aiming adjustment until the adjustment completes as

shown in the procedure. If the procedure do es not complete, the ICC system is inoperable.

1.SET CONSULT-III TO THE LASER BEAM AIMING ADJUSTMENT MODE

1. Start the engine.

2. Connect CONSULT-III and select “Work support” of “LASER”.

3. Select “LASER BEAM ADJUST” after t he “Work support” screen is displayed.

4. Select “START” after the “LASER BEAM ADJUST” screen is displayed.

NOTE:

If the adjustment screen does not appear within approx imately 10 seconds after “LASER BEAM ADJUST”

is selected, the following causes are possible.

The ICC target board is not installed in the correct position.

Adequate space is not secured around the ICC target board.

The laser beam aiming adjustment exceeds its proper installation range.

- Deformation of vehicle body.

- Deformation of unit.

- Deformation of bracket.

The area is not suitable for the adjustment work.

ICC sensor body window is not clean.

The ICC system warning lamp illuminates.

>> GO TO 2.

2.LASER BEAM AIMING ADJUSTMENT

After “ADJUST THE VERTICAL OF LASER BEAM AIMI NG” is displayed on CONSULT-III screen, adjust by

turning the up-down direction adjusting screw until “U/D CORRECT” becomes ±4 or less.

NOTE:

1. ICC target board 2. ICC sensor

L

1.6.5 m (21.3 ft) L2. 4.0 m (13.0 ft) W. 3.5 m (11.5 ft)

JSOIA0027ZZ

Revision: 2010 May2011 QX56

Page 940 of 5598

CHG

ALTERNATORCHG-27

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

B A

O P

N

7. Remove ground harness mounting bolt.

8. Remove alternator mounting bolt (lower), and then alternator mounting bolt (upper).

9. Remove A/T fluid cooler tube (1) from fan shroud (2).

10. Move A/T fluid cooler tube (1) and secure work space.

11. Remove alternator assembly

(2) from underneath the vehicle.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Be careful to tighten “B” terminal nut carefully.

Install alternator, and check tension of belt. Refer to EM-20, "

Checking".

For this model, the power genera tion voltage variable control system that controls the power gener-

ation voltage of the alternator has been adopted. Therefore, the power generation voltage variable

control system operation inspectio n should be performed after replacing the alternator, and then

make sure that the system operates normally. Refer to CHG-17, "

Inspection Procedure".

When installing alternator br acket, tighten mounting bolts in

numerical order as shown in the figure.

JMMIA0365ZZ

JMMIA0366ZZ

JMMIA0367ZZ

JMMIA0456ZZ

Revision: 2010 May2011 QX56

Page 960 of 5598

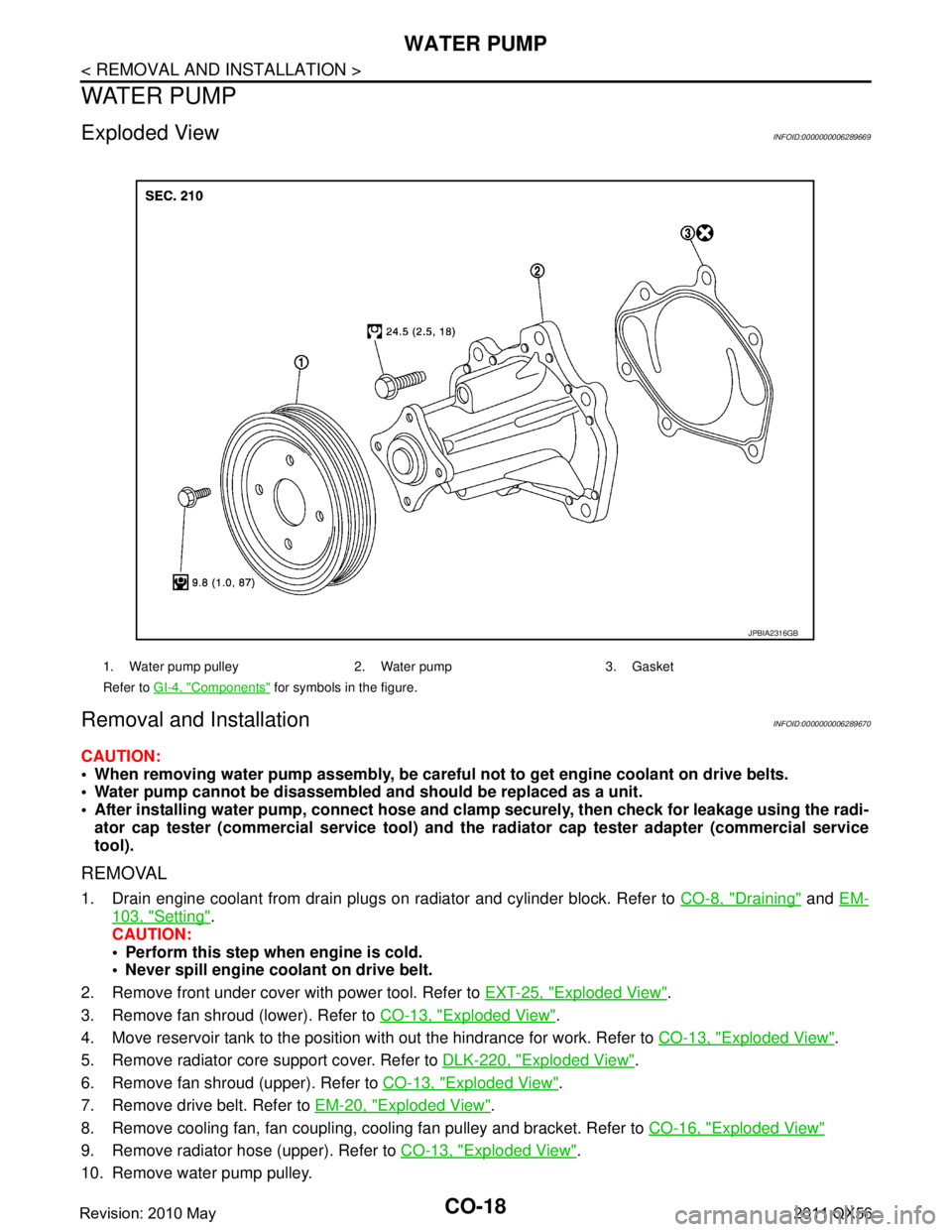

CO-18

< REMOVAL AND INSTALLATION >

WATER PUMP

WATER PUMP

Exploded ViewINFOID:0000000006289669

Removal and InstallationINFOID:0000000006289670

CAUTION:

When removing water pump assembly, be careful not to get engine coolant on drive belts.

Water pump cannot be disassembled and should be replaced as a unit.

After installing water pump, co nnect hose and clamp securely, then check for leakage using the radi-

ator cap tester (commercial service tool) and the radiator cap tester adapter (commercial service

tool).

REMOVAL

1. Drain engine coolant from drain plugs on radiator and cylinder block. Refer to CO-8, "Draining" and EM-

103, "Setting".

CAUTION:

Perform this step when engine is cold.

Never spill engine coolant on drive belt.

2. Remove front under cover with power tool. Refer to EXT-25, "

Exploded View".

3. Remove fan shroud (lower). Refer to CO-13, "

Exploded View".

4. Move reservoir tank to the position with out the hindrance for work. Refer to CO-13, "

Exploded View".

5. Remove radiator core support cover. Refer to DLK-220, "

Exploded View".

6. Remove fan shroud (upper). Refer to CO-13, "

Exploded View".

7. Remove drive belt. Refer to EM-20, "

Exploded View".

8. Remove cooling fan, fan coupling, cooling fan pulley and bracket. Refer to CO-16, "

Exploded View"

9. Remove radiator hose (upper). Refer to CO-13, "Exploded View".

10. Remove water pump pulley.

1. Water pump pulley 2. Water pump 3. Gasket

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA2316GB

Revision: 2010 May2011 QX56

Page 963 of 5598

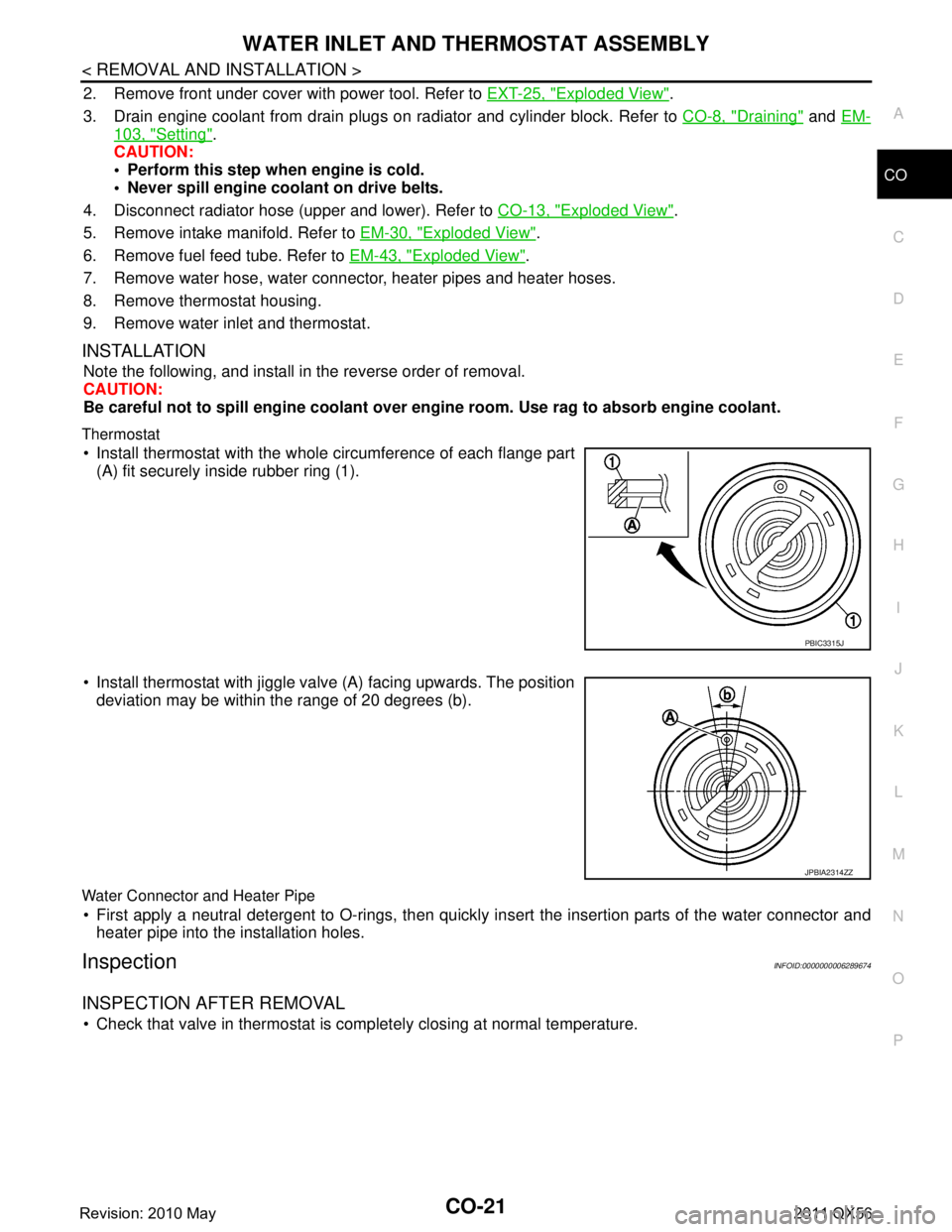

WATER INLET AND THERMOSTAT ASSEMBLYCO-21

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

2. Remove front under cover with power tool. Refer to

EXT-25, "Exploded View".

3. Drain engine coolant from drain plugs on radiator and cylinder block. Refer to CO-8, "

Draining" and EM-

103, "Setting".

CAUTION:

Perform this step when engine is cold.

Never spill engine coolant on drive belts.

4. Disconnect radiator hose (upper and lower). Refer to CO-13, "

Exploded View".

5. Remove intake manifold. Refer to EM-30, "

Exploded View".

6. Remove fuel feed tube. Refer to EM-43, "

Exploded View".

7. Remove water hose, water connector, heater pipes and heater hoses.

8. Remove thermostat housing.

9. Remove water inlet and thermostat.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Be careful not to spill engine coolant over en gine room. Use rag to absorb engine coolant.

Thermostat

Install thermostat with the whole circumference of each flange part

(A) fit securely inside rubber ring (1).

Install thermostat with jiggle valve (A) facing upwards. The position deviation may be within the range of 20 degrees (b).

Water Connector and Heater Pipe

First apply a neutral detergent to O-rings, then quickly in sert the insertion parts of the water connector and

heater pipe into the installation holes.

InspectionINFOID:0000000006289674

INSPECTION AFTER REMOVAL

Check that valve in thermostat is co mpletely closing at normal temperature.

PBIC3315J

JPBIA2314ZZ

Revision: 2010 May2011 QX56

Page 966 of 5598

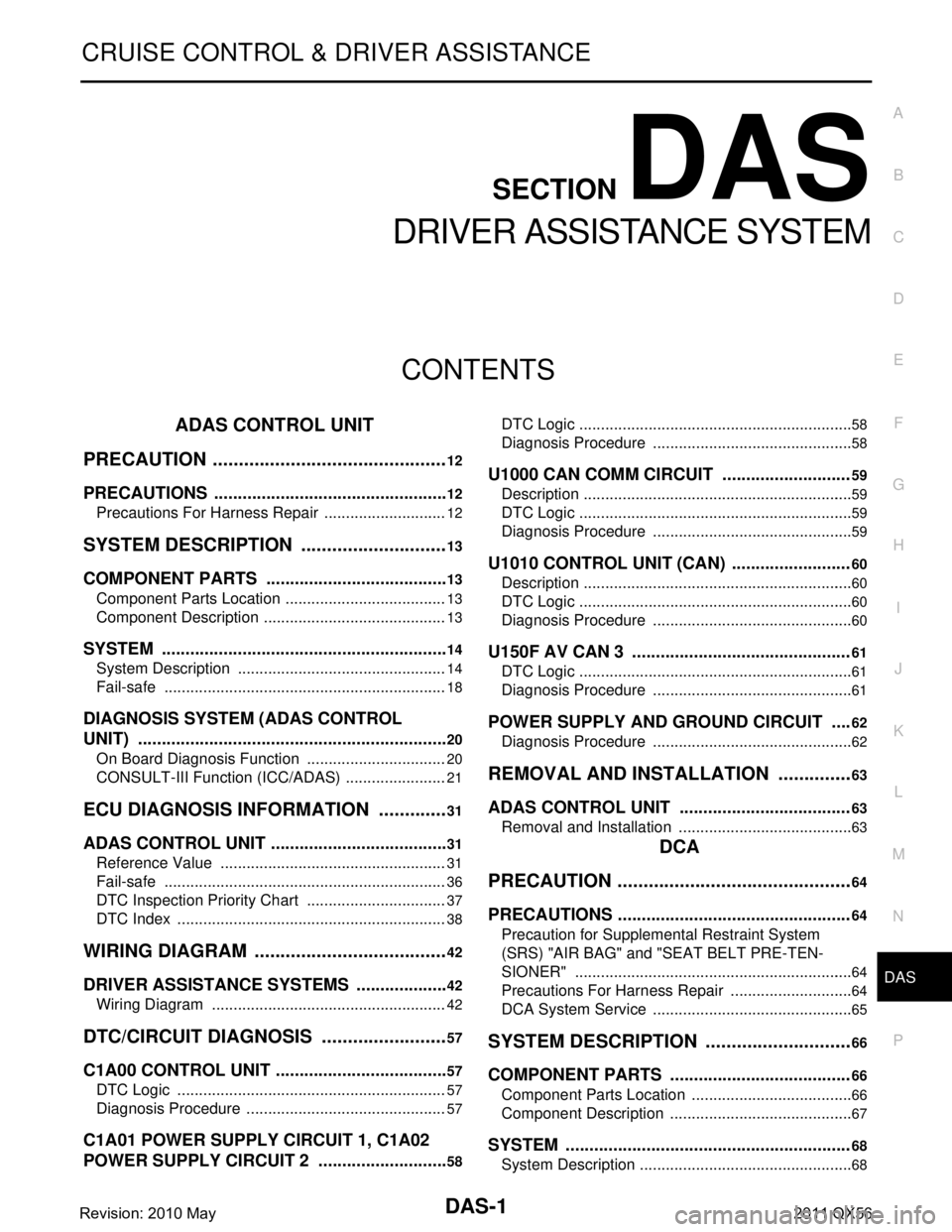

DAS-1

CRUISE CONTROL & DRIVER ASSISTANCE

C

DE

F

G H

I

J

K L

M B

DAS

SECTION DAS

N

P A

CONTENTS

DRIVER ASSISTANCE SYSTEM

ADAS CONTROL UNIT

PRECAUTION ................ ..............................

12

PRECAUTIONS .............................................. ....12

Precautions For Harness Repair ......................... ....12

SYSTEM DESCRIPTION .............................13

COMPONENT PARTS ................................... ....13

Component Parts Location .................................. ....13

Component Description ...........................................13

SYSTEM .............................................................14

System Description ............................................. ....14

Fail-safe ..................................................................18

DIAGNOSIS SYSTEM (ADAS CONTROL

UNIT) ..................................................................

20

On Board Diagnosis Function ............................. ....20

CONSULT-III Function (ICC/ADAS) ........................21

ECU DIAGNOSIS INFORMATION ..............31

ADAS CONTROL UNIT .................................. ....31

Reference Value ................................................. ....31

Fail-safe ..................................................................36

DTC Inspection Priority Chart .................................37

DTC Index ...............................................................38

WIRING DIAGRAM ......................................42

DRIVER ASSISTANCE SYSTEMS ................ ....42

Wiring Diagram ................................................... ....42

DTC/CIRCUIT DIAGNOSIS .........................57

C1A00 CONTROL UNIT ................................. ....57

DTC Logic ........................................................... ....57

Diagnosis Procedure ...............................................57

C1A01 POWER SUPPLY CIRCUIT 1, C1A02

POWER SUPPLY CIRCUIT 2 ............................

58

DTC Logic ............................................................ ....58

Diagnosis Procedure ...............................................58

U1000 CAN COMM CIRCUIT ...........................59

Description ...............................................................59

DTC Logic ................................................................59

Diagnosis Procedure ...............................................59

U1010 CONTROL UNIT (CAN) .........................60

Description ...............................................................60

DTC Logic ................................................................60

Diagnosis Procedure ...............................................60

U150F AV CAN 3 ..............................................61

DTC Logic ................................................................61

Diagnosis Procedure ...............................................61

POWER SUPPLY AND GROUND CIRCUIT ....62

Diagnosis Procedure ...............................................62

REMOVAL AND INSTALLATION ...............63

ADAS CONTROL UNIT ....................................63

Removal and Installation ..................................... ....63

DCA

PRECAUTION ............... ...............................

64

PRECAUTIONS .................................................64

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

64

Precautions For Harness Repair .............................64

DCA System Service ...............................................65

SYSTEM DESCRIPTION .............................66

COMPONENT PARTS ......................................66

Component Parts Location .................................. ....66

Component Description ...........................................67

SYSTEM ............................................................68

System Description .............................................. ....68

Revision: 2010 May2011 QX56

Page 967 of 5598

DAS-2

Fail-safe (ADAS Control Unit) .................................72

Fail-safe (ICC Sensor) ............................................72

OPERATION ......................................................73

Switch Name and Function .................................. ...73

Menu Displayed by Pressing Each Switch .............73

HANDLING PRECAUTION ................................76

Precautions for Distance Control Assist .............. ...76

DIAGNOSIS SYSTEM (ADAS CONTROL

UNIT) ............................................................... ...

78

On Board Diagnosis Function .............................. ...78

CONSULT-III Function (ICC/ADAS) .......................79

DIAGNOSIS SYSTEM (ICC SENSOR) ..............89

CONSULT-III Function (LASER) ............................89

DIAGNOSIS SYSTEM (ACCELERATOR

PEDAL ACTUATOR) ...................................... ...

91

CONSULT-III Function (ACCELERATOR PEDAL

ACT) .................................................................... ...

91

ECU DIAGNOSIS INFORMATION ..............93

ADAS CONTROL UNIT .................................. ...93

Reference Value .................................................. ...93

Fail-safe ..................................................................98

DTC Inspection Priority Chart .................................99

DTC Index .............................................................100

ICC SENSOR ...................................................104

Reference Value .................................................. ..104

Fail-safe .................................................................105

DTC Inspection Priority Chart ................................105

DTC Index .............................................................105

ACCELERATOR PEDAL ACTUATOR ...........107

Reference Value .................................................. ..107

DTC Inspection Priority Chart ................................108

DTC Index .............................................................108

WIRING DIAGRAM ....................................109

DRIVER ASSISTANCE SYSTEMS ................ .109

Wiring Diagram .................................................... ..109

BASIC INSPECTION ..................................124

DIAGNOSIS AND REPAIR WORK FLOW ..... .124

Work Flow ............................................................ ..124

ADDITIONAL SERVICE WHEN REPLACING

ICC SENSOR ...................................................

126

Description ........................................................... ..126

Work Procedure .....................................................126

ADDITIONAL SERVICE WHEN REPLACING

ACCELERATOR PEDAL ASSEMBLY ............

127

Description ........................................................... ..127

Work Procedure .....................................................127

ACTION TEST ..................................................128

Description ........................................................... .128

Work Procedure ....................................................128

DTC/CIRCUIT DIAGNOSIS .......................129

C1A00 CONTROL UNIT ................................. ..129

DTC Logic ............................................................ .129

Diagnosis Procedure .............................................129

C1A01 POWER SUPPLY CIRCUIT 1, C1A02

POWER SUPPLY CIRCUIT 2 ...........................

130

DTC Logic ............................................................ .130

Diagnosis Procedure .............................................130

C1A03 VEHICLE SPEED SENSOR .................131

DTC Logic ............................................................ .131

Diagnosis Procedure .............................................131

C1A04 ABS/TCS/VDC SYSTEM ......................133

DTC Logic ............................................................ .133

Diagnosis Procedure .............................................133

C1A05 BRAKE SW/STOP LAMP SW ..............134

DTC Logic ............................................................ .134

Diagnosis Procedure .............................................134

Component Inspection (ICC Brake Switch) ..........137

Component Inspection (Stop Lamp Switch) ..........137

C1A06 OPERATION SW ..................................138

DTC Logic ............................................................ .138

Diagnosis Procedure .............................................138

Component Inspection ..........................................139

C1A12 LASER BEAM OFF CENTER ..............140

DTC Logic ............................................................ .140

Diagnosis Procedure .............................................140

C1A13 STOP LAMP RELAY ............................141

DTC Logic ............................................................ .141

Diagnosis Procedure .............................................141

Component Inspection ..........................................146

C1A14 ECM ......................................................147

DTC Logic ............................................................ .147

Diagnosis Procedure .............................................147

C1A15 GEAR POSITION .................................148

Description ........................................................... .148

DTC Logic .............................................................148

Diagnosis Procedure .............................................148

C1A16 RADAR STAIN ................................... ..150

DTC Logic ............................................................ .150

Diagnosis Procedure .............................................150

C1A17 ICC SENSOR ........................................151

DTC Logic ............................................................ .151

Diagnosis Procedure .............................................151

C1A18 LASER AIMING INCMP .......................152

DTC Logic ............................................................ .152

Revision: 2010 May2011 QX56

Page 970 of 5598

DAS-5

C

DE

F

G H

I

J

K L

M B

DAS

N

P A

Description ..........................................................

..

208

Diagnosis Procedure .............................................208

NORMAL OPERATING CONDITION ...............210

Description .......................................................... ..210

REMOVAL AND INSTALLATION .............212

ICC SENSOR .................................................. ..212

Exploded View .................................................... ..212

Removal and Installation .......................................212

ACCELERATOR PEDAL ASSEMBLY ............213

Exploded View .................................................... ..213

DYNAMIC DRIVER ASSISTANCE SWITCH ...214

Exploded View .................................................... ..214

FCW

PRECAUTION ................ ............................

215

PRECAUTIONS .............................................. ..215

Precaution for FCW System Service ................... ..215

SYSTEM DESCRIPTION ...........................216

COMPONENT PARTS ................................... ..216

Component Parts Location .................................. ..216

Component Description .........................................216

SYSTEM ...........................................................218

System Description ............................................. ..218

Fail-safe (ADAS Control Unit) ...............................219

Fail-safe (ICC Sensor) ..........................................220

OPERATION .....................................................221

Switch Name and Function ................................. ..221

Menu Displayed by Pressing Each Switch ............221

HANDLING PRECAUTION ..............................223

Precautions for Forward Collision Warning ......... ..223

DIAGNOSIS SYSTEM (ADAS CONTROL

UNIT) ................................................................

224

On Board Diagnosis Function ............................. ..224

CONSULT-III Function (ICC/ADAS) ......................225

DIAGNOSIS SYSTEM (ICC SENSOR) ............235

CONSULT-III Function (LASER) ...........................235

ECU DIAGNOSIS INFO RMATION ............237

ADAS CONTROL UNIT .................................. ..237

Reference Value ................................................. ..237

Fail-safe ................................................................242

DTC Inspection Priority Chart ...............................243

DTC Index .............................................................244

ICC SENSOR ....................................................248

Reference Value ................................................. ..248

Fail-safe ................................................................249

DTC Inspection Priority Chart ...............................249

DTC Index ........................................................... ..249

WIRING DIAGRAM ....................................251

DRIVER ASSISTANCE SYSTEMS .................251

Wiring Diagram .................................................... ..251

BASIC INSPECTION .................................266

DIAGNOSIS AND REPAIR WORK FLOW .....266

Work Flow ............................................................ ..266

SYMPTOM DIAGNOSIS ............................268

FORWARD COLLISION WARNING SYSTEM

SYMPTOMS ....................................................

268

Symptom Table ................................................... ..268

FCW SYSTEM IS NOT ACTIVATED ..............269

Description .............................................................269

Diagnosis Procedure .............................................269

NORMAL OPERATING CONDITION .............270

Description .............................................................270

REMOVAL AND INSTALLATION .............271

WARNING SYSTEMS SWITCH ......................271

Removal and Installation ..................................... ..271

LDW & LDP

PRECAUTION ............... .............................

272

PRECAUTIONS ...............................................272

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

272

Precautions For Harness Repair ...........................272

Precaution for LDW/LDP System Service .............273

SYSTEM DESCRIPTION ...........................274

COMPONENT PARTS ....................................274

LANE DEPARTURE WARNING (LDW) SYSTEM ..274

LANE DEPARTURE WARNING (LDW) SYSTEM

: Component Parts Location ................................ ..

274

LANE DEPARTURE WARNING (LDW) SYSTEM

: Component Description .......................................

274

LANE DEPARTURE PREVENTION (LDP) SYS-

TEM ........................................................................ ..

275

LANE DEPARTURE PREVENTION (LDP) SYS-

TEM : Component Parts Location .........................

275

LANE DEPARTURE PREVENTION (LDP) SYS-

TEM : Component Description ..............................

276

SYSTEM ..........................................................277

LANE DEPARTURE WARNING (LDW) SYSTEM ..277

LANE DEPARTURE WARNING (LDW) SYSTEM

: System Description ............................................ ..

277

Revision: 2010 May2011 QX56

Page 971 of 5598

DAS-6

LANE DEPARTURE WARNING (LDW) SYSTEM

: Fail-safe (ADAS Control Unit) ..............................

279

LANE DEPARTURE WARNING (LDW) SYSTEM

: Fail-safe (Lane Camera Unit) ..............................

280

LANE DEPARTURE PREVENTION (LDP) SYS-

TEM ........................................................................ ..

280

LANE DEPARTURE PREVENTION (LDP) SYS-

TEM : System Description .....................................

280

LANE DEPARTURE PREVENTION (LDP) SYS-

TEM : Fail-safe (ADAS Control Unit) .....................

283

LANE DEPARTURE PREVENTION (LDP) SYS-

TEM : Fail-safe (Lane Camera Unit) ......................

284

OPERATION ....................................................285

LANE DEPARTURE WARNING (LDW) SYSTEM . ..285

LANE DEPARTURE WARNING (LDW) SYSTEM

: Switch Name and Function ..................................

285

LANE DEPARTURE WARNING (LDW) SYSTEM

: Menu Displayed by Pressing Each Switch ..........

285

LANE DEPARTURE PREVENTION (LDP) SYS-

TEM ........................................................................ ..

286

LANE DEPARTURE PREVENTION (LDP) SYS-

TEM : Switch Name and Function .........................

286

LANE DEPARTURE PREVENTION (LDP) SYS-

TEM : Menu Displayed by Pressing Each Switch ..

286

HANDLING PRECAUTION ..............................288

Precautions for Lane Departure Warning/Lane

Departure Prevention .......................................... ..

288

DIAGNOSIS SYSTEM (ADAS CONTROL

UNIT) ............................................................... .

290

On Board Diagnosis Function .............................. ..290

CONSULT-III Function (ICC/ADAS) ......................291

DIAGNOSIS SYSTEM (LANE CAMERA

UNIT) ................................................................

301

CONSULT-III Function (LANE CAMERA) ........... ..301

ECU DIAGNOSIS INFORMATION .............303

ADAS CONTROL UNIT .................................. .303

Reference Value .................................................. ..303

Fail-safe .................................................................308

DTC Inspection Priority Chart ................................309

DTC Index .............................................................310

LANE CAMERA UNIT .....................................314

Reference Value .................................................. ..314

Fail-safe .................................................................315

DTC Inspection Priority Chart ................................316

DTC Index .............................................................316

WIRING DIAGRAM ....................................317

DRIVER ASSISTANCE SYSTEMS ................ .317

Wiring Diagram .................................................... ..317

BASIC INSPECTION ..................................332

DIAGNOSIS AND REPAIR WORK FLOW ..... ..332

Work Flow ............................................................ .332

Diagnostic Work Sheet .........................................333

PRE-INSPECTION FOR DIAGNOSIS ..............335

Inspection Procedure ........................................... .335

ACTION TEST ..................................................336

Description ........................................................... .336

Inspection Procedure ............................................336

ADDITIONAL SERVICE WHEN REPLACING

LANE CAMERA UNIT ......................................

339

Description ........................................................... .339

Work Procedure ....................................................339

CAMERA AIMING ADJUSTMENT ...................340

Description ........................................................... .340

Work Procedure (Preparation) ..............................340

Work Procedure (Target Setting) ..........................341

Work Procedure (Camera Aiming Adjustment) .....342

Work Procedure (Target Mark Sample) ................343

DTC/CIRCUIT DIAGNOSIS .......................345

C1A00 CONTROL UNIT ................................. ..345

DTC Logic ............................................................ .345

Diagnosis Procedure .............................................345

C1A01 POWER SUPPLY CIRCUIT 1, C1A02

POWER SUPPLY CIRCUIT 2 ...........................

346

DTC Logic ............................................................ .346

Diagnosis Procedure .............................................346

C1A03 VEHICLE SPEED SENSOR .................347

DTC Logic ............................................................ .347

Diagnosis Procedure .............................................347

C1A04 ABS/TCS/VDC SYSTEM ......................348

DTC Logic ............................................................ .348

Diagnosis Procedure .............................................348

C1A05 BRAKE SW/STOP LAMP SW ..............349

DTC Logic ............................................................ .349

Diagnosis Procedure .............................................349

Component Inspection (ICC Brake Switch) ..........352

Component Inspection (Stop Lamp Switch) ..........352

C1A06 OPERATION SW ..................................353

DTC Logic ............................................................ .353

Diagnosis Procedure .............................................353

Component Inspection ..........................................354

C1A14 ECM ......................................................355

DTC Logic ............................................................ .355

Diagnosis Procedure .............................................355

C1A15 GEAR POSITION .................................356

Description ........................................................... .356

DTC Logic .............................................................356

Diagnosis Procedure .............................................356

Revision: 2010 May2011 QX56