ECU INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5467 of 5598

LOW TIRE PRESSURE WARNING CONTROL UNIT

WT-17

< ECU DIAGNOSIS INFORMATION >

C

D F

G H

I

J

K L

M A

B

WT

N

O P

*: Power is supplied to the tire pressure receiver from the low tire pressure warning control unit.

DTC Inspection Priority ChartINFOID:0000000006225498

If some DTCs are displayed at the same time, per form inspections one by one based on the following priority-

chart.

21

(G/R) Ground

Tire pressure receiver front

RH signal (sensitivity) InputIgnition switch ON Approx. 0.7 V

Ignition switch OFF 0 V

22

(BR/Y) Ground

Tire pressure receiver front

LH signal (sensitivity) InputIgnition switch ON Approx. 0.7 V

Ignition switch OFF 0 V

23

(V/W) Ground Tire pressure receiver rear

RH ground

Input Always 0 V

24

(R/B) Ground

Tire pressure receiver rear

LH ground Input Always 0 V

25

(W/L) Ground Tire pressure receiver front

RH ground Input Always 0 V

26

(BR/W) GroundTire pressure receiver front

LH ground

Input Always 0 V

32

(B) Ground Ground — Always 0 V

Te r m i n a l N o .

(Wire color) Description

Condition Value (Approx.)

Signal name Input/

Output

Priority Detected items (DTC)

1 U1000 CAN COMM CIRCUIT

U1010 CONTROL UNIT (CAN)

2 C1704 LOW PRESSURE FL

C1705 LOW PRESSURE FR

C1706 LOW PRESSURE RR

C1707 LOW PRESSURE RL

3 C1755 PR RECEIV COND FL

C1756 PR RECEIV COND FR

C1757 PR RECEIV COND RR

C1758 PR RECEIV COND RL

4 C1708 [NO DATA] FL

C1709 [NO DATA] FR

C1710 [NO DATA] RR

C1711 [NO DATA] RL

5 C1716 [PRESSDATA ERR] FL

C1717 [PRESSDATA ERR] FR

C1718 [PRESSDATA ERR] RR

C1719 [PRESSDATA ERR] RL

7 C1728 RECEIVER ID NO REG

8 C1729 VHCL SPEED SIG ERR

9 C1750 [RECEIVER ERR] FL

C1751 [RECEIVER ERR] FR

C1752 [RECEIVER ERR] RR

C1753 [RECEIVER ERR] RL

10 C1754 CONT UNIT (EEPROM)

Revision: 2010 May2011 QX56

Page 5468 of 5598

WT-18

< ECU DIAGNOSIS INFORMATION >

LOW TIRE PRESSURE WARNING CONTROL UNIT

DTC Index

INFOID:0000000006225499

NOTE:

If some DTCs are displayed at the same time, refer to WT-17, "

DTC Inspection Priority Chart".

DTC Items (CONSULT-III screen terms) Reference

C1704 LOW PRESSURE FL

WT-31, "

DTC Logic"C1705 LOW PRESSURE FR

C1706 LOW PRESSURE RR

C1707 LOW PRESSURE RL

C1708 [NO DATA] FLWT-33, "

DTC Logic"C1709 [NO DATA] FR

C1710 [NO DATA] RRC1711 [NO DATA] RL

C1716 [PRESSDATA ERR] FL

WT-37, "

DTC Logic"C1717 [PRESSDATA ERR] FR

C1718 [PRESSDATA ERR] RR

C1719 [PRESSDATA ERR] RL

C1728 RECEIVER ID NO REGWT-39, "

DTC Logic"

C1729 VHCL SPEED SIG ERRWT-41, "DTC Logic"

C1750 [RECEIVER ERR] FL

WT-42, "

DTC Logic"C1751 [RECEIVER ERR] FR

C1752 [RECEIVER ERR] RR

C1753 [RECEIVER ERR] RL

C1754 CONT UNIT (EEPROM)WT-45, "

DTC Logic"

C1755 PR RECEIV COND FL

WT-47, "

DTC Logic"C1756 PR RECEIV COND FR

C1757 PR RECEIV COND RR

C1758 PR RECEIV COND RL

U1000 CAN COMM CIRCUITWT-49, "

DTC Logic"

U1010 CONTROL UNIT (CAN)WT-50, "DTC Logic"

Revision: 2010 May2011 QX56

Page 5520 of 5598

WW-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION WW

A

B

WW

N

O P

CONTENTS

WIPER & WASHER

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Precaution for Procedure without Cowl Top Cover ......4

SYSTEM DESCRIPTION ..............................5

COMPONENT PARTS ................................... .....5

Component Parts Location .................................. ......5

Component Description ............................................6

Washer Switch ..........................................................6

SYSTEM ..............................................................7

FRONT WIPER AND WASHER SYSTEM ............. ......7

FRONT WIPER AND WASHER SYSTEM : Sys-

tem Diagram ..............................................................

7

FRONT WIPER AND WASHER SYSTEM : Sys-

tem Description .........................................................

7

FRONT WIPER AND WASHER SYSTEM : Fail-

safe ...........................................................................

9

REAR WIPER AND WASHER SYSTEM ............... ....10

REAR WIPER AND WASHER SYSTEM : System

Diagram ...................................................................

10

REAR WIPER AND WASHER SYSTEM : System

Description ..............................................................

10

REAR WIPER AND WASHER SYSTEM :

Fail Safe .................................................................

12

HEADLAMP WASHER SYSTEM .......................... ....12

HEADLAMP WASHER SYSTEM : System Dia-

gram ........................................................................

13

HEADLAMP WASHER SYSTEM : System De-

scription ...................................................................

13

DIAGNOSIS SYSTEM (BCM) ............................14

COMMON ITEM ..................................................... ....14

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

14

WIPER .................................................................... ....15

WIPER : CONSULT-III Function (BCM - WIPER) ....15

DIAGNOSIS SYSTEM (IPDM E/R) ...................18

Diagnosis Description ..............................................18

CONSULT-III Function (IPDM E/R) .........................20

ECU DIAGNOSIS INFORMATION ..............23

BCM, IPDM E/R .................................................23

List of ECU Reference ......................................... ....23

WIRING DIAGRAM ......................................24

WIPER AND WASHER SYSTEM .....................24

Wiring Diagram .................................................... ....24

BASIC INSPECTION ...................................33

DIAGNOSIS AND REPAIR WORKFLOW ........33

Work Flow ............................................................ ....33

DTC/CIRCUIT DIAGNOSIS .........................35

WIPER AND WASHER FUSE ...........................35

Diagnosis Procedure ........................................... ....35

FRONT WIPER MOTOR LO CIRCUIT ..............36

Component Function Check ....................................36

Diagnosis Procedure ...............................................36

FRONT WIPER MOTOR HI CIRCUIT ...............37

Component Function Check ....................................37

Diagnosis Procedure ...............................................37

FRONT WIPER AUTO STOP SIGNAL CIR-

CUIT ..................................................................

38

Component Function Check ....................................38

Diagnosis Procedure ...............................................38

Revision: 2010 May2011 QX56

Page 5533 of 5598

WW-14

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000006349813

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate ea ch device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 5539 of 5598

WW-20

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (IPDM E/R)

CONSULT-III Function (IPDM E/R)

INFOID:0000000006349815

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with IPDM E/R.

SELF DIAGNOSTIC RESULT

Refer to PCS-22, "DTCIndex".

DATA MONITOR

Monitor item

Oil pressure warning lamp does not operate Perform auto active test.

Does the oil pressure warning

lamp blink?YES

Harness or connector be-

tween IPDM E/R and oil

pressure switch

Oil pressure switch

IPDM E/R

NO CAN communication signal

between IPDM E/R and

BCM

CAN communication signal

between BCM and combi-

nation meter

Combination meter

Symptom Inspection contents Possible cause

Diagnosis mode Description

Ecu Identification Allows confirmation of IPDM E/R part number.

Self Diagnostic Result Displays the diagnosis results judged by IPDM E/R.

Data Monitor Displays the real-time input/output data from IPDM E/R input/output data.

Active Test IPDM E/R can provide a drive signal to electronic components to check their operations.

CAN Diag Support Monitor The results of transmit/receive diagnosis of CAN communication can be read.

Monitor Item [Unit] MAIN SIG-

NALS Description

RAD FAN REQ

[1/2/3/4] ×Displays the value of the cooling fan speed request signal received from ECM via

CAN communication.

AC COMP REQ

[Off/On] ×Displays the status of the A/C compressor request signal received from ECM via

CAN communication.

TA I L & C L R R E Q

[Off/On] ×

Displays the status of the position light request signal received from BCM via CAN

communication.

HL LO REQ

[Off/On] ×Displays the status of the low beam request signal received from BCM via CAN

communication.

HL HI REQ

[Off/On] ×Displays the status of the high beam request signal received from BCM via CAN

communication.

FR FOG REQ

[Off/On] ×Displays the status of the front fog light request signal received from BCM via

CAN communication.

FR WIP REQ

[Stop/1LOW/Low/Hi] ×

Displays the status of the front wiper request signal received from BCM via CAN

communication.

WIP AUTO STOP

[STOP P/ACT P] ×

Displays the status of the front wiper auto stop signal judged by IPDM E/R.

WIP PROT

[Off/BLOCK] ×

Displays the status of the front wiper fail-safe operation judged by IPDM E/R.

IGN RLY1 -REQ

[Off/On] Displays the status of the ignition switch ON signal received from BCM via CAN

communication.

IGN RLY

[Off/On] ×

Displays the status of the ignition relay judged by IPDM E/R.

Revision: 2010 May2011 QX56

Page 5542 of 5598

BCM, IPDM E/RWW-23

< ECU DIAGNOSIS INFORMATION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

ECU DIAGNOSIS INFORMATION

BCM, IPDM E/R

List of ECU ReferenceINFOID:0000000006300464

ECU Reference

BCM BCS-33, "

Reference Value"

BCS-54, "Fail-safe"

BCS-56, "DTCInspectionPriorityChart"

BCS-57, "DTCIndex"

IPDM E/R

PCS-15, "

Reference Value"

PCS-21, "Fail-Safe"

PCS-22, "DTCIndex"

Revision: 2010 May2011 QX56

Page 5588 of 5598

FRONT WIPER BLADEWW-69

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

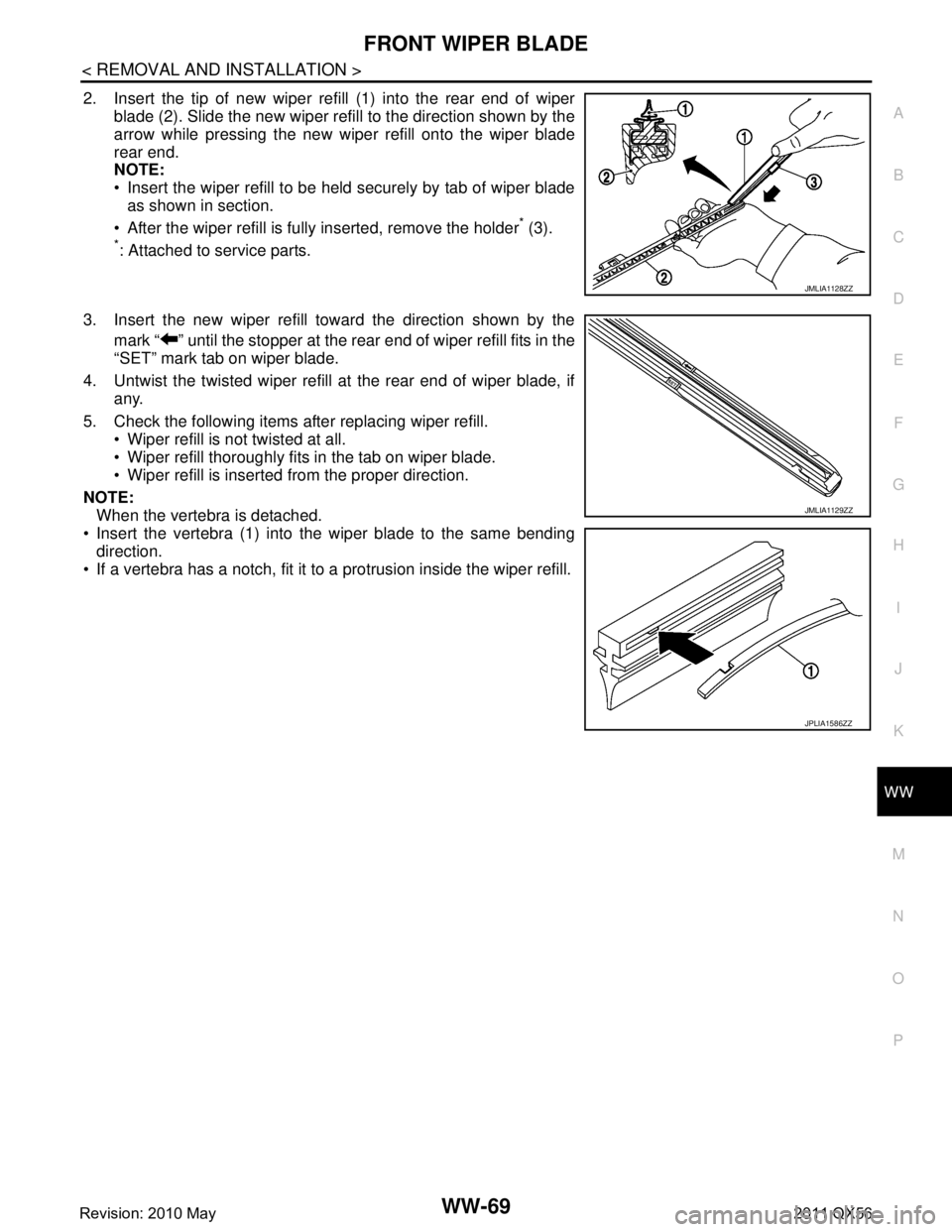

2. Insert the tip of new wiper refill (1) into the rear end of wiper blade (2). Slide the new wiper refill to the direction shown by the

arrow while pressing the new wiper refill onto the wiper blade

rear end.

NOTE:

Insert the wiper refill to be held securely by tab of wiper bladeas shown in section.

After the wiper refill is fully inserted, remove the holder

* (3).

*: Attached to service parts.

3. Insert the new wiper refill toward the direction shown by the mark “ ” until the stopper at the rear end of wiper refill fits in the

“SET” mark tab on wiper blade.

4. Untwist the twisted wiper refill at the rear end of wiper blade, if any.

5. Check the following items after replacing wiper refill. Wiper refill is not twisted at all.

Wiper refill thoroughly fits in the tab on wiper blade.

Wiper refill is inserted from the proper direction.

NOTE: When the vertebra is detached.

Insert the vertebra (1) into the wiper blade to the same bending direction.

If a vertebra has a notch, fit it to a protrusion inside the wiper refill.

JMLIA1128ZZ

JMLIA1129ZZ

JPLIA1586ZZ

Revision: 2010 May2011 QX56

Page 5591 of 5598

WW-72

< REMOVAL AND INSTALLATION >

LIGHT & RAIN SENSOR

LIGHT & RAIN SENSOR

Exploded ViewINFOID:0000000006220417

CAUTION:

When the light & rain sensor is removed from windshield, the light & rain sensor cannot be re-used.

Removal and InstallationINFOID:0000000006220418

REMOVAL

1. Disengage light & rain sensor cover fixing pawls with a remover tool, and then remove rain senor cover.

2. Disconnect light & rain sensor connector.

3. Disengage both sides metal spring clips, and remove the light & rain sensor from the windshield.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Surface of windshield should be cleaned.

Never touch gel/adhesive of new part.

Lock the metal spring clips and inst all the light & rain sensor securely.

1. Light & rain sensor connector 2. Light & rain sensor cover 3. Light & rain sensor

A. Metal spring clip

: Pawl

: Do not reuse

JMLIA0941ZZ

Revision: 2010 May2011 QX56