belt INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3679 of 5598

PERIODIC MAINTENANCEMA-9

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts i

f found

damaged or if the auto belt tensioner reading reaches the maximum limit.

(2) Maintenance-free item. For service procedures, refer to FL section.

(3) First replacement interval is 105,000 miles (168,000 km) or 84 months. After first replacement, replace every 75,000 miles (120,000

km) or 60 months. Use only Genu ine NISSAN Long Life Antifreeze/Coo lant (blue) or equivalent with proper mixture ratio of 50% anti-

freeze and 50% demineralized or distilled water. Mixing any other type of coolant or the use of non-distilled water will reduce the life

expectancy of the factory-fill coolant.

(4) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by INFINITI for reliable vehicle operation. The owner need not perfo rm

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

CHASSIS AND BODY

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary.

NOTE:

(1) Automatic transmission fluid is maintenance-free.

(2) Refer to “Tire rotation” under the “General maintenance” heading earlier in this section.

Engine oil R R R R R R R R

MA-17

Engine oil filter (Use genuine

NISSAN engine oil filter or equiv-

alent.)RRRR R RRR

MA-18

Spark plugs (Iridium-tipped type) Replace every 105,000 miles (168,000 km). MA-19

Intake & exhaust valve clear-

ance*NOTE (4)

EM-12

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference Sec-

tion - Page or -

Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000)

Months 7.5

(12)

6 15

(24)

12 22.5

(36)

18 30

(48)

24 37.5

(60)

30 45

(72)

36 52.5

(84)

42 60

(96)

48

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Sec-

tion - Page or - Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000) Months 7.5

(12) 6 15

(24) 12 22.5

(36) 18 30

(48) 24 37.5

(60) 30 45

(72) 36 52.5

(84) 42 60

(96) 48

Brake lines & cables I I I I MA-28

Brake fluid R RMA-28

Brake pads & rotors I I I IMA-30

BR-16

BR-18

BR-16

BR-18

Transfer fluid & differential gear

oil

IIIIMA-21MA-24

MA-25

Automatic transmission fluid NOTE (1)

—

Steering gear & linkage, axle &

suspension parts II

MA-31

MA-32

Tire rotation NOTE (2) MA-4WT-63

Drive shaft boots and propeller

shaft (4WD models) IIIIMA-33MA-22

MA-23

MA-23

Exhaust system I I

MA-21

In-cabin microfilter R R R RVTL-17

Revision: 2010 May2011 QX56

Page 3682 of 5598

MA-12

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

ENGINE MAINTENANCE

DRIVE BELTS

DRIVE BELTS : Exploded ViewINFOID:0000000006394835

DRIVE BELTS : CheckingINFOID:0000000006394836

WARNING:

Be sure to perform the these steps when engine is stopped.

Check that the indicator (C) (notch on fixed side) of each auto-tensioner is within the possible use range (A).

NOTE:

Check the each auto-tensioners indication when the engine is cold.

When new drive belts is installed, the indicator (notch on fixed side) should be within the range (B) in the\

figure.

Visually check all drive belts for wear, damage or cracks.

If the indicator (notch on fixed side) is out of the possible use range or drive belts are damaged, replace drive

belts.

DRIVE BELTS : Tension AdjustmentINFOID:0000000006394837

Refer to EM-132, "Drive Belts".

ENGINE COOLANT

ENGINE COOLANT : InspectionINFOID:0000000006394844

LEVEL

1. Drive belt 2. Power steering oil pump pulley 3. Alternator pulley

4. Crankshaft pulley 5. A/C compressor 6. Idler pulley

7. Cooling fan pulley 8. Water pump pulley 9. Drive belt auto-tensioner

A. Possible use range B. Range when new drive belt is in-

stalledC. Indicator

D. View D

JPBIA3264ZZ

Revision: 2010 May2011 QX56

Page 3688 of 5598

MA-18

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

3. Warm up the engine and check area around drain plug and oil filter for engine oil leakage.

4. Stop the engine and wait for 10 minutes.

5. Check the engine oil level. Refer to LU-7, "

Inspection".

OIL FILTER

OIL FILTER : Removal and InstallationINFOID:0000000006394843

REMOVAL

1. Remove front under cover.

2. Drain engine oil. Refer to MA-17, "

ENGINE OIL : Draining".

3. Remove oil filter using oil filter wrench [SST: KV10115801 (J- 38956)].

WARNING:

Be careful not to burn yourself, as the engine and engine oil

may be hot.

CAUTION:

The oil filter is equipped with a pressure relief valve.

Use Genuine NISSAN oil filter or equivalent.

When removing, prepare a sh op cloth to absorb any

engine oil leaks or spills.

Do not allow engine oil to adhere to the drive belts.

Completely wipe off any engi ne oil that adheres to the

engine and the vehicle.

INSTALLATION

1. Remove foreign materials adhering to the oil filter seal mating surface.

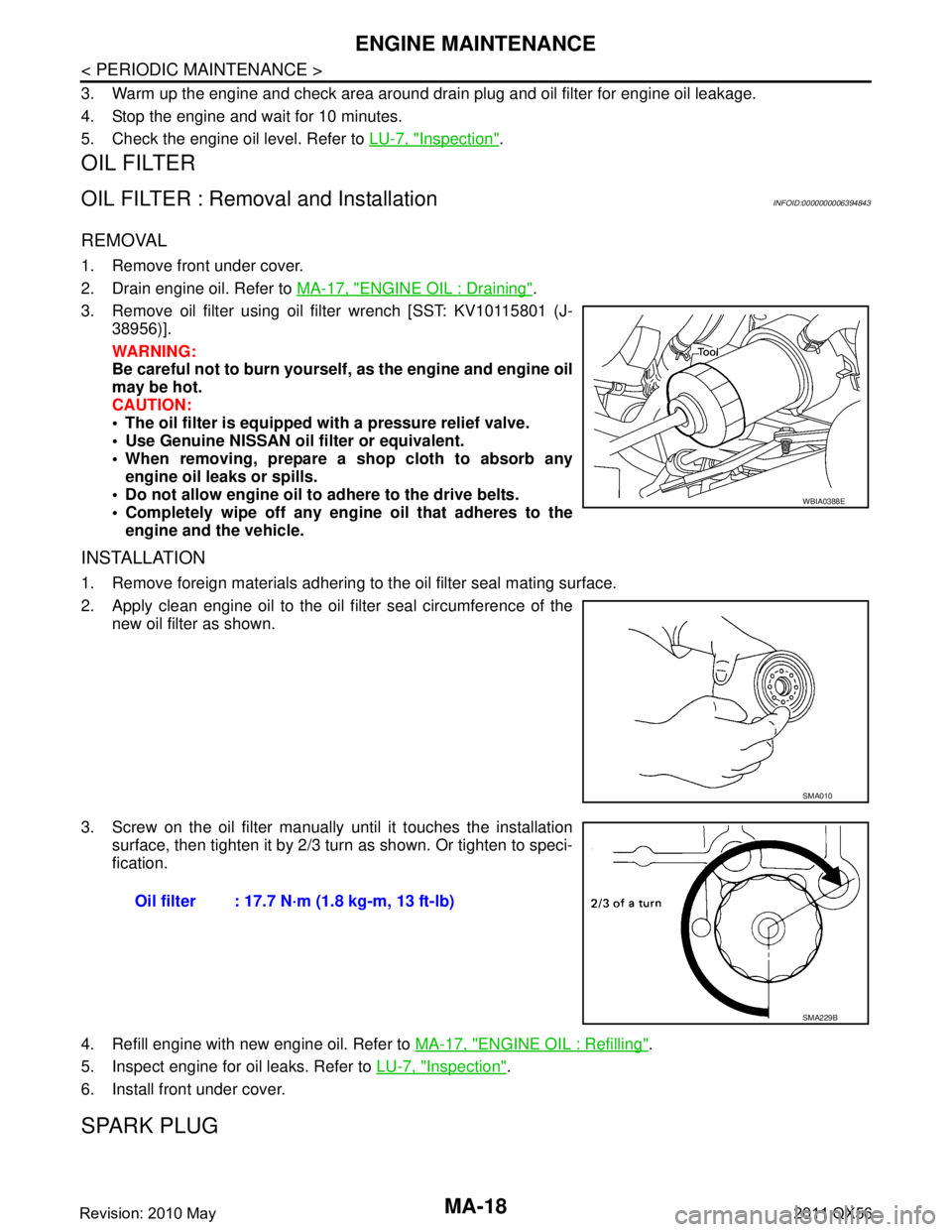

2. Apply clean engine oil to the oil f ilter seal circumference of the

new oil filter as shown.

3. Screw on the oil filter manually until it touches the installation

surface, then tighten it by 2/3 turn as shown. Or tighten to speci-

fication.

4. Refill engine with new engine oil. Refer to MA-17, "

ENGINE OIL : Refilling".

5. Inspect engine for oil leaks. Refer to LU-7, "

Inspection".

6. Install front under cover.

SPARK PLUG

WBIA0388E

SMA010

Oil filter : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

Revision: 2010 May2011 QX56

Page 3704 of 5598

MA-34

< PERIODIC MAINTENANCE >

BODY MAINTENANCE

BODY MAINTENANCE

LOCKS, HINGES AND HOOD LATCH

LOCKS, HINGES AND HOOD LATCH : LubricatingINFOID:0000000006220949

For hood and hood lock illustration.

Hood: Refer to DLK-215, "

Exploded View".

Hood lock: Refer to DLK-238, "

Exploded View".

For front door and front door lock illustration.

Front door: Refer to DLK-224, "

Exploded View".

Front door lock: Refer to DLK-240, "

Exploded View".

For rear door and rear door lock illustration.

Rear door: Refer to DLK-228, "

Exploded View".

Rear door lock: Refer to DLK-243, "

Exploded View".

For back door and back door lock illustration.

Back door: Refer to DLK-232, "

Exploded View".

Back door lock: Refer to DLK-246, "

Exploded View".

SEAT BELT, BUCKLES, RETRACTORS, ANCHORS AND ADJUSTERS

SEAT BELT, BUCKLES, RETRACTORS, ANCHORS AND ADJUSTERS : Inspection

INFOID:0000000006220950

For front seat belt illustration. Refer to SB-6, "SEAT BELT RETRACTOR : Exploded View".

For second seat belt illustration. Refer to SB-11, "

SEAT BELT RETRACTOR : Exploded View".

For third seat belt illustration. Refer to SB-19, "

SEAT BELT RETRACTOR : Exploded View".

CAUTION:

After any collision, inspect all seat belt assembli es, including retractors and other attached hard-

wares (I.e. anchor bolt, guide ra il set). Nissan recommends to replace all seat belt assemblies in use

during a collision, unless not damaged and pr operly operating after minor collision.

Also inspect seat belt assemblies not in use during a collision, and replace if damaged or improperly

operating.

Seat belt pre-tensioner should be replaced even if th e seat belts are not in use during a frontal colli-

sion where the driver and passenger air bags are deployed.

If any component of seat belt assembl y is questionable, do not repair.

Replace as seat belt assembly.

If webbing is cut, frayed, or damaged, replace belt assembly.

Never oil tongue and buckle.

Use a genuine NISSAN seat belt assembly.

For details, refer to SB-4, "

SEAT BELT RETRACTOR : Inspection", SB-10, "SEAT BELT RETRACTOR :

Inspection", SB-17, "SEAT BELT RETRACTOR : Inspection" in SB section.

Check anchors for loose mounting

Check belts for damage

Check retractor for smooth operation

Check function of buckles and tongues when buckled and released

Revision: 2010 May2011 QX56

Page 3705 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-35

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M B

MA

N

O A

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

DRIVE BELTS

DRIVE BELTS : Drive BeltsINFOID:0000000006394853

DRIVE BELT

ENGINE COOLANT

ENGINE COOLANT : Periodical Maintenance SpecificationINFOID:0000000006394856

ENGINE COOLANT CAPACITY (APPROXIMATELY)

Unit: (US qt, Imp qt)

ENGINE OIL

ENGINE OIL : Periodical Maintenance SpecificationINFOID:0000000006394855

ENGINE OIL CAPACITY (APPROXIMATE)

Unit: (US qt, Imp qt)

SPARK PLUG

SPARK PLUG : Spark PlugINFOID:0000000006394854

SPARK PLUG

Unit: mm (in)

ROAD WHEEL

ROAD WHEEL : Road WheelINFOID:0000000006349771

ALUMINUM WHEEL

Tension of drive belts Belt tension is not necessary, as it is automatically adjusted by drive belt auto-tensioner.

Engine coolant capacity [With reservoir tank (“MAX” level)] 14.9 (15-6/8, 13-1/8)

Reservoir tank engine coolant capacity (At “MAX” level) 1.0 (1, 7/8)

Drain and refill

With oil filter change 6.5 (6-7/8, 5-3/4)

Without oil filter change 6.2 (6-4/8, 5-1/2)

Dry engine (engine overhaul) 7.6 (8, 6-3/4)

Make NGK

Standard type DILKAR7B11

Gap Standard 1.1 (0.043)

Limit 1.25 (0.049)

Item Limit

Radial runout Lateral deflection

Less than 0.3 mm (0.012 in)

Vertical deflection

Allowable unbalance Dynamic (At flange) Less than 7 g (0.25 oz) (one side)

Static (At flange) Less than 14 g (0.49 oz)

Revision: 2010 May2011 QX56

Page 3706 of 5598

MIR-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION MIR

A

B

MIR

N

O P

CONTENTS

MIRRORS

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

PREPARATION ............................................5

PREPARATION .............................................. .....5

Commercial Service Tools ................................. ......5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

DOOR MIRROR ..................................................... ......6

DOOR MIRROR : Component Parts Location ..........6

DOOR MIRROR : Component Description ...............6

INSIDE MIRROR .................................................... ......7

INSIDE MIRROR : Component Description ..............7

SYSTEM ..............................................................8

DOOR MIRROR SYSTEM ..................................... ......8

DOOR MIRROR SYSTEM : System Diagram ..........8

DOOR MIRROR SYSTEM : System Description ......8

AUTO ANTI-DAZZLING INSIDE MIRROR SYS-

TEM ........................................................................ ......

9

AUTO ANTI-DAZZLING INSIDE MIRROR SYS-

TEM : System Description .........................................

9

ECU DIAGNOSIS INFORMATION ..............10

DRIVER SEAT CONTROL UNIT, AUTOMAT-

IC DRIVE POSITIONER CONTROL UNIT ..... ....

10

List of ECU Reference ........................................ ....10

WIRING DIAGRAM ......................................11

DOOR MIRROR SYSTEM .................................11

Wiring Diagram .................................................... ....11

AUTO ANTI-DAZZLING INSIDE MIRROR

SYSTEM ............................................................

19

Wiring Diagram - INSIDE MIRROR SYSTEM - ... ....19

BASIC INSPECTION ....... ............................21

DIAGNOSIS AND REPAIR WORKFLOW ........21

Work Flow ............................................................ ....21

DTC/CIRCUIT DIAGNOSIS .........................22

DOOR MIRROR REMOTE CONTROL

SWITCH .............................................................

22

OPEN/CLOSE SWITCH ......................................... ....22

OPEN/CLOSE SWITCH : Component Inspection ....22

SYMPTOM DIAGNOSIS ..............................23

REVERSE INTERLOCK DOOR MIRROR

DOES NOT OPERATE ......................................

23

Diagnosis Procedure ........................................... ....23

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ..............................................................

24

Work Flow ................................................................24

Inspection Procedure ...............................................26

Diagnostic Worksheet ..............................................28

REMOVAL AND INSTALLATION ...............30

INSIDE MIRROR ...............................................30

Exploded View ..................................................... ....30

Removal and Installation .........................................30

OUTSIDE MIRROR ...........................................32

Exploded View .........................................................32

DOOR MIRROR ASSEMBLY ....................................32

Revision: 2010 May2011 QX56

Page 3708 of 5598

PRECAUTIONSMIR-3

< PRECAUTION >

C

DE

F

G H

I

J

K

M A

B

MIR

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006257245

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006257246

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 3744 of 5598

MWI

MWI-1

DRIVER INFORMATION & MULTIMEDIA

C

DE

F

G H

I

J

K L

M B

SECTION MWI

A

O P

CONTENTS

METER, WARNING LAMP & INDICATOR

PRECAUTION ................ ...............................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Commercial Service Tools .................................. ......5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

METER SYSTEM .........................................................6

METER SYSTEM : Component Parts Location .. ......6

METER SYSTEM : Component Description .............7

CLOCK .................................................................. ......7

CLOCK : Component Parts Location ........................8

SYSTEM ..............................................................9

METER SYSTEM .........................................................9

METER SYSTEM : System Diagram ........................9

METER SYSTEM : System Description ....................9

METER SYSTEM : Fail-Safe ..................................12

SPEEDOMETER ................ ........................................13

SPEEDOMETER : System Diagram ................... ....13

SPEEDOMETER : System Description ...................13

TACHOMETER ...................................................... ....13

TACHOMETER : System Diagram .........................14

TACHOMETER : System Description .....................14

ENGINE COOLANT TEMPERATURE GAUGE .... ....14

ENGINE COOLANT TEMPERATURE GAUGE :

System Diagram ......................................................

14

ENGINE COOLANT TEMPERATURE GAUGE :

System Description .................................................

14

FUEL GAUGE ........................................................ ....14

FUEL GAUGE : System Diagram ............................14

FUEL GAUGE : System Description .......................14

ENGINE OIL PRESSURE GAUGE ............................15

ENGINE OIL PRESSURE GAUGE : System Dia-

gram .................................................................... ....

15

ENGINE OIL PRESSURE GAUGE : System De-

scription ...................................................................

15

VOLTMETER ......................................................... ....15

VOLTMETER : System Diagram .............................15

VOLTMETER : System Description .........................15

OIL PRESSURE WARNING LAMP ...........................15

OIL PRESSURE WARNING LAMP : System Dia-

gram .................................................................... ....

15

OIL PRESSURE WARNING LAMP : System De-

scription ...................................................................

16

MASTER WARNING LAMP ................................... ....16

MASTER WARNING LAMP : System Diagram .......16

MASTER WARNING LAMP : System Description ....16

METER ILLUMINATION CONTROL ..................... ....16

METER ILLUMINATION CONTROL : System Di-

agram ......................................................................

16

METER ILLUMINATION CONTROL : System De-

scription ...................................................................

16

METER EFFECT FUNCTION ................................ ....17

METER EFFECT FUNCTION : System Diagram ....17

METER EFFECT FUNCTION : System Descrip-

tion ...........................................................................

17

INFORMATION DISPLAY ...................................... ....19

INFORMATION DISPLAY : System Diagram ..........19

INFORMATION DISPLAY : System Description .....20

OPERATION .....................................................28

Switch Name and Function ......................................28

Revision: 2010 May2011 QX56

Page 3747 of 5598

MWI-4

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006369687

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Revision: 2010 May2011 QX56

Page 3776 of 5598

MWI

DIAGNOSIS SYSTEM (COMBINATION METER)

MWI-33

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

K L

M B A

O P

*: DDS (hill descent control) NOTE:

Some items are not available according to vehicle specification.

SPECIAL FUNCTION

Special menu

W/L ON HISTORY

Stores histories when warning/indicator lamp is turned on.

“W/L ON HISTORY” indicates the “TIME” when the warning/ indicator lamp is turned on.

The “TIME” above is:

- 0: The condition that the warning/indicator lamp has been turned on 1 or more times after starting the engine and waiting for 30 seconds.

- 1 - 39: The number of times the engine was restarted after the 0 condition.

- NO W/L ON HISTORY: Stores NO (0) turning on history of warning/indicator lamp.

NOTE:

W/L ON HISTORY is not stored for approximately 30 seconds after the engine starts.

Brake warning lamp does not store any history when the parking brake is applied or the brake fluid level gets

low.

Display Item

AT SFT DWN SW

[On/Off] Status of manual mode shift down switch.

PKB SW

[On/Off] Status of parking brake switch.

BUCKLE SW

[On/Off] Status of seat belt buckle switch (driver side).

BRAKE OIL SW

[On/Off] Status of brake fluid level switch.

A/C AMP CONN

[Off] This item is displayed, but cannot be monitored.

ENTER SW

[On/Off] Status of (ENTER) switch.

SELECT SW

[On/Off] Status of (SELECT) switch.

DISTANCE

[km] Value of distance to empty calculated by combination meter.

OUTSIDE TEMP

[ ° C or °F] Ambient temperature value converted from ambient sensor signal received from

ambient sensor.

NOTE:

This may not match with the temperature value indicated on the information dis-

play. (Because the information display value is a corrected value from the ambient

sensor input value.)

FUEL LOW SIG

[On/Off] Status of fuel level low warning signal to output to AV control unit via CAN com-

munication.

TOW MODE IND

[On/Off] Status of TOW mode indicator lamp judged from TOW mode indicator lamp signal

received from TCM with CAN communication line.

BUZZER

[On/Off] XBuzzer status (in the combination meter) is detected from the buzzer output signal

received from each unit via CAN communication and the warning output condition

of the combination meter.

Display item [Unit]

MAIN

SIGNALS Description

Display item Description

W/L ON HISTORY Lighting history of warning lamp and indicator lamp can be checked.

Revision: 2010 May2011 QX56