hood release INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2331 of 5598

![INFINITI QX56 2011 Factory Service Manual

P0420, P0430 THREE WAY CATALYST FUNCTIONEC-307

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0420, P0430 THREE WAY CATALYST FUNCTION

DTC LogicINFOID:0000000006217851

DTC DETECTI INFINITI QX56 2011 Factory Service Manual

P0420, P0430 THREE WAY CATALYST FUNCTIONEC-307

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0420, P0430 THREE WAY CATALYST FUNCTION

DTC LogicINFOID:0000000006217851

DTC DETECTI](/img/42/57033/w960_57033-2330.png)

P0420, P0430 THREE WAY CATALYST FUNCTIONEC-307

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0420, P0430 THREE WAY CATALYST FUNCTION

DTC LogicINFOID:0000000006217851

DTC DETECTION LOGIC

The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen storage capacity

will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decr

eases, the heated oxygen sensor 2

switching frequency will increase.

When the frequency ratio of A/F sensor 1 and heated oxygen sensor

2 approaches a specified limit value, the three way catalyst (mani-

fold) malfunction is diagnosed.

DTC CONFIRMATION PROCEDURE

1.INSPECTION START

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

Will CONSULT-III be used?

YES >> GO TO 2.

NO >> GO TO 6.

2.PERFORM DTC CONFIRMATION PROCEDURE-I

WITH CONSULT-III

TESTING CONDITION:

Do not maintain engine speed for mo re than the specified minutes below.

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

6. Let engine idle for 1 minute.

7. Select “DATA MONITOR” mode with CONSULT-III.

8. Check that “COOLAN TEMP/S” indicates more than 70 °C (158 °F).

If not, warm up engine and go to next step when “COOLAN TEMP/S” indication reaches to 70°C (158 °F).

9. Open engine hood.

10. Select “DTC & SRT CONFIRMATION” then “SRT WORK SUPPORT” mode with CONSULT-III.

11. Rev engine between 2,000 and 3,000 rpm and hold it for 3 consecutive minutes then release the acceler-

ator pedal completely.

12. Check the indication of “CATALYST”.

Which is displayed on CONSULT-III screen?

CMPLT >> GO TO 5.

INCMP >> GO TO 3.

PBIB2055E

DTC No. Trouble diagnosis name

(Trouble diagnosis content) DTC detecting condition Possible cause

P0420 TW CATALYST SYS-B1

[Catalyst system efficiency

below threshold (bank 1)]

Three way catalyst (manifold) does not

operate properly.

Three way catalyst (manifold) does not have enough oxygen storage capacity. Three way catalyst (manifold)

Exhaust tube

Intake air leakage

Fuel injector

Fuel injector leakage

Spark plug

Improper ignition timing

P0430

TW CATALYST SYS-B2

[Catalyst system efficiency

below threshold (bank 2)]

Revision: 2010 May2011 QX56

Page 2662 of 5598

EM-100

< UNIT REMOVAL AND INSTALLATION >

ENGINE ASSEMBLY

3. Install engine slinger on both front right and front left sides of theengine.

4. Hoist the slinger to obtain room for engine assembly. CAUTION:

Use an engine lifter to prevent the engine slinger from fall-

ing and damaging the rocker cover.

REMOVAL

Outline

At first, remove the transmission and transfer assemb ly, steering gear and front final drive facing downward.

Then remove the engine.

Preparation

1. Remove engine cover. Refer to EM-25, "Exploded View".

2. Release fuel pressure. Refer to EC-153, "

Work Procedure".

3. Remove battery and tray. Refer to PG-164, "

Exploded View".

4. Remove the following components and related parts: Hood assembly. Refer to DLK-215, "

Exploded View".

Front under cover. Refer to EXT-25, "

Exploded View".

Front road wheel and tires. Refer to WT-64, "

Exploded View".

5. Drain engine oil. Refer to LU-8, "

Draining".

6. Drain engine coolant. Refer to CO-8, "

Draining".

CAUTION:

Perform this step when engine is cold.

Never spill engine coolant on drive belts.

7. Drain power steering fluid. Refer to ST-54, "

Exploded View".

Engine Room Front

1. Remove drive belt. Refer to EM-20, "Exploded View".

2. Remove fan shroud. Refer to CO-13, "

Exploded View".

3. Remove cooling fan and fan coupling. Refer to CO-16, "

Exploded View".

4. Remove radiator hoses (upper and lower).

5. Remove radiator.

Vehicle Underbody

1. Remove exhaust front tube. Refer to EX-5, "Exploded View".

2. Remove protector A and B. Refer to SCS-32, "

FRONT TUBE ASSEMBLY : Exploded View".

3. Remove front suspension rear cross member. Refer to TM-205, "

2WD : Exploded View" (2WD models) or

TM-208, "

4WD : Exploded View" (4WD models).

4. Remove oil cooler. Refer to LU-11, "

Exploded View".

A : Engine front slinger (bank 2)

B : Engine front slinger (bank 1)

Slinger bolts:

: 45.0 N·m (4.6 kg-m, 33 ft-lb)

JPBIA3969ZZ

JPBIA2507ZZ

Revision: 2010 May2011 QX56

Page 2876 of 5598

COWL TOPEXT-21

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

COWL TOP

Exploded ViewINFOID:0000000006367603

Removal and InstallationINFOID:0000000006367604

REMOVAL

1. Fully open hood assembly.

2. Remove front wiper arm (LH and RH). Refer to WW-66, "

Removal and Installation".

3. Remove front fender cover (LH and RH).

4. Disconnect front wa sher tube connector.

5. Remove cowl top cover fixing clips.

6. Pull forward to release cowl top cover (1) from windshield glass. CAUTION:

When performing the procedur e after removing cowl top

cover, cover the lower end of windshield glass with ure-

thane etc.

7. Remove the following parts after removing cowl top cover. Cowl top seal

Washer nozzle (LH and RH)

Washer tube

1. Front fender cover RH 2. EPT seal [t: 15.0 mm (0.591 in)] 3. Cowl top cover seal

4. Cowl top cover 5. Front fender cover LH 6. Double-sided tape

[t: 1.2 mm (0.047 in)]

7. EPT seal [t: 3.0 mm (0.118 in)]

: Clip

: Pawl

: Vehicle front

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA5222ZZ

JMKIA1984ZZ

Revision: 2010 May2011 QX56

Page 2878 of 5598

FENDER PROTECTOREXT-23

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

FENDER PROTECTOR

FENDER PROTECTOR

FENDER PROTECTOR : Exploded ViewINFOID:0000000006367605

FENDER PROTECTOR

FENDER PROTECTOR : Remo val and InstallationINFOID:0000000006367606

REMOVAL

1. Remove mounting bolts, from front lower.

2. Release front fender protector fixing clips, and then remove front fender protector.

3. Disengage hoodledge insulator fixing pawls, and then remove hoodledge insulator.

INSTALLATION

Install in the reverse order of removal.

REAR WHEEL HOUSE PROTECTOR

1. Fender protector 2. U nut 3. Over fender

4. Fender 5. Hoodledge insurator 6. Fender clip

A: To hoodledge panel

JMKIA5463ZZ

Revision: 2010 May2011 QX56

Page 2975 of 5598

HOW TO READ WIRING DIAGRAMSGI-11

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

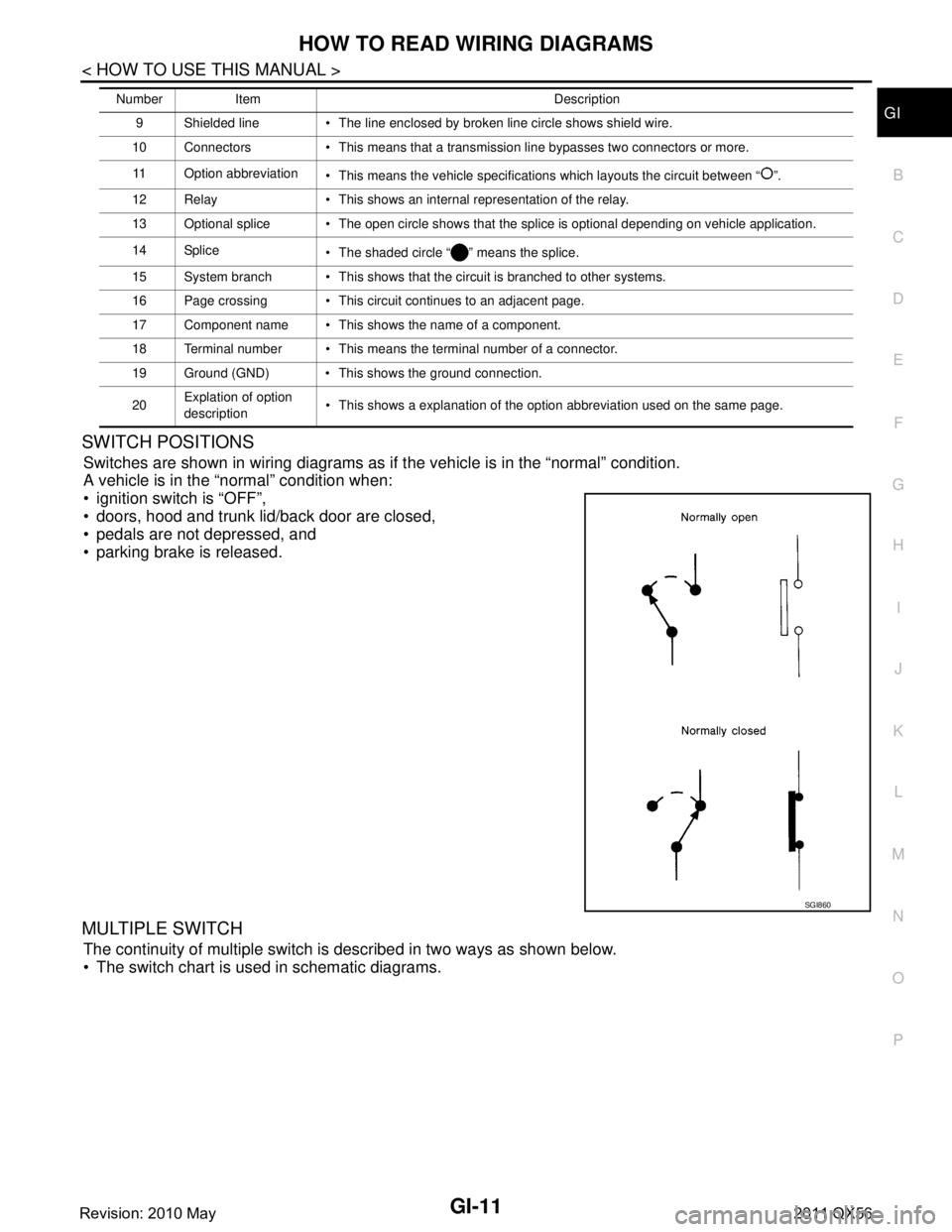

SWITCH POSITIONS

Switches are shown in wiring diagrams as if the vehicle is in the “normal” condition.

A vehicle is in the “normal” condition when:

ignition switch is “OFF”,

doors, hood and trunk lid/back door are closed,

pedals are not depressed, and

parking brake is released.

MULTIPLE SWITCH

The continuity of multiple switch is described in two ways as shown below.

The switch chart is used in schematic diagrams.

9 Shielded line The line enclosed by broken line circle shows shield wire.

10 Connectors This means that a transmission line bypasses two connectors or more.

11 Option abbreviation This means the vehicle specifications which layouts the circuit between “ ”.

12 Relay This shows an internal representation of the relay.

13 Optional splice The open circle shows that the splice is optional depending on vehicle application.

14 Splice The shaded circle “ ” means the splice.

15 System branch This shows that the circuit is branched to other systems.

16 Page crossing This circuit continues to an adjacent page.

17 Component name This shows the name of a component.

18 Terminal number This means the terminal number of a connector.

19 Ground (GND) This shows the ground connection.

20 Explation of option

description This shows a explanation of the option abbreviation used on the same page.

Number Item Description

SGI860

Revision: 2010 May2011 QX56

Page 3674 of 5598

MA-4

< PERIODIC MAINTENANCE >

GENERAL MAINTENANCE

PERIODIC MAINTENANCE

GENERAL MAINTENANCE

Explanation of General MaintenanceINFOID:0000000006287728

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed fr om time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive wear. WT-69

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary. —

Tire rotation Tires should be rotated every 12,000km (7,500 miles). If the vehicle is equipped

with different sized tires in the front and rear, tires cannot be rotated. WT-63

Tire Pressure Moni-

toring System (TPMS)

transmitter compo-

nentsReplace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

WT-66

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. FSU-7

RSU-6

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. —

Windshield wiper

blades Check for cracks or wear if they do not wipe properly. —

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

door. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently. MA-34

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head-

lamp aim. Clean the headlamps on a regular basis. —

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly. —

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner. —

Steering wheel Check that it has the specified play. Check for changes in the steering condi-

tion, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) —

Revision: 2010 May2011 QX56

Page 3675 of 5598

GENERAL MAINTENANCEMA-5

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should

be checked periodically (e.g. each time you check the engine oil or refuel).

Seats Check seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restrains move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seatbacks. —

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage. MA-34

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to

keep the floor mats away from the pedal. BR-7

BR-15

Parking brake

Check that the lever or pedal has the proper travel and make sure that the ve-

hicle is held securely on a fairly steep hill when only the parking brake is ap-

plied. PB-3

Automatic transmis-

sion “Park” mecha-

nismCheck that the lock release button on the selector lever operates properly and

smoothly. On a fairly steep hill check that the vehicle is held securely with the

selector lever in the P (Park) position without applying any brakes.

—

Item

Reference page

Item Reference page

Windshield washer

fluid Check that there is adequate fluid in the tank. —

Engine coolant level Check the coolant level when the engine is cold. MA-12

Radiator and hosesCheck the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the hoses have no cracks, deformation, de-

terioration or loose connections. MA-16

Brake fluid levels

Make sure that the brake fluid level is between the “MAX” and “MIN” lines on the

reservoir(s). MA-28

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN”

lines. Vehicles operated in high temperatures or under severe conditions re-

quire frequent checks of the battery fluid level. PG-159

Engine drive belts

Make sure that no belt is frayed, worn, cracked or oily. MA-12

Engine oil levelCheck the level on the oil level gauge after parking the vehicle on a level spot

and turning off the engine. LU-7

Power steering fluid

level and linesCheck the level on the dipstick with the engine off. Check the lines for improper

attachment, leaks, cracks, etc.

MA-32

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate

the trouble and correct it. MA-21

Underbody

The underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around

the exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately. —

Revision: 2010 May2011 QX56

Page 3704 of 5598

MA-34

< PERIODIC MAINTENANCE >

BODY MAINTENANCE

BODY MAINTENANCE

LOCKS, HINGES AND HOOD LATCH

LOCKS, HINGES AND HOOD LATCH : LubricatingINFOID:0000000006220949

For hood and hood lock illustration.

Hood: Refer to DLK-215, "

Exploded View".

Hood lock: Refer to DLK-238, "

Exploded View".

For front door and front door lock illustration.

Front door: Refer to DLK-224, "

Exploded View".

Front door lock: Refer to DLK-240, "

Exploded View".

For rear door and rear door lock illustration.

Rear door: Refer to DLK-228, "

Exploded View".

Rear door lock: Refer to DLK-243, "

Exploded View".

For back door and back door lock illustration.

Back door: Refer to DLK-232, "

Exploded View".

Back door lock: Refer to DLK-246, "

Exploded View".

SEAT BELT, BUCKLES, RETRACTORS, ANCHORS AND ADJUSTERS

SEAT BELT, BUCKLES, RETRACTORS, ANCHORS AND ADJUSTERS : Inspection

INFOID:0000000006220950

For front seat belt illustration. Refer to SB-6, "SEAT BELT RETRACTOR : Exploded View".

For second seat belt illustration. Refer to SB-11, "

SEAT BELT RETRACTOR : Exploded View".

For third seat belt illustration. Refer to SB-19, "

SEAT BELT RETRACTOR : Exploded View".

CAUTION:

After any collision, inspect all seat belt assembli es, including retractors and other attached hard-

wares (I.e. anchor bolt, guide ra il set). Nissan recommends to replace all seat belt assemblies in use

during a collision, unless not damaged and pr operly operating after minor collision.

Also inspect seat belt assemblies not in use during a collision, and replace if damaged or improperly

operating.

Seat belt pre-tensioner should be replaced even if th e seat belts are not in use during a frontal colli-

sion where the driver and passenger air bags are deployed.

If any component of seat belt assembl y is questionable, do not repair.

Replace as seat belt assembly.

If webbing is cut, frayed, or damaged, replace belt assembly.

Never oil tongue and buckle.

Use a genuine NISSAN seat belt assembly.

For details, refer to SB-4, "

SEAT BELT RETRACTOR : Inspection", SB-10, "SEAT BELT RETRACTOR :

Inspection", SB-17, "SEAT BELT RETRACTOR : Inspection" in SB section.

Check anchors for loose mounting

Check belts for damage

Check retractor for smooth operation

Check function of buckles and tongues when buckled and released

Revision: 2010 May2011 QX56

Page 3857 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS-16

< ECU DIAGNOSIS INFORMATION >[IPDM E/R]

IPDM E/R

ST/INHI RLYIgnition switch ON Off

At engine cranking INHI ON

→ ST ON

The status of starter relay or starter control relay cannot be recogniz INFINITI QX56 2011 Factory Service Manual

PCS-16

< ECU DIAGNOSIS INFORMATION >[IPDM E/R]

IPDM E/R

ST/INHI RLYIgnition switch ON Off

At engine cranking INHI ON

→ ST ON

The status of starter relay or starter control relay cannot be recogniz](/img/42/57033/w960_57033-3856.png)

PCS-16

< ECU DIAGNOSIS INFORMATION >[IPDM E/R]

IPDM E/R

ST/INHI RLYIgnition switch ON Off

At engine cranking INHI ON

→ ST ON

The status of starter relay or starter control relay cannot be recognized by

the battery voltage malfunction, etc. when the starter relay is ON and the

starter control relay is OFF. UNKWN

DETENT SW Ignition switch ON Pull the selector lever with selec-

tor lever in P position.

Selector lever in any position oth-

er than P. Off

Release the selector lever with selector lever in P position. On

S/L RLY -REQ None of the conditions below are present. Off

Open the driver door after the ignition switch is turned OFF (for a few

seconds).

Press the push-button ignition switch when the steering lock is activat-

ed. On

S/L STATE Steering lock is locked. LOCK

Steering lock is unlocked. UNLK

[DTC: B210A] is detected. UNKWN

OIL P SW Ignition switch OFF or ACC

Open

Ignition switch ON (engine running)

Ignition switch ON (engine stopped) Close

HOOD SW Close the hood Off

Open the hood On

HL WASHER REQ Not operating Off

Headlamp washer operating On

THFT HRN REQ Not operation Off

Panic alarm is activated

Theft warning alarm is activated

On

HORN CHIRP Not operation Off

Door locking with Intelligent Key (horn chirp mode) On

Monitor Item Condition Value/Status

Revision: 2010 May2011 QX56

Page 4616 of 5598

![INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSSEC-9

< SYSTEM DESCRIPTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Then, when the power supply position is turned ON, BCM performs ID verification between BC INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSSEC-9

< SYSTEM DESCRIPTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Then, when the power supply position is turned ON, BCM performs ID verification between BC](/img/42/57033/w960_57033-4615.png)

COMPONENT PARTSSEC-9

< SYSTEM DESCRIPTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Then, when the power supply position is turned ON, BCM performs ID verification between BCM and ECM. If

the ID verification result is OK, ECM can start engine.

ECMINFOID:0000000006226155

ECM controls the engine.

When power supply position is turned ON, BCM starts communication with ECM and performs the ID verifica-

tion between BCM and ECM.

If the verification result is OK, the engine can start. If the verification result is NG, the engine can not start.

IPDM E/RINFOID:0000000006226156

IPDM E/R has steering lock relay, starter relay and starte r control relay inside. Steering lock relay is used for

the steering lock/unlock function. Starter relay and star ter control relay are used for the engine starting func-

tion. IPDM E/R controls these relays while communicating with BCM.

NATS Antenna Amp.INFOID:0000000006226157

The ID verification is performed between BCM and transponder in Intelligent Key via NATS antenna amp.

when Intelligent Key backside is contacted to push-button i gnition switch in case that Intelligent Key battery is

discharged. If the ID verification result is OK, the release of steering lock and the operation of starting engine

is available.

TCMINFOID:0000000006226158

TCM transmits the shift position signal (P/N position) to BCM and IPDM E/R. And further, TCM transmits the

shift position signal (P/N position) to BCM via CAN communication.

BCM confirms the A/T shift selector position with the following 5 signals.

P position signal from A/T shift selector (detention switch)

P/N position signal from TCM

P position signal from IPDM E/R (CAN)

P/N position signal from IPDM E/R (CAN)

P/N position signal from TCM (CAN)

IPDM E/R confirms the A/T shift sele ctor position with the following 3 signals.

P position signal from A/T shift selector (detention switch)

P/N position signal from TCM

P/N position signal from BCM (CAN)

Combination MeterINFOID:0000000006226159

Combination meter transmits the vehicle speed signal to BCM via CAN communication.

BCM also receives the vehicle speed signal from ABS ac tuator and electric unit (control unit) via CAN commu-

nication. BCM compares both signals to detect the vehicle speed.

Door SwitchINFOID:0000000006226160

Door switch detects door open/close condition and then transmits ON/OFF signal to BCM.

Hood SwitchINFOID:0000000006226161

Hood switch detects that hood is open, and then transmits the signal to IPDM E/R. IPDM E/R transmits hood

switch signal to BCM via CAN communication.

Inside Key AntennaINFOID:0000000006226162

Inside key antenna detects whether Intelligent Key is inside the vehicle, and transmits the signal to BCM.

Three inside key antennas are installed in t he instrument center, console and luggage room.

Intelligent KeyINFOID:0000000006226163

Each Intelligent key has an individual electronic ID , and transmits the ID signal by request from BCM.

Carrying the Intelligent Key whose ID is registered in BCM, the driver can performs door lock/unlock operation

and push-button ignition switch operation.

Revision: 2010 May2011 QX56