body int INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4463 of 5598

SE-4

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006237842

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Service NoticeINFOID:0000000006217352

When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

Handle trim, molding, instruments, grille, etc. carefull y during removing or installing. Be careful not to oil or

damage them.

Apply sealing compound where necessary when installing parts.

When applying sealing compound, be careful that t he sealing compound never protrudes from parts.

When replacing any metal parts (for example body outer panel, members, etc.), always take rust prevention

measures.

Precaution for WorkINFOID:0000000006217353

When removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, al ways protect it with a shop cloth.

When removing (disengaging) components with a screwdriver or similar tool, always wrap the component

with a shop cloth or vinyl tape to protect it.

Protect the removed parts with a shop cloth and keep them.

Replace a deformed or damaged clip.

If a part is specified as a non-reusable part, always replace it with new one.

Always tighten bolts and nuts securely to the specified torque.

After reinstallation is complete, always check that each part works normally.

Follow the steps below to clean components.

- Water soluble foul: Dip a soft cloth into lukewarm water, and wring the water out of the cloth to wipe the fouled area.

Then rub with a soft and dry cloth.

Revision: 2010 May2011 QX56

Page 4559 of 5598

SE-100

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-cl utch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis ear: J-39570, Engine ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the components in the area that is are suspected to be the cause of the noise.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

Tapping or pushing/pulling the component that is are suspected to be the cause of the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

Feeling for a vibration by hand by touching the component (s) that is are suspected to be the cause of the

noise.

Placing a piece of paper between components that are suspected to be the cause of the noise.

Looking for loose components and contact marks. Refer to SE-101, "

Inspection Procedure".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loos ening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A Nissan Squeak and Rattle Kit (J-43980) is available through the authorized Nissan Parts

Department.

CAUTION:

Never use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Departm ent for the latest parts information.

The following materials are contained in the Nissan Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94 ×5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-

71L02:15 ×25 mm (0.59 ×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-

50Y00: 10 mm (0.39 in) thick, 50 ×50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97in)

FELT CLOTHTAPE

Used to insulate where movement does not occu r. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59 ×0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Revision: 2010 May2011 QX56

Page 4608 of 5598

SEC-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G H

I

J

L

M

SECTION SEC

A

B

SEC

N

O P

CONTENTS

SECURITY CONTROL SYSTEM

WITH INTELLIGE NT KEY SYSTEM

PRECAUTION ................ ...............................

5

PRECAUTIONS .............................................. .....5

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

5

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

5

Precaution for Procedure without Cowl Top Cover ......6

SYSTEM DESCRIPTION ..............................7

COMPONENT PARTS ................................... .....7

Component Parts Location .................................. ......7

Component Description .............................................8

A/T Shift Selector (Detention Switch) ........................8

BCM ..........................................................................8

ECM ..........................................................................9

IPDM E/R ..................................................................9

NATS Antenna Amp. .................................................9

TCM ..........................................................................9

Combination Meter ....................................................9

Door Switch ...............................................................9

Hood Switch ..............................................................9

Inside Key Antenna ...................................................9

Intelligent Key ............................................................9

Push-button Ignition Switch .....................................10

Remote Keyless Entry Receiver .............................10

Security Indicator Lamp ..........................................10

Starter Control Relay ...............................................10

Starter Relay ...........................................................10

Steering Lock Relay ................................................10

Steering Lock Unit ...................................................10

Stop Lamp Switch ...................................................10

Transmission Range Switch ....................................10

Vehicle Information Display .....................................11

SYSTEM .............................................................12

INTELLIGENT KEY SYSTEM/ENGINE START

FUNCTION ............................................................. ....

12

INTELLIGENT KEY SYSTEM/ENGINE START

FUNCTION : System Diagram ................................

12

INTELLIGENT KEY SYSTEM/ENGINE START

FUNCTION : System Description ............................

12

INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS ....14

INFINITI VEHICLE IMMOBILIZER SYSTEM-

NATS : System Diagram .........................................

15

INFINITI VEHICLE IMMOBILIZER SYSTEM-

NATS : System Description .....................................

15

VEHICLE SECURITY SYSTEM .................................17

VEHICLE SECURITY SYSTEM : System Dia-

gram .................................................................... ....

17

VEHICLE SECURITY SYSTEM : System Descrip-

tion ...........................................................................

18

DIAGNOSIS SYSTEM (BCM) ...........................21

COMMON ITEM ..................................................... ....21

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

21

INTELLIGENT KEY ................................................ ....22

INTELLIGENT KEY : CONSULT-III Function

(BCM - INTELLIGENT KEY) ....................................

22

THEFT ALM ........................................................... ....26

THEFT ALM : CONSULT-III Function (BCM -

THEFT) ................................................................ ....

26

IMMU ...................................................................... ....27

IMMU : CONSULT-III Function (BCM - IMMU) ........27

DIAGNOSIS SYSTEM (IPDM E/R) ...................28

CONSULT-III Function (IPDM E/R) .........................28

ECU DIAGNOSIS INFORMATION ..............30

ECM, IPDM E/R, BCM .......................................30

List of ECU Reference ......................................... ....30

Revision: 2010 May2011 QX56

Page 4614 of 5598

![INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSSEC-7

< SYSTEM DESCRIPTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006226151

1. Insid INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSSEC-7

< SYSTEM DESCRIPTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006226151

1. Insid](/img/42/57033/w960_57033-4613.png)

COMPONENT PARTSSEC-7

< SYSTEM DESCRIPTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006226151

1. Inside key antenna (console) Refer to DLK-11, "

DOOR LOCK

SYSTEM :

ComponentPartsLocation". 2. A/T assembly

Refer to TM-10, "

A/T CONTROL

SYSTEM : Compon ent Parts Loca-

tion". 3. Push-button ignition switch

4. NATS antenna amp. 5. Inside key antenna (instrument cen- ter)

Refer to DLK-11, "

DOOR LOCK

SYSTEM :

ComponentPartsLocation". 6. IPDM E/R

Refer to PCS-4, "

Component Parts

Location".

7. ECM Refer to EC-16, "

Component Parts

Location"). 8. Horn 9. ABS actuator and electric unit (con-

trol unit)

Refer to BRC-10, "Component Parts

Location".

10. Stop lamp switch Refer to EC-16, "

Component Parts

Location". 11 . B C M

Refer to BCS-4, "

BODY CONTROL

SYSTEM : Compon ent Parts Loca-

tion". 12. Combination meter

Refer to MWI-6, "

METER SYSTEM :

Component Parts Location".

JMKIA5243ZZ

Revision: 2010 May2011 QX56

Page 4628 of 5598

![INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (BCM)SEC-21

< SYSTEM DESCRIPTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu nction (BCM - COMMO INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (BCM)SEC-21

< SYSTEM DESCRIPTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu nction (BCM - COMMO](/img/42/57033/w960_57033-4627.png)

DIAGNOSIS SYSTEM (BCM)SEC-21

< SYSTEM DESCRIPTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu nction (BCM - COMMON ITEM)INFOID:0000000006365349

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate each device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defo gger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 4768 of 5598

COLLISION DIAGNOSISSR-5

< BASIC INSPECTION >

C

DE

F

G

I

J

K L

M A

B

SR

N

O P

BASIC INSPECTION

COLLISION DIAGNOSIS

FOR FRONTAL COLLISION

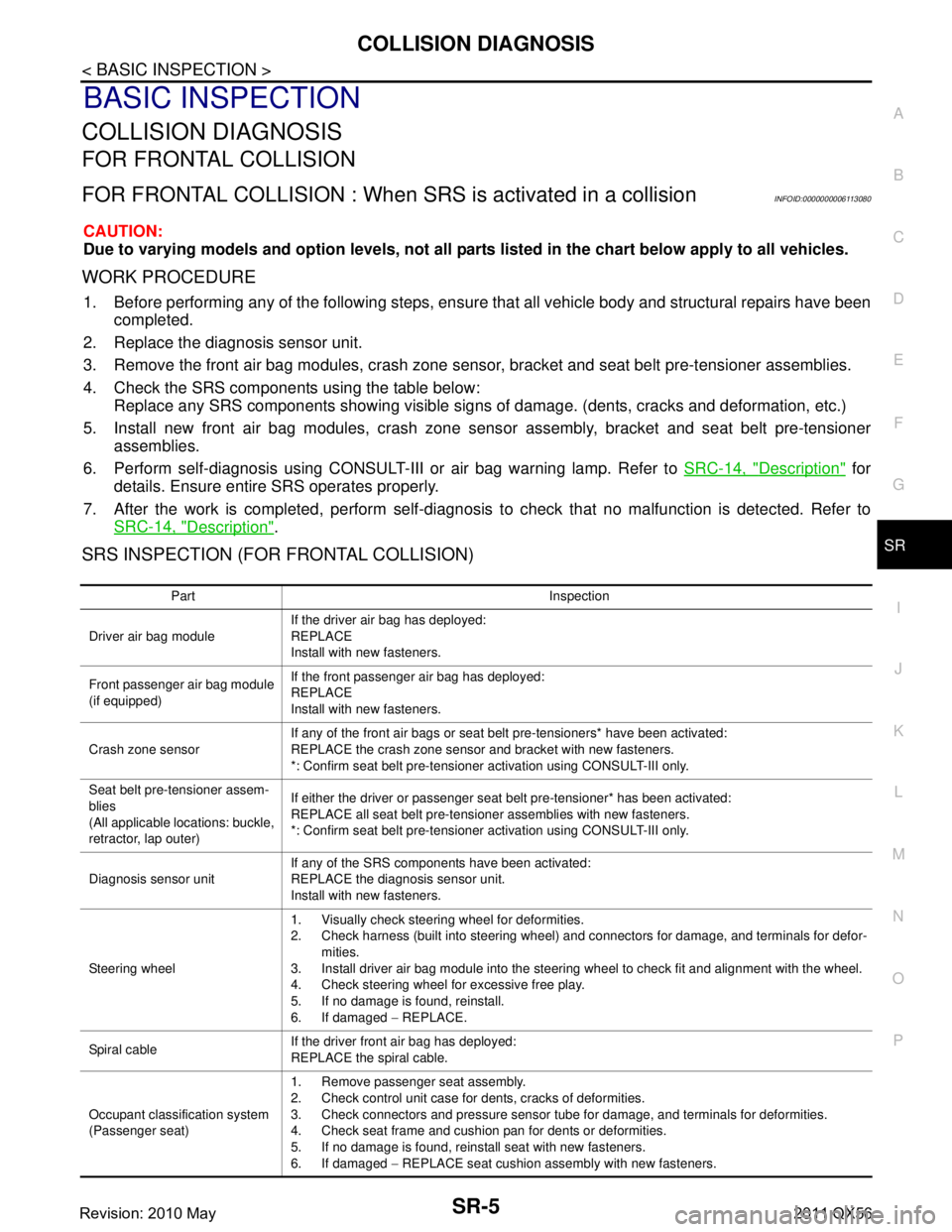

FOR FRONTAL COLLISION : When SR S is activated in a collisionINFOID:0000000006113080

CAUTION:

Due to varying models and option levels, not all parts listed in the chart below apply to all vehicles.

WORK PROCEDURE

1. Before performing any of the following steps, ensur e that all vehicle body and structural repairs have been

completed.

2. Replace the diagnosis sensor unit.

3. Remove the front air bag modules, crash zone sensor , bracket and seat belt pre-tensioner assemblies.

4. Check the SRS components using the table below: Replace any SRS components showing visible signs of damage. (dents, cracks and deformation, etc.)

5. Install new front air bag modules, crash zone sens or assembly, bracket and seat belt pre-tensioner

assemblies.

6. Perform self-diagnosis using CONSULT-III or air bag warning lamp. Refer to SRC-14, "

Description" for

details. Ensure entire SRS operates properly.

7. After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to

SRC-14, "

Description".

SRS INSPECTION (FOR FRONTAL COLLISION)

Part Inspection

Driver air bag module If the driver air bag has deployed:

REPLACE

Install with new fasteners.

Front passenger air bag module

(if equipped) If the front passenger air bag has deployed:

REPLACE

Install with new fasteners.

Crash zone sensor If any of the front air bags or seat belt pre-tensioners* have been activated:

REPLACE the crash zone sensor and bracket with new fasteners.

*: Confirm seat belt pre-tensioner activation using CONSULT-III only.

Seat belt pre-tensioner assem-

blies

(All applicable locations: buckle,

retractor, lap outer) If either the driver or passenger seat belt pre-tensioner* has been activated:

REPLACE all seat belt pre-tensioner assemblies with new fasteners.

*: Confirm seat belt pre-tensioner activation using CONSULT-III only.

Diagnosis sensor unit If any of the SRS components have been activated:

REPLACE the diagnosis sensor unit.

Install with new fasteners.

Steering wheel 1. Visually check steering wheel for deformities.

2. Check harness (built into steering wheel) and connectors for damage, and terminals for defor-

mities.

3. Install driver air bag module into the steering wheel to check fit and alignment with the wheel.

4. Check steering wheel for excessive free play.

5. If no damage is found, reinstall.

6. If damaged − REPLACE.

Spiral cable If the driver front air bag has deployed:

REPLACE the spiral cable.

Occupant classification system

(Passenger seat) 1. Remove passenger seat assembly.

2. Check control unit case for dents, cracks of deformities.

3. Check connectors and pressure sensor tube for damage, and terminals for deformities.

4. Check seat frame and cushion pan for dents or deformities.

5. If no damage is found, reinstall seat with new fasteners.

6. If damaged

− REPLACE seat cushion assembly with new fasteners.

Revision: 2010 May2011 QX56

Page 4769 of 5598

SR-6

< BASIC INSPECTION >

COLLISION DIAGNOSIS

FOR FRONTAL COLLISION : When SRS is not activated in a collision

INFOID:0000000006113081

CAUTION:

Due to varying models and option levels, not all part s listed in the chart below apply to all vehicles.

WORK PROCEDURE

1. Before performing any of the following steps, ensur e that all vehicle body and structural repairs have been

completed.

2. Check the SRS components using the table below: Replace any SRS components showing visible signs of damage. (dents, cracks and deformation, etc.)

3. Perform self-diagnosis using CONSULT-III or air bag warning lamp. Refer to SRC-14, "

Description" for

details. Ensure entire SRS operates properly.

4. After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to

SRC-14, "

Description".

SRS INSPECTION (FOR FRONTAL COLLISION)

Harness and connectors 1. Check connectors for poor connection, damage, and terminals for deformities.

2. Check harness for binding, chafing, cuts, or deformities.

3. If no damage is found, reinstall the harness and connectors.

4. If damaged

− REPLACE the damaged harness. Do not attempt to repair, splice or modify any

SRS harness.

Instrument panel assembly If the front passenger air bag has deployed:

REPLACE the instrument panel assembly. (integrated type)

Part Inspection

Part Inspection

Driver air bag module If the driver air bag has NOT been deployed:

1. Remove driver air bag module. Check harness cover and connectors for damage, terminals for

deformities, and harness for binding.

2. Install driver air bag module into the steering wheel to check fit and alignment with the wheel.

3. If no damage is found, reinstall with new fasteners.

4. If damaged − REPLACE. Install driver air bag module with new fasteners.

Front passenger air bag module

(if equipped) If the front passenger air bag has NOT been deployed:

1. Remove front passenger air bag module. Check harness cover and connectors for damage, ter-

minals for deformities, and harness for binding.

2. Install front passenger air bag module into the instrument panel to check fit with the instrument panel.

3. If no damage is found, reinstall with new fasteners.

4. If damaged − REPLACE. Install front passenger air bag modules with new fasteners.

Crash zone sensor If the front air bags or seat belt pre-tensioners have NOT been activated:

1. Remove the crash zone sensor. Check harness connectors for damage, terminals for deformi-

ties, and harness for binding.

2. Check for visible signs of damage (dents, cracks, deformation, etc.) of the crash zone sensor and bracket.

3. Install the crash zone sensor to check fit.

4. If no damage is found, reinstall with new fasteners.

5. If damaged − REPLACE the crash zone sensor and bracket with new fasteners.

Seat belt pre-tensioner assem-

blies

(All applicable locations: buckle,

retractor, lap outer) If the pre-tensioners have NOT been activated:

1. Remove seat belt pre-tensioners.

Check harness cover and connectors for damage , terminals for deformities, and harness for

binding.

2. Check belts for damage and anchors for loose mounting.

3. Check retractor for smooth operation.

4. Check seat belt adjuster for damage.

5. Check for deformities of the center pillar inner.

6. If the center pillar inner has no damage, REPLACE the seat belt pre-tensioner assembly.

7. If no damage is found, reinstall seat belt pre-tensioner assembly.

8. If damaged − REPLACE. Install the seat belt pre-tensioners with new fasteners.

Revision: 2010 May2011 QX56

Page 4770 of 5598

COLLISION DIAGNOSISSR-7

< BASIC INSPECTION >

C

DE

F

G

I

J

K L

M A

B

SR

N

O P

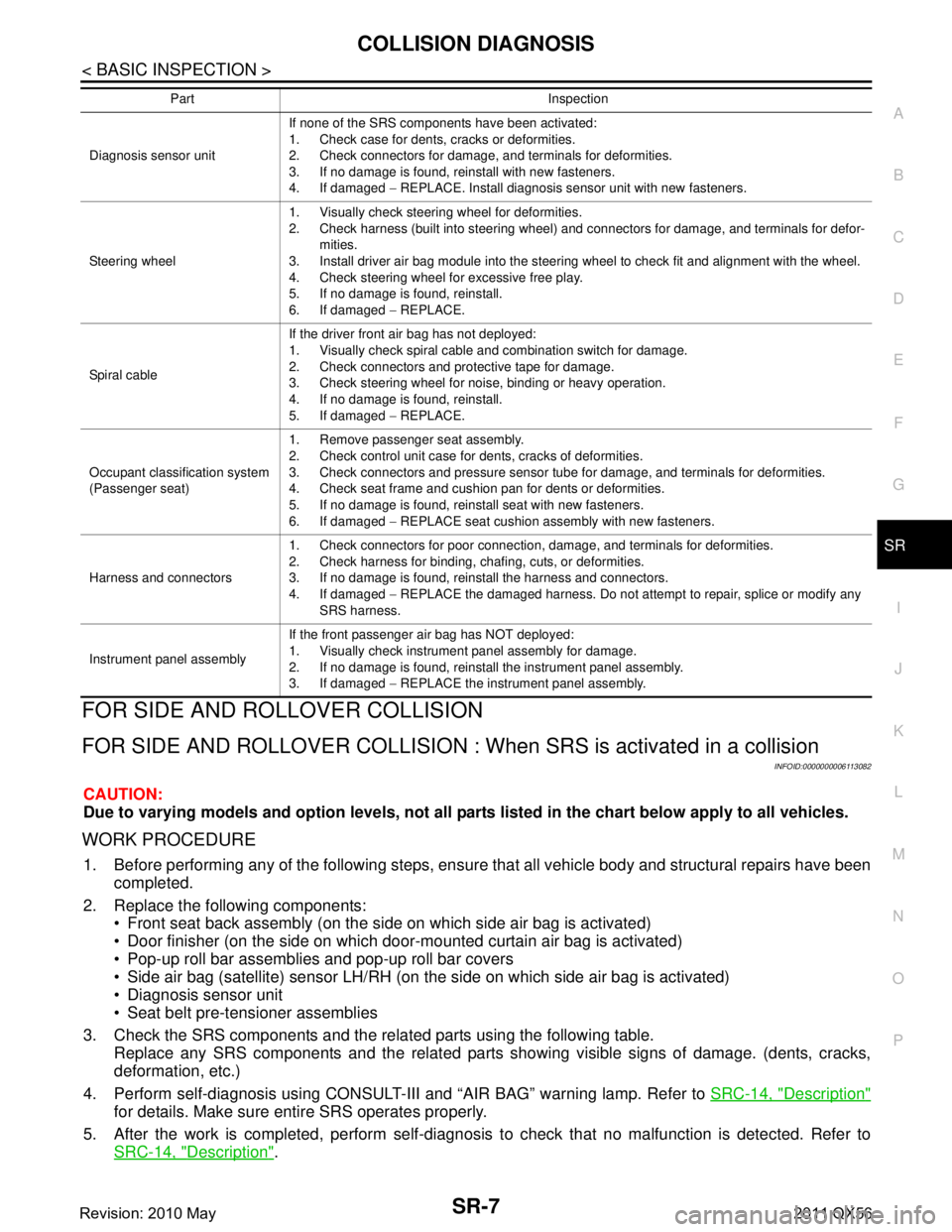

FOR SIDE AND ROLLOVER COLLISION

FOR SIDE AND ROLLOVER CO LLISION : When SRS is activated in a collision

INFOID:0000000006113082

CAUTION:

Due to varying models and option levels, not all parts listed in the chart below apply to all vehicles.

WORK PROCEDURE

1. Before performing any of the following steps, ensur e that all vehicle body and structural repairs have been

completed.

2. Replace the following components: Front seat back assembly (on the side on which side air bag is activated)

Door finisher (on the side on which door-mounted curtain air bag is activated)

Pop-up roll bar assemblies and pop-up roll bar covers

Side air bag (satellite) sensor LH/RH (on the side on which side air bag is activated)

Diagnosis sensor unit

Seat belt pre-tensioner assemblies

3. Check the SRS components and the related parts using the following table. Replace any SRS components and the related parts s howing visible signs of damage. (dents, cracks,

deformation, etc.)

4. Perform self-diagnosis using CONSULT-III and “AIR BAG” warning lamp. Refer to SRC-14, "

Description"

for details. Make sure entire SRS operates properly.

5. After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to

SRC-14, "

Description".

Diagnosis sensor unit If none of the SRS components have been activated:

1. Check case for dents, cracks or deformities.

2. Check connectors for damage, and terminals for deformities.

3. If no damage is found, reinstall with new fasteners.

4. If damaged

− REPLACE. Install diagnosis sensor unit with new fasteners.

Steering wheel 1. Visually check steering wheel for deformities.

2. Check harness (built into steering wheel) and connectors for damage, and terminals for defor-

mities.

3. Install driver air bag module into the steering wheel to check fit and alignment with the wheel.

4. Check steering wheel for excessive free play.

5. If no damage is found, reinstall.

6. If damaged − REPLACE.

Spiral cable If the driver front air bag has not deployed:

1. Visually check spiral cable and combination switch for damage.

2. Check connectors and protective tape for damage.

3. Check steering wheel for noise, binding or heavy operation.

4. If no damage is found, reinstall.

5. If damaged

− REPLACE.

Occupant classification system

(Passenger seat) 1. Remove passenger seat assembly.

2. Check control unit case for dents, cracks of deformities.

3. Check connectors and pressure sensor tube for damage, and terminals for deformities.

4. Check seat frame and cushion pan for dents or deformities.

5. If no damage is found, reinstall seat with new fasteners.

6. If damaged

− REPLACE seat cushion assembly with new fasteners.

Harness and connectors 1. Check connectors for poor connection, damage, and terminals for deformities.

2. Check harness for binding, chafing, cuts, or deformities.

3. If no damage is found, reinstall the harness and connectors.

4. If damaged

− REPLACE the damaged harness. Do not attempt to repair, splice or modify any

SRS harness.

Instrument panel assembly If the front passenger air bag has NOT deployed:

1. Visually check instrument panel assembly for damage.

2. If no damage is found, reinstall the instrument panel assembly.

3. If damaged

− REPLACE the instrument panel assembly.

Part Inspection

Revision: 2010 May2011 QX56

Page 4771 of 5598

SR-8

< BASIC INSPECTION >

COLLISION DIAGNOSIS

SRS INSPECTION (FOR SIDE AND ROLLOVER COLLISION)

FOR SIDE AND ROLLOVER COLLISION : When SRS is not activated in a collision

INFOID:0000000006113083

CAUTION:

Due to varying models and option levels, not all part s listed in the chart below apply to all vehicles.

WORK PROCEDURE

1. Before performing any of the following steps, ensur e that all vehicle body and structural repairs have been

completed.

2. Check the SRS components and the related parts using the following table. If the front seat back assembly is damaged, t he front seat back assembly must be replaced.

If the door finisher assembly is damaged, the door finisher assembly and door-mounted curtain air bag

module must be replaced.

3. Perform self-diagnosis using CONSULT-III and “AIR BAG” warning lamp. Refer to SRC-14, "

Description"

for details. Make sure entire SRS operates properly.

4. After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to

SRC-14, "

Description".

SRS INSPECTION (FOR SIDE AND ROLLOVER COLLISION)

Part Inspection

Side curtain air bag module LH If the side curtain air bag LH has deployed:

REPLACE the side curtain air bag module LH.

Install with new fasteners.

Side curtain air bag module RH If the side curtain air bag RH has deployed:

REPLACE the side curtain air bag module RH.

Install with new fasteners.

Front side air bag module LH If the front side air bag LH has deployed:

REPLACE front seatback assembly LH.

Front side air bag module RH If the front side air bag RH has deployed:

REPLACE front seatback assembly RH.

Side air bag (satellite) sensor

(LH or RH) If any of the SRS components have deployed:

REPLACE the side air bag (satellite) sensor on the collision side with new fasteners.

Diagnosis sensor unit If any of the SRS components have deployed:

REPLACE the diagnosis sensor unit with new fasteners.

Seat belt pre-tensioner assem-

blies

(All applicable locations: buckle,

retractor, lap outer) If either the driver or passenger seat belt pre-tensioner* has been activated:

REPLACE all seat belt pre-tensioner assemblies with new fasteners.

*: Confirm seat belt pre-tensioner activation using CONSULT-III only.

Center inner pillar 1. Check the center inner pillar on the collision side for damage (dents, cracks, deformation, etc.).

2. If damaged

− REPAIR the center inner pillar.

Trim/headlining 1. Check for visible signs of damage (dents, cracks, deformation, etc.) of the interior trim on the

collision side.

2. If damaged − REPLACE the damaged trim parts.

Door-mounted curtain air bag

module LH If the door-mounted curtain air bag module LH has deployed:

REPLACE the door finisher LH and door-mounted curtain air bag module.

Install with new fasteners.

Door-mounted curtain air bag

module RH If the door-mounted curtain air bag module RH has deployed:

REPLACE the door finisher RH and door-mounted curtain air bag module.

Install with new fasteners.

Pop-up roll bar assemblies If the pop-up roll bar has deployed:

REPLACE pop-up roll bar assemblies and pop-up roll bar covers.

Install with new fasteners.

Revision: 2010 May2011 QX56

Page 5038 of 5598

POWER STEERING OIL PUMPST-51

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

1. Apply recommended grease to oil seal lips (1). Apply recom- mended fluid to around oil seal. Install oil seal to body assembly,

using a drift.

CAUTION:

Never reuse oil seal.

2. Apply recommended fluid to drive shaft, and press drive shaft into body assembly, then install snap ring.

CAUTION:

Never reuse snap ring.

3. Apply recommended fluid to O-ring, and then install O-ring into body assembly.

CAUTION:

Never reuse O-ring.

4. Install side plate to body assembly.

5. Install dowel pin (1) into dowel pin hole (A), and then install cam ring (2) pointing it's D

1 side toward the body assembly (3) side

as shown in the figure.

When installing cam ring, turn carved face with a letter E (B) of

it to rear cover.

CAUTION:

Do not confuse the assembling direction of cam ring. If

cam ring is installed facing th e incorrect direction, it may

cause oil pump operation malfunction.

SGIA1150E

SGIA0422E

JSGIA0110ZZ

Revision: 2010 May2011 QX56