hood open INFINITI QX56 2011 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2331 of 5598

![INFINITI QX56 2011 Factory User Guide

P0420, P0430 THREE WAY CATALYST FUNCTIONEC-307

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0420, P0430 THREE WAY CATALYST FUNCTION

DTC LogicINFOID:0000000006217851

DTC DETECTI INFINITI QX56 2011 Factory User Guide

P0420, P0430 THREE WAY CATALYST FUNCTIONEC-307

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0420, P0430 THREE WAY CATALYST FUNCTION

DTC LogicINFOID:0000000006217851

DTC DETECTI](/img/42/57033/w960_57033-2330.png)

P0420, P0430 THREE WAY CATALYST FUNCTIONEC-307

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0420, P0430 THREE WAY CATALYST FUNCTION

DTC LogicINFOID:0000000006217851

DTC DETECTION LOGIC

The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen storage capacity

will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decr

eases, the heated oxygen sensor 2

switching frequency will increase.

When the frequency ratio of A/F sensor 1 and heated oxygen sensor

2 approaches a specified limit value, the three way catalyst (mani-

fold) malfunction is diagnosed.

DTC CONFIRMATION PROCEDURE

1.INSPECTION START

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

Will CONSULT-III be used?

YES >> GO TO 2.

NO >> GO TO 6.

2.PERFORM DTC CONFIRMATION PROCEDURE-I

WITH CONSULT-III

TESTING CONDITION:

Do not maintain engine speed for mo re than the specified minutes below.

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Turn ignition switch ON.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

6. Let engine idle for 1 minute.

7. Select “DATA MONITOR” mode with CONSULT-III.

8. Check that “COOLAN TEMP/S” indicates more than 70 °C (158 °F).

If not, warm up engine and go to next step when “COOLAN TEMP/S” indication reaches to 70°C (158 °F).

9. Open engine hood.

10. Select “DTC & SRT CONFIRMATION” then “SRT WORK SUPPORT” mode with CONSULT-III.

11. Rev engine between 2,000 and 3,000 rpm and hold it for 3 consecutive minutes then release the acceler-

ator pedal completely.

12. Check the indication of “CATALYST”.

Which is displayed on CONSULT-III screen?

CMPLT >> GO TO 5.

INCMP >> GO TO 3.

PBIB2055E

DTC No. Trouble diagnosis name

(Trouble diagnosis content) DTC detecting condition Possible cause

P0420 TW CATALYST SYS-B1

[Catalyst system efficiency

below threshold (bank 1)]

Three way catalyst (manifold) does not

operate properly.

Three way catalyst (manifold) does not have enough oxygen storage capacity. Three way catalyst (manifold)

Exhaust tube

Intake air leakage

Fuel injector

Fuel injector leakage

Spark plug

Improper ignition timing

P0430

TW CATALYST SYS-B2

[Catalyst system efficiency

below threshold (bank 2)]

Revision: 2010 May2011 QX56

Page 2332 of 5598

![INFINITI QX56 2011 Factory User Guide

EC-308

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0420, P0430 THREE

WAY CATALYST FUNCTION

3.PERFORM DTC CONFIRMATION PROCEDURE-II

1. Wait 5 seconds at idle.

2. Rev engine between 2,000 and 3,000 rpm and mai INFINITI QX56 2011 Factory User Guide

EC-308

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0420, P0430 THREE

WAY CATALYST FUNCTION

3.PERFORM DTC CONFIRMATION PROCEDURE-II

1. Wait 5 seconds at idle.

2. Rev engine between 2,000 and 3,000 rpm and mai](/img/42/57033/w960_57033-2331.png)

EC-308

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0420, P0430 THREE

WAY CATALYST FUNCTION

3.PERFORM DTC CONFIRMATION PROCEDURE-II

1. Wait 5 seconds at idle.

2. Rev engine between 2,000 and 3,000 rpm and maintain it until “INCMP” of “CATALYST” changes to “CMPLT” (It will take approximately 5 minutes).

Does the indication change to

“CMPLT”?

YES >> GO TO 5.

NO >> GO TO 4.

4.PERFORM DTC CONFIRMATION PROCEDURE AGAIN

1. Stop engine and cool it down to less than 70 °C (158 °F).

2. Perform DTC CONFIRMATION PROCEDURE again.

>> GO TO 2.

5.PERFORM DTC CONFIRMATION PROCEDURE-III

Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Go to EC-309, "Diagnosis Procedure".

NO >> INSPECTION END

6.PERFORM COMPONENT FUNCTION CHECK

WITH GST

Perform component function check. Refer to EC-308, "

Component Function Check".

NOTE:

Use component function check to check the overall functi on of the three way catalyst (manifold). During this

check, a 1st trip DTC might not be confirmed.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-309, "

Diagnosis Procedure"

Component Function CheckINFOID:0000000006217852

1.PERFORM COMPONENT FUNCTION CHECK

WITH GST

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Open engine hood.

6. Check the voltage between ECM harness connector terminals under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-309, "

Diagnosis Procedure".

DTC ECM

Condition Voltage

Connector +–

Terminal Terminal

P0420 F110 96

[HO2S2

(bank 1)] 100Keeping engine speed at 2,500 rpm

constant under no load The voltage fluctuation cycle takes more

than 5 seconds.

1 cycle: 0.6 - 1.0

→ 0 - 0.3 → 0.6 - 1.0

P0430 87

[HO2S2

(bank 2)]

Revision: 2010 May2011 QX56

Page 2737 of 5598

![INFINITI QX56 2011 Factory User Guide

DIAGNOSIS SYSTEM (IPDM E/R)EXL-27

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000006368066

AUTO ACTIVE TEST

Descr INFINITI QX56 2011 Factory User Guide

DIAGNOSIS SYSTEM (IPDM E/R)EXL-27

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000006368066

AUTO ACTIVE TEST

Descr](/img/42/57033/w960_57033-2736.png)

DIAGNOSIS SYSTEM (IPDM E/R)EXL-27

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000006368066

AUTO ACTIVE TEST

Description

In auto active test, the IPDM E/R sends a drive signal to the following systems to check their operation.

Oil pressure warning lamp

Rear window defogger

Front wiper (LO, HI)

Parking lamp

License plate lamp

Tail lamp

Side marker lamp

Front fog lamp

Headlamp (LO, HI)

A/C compressor (magnet clutch)

Operation Procedure

CAUTION:

Never perform auto active test in the following conditions.

Engine is running.

CONSULT-III is connected.

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn the ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, pr ess the driver door switch 10 times. Then turn the

ignition switch OFF.

CAUTION:

Close passenger door.

4. Turn the ignition switch ON within 10 seconds. Af ter that the horn sounds once and the auto active test

starts.

CAUTION:

Engine starts when ignition switch is turned ON while brake pedal is depressed.

5. The oil pressure warning lamp starts blinking when the auto active test starts.

6. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test has to be cancelled halfw ay through test, turn the ignition switch OFF.

When auto active test is not activated, door swit ch may be the cause. Check door switch. Refer to DLK-117,

"ComponentFunctionCheck".

Inspection in Auto Active Test

When auto active test is actuated, the following operation sequence is repeated 3 times.

Operation

sequence Inspection location Operation

1 Oil pressure warning lamp Blinks continuously during operation of auto active test

2 Rear window defogger 10 seconds

3 Front wiper LO for 5 seconds → HI for 5 seconds

4 Parking lamp

License plate lamp

Tail lamp

Side marker lamp

Front fog lamp 10 seconds

Revision: 2010 May2011 QX56

Page 2740 of 5598

![INFINITI QX56 2011 Factory User Guide

EXL-30

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

Te s t i t e m

PUSH SW

[Off/On]Displays the status of the push-button ignition switch judged by IPDM E/R.

INTER/NP S INFINITI QX56 2011 Factory User Guide

EXL-30

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

Te s t i t e m

PUSH SW

[Off/On]Displays the status of the push-button ignition switch judged by IPDM E/R.

INTER/NP S](/img/42/57033/w960_57033-2739.png)

EXL-30

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

Te s t i t e m

PUSH SW

[Off/On]Displays the status of the push-button ignition switch judged by IPDM E/R.

INTER/NP SW

[Off/On] Displays the status of the shift position judged by IPDM E/R.

ST RLY CONT

[Off/On] Displays the status of the starter relay status signal received from BCM via CAN

communication.

IHBT RLY -REQ

[Off/On] Displays the status of the starter control relay signal received from BCM via CAN

communication.

ST/INHI RLY

[Off/ ST ON/INHI ON/UNKWN] Displays the status of the starter relay and starter control relay judged by IPDM

E/R.

DETENT SW

[Off/On] Displays the status of the A/T shift selector (detention switch) judged by IPDM E/

R.

S/L RLY -REQ

[Off/On] Displays the status of the steering lock relay signal received from BCM via CAN

communication.

S/L STATE

[LOCK/UNLK/UNKWN] Displays the status of the steering lock judged by IPDM E/R.

OIL P SW

[Open/Close] Displays the status of the oil pressure switch judged by IPDM E/R.

HOOD SW

[Off/On] Displays the status of the hood switch judged by IPDM E/R.

HL WASHER REQ

[Off/On] Displays the status of the headlamp washer request signal received from BCM via

CAN communication.

THFT HRN REQ

[Off/On] Displays the status of the theft warning horn request signal received from BCM

via CAN communication.

HORN CHIRP

[Off/On] Displays the status of the horn reminder signal received from BCM via CAN com-

munication.

Monitor Item

[Unit] MAIN SIG-

NALS Description

Test item Operation Description

CORNERING LAMP LH

NOTE:

This item is indicated, but cannot be tested.

RH

HORN On Operates horn relay for 20 ms.

REAR DEFOGGER Off OFF

On Operates the rear window defogger relay.

FRONT WIPER Off OFF

Lo Operates the front wiper relay.

Hi Operates the front wiper relay and front wiper high relay.

MOTOR FAN* 1OFF

2 Transmits 50% pulse duty signal (PWM signal) to the cooling fan control module.

3 Transmits 75% pulse duty signal (PWM signal) to the cooling fan control module.

4

Transmits 100% pulse duty signal (PWM signal) to the cooling fan control mod-

ule.

HEAD LAMP WASHER On Operates the headlamp washer relay for 1 second.

Revision: 2010 May2011 QX56

Page 2868 of 5598

FRONT BUMPEREXT-13

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

Removal and InstallationINFOID:0000000006367598

REMOVAL

CAUTION:

Bumper fascia is made of resin. Never apply strong force to it, and be careful to prevent contact with

oil.

1. Fully open hood assembly.

2. Remove front grille. Refer to EXT-19, "

Removal and Installation".

3. Remove bumper molding. 1. Remove front fender drip cover. Refer to DLK-223, "

FRONT FENDER DRIP COVER : Removal and

Installation".

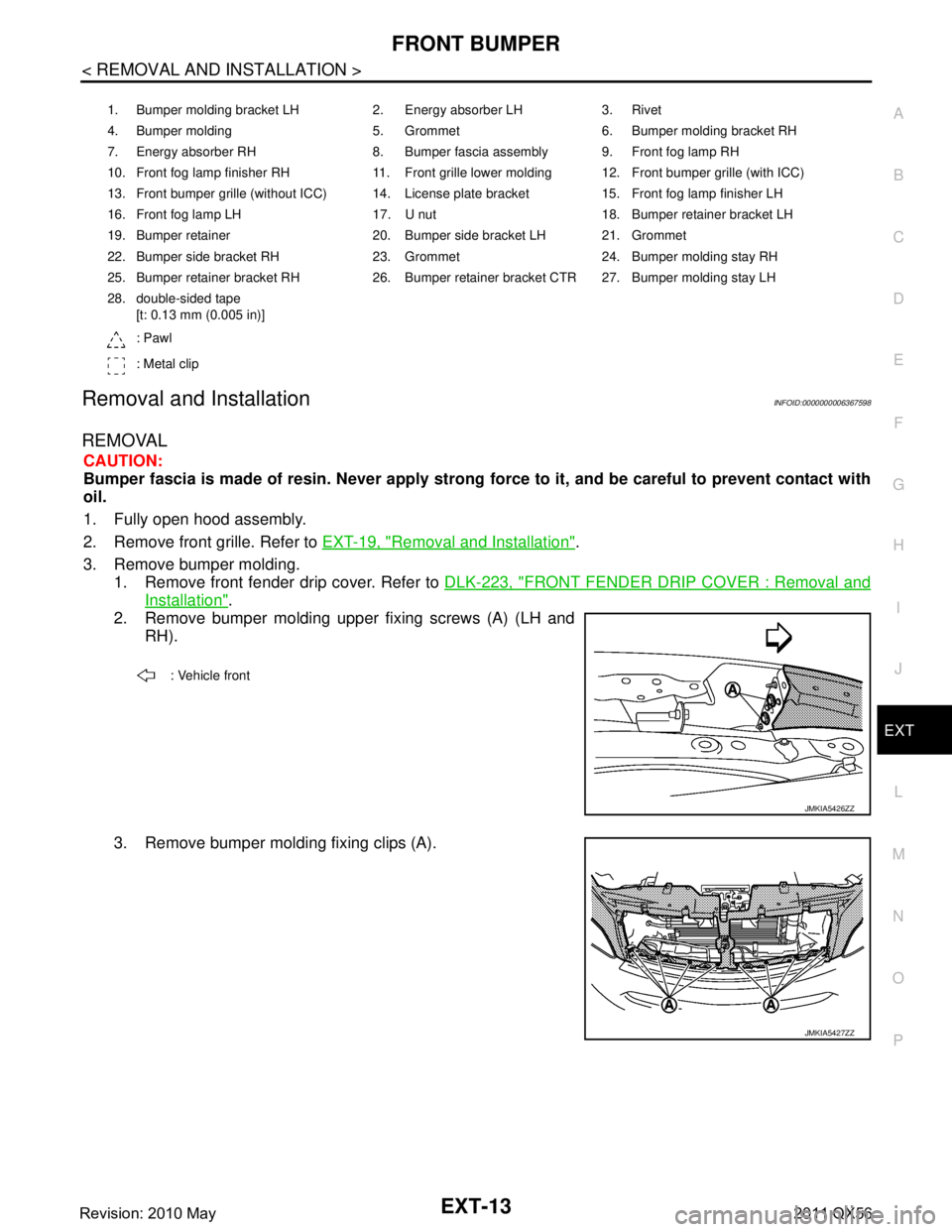

2. Remove bumper molding upper fixing screws (A) (LH and

RH).

3. Remove bumper molding fixing clips (A).

1. Bumper molding bracket LH 2. Energy absorber LH 3. Rivet

4. Bumper molding 5. Grommet 6. Bumper molding bracket RH

7. Energy absorber RH 8. Bumper fascia assembly 9. Front fog lamp RH

10. Front fog lamp finisher RH 11. Front grille lower molding 12. Front bumper grille (with ICC)

13. Front bumper grille (without ICC) 14. License plate bracket 15. Front fog lamp finisher LH

16. Front fog lamp LH 17. U nut 18. Bumper retainer bracket LH

19. Bumper retainer 20. Bumper side bracket LH 21. Grommet

22. Bumper side bracket RH 23. Grommet 24. Bumper molding stay RH

25. Bumper retainer bracket RH 26. Bumper retainer bracket CTR 27. Bumper molding stay LH

28. double-sided tape [t: 0.13 mm (0.005 in)]

: Pawl

: Metal clip

: Vehicle front

JMKIA5426ZZ

JMKIA5427ZZ

Revision: 2010 May2011 QX56

Page 2874 of 5598

FRONT GRILLEEXT-19

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

FRONT GRILLE

Exploded ViewINFOID:0000000006367601

Removal and InstallationINFOID:0000000006367602

REMOVAL

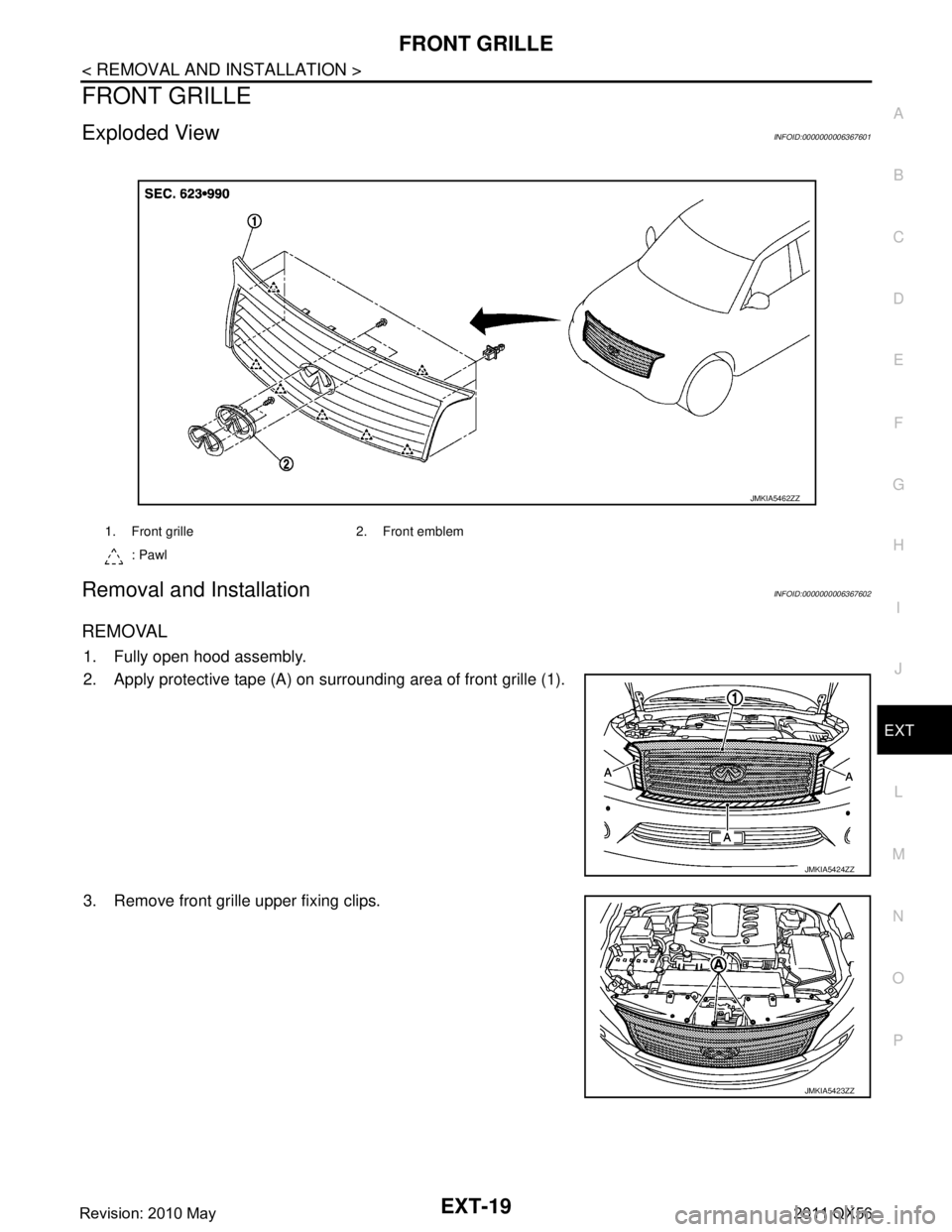

1. Fully open hood assembly.

2. Apply protective tape (A) on surrounding area of front grille (1).

3. Remove front grille upper fixing clips.

1. Front grille 2. Front emblem : Pawl

JMKIA5462ZZ

JMKIA5424ZZ

JMKIA5423ZZ

Revision: 2010 May2011 QX56

Page 2876 of 5598

COWL TOPEXT-21

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

COWL TOP

Exploded ViewINFOID:0000000006367603

Removal and InstallationINFOID:0000000006367604

REMOVAL

1. Fully open hood assembly.

2. Remove front wiper arm (LH and RH). Refer to WW-66, "

Removal and Installation".

3. Remove front fender cover (LH and RH).

4. Disconnect front wa sher tube connector.

5. Remove cowl top cover fixing clips.

6. Pull forward to release cowl top cover (1) from windshield glass. CAUTION:

When performing the procedur e after removing cowl top

cover, cover the lower end of windshield glass with ure-

thane etc.

7. Remove the following parts after removing cowl top cover. Cowl top seal

Washer nozzle (LH and RH)

Washer tube

1. Front fender cover RH 2. EPT seal [t: 15.0 mm (0.591 in)] 3. Cowl top cover seal

4. Cowl top cover 5. Front fender cover LH 6. Double-sided tape

[t: 1.2 mm (0.047 in)]

7. EPT seal [t: 3.0 mm (0.118 in)]

: Clip

: Pawl

: Vehicle front

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA5222ZZ

JMKIA1984ZZ

Revision: 2010 May2011 QX56

Page 2975 of 5598

HOW TO READ WIRING DIAGRAMSGI-11

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

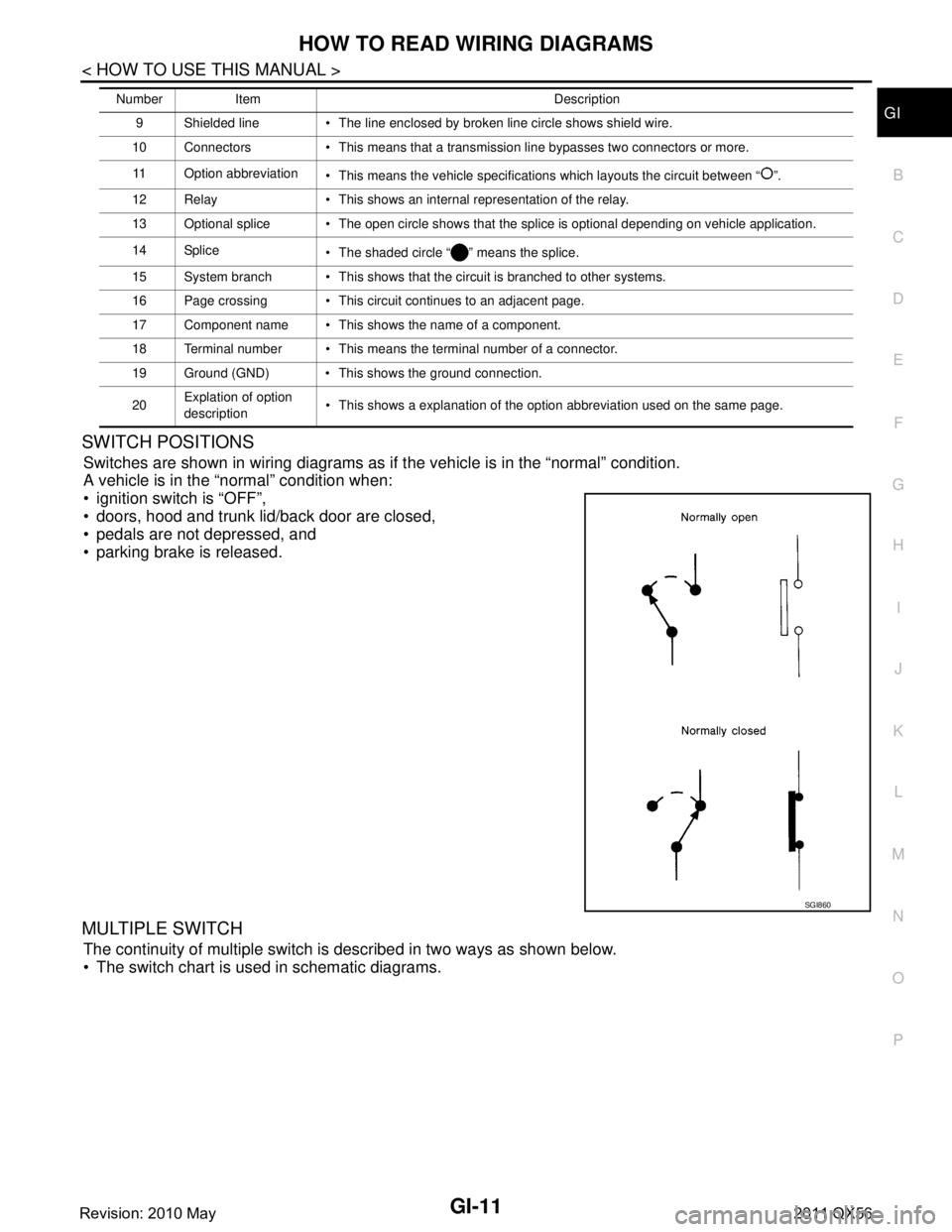

SWITCH POSITIONS

Switches are shown in wiring diagrams as if the vehicle is in the “normal” condition.

A vehicle is in the “normal” condition when:

ignition switch is “OFF”,

doors, hood and trunk lid/back door are closed,

pedals are not depressed, and

parking brake is released.

MULTIPLE SWITCH

The continuity of multiple switch is described in two ways as shown below.

The switch chart is used in schematic diagrams.

9 Shielded line The line enclosed by broken line circle shows shield wire.

10 Connectors This means that a transmission line bypasses two connectors or more.

11 Option abbreviation This means the vehicle specifications which layouts the circuit between “ ”.

12 Relay This shows an internal representation of the relay.

13 Optional splice The open circle shows that the splice is optional depending on vehicle application.

14 Splice The shaded circle “ ” means the splice.

15 System branch This shows that the circuit is branched to other systems.

16 Page crossing This circuit continues to an adjacent page.

17 Component name This shows the name of a component.

18 Terminal number This means the terminal number of a connector.

19 Ground (GND) This shows the ground connection.

20 Explation of option

description This shows a explanation of the option abbreviation used on the same page.

Number Item Description

SGI860

Revision: 2010 May2011 QX56

Page 3081 of 5598

PERFORMANCE TESTHA-25

< BASIC INSPECTION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

PERFORMANCE TEST

InspectionINFOID:0000000006276158

INSPECTION PROCEDURE

1. Connect recovery/recycling/recharging equipment (for HFC-134a) or manifold gauge.

2. Start the engine, and set to the following condition.

Test condition

3. Maintain test condition until A/C system becomes stable. (Approximately 10 minutes)

4. Check that test results of “recirculating-to-disc harge air temperature” and “ambient air temperature-to-

operating pressure” are within the specified value.

5. When test results are within the specified value, inspection is complete. If any of test result is out of the specified value, perform diagnosis by gauge pressure. Refer to HA-27,

"Symptom Table".

RECIRCULATING-TO-DISCHARGE AIR TEMPERATURE TABLE

FRONT

REAR

Surrounding condition Indoors or in the shade (in a well-ventilated place)

Vehicle conditionDoor Closed

Door glass Full open

Hood Open

Engine speed Idle speed

A/C condition (front/rear) Temperature control switch or dial Full cold

A/C switch ON

Air outlet VENT (ventilation)

Intake door position Recirculation

Fan speed Maximum speed set

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature from center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 – 60 20 (68) 6.8 - 8.8 (44 - 48)

25 (77) 10.4 -

12.9 (51 - 55)

30 (86) 13.9 - 16.9 (57 - 63)

35 (95) 17.3 - 20.8 (63 - 70)

60 – 70 20 (68) 8.8 - 10.8 (48 - 52)

25 (77) 12.9 -

15.4 (55 - 60)

30 (86) 16.9 - 19.9 (63 - 68)

35 (95) 20.8 - 24.3 (70 - 76)

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature from rear ventilator grille A RH*

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 – 60 20 (68) 11.4 -

13.4 (53 - 56)

25 (77) 15.8 - 18.3 (60 - 65)

30 (86) 20.9 - 23.9 (70 - 75)

35 (95) 25.9 - 29.4 (79 - 85)

Revision: 2010 May2011 QX56

Page 3674 of 5598

MA-4

< PERIODIC MAINTENANCE >

GENERAL MAINTENANCE

PERIODIC MAINTENANCE

GENERAL MAINTENANCE

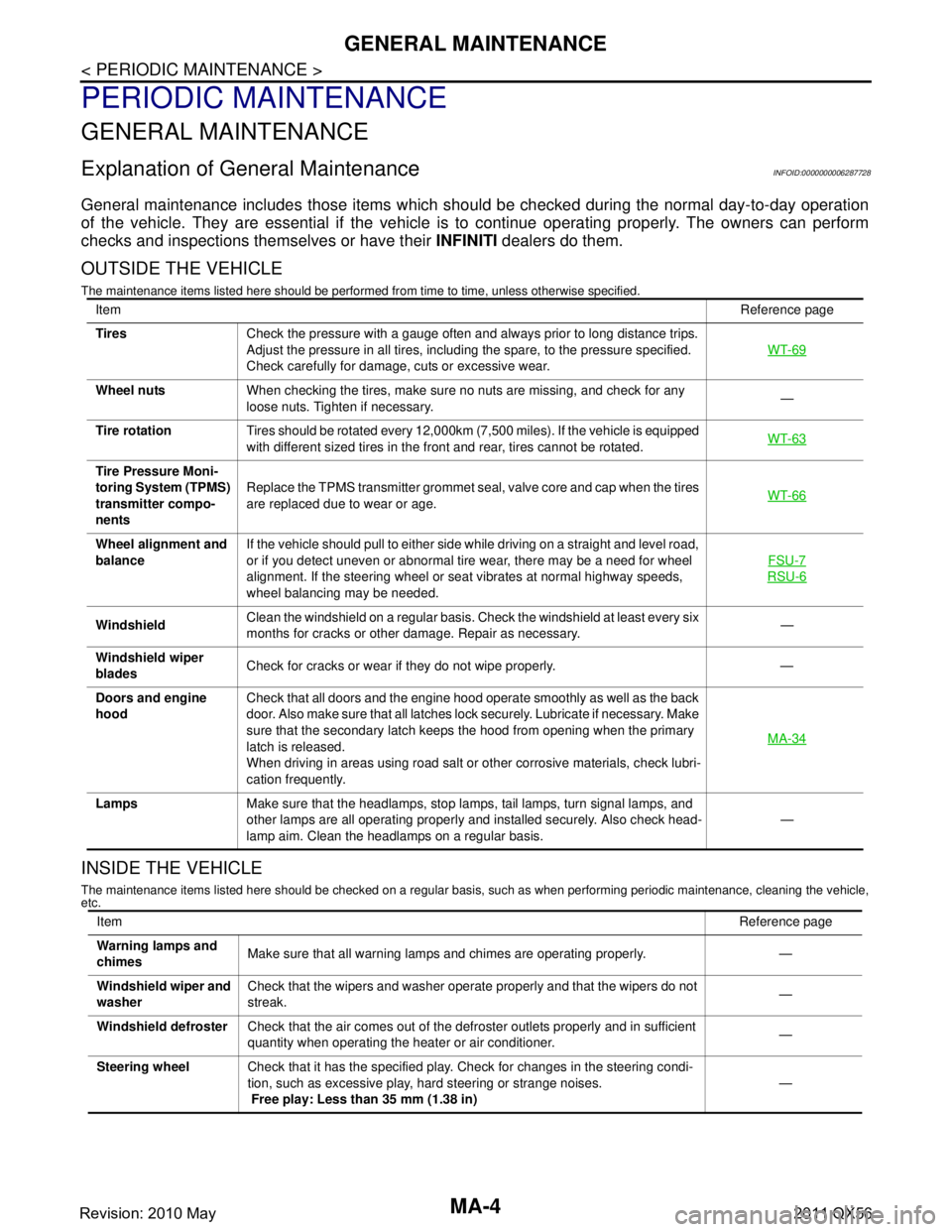

Explanation of General MaintenanceINFOID:0000000006287728

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed fr om time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive wear. WT-69

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary. —

Tire rotation Tires should be rotated every 12,000km (7,500 miles). If the vehicle is equipped

with different sized tires in the front and rear, tires cannot be rotated. WT-63

Tire Pressure Moni-

toring System (TPMS)

transmitter compo-

nentsReplace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

WT-66

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. FSU-7

RSU-6

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. —

Windshield wiper

blades Check for cracks or wear if they do not wipe properly. —

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

door. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently. MA-34

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head-

lamp aim. Clean the headlamps on a regular basis. —

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly. —

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner. —

Steering wheel Check that it has the specified play. Check for changes in the steering condi-

tion, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) —

Revision: 2010 May2011 QX56