center console INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3374 of 5598

FLOOR TRIMINT-25

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

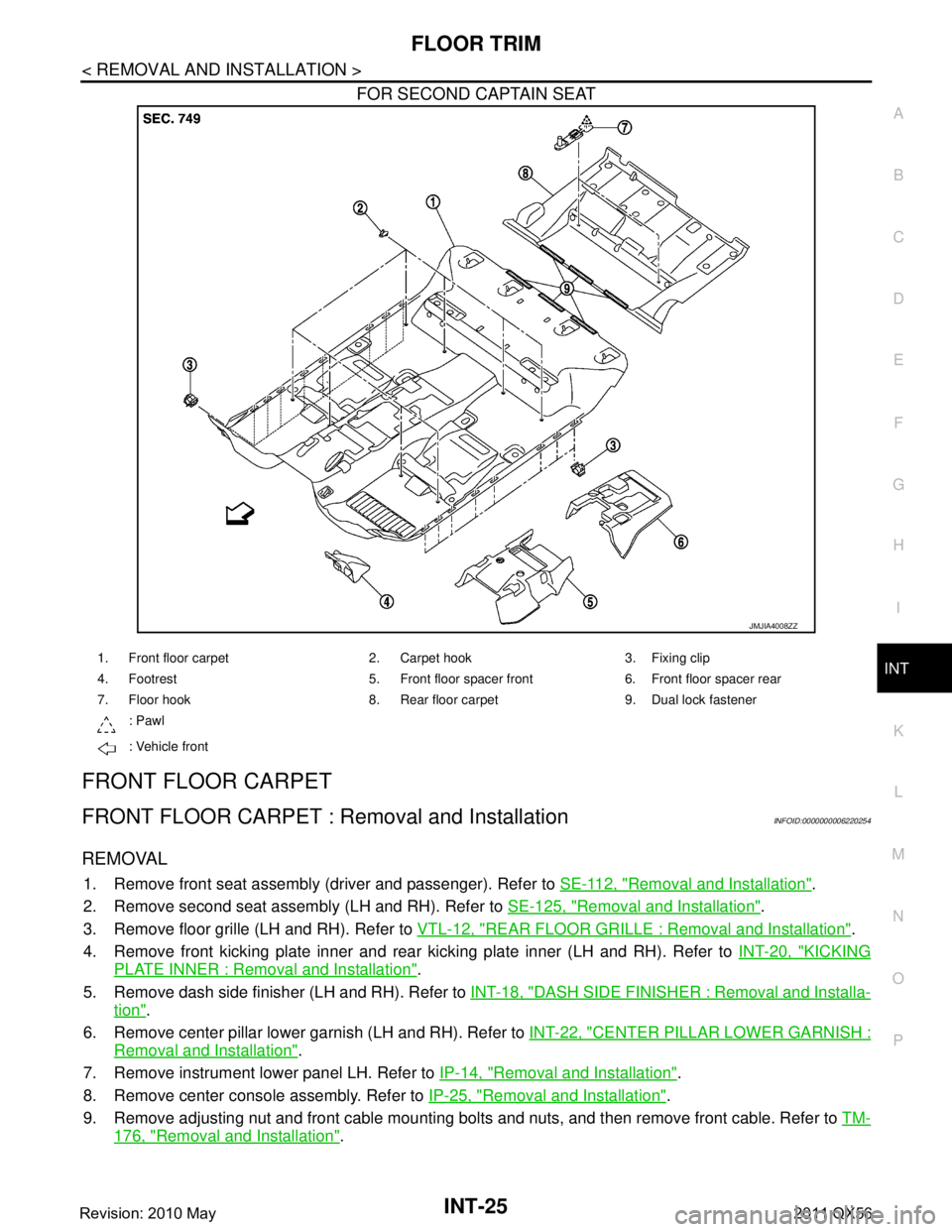

FOR SECOND CAPTAIN SEAT

FRONT FLOOR CARPET

FRONT FLOOR CARPET : Re moval and InstallationINFOID:0000000006220254

REMOVAL

1. Remove front seat assembly (driver and passenger). Refer to SE-112, "Removal and Installation".

2. Remove second seat assembly (LH and RH). Refer to SE-125, "

Removal and Installation".

3. Remove floor grille (LH and RH). Refer to VTL-12, "

REAR FLOOR GRILLE : Removal and Installation".

4. Remove front kicking plate inner and rear kicking plate inner (LH and RH). Refer to INT-20, "

KICKING

PLATE INNER : Removal and Installation".

5. Remove dash side finisher (LH and RH). Refer to INT-18, "

DASH SIDE FINISHER : Removal and Installa-

tion".

6. Remove center pillar lower garnish (LH and RH). Refer to INT-22, "

CENTER PILLAR LOWER GARNISH :

Removal and Installation".

7. Remove instrument lower panel LH. Refer to IP-14, "

Removal and Installation".

8. Remove center console assembly. Refer to IP-25, "

Removal and Installation".

9. Remove adjusting nut and front cable mounting bolts and nuts, and then remove front cable. Refer to TM-

176, "Removal and Installation".

JMJIA4008ZZ

1. Front floor carpet 2. Carpet hook 3. Fixing clip

4. Footrest 5. Front floor spacer front 6. Front floor spacer rear

7. Floor hook 8. Rear floor carpet 9. Dual lock fastener

: Pawl

: Vehicle front

Revision: 2010 May2011 QX56

Page 3375 of 5598

INT-26

< REMOVAL AND INSTALLATION >

FLOOR TRIM

10. Remove the following parts after removing the center console assembly. Remove ground bolt (G).

Disconnect floor harness connectors (A) and (E).

Disconnect yaw rate/side/decel G sensor harness connector (C). Refer to BRC-138, "

Exploded View".

Disconnect diagnosis sensor unit harness connector (D). Refer to SR-26, "

Exploded View".

Remove floor harness clamps (B) and (F).

11. Remove A/T shift selector assembly mounting bolts. Refer to TM-176, "

Removal and Installation".

12. Remove floor duct 1 (LH and RH). Refer to VTL-11, "

FLOOR DUCT 1 : Removal and Installation".

13. Disconnect drain hose (1) and remove instrument stay mounting nuts (A), and then remove instrument stay (2) (LH and RH).

14. Disengage front floor carpet from front floor carpet fixing clips (A).

JMJIA4226ZZ

JMJIA4225ZZ

JMJIA1560ZZ

Revision: 2010 May2011 QX56

Page 3391 of 5598

IP-1

BODY INTERIOR

C

DE

F

G H

I

K L

M

SECTION IP

A

B

IP

N

O P

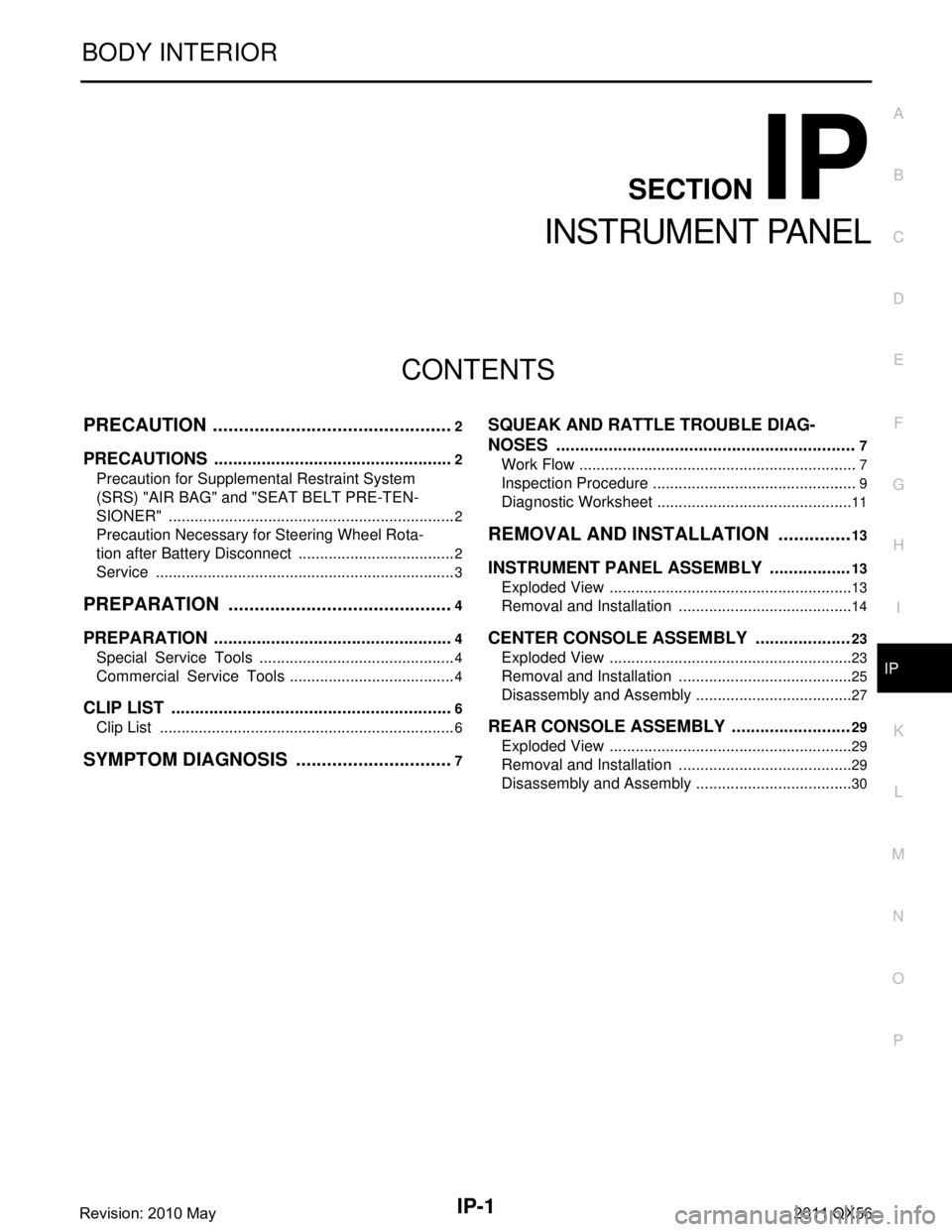

CONTENTS

INSTRUMENT PANEL

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

2

Service ......................................................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tools ........................................ ......4

Commercial Service Tools .......................................4

CLIP LIST ............................................................6

Clip List ............................................................... ......6

SYMPTOM DIAGNOSIS ...............................7

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ...............................................................

7

Work Flow ............................................................ .....7

Inspection Procedure ................................................9

Diagnostic Worksheet ..............................................11

REMOVAL AND INSTALLATION ...............13

INSTRUMENT PANEL ASSEMBLY .................13

Exploded View ..................................................... ....13

Removal and Installation .........................................14

CENTER CONSOLE ASSEMBLY ....................23

Exploded View .........................................................23

Removal and Installation .........................................25

Disassembly and Assembly .....................................27

REAR CONSOLE ASSEMBLY .........................29

Exploded View .........................................................29

Removal and Installation .........................................29

Disassembly and Assembly .....................................30

Revision: 2010 May2011 QX56

Page 3399 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESIP-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.591 ×0.984 in) pad

68239-13E00: 5 mm (0.197 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that is visible or does not fit. Only lasts a few months.

SILICONE SPRAY

Used when grease cannot be applied.

DUCT TAPE

Used to eliminate movement.

CONFIRM THE REPAIR

After repair is complete, test drive the vehicle to confi rm that the cause of noise is repaired by test driving the

vehicle. Operate the vehicle under the same conditions as when the noise originally occurred. Refer to the

notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000006425524

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by

applying felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate

wiring harness.

CAUTION:

Never use silicone spray to isolate a squeak or ra ttle. If the area is saturated with silicone, the

recheck of repair becomes impossible.

CENTER CONSOLE

Components to check include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Check the following items:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon connection to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping, moving the components, or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. The areas can usually be insula ted with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition check for the following items:

Revision: 2010 May2011 QX56

Page 3404 of 5598

IP-14

< REMOVAL AND INSTALLATION >

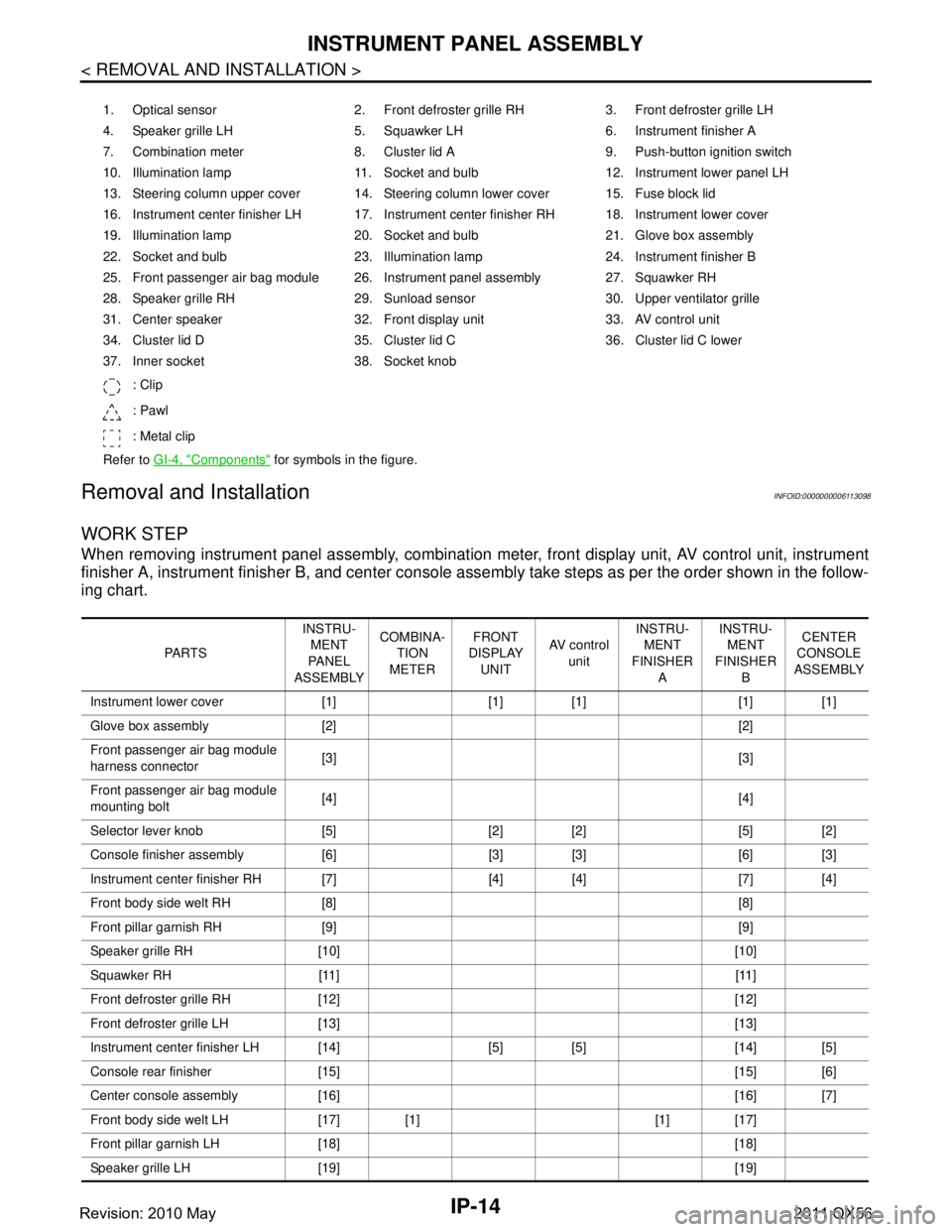

INSTRUMENT PANEL ASSEMBLY

Removal and Installation

INFOID:0000000006113098

WORK STEP

When removing instrument panel assembly, combination meter, front display unit, AV control unit, instrument

finisher A, instrument fini sher B, and center console assembly take st eps as per the order shown in the follow-

ing chart.

1. Optical sensor 2. Front defroster grille RH 3. Front defroster grille LH

4. Speaker grille LH 5. Squawker LH 6. Instrument finisher A

7. Combination meter 8. Cluster lid A 9. Push-button ignition switch

10. Illumination lamp 11. Socket and bulb 12. Instrument lower panel LH

13. Steering column upper cover 14. Steering column lower cover 15. Fuse block lid

16. Instrument center finisher LH 17. Instrument center finisher RH 18. Instrument lower cover

19. Illumination lamp 20. Socket and bulb 21. Glove box assembly

22. Socket and bulb 23. Illumination lamp 24. Instrument finisher B

25. Front passenger air bag module 26. Instrument panel assembly 27. Squawker RH

28. Speaker grille RH 29. Sunload sensor 30. Upper ventilator grille

31. Center speaker 32. Front display unit 33. AV control unit

34. Cluster lid D 35. Cluster lid C 36. Cluster lid C lower

37. Inner socket 38. Socket knob

: Clip

: Pawl

: Metal clip

Refer to GI-4, "

Components" for symbols in the figure.

PA R T S INSTRU-

MENT

PA N E L

ASSEMBLY COMBINA-

TION

METER FRONT

DISPLAY

UNIT AV c o n t r o l

unit INSTRU-

MENT

FINISHER A INSTRU-

MENT

FINISHER B CENTER

CONSOLE

ASSEMBLY

Instrument lower cover [1] [1] [1] [1] [1]

Glove box assembly [2] [2]

Front passenger air bag module

harness connector [3] [3]

Front passenger air bag module

mounting bolt [4] [4]

Selector lever knob [5] [2] [2] [5] [2]

Console finisher assembly [6] [3] [3] [6] [3]

Instrument center finisher RH [7] [4] [4] [7] [4]

Front body side welt RH [8] [8]

Front pillar garnish RH [9] [9]

Speaker grille RH [10] [10]

Squawker RH [11] [11]

Front defroster grille RH [12] [12]

Front defroster grille LH [13] [13]

Instrument center finisher LH [14] [5] [5] [14] [5]

Console rear finisher [15] [15] [6]

Center console assembly [16] [16] [7]

Front body side welt LH [17] [1] [1] [17]

Front pillar garnish LH [18] [18]

Speaker grille LH [19] [19]

Revision: 2010 May2011 QX56

Page 3405 of 5598

![INFINITI QX56 2011 Factory Owners Manual

INSTRUMENT PANEL ASSEMBLYIP-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

[ ]:Number indicates step in removal procedures.

WARNING:

Before servicing, turn igni tion switch OFF, disc INFINITI QX56 2011 Factory Owners Manual

INSTRUMENT PANEL ASSEMBLYIP-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

[ ]:Number indicates step in removal procedures.

WARNING:

Before servicing, turn igni tion switch OFF, disc](/img/42/57033/w960_57033-3404.png)

INSTRUMENT PANEL ASSEMBLYIP-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

[ ]:Number indicates step in removal procedures.

WARNING:

Before servicing, turn igni tion switch OFF, disconnect battery ne gative terminal, and wait 3 minutes or

more.

CAUTION:

When removing, always use a remover tool that is made of plastic.

REMOVAL

1. Remove instrument lower cover.

1. Pull disengaged pawls downward.

2. Pull back instrument lower cover.

3. Disconnect harness connectors.

Squawker LH [20] [20]

Instrument lower panel LH [21] [2] [2] [21]

Disconnect meter control switch

harness connector [22] [3] [3] [22]

Driver air bag module [23] [23]

Steering wheel [24] [24]

Steering column cover [25] [25]

Combination switch [26] [26]

Spiral cable [27] [27]

Cluster lid A [28] [4] [4] [28]

Combination meter [29] [5] [29]

Instrument finisher A [5]

Upper ventilator grille [30] [30]

Center speaker [31] [31]

Cluster lid C [32] [6] [6] [32]

Cluster lid C lower [33] [7] [33]

AV control unit [34] [8] [34]

Cluster lid D [35] [7] [35]

Front display unit [36] [8] [36]

instrument panel assembly

mounting screws and bolts [37] [37]

Squawker LH harness clip [38] [38]

Instrument panel assembly [39] [39]

Instrument finisher B [40]

PA R T S

INSTRU-

MENT

PA N E L

ASSEMBLY COMBINA-

TION

METER FRONT

DISPLAY UNIT AV c o n t r o l

unit INSTRU-

MENT

FINISHER A INSTRU-

MENT

FINISHER B CENTER

CONSOLE

ASSEMBLY

: Pawl

JMJIA3828ZZ

Revision: 2010 May2011 QX56

Page 3406 of 5598

IP-16

< REMOVAL AND INSTALLATION >

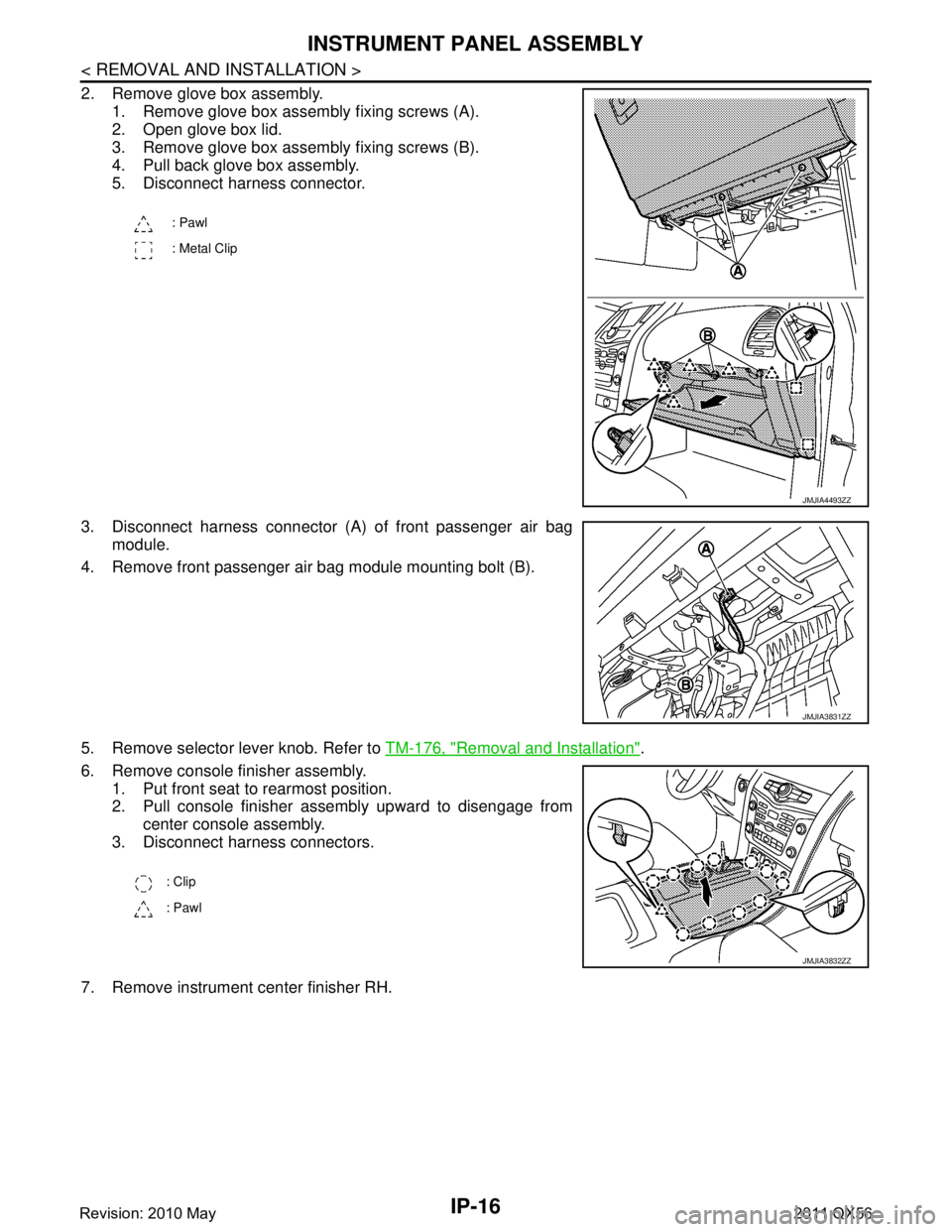

INSTRUMENT PANEL ASSEMBLY

2. Remove glove box assembly.1. Remove glove box assembly fixing screws (A).

2. Open glove box lid.

3. Remove glove box assembly fixing screws (B).

4. Pull back glove box assembly.

5. Disconnect harness connector.

3. Disconnect harness connector (A) of front passenger air bag module.

4. Remove front passenger air bag module mounting bolt (B).

5. Remove selector lever knob. Refer to TM-176, "

Removal and Installation".

6. Remove console finisher assembly. 1. Put front seat to rearmost position.

2. Pull console finisher assembly upward to disengage from

center console assembly.

3. Disconnect harness connectors.

7. Remove instrument center finisher RH.

: Pawl

: Metal Clip

JMJIA4493ZZ

JMJIA3831ZZ

: Clip

: Pawl

JMJIA3832ZZ

Revision: 2010 May2011 QX56

Page 3408 of 5598

IP-18

< REMOVAL AND INSTALLATION >

INSTRUMENT PANEL ASSEMBLY

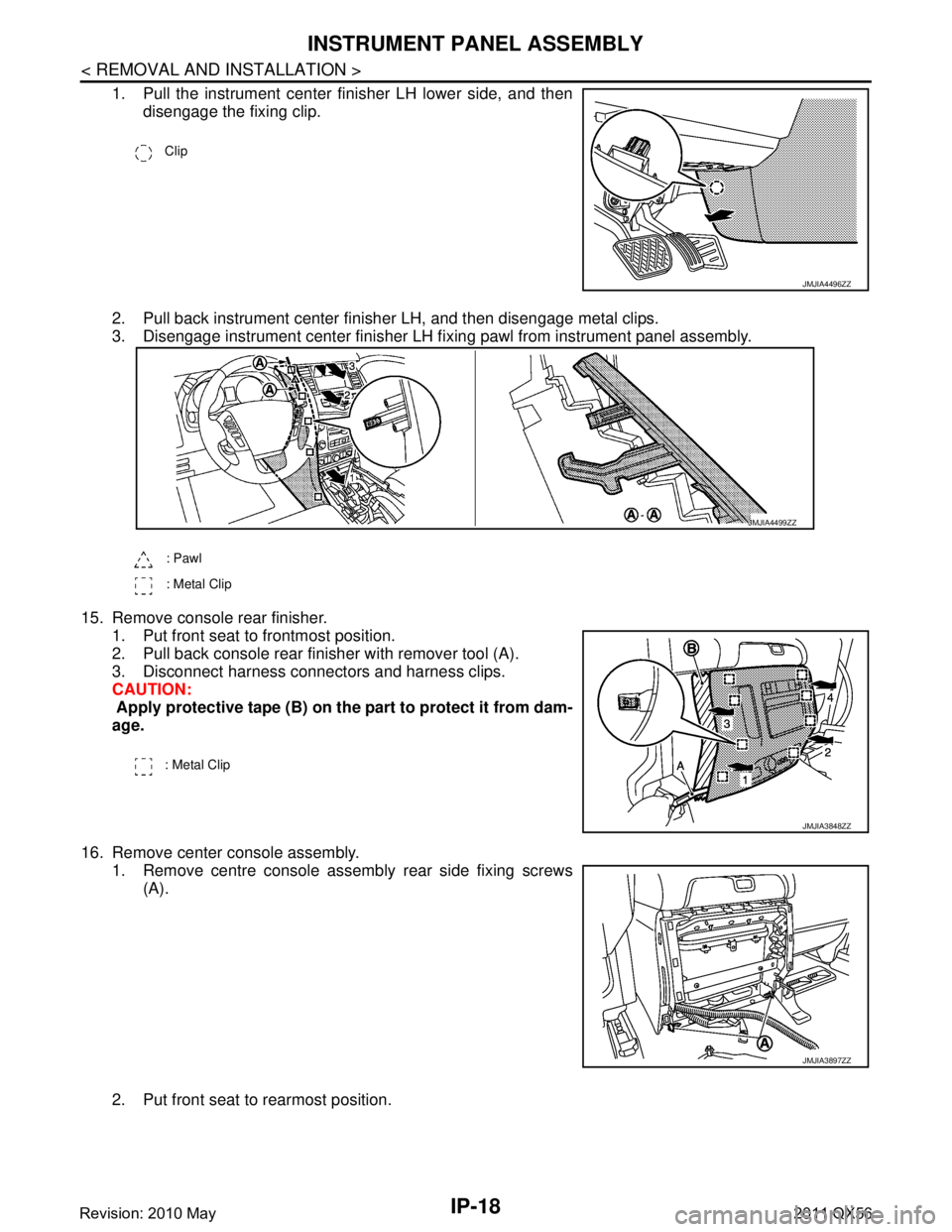

1. Pull the instrument center finisher LH lower side, and thendisengage the fixing clip.

2. Pull back instrument center finisher LH, and then disengage metal clips.

3. Disengage instrument center finisher LH fi xing pawl from instrument panel assembly.

15. Remove console rear finisher. 1. Put front seat to frontmost position.

2. Pull back console rear finisher with remover tool (A).

3. Disconnect harness connectors and harness clips.

CAUTION:

Apply protective tape (B) on the part to protect it from dam-

age.

16. Remove center console assembly. 1. Remove centre console assembly rear side fixing screws(A).

2. Put front seat to rearmost position.

Clip

JMJIA4496ZZ

: Pawl

: Metal Clip

JMJIA4499ZZ

: Metal Clip

JMJIA3848ZZ

JMJIA3897ZZ

Revision: 2010 May2011 QX56

Page 3409 of 5598

INSTRUMENT PANEL ASSEMBLYIP-19

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

3. Remove center console assembly front fixing screws (B).

4. Lift up center console assembly back side, and then remove center console assembly.

17. Remove front body side welt LH. Refer to INT-20, "

BODY SIDE WELT : Removal and Installation".

18. Remove front pillar garnish LH. Refer to INT-19, "

FRONT PILLAR GARNISH : Removal and Installation".

19. Remove speaker grille LH. 1. Disengage speaker grille LH fixing pawls with remover tool (A).

2. Pull up speaker grille LH.

CAUTION:

Apply protective tape (B) on the part to protect it from dam-

age.

20. Remove squawker LH. Refer to AV-218, "

Removal and Installation".

21. Remove instrument lower panel LH. 1. Remove food opener lever fixing bolts. Refer to DLK-238, "

Removal and Installation"

2. Pull back instrument lower panel LH, and then disengage

the clips and pawl.

3. Disconnect harness connectors and aspirator duct.

22. Disconnect meter control s witch harness connector (A).

23. Remove driver air bag module. Refer to SR-11, "

Removal and Installation".

24. Remove steering wheel. Refer to ST-33, "

Removal and Installation".

JMJIA3898ZZ

: Pawl

JMJIA3839ZZ

: Clip

: Pawl

JMJIA3840ZZ

JMJIA3841ZZ

Revision: 2010 May2011 QX56

Page 3411 of 5598

INSTRUMENT PANEL ASSEMBLYIP-21

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

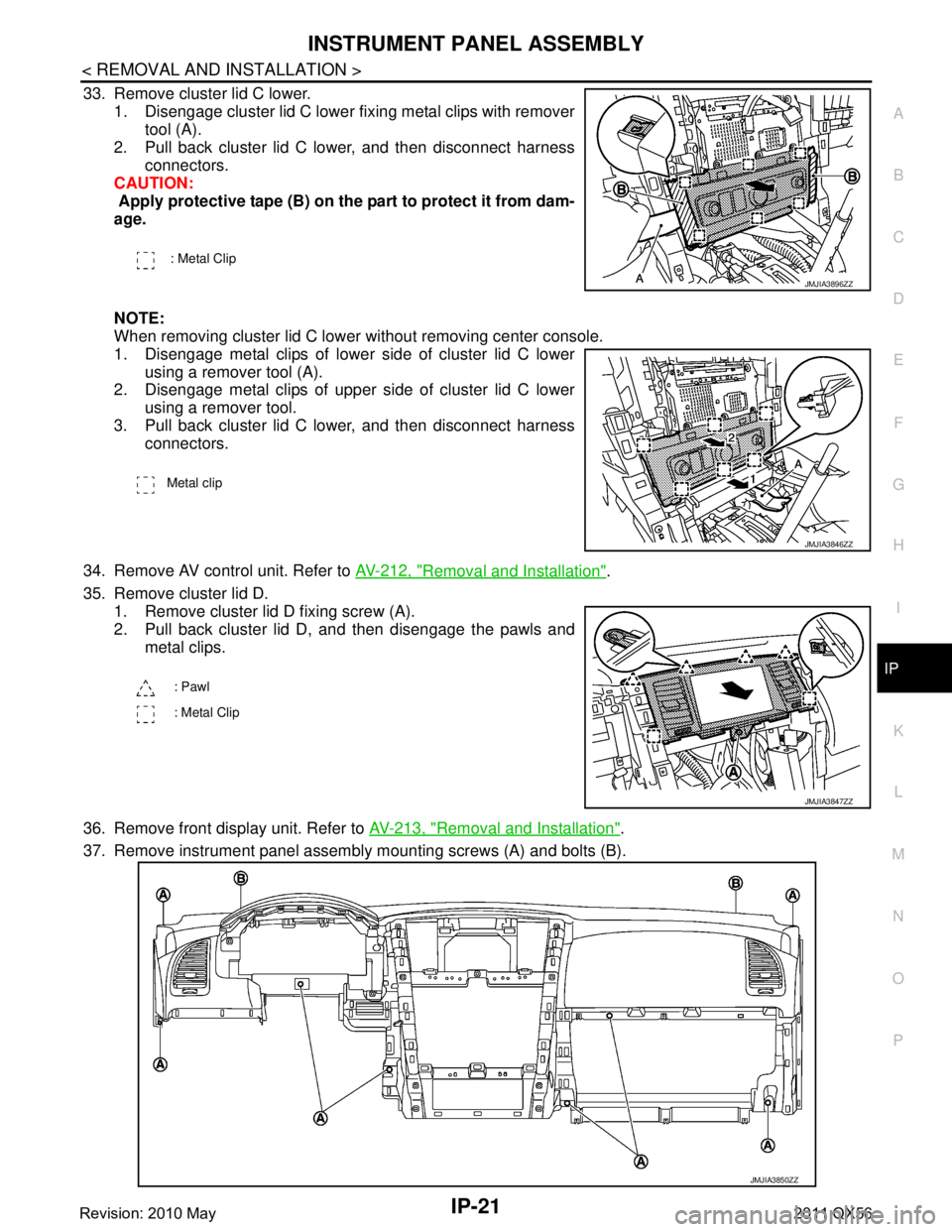

33. Remove cluster lid C lower. 1. Disengage cluster lid C lower fixing metal clips with remover tool (A).

2. Pull back cluster lid C lower, and then disconnect harness

connectors.

CAUTION:

Apply protective tape (B) on the part to protect it from dam-

age.

NOTE:

When removing cluster lid C lower without removing center console.

1. Disengage metal clips of lower side of cluster lid C lower

using a remover tool (A).

2. Disengage metal clips of upper side of cluster lid C lower

using a remover tool.

3. Pull back cluster lid C lower, and then disconnect harness connectors.

34. Remove AV control unit. Refer to AV-212, "

Removal and Installation".

35. Remove cluster lid D. 1. Remove cluster lid D fixing screw (A).

2. Pull back cluster lid D, and then disengage the pawls and metal clips.

36. Remove front display unit. Refer to AV-213, "

Removal and Installation".

37. Remove instrument panel assembly mounting screws (A) and bolts (B).

: Metal Clip

JMJIA3896ZZ

Metal clip

JMJIA3846ZZ

: Pawl

: Metal Clip

JMJIA3847ZZ

JMJIA3850ZZ

Revision: 2010 May2011 QX56