length INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4212 of 5598

RAX-16

< REMOVAL AND INSTALLATION >

REAR DRIVE SHAFT

2. Install boot and boot bands to shaft.CAUTION:

Wrap serration on shaft with tape (A) to protect the bootfrom damage.

Never reuse boot and boot band.

3. Remove the tape wrapped around the serration on shaft.

4. Install ball cage/steel ball/inner race assembly (1), align it with the matching marks on shaft (2) put during the removal.

5. Secure ball cage/steel ball/inner race assembly onto shaft with snap ring (3).

CAUTION:

Never reuse snap ring.

6. Apply the appropriate amount of grease onto housing and slid- ing surface.

7. Install stopper ring to housing. CAUTION:

Never reuse stopper ring.

8. After installed, pull shaft to check engagement between housing and stopper ring.

9. Install boot securely into grooves (indicated by “*” marks) shown in the figure.

CAUTION:

If grease adheres to the boot mounting surfaces (indicated

by “*” marks) on shaft or housing, boot may be removed.

Remove all grease from the surfaces.

10. To prevent deformation of the boot, adjust the boot installation

length (L) to the value shown below by inserting the suitable tool

into the inside of boot from the large diameter side of boot and

discharging inside air.

CAUTION:

If the boot installation length is outsid e the standard, it may cause breakage of boot.

Be careful not to touch the inside of the boot with the tip of tool.

11. Install boot bands securely as shown in the figure. CAUTION:

Never reuse boot band.

12. Secure housing and shaft, and then check that they are in the correct position when rotating boot. Install them with boot band

when the mounting positi ons become incorrect.

CAUTION:

Never reuse boot band.

InspectionINFOID:0000000006225472

INSPECTION AFTER REMOVAL

JPDIF0009ZZ

Grease amount : Refer to RAX-18, "Drive Shaft".

L: Refer to RAX-18, "

Drive Shaft".

JPDIG0004ZZ

JPDIG0137ZZ

PDIA1188J

Revision: 2010 May2011 QX56

Page 4214 of 5598

RAX-18

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel Hub and Bearing AssemblyINFOID:0000000006225473

Drive ShaftINFOID:0000000006225474

Item Standard

Axial end play 0.05 mm (0.002 in) or less

ItemStandard

Wheel side Final drive side

Grease quantity 145 – 165 g (5.11 – 5.82 oz) 175 – 195 g (6.17 – 6.88 oz)

Boots installed length 134.5 mm (5.30 in) 147.9 mm (5.82 in)

Revision: 2010 May2011 QX56

Page 4279 of 5598

SB-4

< REMOVAL AND INSTALLATION >

FRONT SEAT BELT

REMOVAL AND INSTALLATION

FRONT SEAT BELT

SEAT BELT RETRACTOR

SEAT BELT RETRACTOR : InspectionINFOID:0000000006217615

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies including retractors and attached hardware after any collision.

NISSAN/INFINITI recommends that all seat belt assemblies in use during a collision be replaced

unless the collision was minor and th e belts show no damage and continue to operate properly. Fail-

ure to do so could result in seri ous personal injury in an accident. Seat belt assemblies not in use dur-

ing a collision should also be re placed if either damage or improper operation was noted. Seat belt

pre-tensioners should be replaced even if the seat be lts were not in use during a frontal collision in

which the air bags were deployed.

Replace any seat belt assembly (including anchor bolts) if:

The seat belt is in use at the time of a collision (e xcept for minor collisions and the belts, retractors and buck-

les show no damage and continue to operate properly).

The seat belt is damaged in an accident (i.e. to rn webbing, bent retractor or guide, etc.).

The seat belt attaching point is damaged in an accident . Inspect the seat belt attaching area for damage or

distortion and repair if necessary before installing a new seat belt assembly.

Anchor bolts are deformed or worn out.

The seat belt pre-tensioners must be replaced even if t he seat belts were not in use during the collision in

which the air bags were deployed.

PRELIMINARY CHECKS

1. Check the seat belt warning lamp for proper operation as per the following:

a. Turn ignition switch ON. The seat belt warning lamp should illuminate.

b. Fasten driver seat belt. The seat belt warning lamp should turn OFF.

2. If the air bag warning lamp is blinking, perform self-diagnosis with CONSULT-III and air bag warning lamp. Refer to SRC-14, "

Description".

3. Check that the seat belt retractor, s eat belt anchor and buckle bolts are tightened firmly.

4. Check the shoulder seat belt guide and shoulder belt height adjuster for front seats. Check that guide

swivels freely and that webbing lays flat and does not bind in guide. Check that height adjuster operates

properly and holds securely.

5. Check retractor operation:

a. Fully extend the seat belt webbing and c heck for twists, tears or other damage.

b. Allow the seat belt to retract. Check that webbing retu rns smoothly and completely into the retractor. If the

seat belt does not return smoothly, wipe the inside of the loops with a clean paper cloth. Dirt build-up in the

loops of the upper anchors can cause the seat belts to retract slowly.

c. Fasten the seat belt. Check that seat belt returns sm oothly and completely to the retractor. If the webbing

does not return smoothly, the cause may be an accumulation of dust or dirt. Use the “SEAT BELT TAPE

SET” and perform the following steps.

Inspect the front seat belt through-anchor

1. Pull the seat belt out to a length of 500 mm (19.69 in) or more.

2. Fix the seat belt at the center pillar webbing opening with a clip or other device.

3. Pass a thin wire through the through-anchor webbing opening. Hold both ends of the wire and pull it tightly while moving it up and down several times along the webbing opening surface to remove dirt

stuck there.

4. Any dirt that cannot be removed with the wir e can be removed by cleaning the opening with a clean

cloth.

5. Apply tape at the point where the webbi ng contacts the through-anchor webbing opening.

NOTE:

Apply the tape so that there is no slack or wrinkling.

6. Remove the clip fixing the seat belt and check that the webbing returns smoothly.

6. Repeat steps above if necessary to check the other seat belts.

Revision: 2010 May2011 QX56

Page 4280 of 5598

FRONT SEAT BELTSB-5

< REMOVAL AND INSTALLATION >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

SEAT BELT RETRACTOR ON-VEHICLE CHECK

Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)

NOTE:

All seat belt retractors are Emergency Locking Retr actors (ELR) type. In an emergency (sudden stop) the

retractor will lock and prevent the webbing from extendi ng any further. All 3-point type seat belt retractors

except the driver seat belt also have an Automati c Locking Retractors (ALR) mode. The ALR mode (also

called child restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt

is fully extended. When the webbing is then retracted part ially, the ALR mode automatically locks the seat belt

in a specific position so the webbi ng cannot be extended any further. To c ancel the ALR mode, allow the seat

belt to fully wind back into the retractor.

Check the seat belt retractors with the following test(s ) to determine if a retractor assembly is operating prop-

erly.

ELR Function Stationary Check

Grasp the shoulder webbing and pull forward quickly. The retractor should lock and prevent the belt from

extending further.

ALR Function Stationary Check

1. Pull out the entire length of seat bel t from retractor until a click is heard.

2. Retract the webbing partially. A clicking noise should be heard as the webbing retracts indicating that the

retractor is in the Automatic Locking Retractors (ALR) mode.

3. Grasp the seat belt and try to pull out the retractor. The webbing must lock and not extend any further. If it

does not operate normally, replace the retractor assembly.

4. Allow the entire length of the webbing to retract to cancel the automatic locking mode.

ELR Function Moving Check

WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be p aved and dry. Never perform the following test on

wet or gravel roads or on public streets and highways. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event that the

retractor does not lock.

1. Fasten driver seat belt. Buckle a passenger into the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h ( 10 MPH). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brac e themselves in the event that the retractor does

not lock. Apply brakes firmly and make a very hard stop.

During stopping, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock,

perform the retractor off-vehicle check.

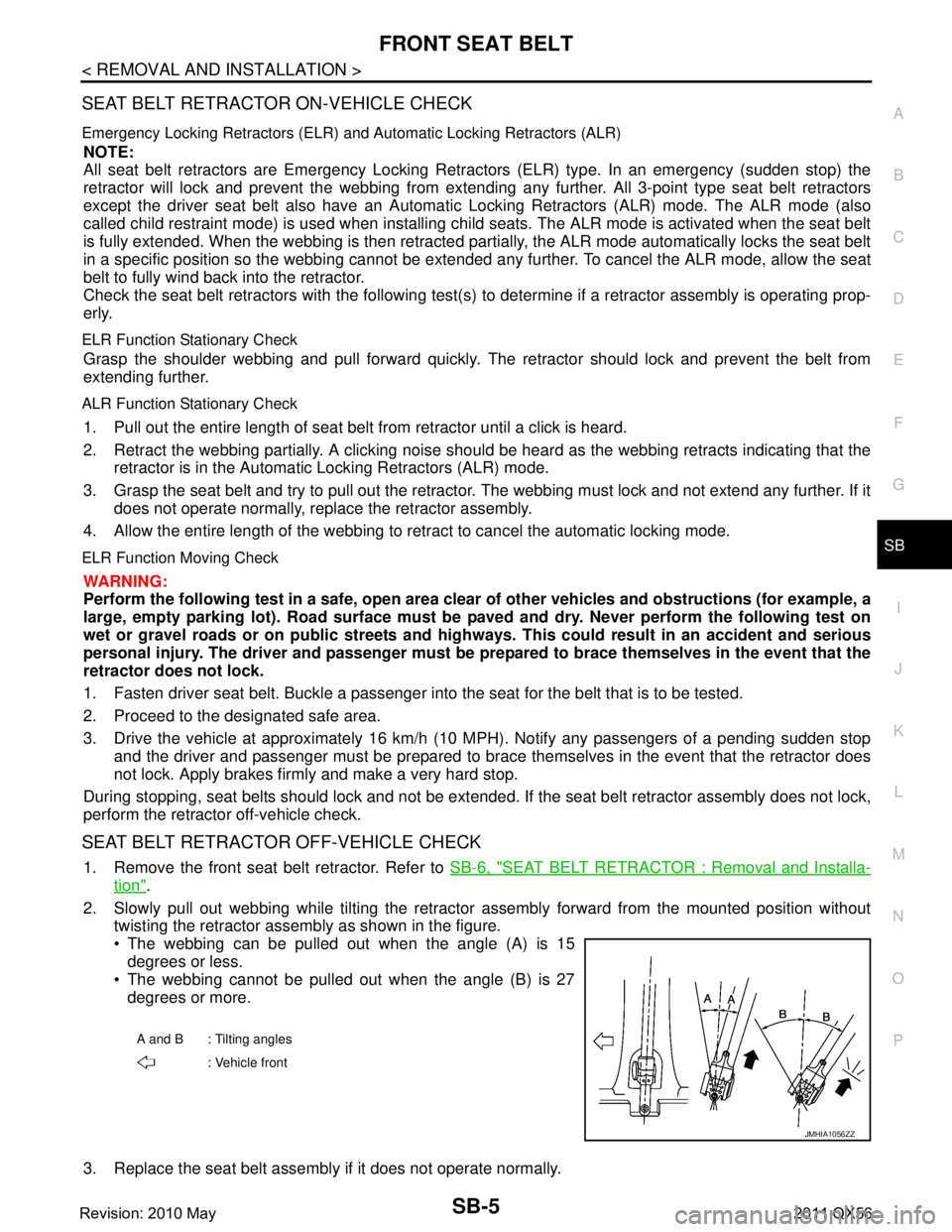

SEAT BELT RETRACTOR OFF-VEHICLE CHECK

1. Remove the front seat belt retractor. Refer to SB-6, "SEAT BELT RETRACTOR : Removal and Installa-

tion".

2. Slowly pull out webbing while tilting the retracto r assembly forward from the mounted position without

twisting the retractor assembly as shown in the figure.

The webbing can be pulled out when the angle (A) is 15

degrees or less.

The webbing cannot be pulled out when the angle (B) is 27

degrees or more.

3. Replace the seat belt assembly if it does not operate normally.

A and B : Tilting angles : Vehicle front

JMHIA1056ZZ

Revision: 2010 May2011 QX56

Page 4285 of 5598

SB-10

< REMOVAL AND INSTALLATION >

SECOND SEAT BELT

SECOND SEAT BELT

SEAT BELT RETRACTOR

SEAT BELT RETRACTOR : InspectionINFOID:0000000006217621

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies including retractors and attached hardware after any collision.

NISSAN/INFINITI recommends that all seat belt assemblies in use during a collision be replaced

unless the collision was minor and th e belts show no damage and continue to operate properly. Fail-

ure to do so could result in seri ous personal injury in an accident. Seat belt assemblies not in use dur-

ing a collision should also be re placed if either damage or improper operation was noted. Seat belt

pre-tensioners should be replaced even if the seat be lts were not in use during a frontal collision in

which the air bags were deployed.

Replace any seat belt assembly (including anchor bolts) if:

The seat belt is in use at the time of a collision (e xcept for minor collisions and the belts, retractors and buck-

les show no damage and continue to operate properly).

The seat belt is damaged in an accident (i.e. to rn webbing, bent retractor or guide, etc.).

The seat belt attaching point is damaged in an accident . Inspect the seat belt attaching area for damage or

distortion and repair if necessary before installing a new seat belt assembly.

Anchor bolts are deformed or worn out.

The seat belt pre-tensioners must be replaced even if t he seat belts were not in use during the collision in

which the air bags were deployed.

PRELIMINARY CHECKS

1. Check that the seat belt retractor, s eat belt anchor and buckle bolts are tightened firmly.

2. Check retractor operation:

a. Fully extend the seat belt webbing and c heck for twists, tears or other damage.

b. Allow the seat belt to retract. Check that webbing retu rns smoothly and completely into the retractor. If the

seat belt does not return smoothly, wipe the inside of the loops with a clean paper cloth. Dirt build-up in the

loops of that upper anchors can cause the seat belts to retract slowly.

c. Fasten the seat belt. Check that seat belt returns sm oothly and completely to the retractor. If the webbing

does not return smoothly, the cause may be an accumulation of dust or dirt. Use the “SEAT BELT TAPE

SET” and perform the following steps.

3. Repeat steps above if necessary to check the other seat belts.

SEAT BELT RETRACTOR ON-VEHICLE CHECK

Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)

NOTE:

All seat belt retractors are Emergency Locking Retr actors (ELR) type. In an emergency (sudden stop) the

retractor will lock and prevent the webbing from extendi ng any further. All 3-point type seat belt retractors

except the driver seat belt also have an Automati c Locking Retractors (ALR) mode. The ALR mode (also

called child restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt

is fully extended. When the webbing is then retracted part ially, the ALR mode automatically locks the seat belt

in a specific position so the webbing cannot be extended any further. To cancel the ALR mode, allow the seat

belt to fully wind back into the retractor.

Check the seat belt retractors with the following test(s ) to determine if a retractor assembly is operating prop-

erly.

ELR Function Stationary Check

Grasp the shoulder webbing and pull forward quickly. T he retractor should lock and prevent the belt from

extending further.

ALR Function Stationary Check

1. Pull out the entire length of seat belt from retractor until a click is heard.

2. Retract the webbing partially. A clicking noise should be heard as the webbing retracts indicating that the retractor is in the Automatic Locking Retractors (ALR) mode.

Revision: 2010 May2011 QX56

Page 4286 of 5598

SECOND SEAT BELTSB-11

< REMOVAL AND INSTALLATION >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

3. Grasp the seat belt and try to pull out the retractor. The webbing must lock and not extend any further. If it

does not operate normally, replace the retractor assembly.

4. Allow the entire length of the webbing to retract to cancel the automatic locking mode.

ELR Function Moving Check

WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be p aved and dry. Never perform the following test on

wet or gravel roads or on public streets and highways. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event that the

retractor does not lock.

1. Fasten driver seat belt. Buckle a passenger into the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h ( 10 MPH). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brac e themselves in the event that the retractor does

not lock. Apply brakes firmly and make a very hard stop.

During stopping, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock,

perform the retractor off-vehicle check.

SEAT BELT RETRACTOR OFF-VEHICLE CHECK

1. Remove the second seat belt retractor. Refer to SB-13, "SEAT BELT RETRACTOR : Removal and Instal-

lation".

2. Slowly pull out webbing while tilting the retracto r assembly forward from the mounted position without

twisting the retractor assembly as shown in the figure.

a. Outer seat belt retractor The webbing can be pulled out when the angle (A) is 15degrees or less.

The webbing cannot be pulled out when the angle (B) is 27

degrees or more.

b. Center seat belt retractor The webbing can be pulled out when the angle (A) is 25

degrees or less.

The webbing cannot be pulled out when the angle (B) is 39

degrees or more.

3. Replace the seat belt assembly if it does not operate normally.

SEAT BELT RETRACTOR : Exploded ViewINFOID:0000000006217622

BENCH SEAT

A and B : Tilting angles : Vehicle front

JMHIA1064ZZ

A and B : Tilting angles

: Vehicle front

JMHIA0561ZZ

Revision: 2010 May2011 QX56

Page 4292 of 5598

THIRD SEAT BELTSB-17

< REMOVAL AND INSTALLATION >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

THIRD SEAT BELT

SEAT BELT RETRACTOR

SEAT BELT RETRACTOR : InspectionINFOID:0000000006217627

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies in cluding retractors and attached hardware after any collision.

NISSAN/INFINITI recommends that all seat belt assemblies in use during a collision be replaced

unless the collision was minor and th e belts show no damage and continue to operate properly. Fail-

ure to do so could result in serious personal inju ry in an accident. Seat belt assemblies not in use dur-

ing a collision should also be replaced if either da mage or improper operation was noted. Seat belt

pre-tensioners should be replaced even if the seat be lts were not in use during a frontal collision in

which the air bags were deployed.

Replace any seat belt assembly (including anchor bolts) if:

The seat belt is in use at the time of a collision (exc ept for minor collisions and the belts, retractors and buck-

les show no damage and continue to operate properly).

The seat belt is damaged in an accident (i.e. to rn webbing, bent retractor or guide, etc.).

The seat belt attaching point is damaged in an accident . Inspect the seat belt attaching area for damage or

distortion and repair if necessary before installing a new seat belt assembly.

Anchor bolts are deformed or worn out.

The seat belt pre-tensioners must be replaced even if t he seat belts were not in use during the collision in

which the air bags were deployed.

PRELIMINARY CHECKS

1. Check that the seat belt retractor, seat belt anchor and buckle bolts are tightened firmly.

2. Check retractor operation:

a. Fully extend the seat belt webbing and check for twists, tears or other damage.

b. Allow the seat belt to retract. Check that webbing retu rns smoothly and completely into the retractor. If the

seat belt does not return smoothly, wipe the inside of t he loops with a clean paper cloth. Dirt build-up in the

loops of that upper anchors can cause the seat belts to retract slowly.

c. Fasten the seat belt. Check that seat belt returns sm oothly and completely to the retractor. If the webbing

does not return smoothly, the cause may be an accu mulation of dust or dirt. Use the “SEAT BELT TAPE

SET” and perform the following steps.

3. Repeat steps above if necessary to check the other seat belts.

SEAT BELT RETRACTOR ON-VEHICLE CHECK

Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)

NOTE:

All seat belt retractors are Emergency Locking Retr actors (ELR) type. In an emergency (sudden stop) the

retractor will lock and prevent the webbing from extendi ng any further. All 3-point type seat belt retractors

except the driver seat belt also have an Automati c Locking Retractors (ALR) mode. The ALR mode (also

called child restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt

is fully extended. When the webbing is then retracted part ially, the ALR mode automatically locks the seat belt

in a specific position so the webbi ng cannot be extended any further. To c ancel the ALR mode, allow the seat

belt to fully wind back into the retractor.

Check the seat belt retractors with the following test(s ) to determine if a retractor assembly is operating prop-

erly.

ELR Function Stationary Check

Grasp the shoulder webbing and pull forward quickly. The retractor should lock and prevent the belt from

extending further.

ALR Function Stationary Check

1. Pull out the entire length of seat bel t from retractor until a click is heard.

2. Retract the webbing partially. A clicking noise should be heard as the webbing retracts indicating that the

retractor is in the Automatic Locking Retractors (ALR) mode.

Revision: 2010 May2011 QX56

Page 4293 of 5598

SB-18

< REMOVAL AND INSTALLATION >

THIRD SEAT BELT

3. Grasp the seat belt and try to pull out the retractor. The webbing must lock and not extend any further. If it

does not operate normally, replace the retractor assembly.

4. Allow the entire length of the webbing to re tract to cancel the automatic locking mode.

ELR Function Moving Check

WARNING:

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be p aved and dry. Never perform the following test on

wet or gravel roads or on public streets and highw ays. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event that the

retractor does not lock.

1. Fasten driver seat belt. Buckle a passenger in to the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h ( 10 MPH). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brace themselves in the event that the retractor does

not lock. Apply brakes firmly and make a very hard stop.

During stopping, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock,

perform the retractor off-vehicle check.

SEAT BELT RETRACTOR OFF-VEHICLE CHECK

1. Remove the third seat belt retractor. Refer to SB-19, "SEAT BELT RETRACTOR : Removal and Installa-

tion".

2. Slowly pull out webbing while tilting the retracto r assembly forward from the mounted position without

twisting the retractor assembly as shown in the figure.

a. Outer seat belt retractor The webbing can be pulled out when the angle (A) is 15degrees or less.

The webbing cannot be pulled out when the angle (B) is 27

degrees or more.

b. Center seat belt retractor The webbing can be pulled out when the angle (A) is 15

degrees or less.

The webbing cannot be pulled out when the angle (B) is 27

degrees or more.

3. Replace the seat belt assembly if it does not operate normally.

A and B : Tilting angles : Vehicle front

JMHIA1064ZZ

A and B : Tilting angles: Vehicle front

JMHIA0522ZZ

Revision: 2010 May2011 QX56

Page 4989 of 5598

ST-2

STEERING WHEEL ...........................................33

Exploded View ..................................................... ...33

Removal and Installation ........................................33

STEERING COLUMN ........................................34

Exploded View ..................................................... ...34

Removal and Installation ........................................34

Inspection ...............................................................35

STEERING SHAFT ............................................37

Exploded View ..................................................... ...37

Removal and Installation ........................................37

Inspection ...............................................................39

STEERING GEAR AND LINKAGE ....................41

Exploded View ..................................................... ...41

Removal and Installation ........................................42

Disassembly and Assembly ....................................43

Inspection ...............................................................46

POWER STEERING OIL PUMP ........................48

Exploded View ..................................................... ...48

Removal and Installation ........................................49

Disassembly and Assembly ....................................50

Inspection ...............................................................52

HYDRAULIC LINE .......................................... ...54

Exploded View ..................................................... ...54

HEATED STEERING WHEEL SWITCH ............56

Exploded View ..................................................... ...56

Removal and Installation .........................................56

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................................

57

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

57

General Specifications ......................................... ...57

Steering Wheel Axial End Play and Play ................57

Steering Wheel Turning Force ................................57

Steering Angle ........................................................57

Steering Column Length .........................................57

Steering Column Mounting Dimensions ..................57

Steering Column Operating Range .........................57

Steering Shaft Sliding Range ..................................58

Rack Sliding Force ..................................................58

Rack Stroke ............................................................58

Socket Swing Force and Rotating Torque ..............58

Socket Axial End Play .............................................58

Inner Socket Length ................................................58

Relief Oil Pressure ..................................................58

Revision: 2010 May2011 QX56

Page 5022 of 5598

STEERING COLUMNST-35

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

If necessary, remove telescopic motor, tilt motor, and brackets.

12. Perform inspection after removal. Refer to ST-35, "

Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

To install the slide plate (1), create clearance (L) in the steering col-

umn assembly mounting area (2) as follows.

Tighten the mounting bolts and nuts in the order shown in the fig- ure when installing the steering column assembly.

Be careful of the following points when installing the steering col- umn assembly.

CAUTION:

Never give axial impact to steering column assembly during installation.

Never move steering gear assembly.

Perform inspection after installation. Refer to ST-35, "

Inspection".

InspectionINFOID:0000000006225603

INSPECTION AFTER REMOVAL

Check each part of steering column assembly for damage or other malfunctions. Replace if necessary.

Measure steering column assembly rotating torque using a preload gauge [SST: ST3127S000 (J-25765-A)]. Replace steering column assembly if outside the standard.

Measure the length (L) as shown, if vehicle has been involved in a minor collision. Replace steering column assembly if out side the

standard. L : 2.0 mm (0.079 in)

JSGIA0315ZZ

JPGIA0026ZZ

Rotating torque : Refer to

ST-57, "Steering Column Operating Range".

L : Refer to ST-57, "

Steering Column Length".

JSGIA0797ZZ

Revision: 2010 May2011 QX56