length INFINITI QX56 2011 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2621 of 5598

OIL PAN (UPPER)EM-59

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

a. Use a scraper (A) to remove old liquid gasket from mating sur-

faces.

Also remove the old liquid gasket from mating surface of cylin-der block.

Remove old liquid gasket from the bolt holes and threads.

CAUTION:

Never scratch or damage th e mating surfaces when clean-

ing off old liquid gasket.

b. Install new O-rings on the bottom of cylinder block and oil pump.

c. Apply a continuous bead of liquid gasket with tube pre sser (commercial service tool) to the cylinder block

mating surfaces of oil pan (upper) to a limited portion as shown in the figure.

Use Genuine RTV silicone sealant or equivalent. Refer to GI-22, "

Recommended Chemical Prod-

ucts and Sealants".

CAUTION:

Attaching must be done with in 5 minutes after coating.

d. Tighten mounting bolts in numerical order as shown in the fig- ure.

CAUTION:

Install avoiding misal ignment of O-rings.

NOTE:

Tighten mounting bolts No. 1 and 2 in two steps. The numerical

order No. 9 and 16 shown second steps.

There are four types of mounting bolts. Refer to the following for locating bolts.

e. Tighten transmission joint bolts.

f. Install rear plate cover.

2. Install oil strainer.

JPBIA3503ZZ

a. : 5.5 - 7.5 mm (0.217 - 0.295 in) b. : φ4.0 - 5.0 mm (0.157 - 0.197 in)

: Engine front

JPBIA3504ZZ

: Engine front

JPBIA3502ZZ

Order number for tightening 17, 18 2 (16), 3, 5, 6, 7, 8, 10,

11, 14, 15 1(9), 4 12, 13

Bolt size M6 M8

Bolt length 45 mm (1.77 in) 25 mm (0.98 in) 30.0 mm (1.18 in) 120 mm (4.72 in)

Tightening torque 9.0 N· (0.92 kg-m, 80

in-lb) 22.0 N·m (2.2 kg-m, 16 ft-lb)

Revision: 2010 May2011 QX56

Page 2697 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-135

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M A

EM

NP

O

Cylinder HeadINFOID:0000000006289594

CYLINDER HEAD

Unit: mm (in)

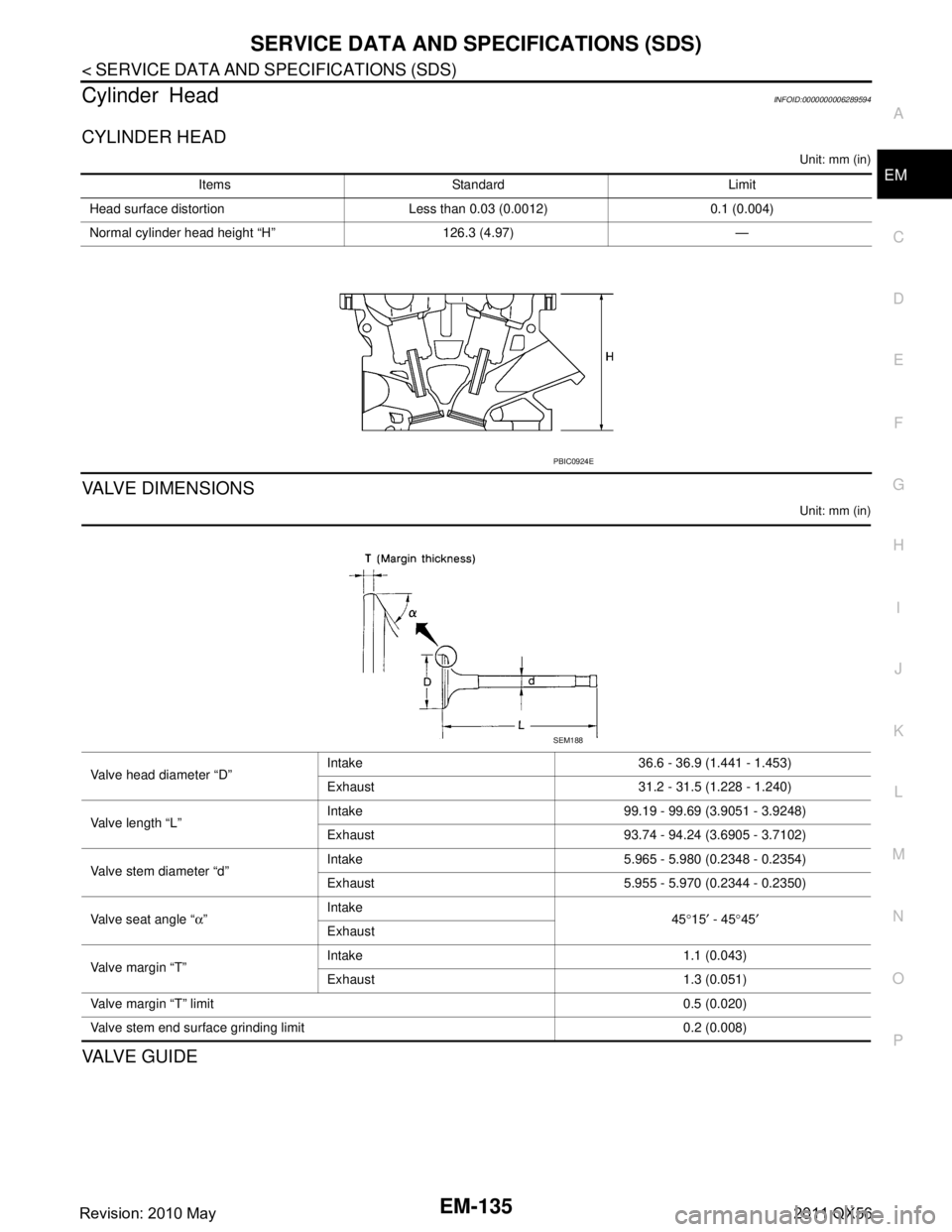

VALVE DIMENSIONS

Unit: mm (in)

VA LV E G U I D E

Items Standard Limit

Head surface distortion Less than 0.03 (0.0012) 0.1 (0.004)

Normal cylinder head height “H” 126.3 (4.97) —

PBIC0924E

Valve head diameter “D” Intake 36.6 - 36.9 (1.441 - 1.453)

Exhaust 31.2 - 31.5 (1.228 - 1.240)

Valve length “L” Intake 99.19 - 99.69 (3.9051 - 3.9248)

Exhaust 93.74 - 94.24 (3.6905 - 3.7102)

Valve stem diameter “d” Intake 5.965 - 5.980 (0.2348 - 0.2354)

Exhaust 5.955 - 5.970 (0.2344 - 0.2350)

Valve seat angle “ α” Intake

45°15 ′ - 45 °45 ′

Exhaust

Valve margin “T” Intake 1.1 (0.043)

Exhaust 1.3 (0.051)

Valve margin “T” limit 0.5 (0.020)

Valve stem end surface grinding limit 0.2 (0.008)

SEM188

Revision: 2010 May2011 QX56

Page 2698 of 5598

EM-136

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

*: Parts settings are for exhaust side only

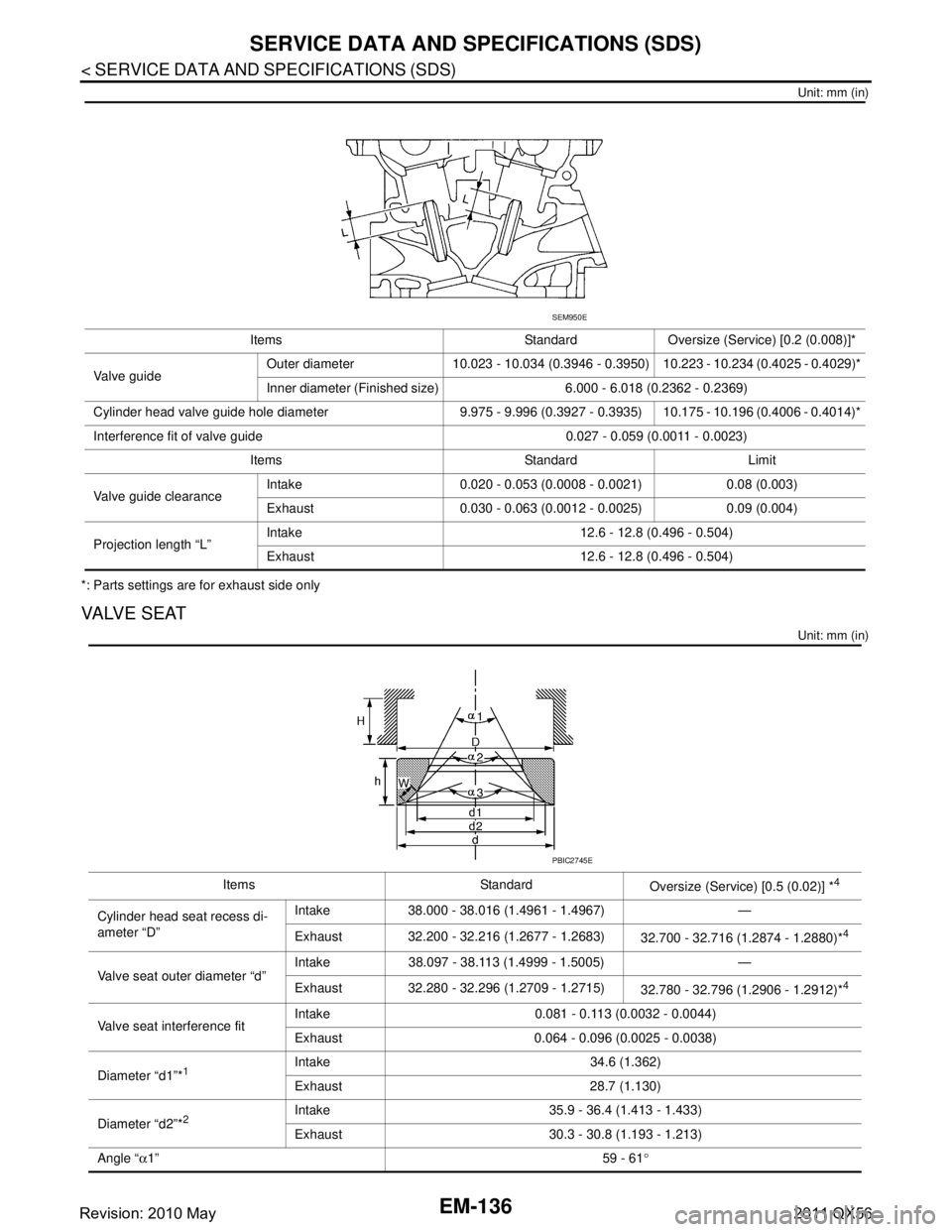

VALVE SEAT

Unit: mm (in)

Items Standard Oversize (Service) [0.2 (0.008)]*

Va l v e g u i d e Outer diameter 10.023 - 10.034 (0.3946 - 0.3950) 10.223 - 10.234 (0.4025 - 0.4029)*

Inner diameter (Finished size) 6.000 - 6.018 (0.2362 - 0.2369)

Cylinder head valve guide hole diameter 9.975 - 9.996 (0.3927 - 0.3935) 10.175 - 10.196 (0.4006 - 0.4014)*

Interference fit of valve guide 0.027 - 0.059 (0.0011 - 0.0023) Items Standard Limit

Valve guide clearance Intake 0.020 - 0.053 (0.0008 - 0.0021) 0.08 (0.003)

Exhaust 0.030 - 0.063 (0.0012 - 0.0025) 0.09 (0.004)

Projection length “L” Intake 12.6 - 12.8 (0.496 - 0.504)

Exhaust 12.6 - 12.8 (0.496 - 0.504)

SEM950E

Items Standard

Oversize (Service) [0.5 (0.02)] *4

Cylinder head seat recess di-

ameter “D”Intake 38.000 - 38.016 (1.4961 - 1.4967) —

Exhaust 32.200 - 32.216 (1.2677 - 1.2683)

32.700 - 32.716 (1.2874 - 1.2880)*

4

Valve seat outer diameter “d”Intake 38.097 - 38.113 (1.4999 - 1.5005) —

Exhaust 32.280 - 32.296 (1.2709 - 1.2715)

32.780 - 32.796 (1.2906 - 1.2912)*4

Valve seat interference fitIntake 0.081 - 0.113 (0.0032 - 0.0044)

Exhaust 0.064 - 0.096 (0.0025 - 0.0038)

Diameter “d1”*

1Intake 34.6 (1.362)

Exhaust 28.7 (1.130)

Diameter “d2”*

2Intake 35.9 - 36.4 (1.413 - 1.433)

Exhaust 30.3 - 30.8 (1.193 - 1.213)

Angle “ α1” 59 - 61°

PBIC2745E

Revision: 2010 May2011 QX56

Page 2925 of 5598

![INFINITI QX56 2011 Factory User Guide

FRONT DRIVE SHAFTFAX-25

< REMOVAL AND INSTALLATION > [4WD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

9. Install the boot securely into grooves (indicated by “*” marks) shown in the figure.

CAUTION:

If gr INFINITI QX56 2011 Factory User Guide

FRONT DRIVE SHAFTFAX-25

< REMOVAL AND INSTALLATION > [4WD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

9. Install the boot securely into grooves (indicated by “*” marks) shown in the figure.

CAUTION:

If gr](/img/42/57033/w960_57033-2924.png)

FRONT DRIVE SHAFTFAX-25

< REMOVAL AND INSTALLATION > [4WD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

9. Install the boot securely into grooves (indicated by “*” marks) shown in the figure.

CAUTION:

If grease adheres to the boot mounting surface (indicated

by “*” mark) on the shaft or housing, boot may come off.

Remove all grease from the surfaces.

10. To prevent the deformation of the boot, adjust the boot installa- tion length (L) to the specified value shown below by inserting

the suitable tool into inside of the boot from the large diameter

side of boot and discharging the inside air.

CAUTION:

If the boot installation length is outsid e the standard, it may cause breakage of boot.

Be careful not to touch the inside of the boot with the tip of tool.

11. Install new boot bands securely. CAUTION:

Never reuse boot band.

a. Small boot band

i. Secure the ends of the boot with boot bands using the boot band crimping tool [SST: KV40107300 ( −)] (A).

CAUTION:

Secure boot band so that dimension (M) meets the specifi-

cation as shown in the figure.

b. Large boot band

i. Put boot band in the groove on drive shaft boot. Then fit pawls ( ) into holes to temporary installation.

NOTE:

For the large diameter side, fit projection (A) and guide slit (B) at

first.L : Refer to

FAX-29, "

Drive Shaft".

JPDIG0136ZZ

PDIA1187J

M : 1.0 – 4.0 mm (0.039 – 0.157 in)

DSF0047D

SDIA3557E

Revision: 2010 May2011 QX56

Page 2927 of 5598

![INFINITI QX56 2011 Factory User Guide

FRONT DRIVE SHAFTFAX-27

< REMOVAL AND INSTALLATION > [4WD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

2. Install boot and boot bands to shaft. CAUTION:

Wrap serration on shaft with tape (A) to protect the b INFINITI QX56 2011 Factory User Guide

FRONT DRIVE SHAFTFAX-27

< REMOVAL AND INSTALLATION > [4WD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

2. Install boot and boot bands to shaft. CAUTION:

Wrap serration on shaft with tape (A) to protect the b](/img/42/57033/w960_57033-2926.png)

FRONT DRIVE SHAFTFAX-27

< REMOVAL AND INSTALLATION > [4WD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

2. Install boot and boot bands to shaft. CAUTION:

Wrap serration on shaft with tape (A) to protect the bootfrom damage.

Never reuse boot and boot band.

3. Remove the tape wrapped around the serration on shaft.

4. Install ball cage/steel ball/inner race assembly (1), align it with the matching marks on shaft (2) put during the removal.

5. Secure ball cage/steel ball/inner race assembly onto shaft with snap ring (3).

CAUTION:

Never reuse snap ring.

6. Apply the appropriate amount of grease onto housing and slid- ing surface.

7. Install housing to shaft.

8. Install stopper ring to housing. CAUTION:

Never reuse stopper ring.

9. After installed, pull shaft to check engagement between housing and stopper ring.

10. Install boot securely into grooves (indicated by “*” marks) shown in the figure.

CAUTION:

If grease adheres to the bo ot mounting surfaces (indicated

by “*” marks) on shaft or housing, boot may be removed.

Remove all grease from the surfaces.

11. To prevent deformation of the boot, adjust the boot installation

length (L) to the value shown below by inserting the suitable tool

into the inside of boot from the large diameter side of boot and

discharging inside air.

CAUTION:

If the boot installation length is outsid e the standard, it may cause breakage of boot.

Be careful not to touch the inside of the boot with the tip of tool.

12. Install boot bands securely as shown in the figure. CAUTION:

Never reuse boot band.

13. Secure housing and shaft, and then check that they are in the correct position when rotating boot. Install them with boot band

when the mounting positions become incorrect.

CAUTION:

Never reuse boot band.

14. Install dust shield to housing. CAUTION:

Never reuse dust shield.

15. Install circular clip to housing. CAUTION:

Never reuse circular clip.

JPDIF0009ZZ

Grease amount : Refer to FAX-29, "Drive Shaft".

L : Refer to FAX-29, "

Drive Shaft".

JPDIG0004ZZ

JPDIF0224ZZ

PDIA1188J

Revision: 2010 May2011 QX56

Page 2929 of 5598

![INFINITI QX56 2011 Factory User Guide

SERVICE DATA AND SPECIFICATIONS (SDS)

FAX-29

< SERVICE DATA AND SPECIFICATIONS (SDS) [4WD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SD INFINITI QX56 2011 Factory User Guide

SERVICE DATA AND SPECIFICATIONS (SDS)

FAX-29

< SERVICE DATA AND SPECIFICATIONS (SDS) [4WD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SD](/img/42/57033/w960_57033-2928.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

FAX-29

< SERVICE DATA AND SPECIFICATIONS (SDS) [4WD]

C

EF

G H

I

J

K L

M A

B

FA X

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel Hub and Bearing AssemblyINFOID:0000000006225407

Drive ShaftINFOID:0000000006225408

Item Standard

Axial end play 0.05 mm (0.002 in) or less

ItemStandard

Wheel side Final drive side

Grease quantity 205 – 225 g (7.23 – 7.94 oz) 130 – 150 g (4.59 – 5.29 oz)

Boots installed length 157.8 mm (6.21 in) 196.4 mm (7.73 in)

Revision: 2010 May2011 QX56

Page 2950 of 5598

FSU-8

< PERIODIC MAINTENANCE >

WHEEL ALIGNMENT

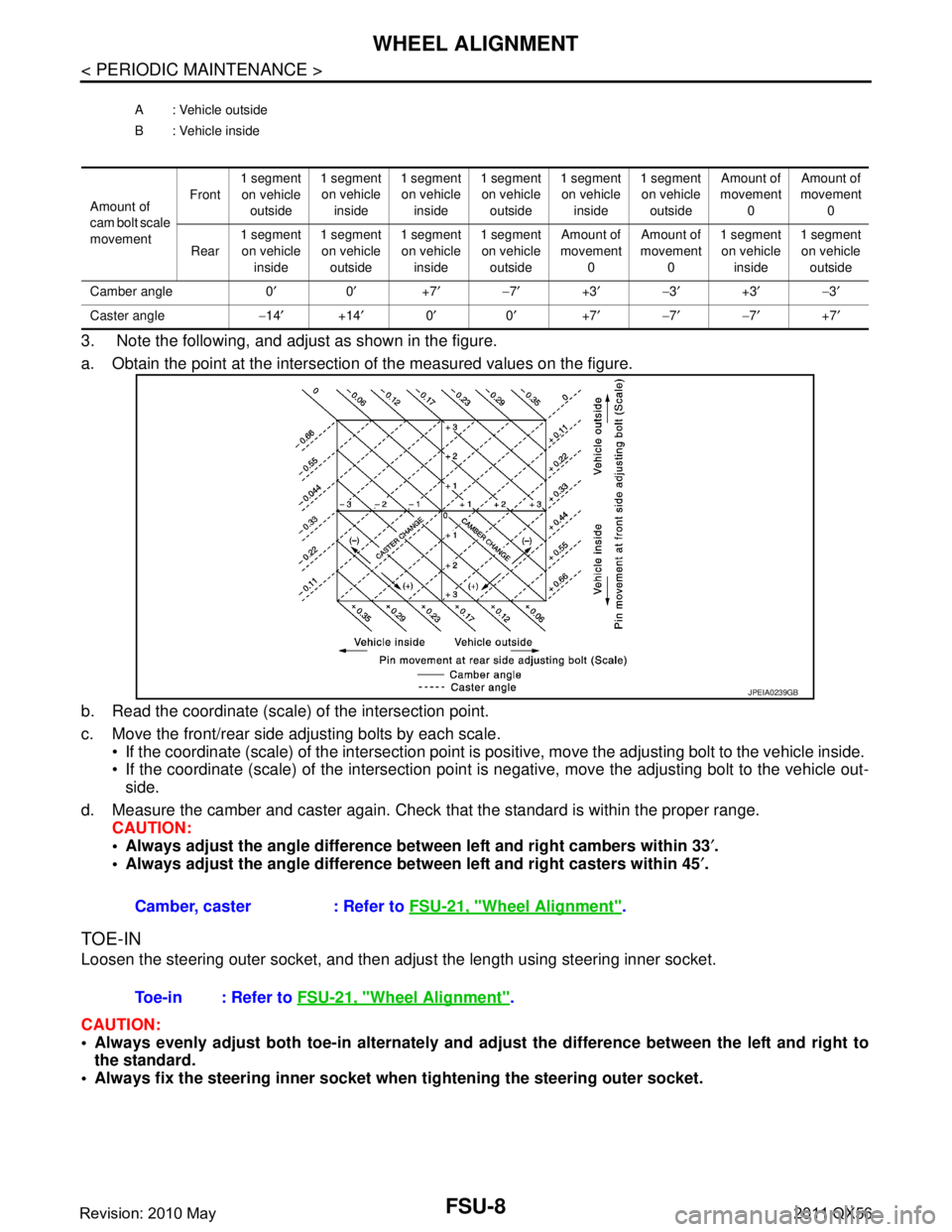

3. Note the following, and adjust as shown in the figure.

a. Obtain the point at the intersection of the measured values on the figure.

b. Read the coordinate (scale) of the intersection point.

c. Move the front/rear side adjusting bolts by each scale. If the coordinate (scale) of the intersection point is positive, move the adjusting bolt to the vehicle inside.

If the coordinate (scale) of the intersection point is negative, move the adjusting bolt to the vehicle out-

side.

d. Measure the camber and caster again. Check that the standard is within the proper range.

CAUTION:

Always adjust the angle difference betw een left and right cambers within 33′.

Always adjust the angle difference be tween left and right casters within 45′.

TOE-IN

Loosen the steering outer socket, and then adjus t the length using steering inner socket.

CAUTION:

Always evenly adjust both toe-in alternately and adjust the difference between the left and right to

the standard.

Always fix the steering inner socket when tightening the steering outer socket.

A : Vehicle outside

B : Vehicle inside

Amount of

cam bolt scale

movement Front

1 segment

on vehicle outside 1 segment

on vehicle inside 1 segment

on vehicle inside 1 segment

on vehicle outside 1 segment

on vehicle inside 1 segment

on vehicle outside Amount of

movement 0 Amount of

movement 0

Rear 1 segment

on vehicle inside 1 segment

on vehicle outside 1 segment

on vehicle inside 1 segment

on vehicle outside Amount of

movement 0 Amount of

movement 0 1 segment

on vehicle inside 1 segment

on vehicle outside

Camber angle 0 ′0′ +7′− 7′ +3′− 3′ +3′− 3′

Caster angle −14 ′ +14′ 0′ 0′ +7′− 7′− 7′ +7′

Camber, caster : Refer to FSU-21, "Wheel Alignment".

JPEIA0239GB

Toe-in : Refer to FSU-21, "Wheel Alignment".

Revision: 2010 May2011 QX56

Page 2989 of 5598

IDENTIFICATION INFORMATIONGI-25

< VEHICLE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

DimensionsINFOID:0000000006280863

Unit: mm (in)

Wheels & TiresINFOID:0000000006280864

: Vehicle front

JPAIA0770ZZ

Overall length 5,290 (208.3)

Overall width 2,030 (79.9)

Overall height 1,925 (75.8)

Front tread 1,715 (67.5)

Rear tread 1,725 (67.9)

Wheelbase 3,075 (121.1)

ConventionalTire

20 inch P275/60R20 114H

22 inch P275/50R22 111H

Road wheel 20 inch

(Aluminum)

Size 20

× 8J

Offset 30 mm (1.18 in)

22 inch

(Aluminum) Size 22

× 8J

Offset 30 mm (1.18 in)

Spare Tire

20 inch P275/60R20 114H

22 inch P275/50R22 111H

Road wheel 20 inch

(Aluminum)

Size 20

× 8J

Offset 30 mm (1.18 in)

22 inch

(Aluminum) Size 22

× 8J

Offset 30 mm (1.18 in)

Revision: 2010 May2011 QX56

Page 2994 of 5598

GI-30

< PRECAUTION >

PRECAUTIONS

To reinstall the rubber hose securely, check that hose insertionlength and orientation is correct. (If tube is equipped with hose

stopper, insert rubber hose into tube until it butts up against hose

stopper.)

HOSE CLAMPING

If old rubber hose is re-used, install hose clamp in its original posi-tion (at the indentation where the old clamp was). If there is a trace

of tube bulging left on the old rubber hose, align rubber hose at

that position.

Discard old clamps; replace with new ones.

After installing plate clamps, apply force to them in the direction of the arrow, tightening rubber hose equally all around.

Engine OilsINFOID:0000000006280874

Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin contact

with used oil.

If skin contact is made, wash thoroughly with soap or hand cleaner as soon as possible.

HEALTH PROTECTION PRECAUTIONS

Avoid prolonged and repeated contact with oils, particularly used engine oils.

Wear protective clothing, including impervious gloves where practicable.

Do not put oily rags in pockets.

Avoid contaminating clothes, pa rticularly underpants, with oil.

Heavily soiled clothing and oil-impregnated footwear should not be worn. Overalls must be cleaned regu-

larly.

First aid treatment should be obtained immediately for open cuts and wounds.

Use barrier creams, applying them before each work period, to help the removal of oil from the skin.

Wash with soap and water to ensure all oil is removed (skin cleansers and nail brushes will help). Prepara-

tions containing lanolin replace the natural skin oils which have been removed.

Do not use gasoline, kerosene, diesel fuel, gas oil, thinners or solvents for cleaning skin.

If skin disorders develop, obtain medical advice without delay.

Where practical, degrease components prior to handling.

Where there is a risk of eye contact, eye protection should be worn, for example, chemical goggles or face

shields; in addition an eye wash facility should be provided.

ENVIRONMENTAL PROTECTION PRECAUTIONS

SMA020D

SMA021D

SMA022D

Revision: 2010 May2011 QX56

Page 4210 of 5598

RAX-14

< REMOVAL AND INSTALLATION >

REAR DRIVE SHAFT

9. Install the boot securely into grooves (indicated by “*” marks)shown in the figure.

CAUTION:

If grease adheres to the boot mounting surface (indicated

by “*” mark) on the shaft or housing, boot may come off.

Remove all grease from the surfaces.

10. To prevent the deformation of the boot, adjust the boot installa- tion length (L) to the specified value shown below by inserting

the suitable tool into inside of the boot from the large diameter

side of boot and discharging the inside air.

CAUTION:

If the boot installation length is outsid e the standard, it may cause breakage of boot.

Be careful not to touch the inside of the boot with the tip of tool.

11. Install new boot bands securely. CAUTION:

Never reuse boot band.

a. Small boot band

i. Secure the ends of the boot with boot bands using the boot band crimping tool [SST: KV40107300 ( −)] (A).

CAUTION:

Secure boot band so that dimension (M) meets the specifi-

cation as shown in the figure.

b. Large boot band

i. Put boot band in the groove on drive shaft boot. Then fit pawls ( ) into holes to temporary installation.

NOTE:

For the large diameter side, fit projection (A) and guide slit (B) at

first.L: Refer to

RAX-18, "

Drive Shaft".

JPDIG0136ZZ

PDIA1187J

M : 1.0 – 4.0 mm (0.039 – 0.157 in)

DSF0047D

SDIA3557E

Revision: 2010 May2011 QX56