radiator INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 961 of 5598

WATER PUMPCO-19

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

11. Remove water pump. Refer to

CO-18, "Exploded View".

Engine coolant will leak from cylinder block, so have a receptacle ready under vehicle.

CAUTION:

Handle the water pump vane so that it does not contact any other parts.

Never disassemble water pump.

INSTALLATION

Install in the reverse order of removal.

InspectionINFOID:0000000006289671

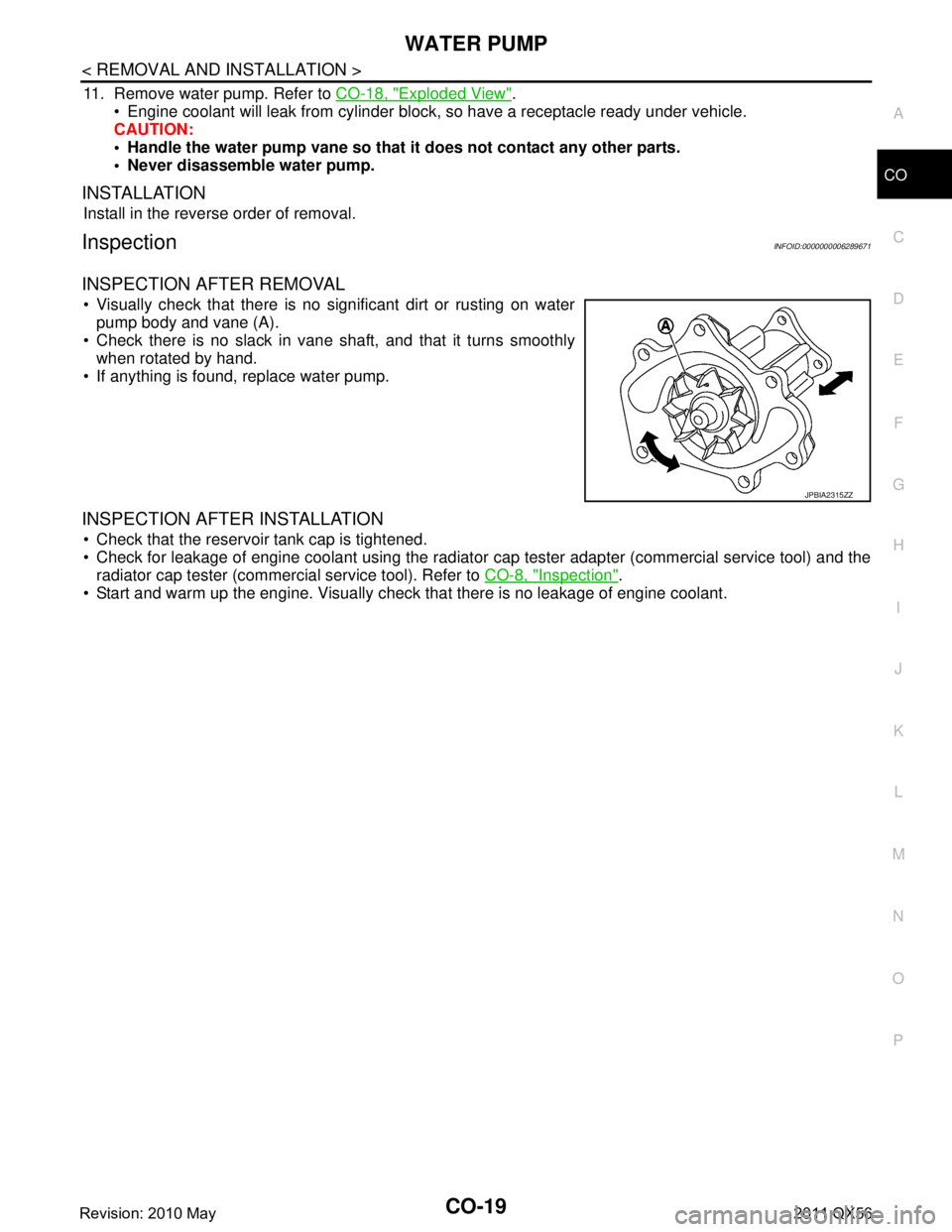

INSPECTION AFTER REMOVAL

Visually check that there is no significant dirt or rusting on water pump body and vane (A).

Check there is no slack in vane shaft, and that it turns smoothly when rotated by hand.

If anything is found, replace water pump.

INSPECTION AFTER INSTALLATION

Check that the reservoir tank cap is tightened.

Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-8, "

Inspection".

Start and warm up the engine. Visually check that there is no leakage of engine coolant.

JPBIA2315ZZ

Revision: 2010 May2011 QX56

Page 962 of 5598

CO-20

< REMOVAL AND INSTALLATION >

WATER INLET AND THERMOSTAT ASSEMBLY

WATER INLET AND THERMOSTAT ASSEMBLY

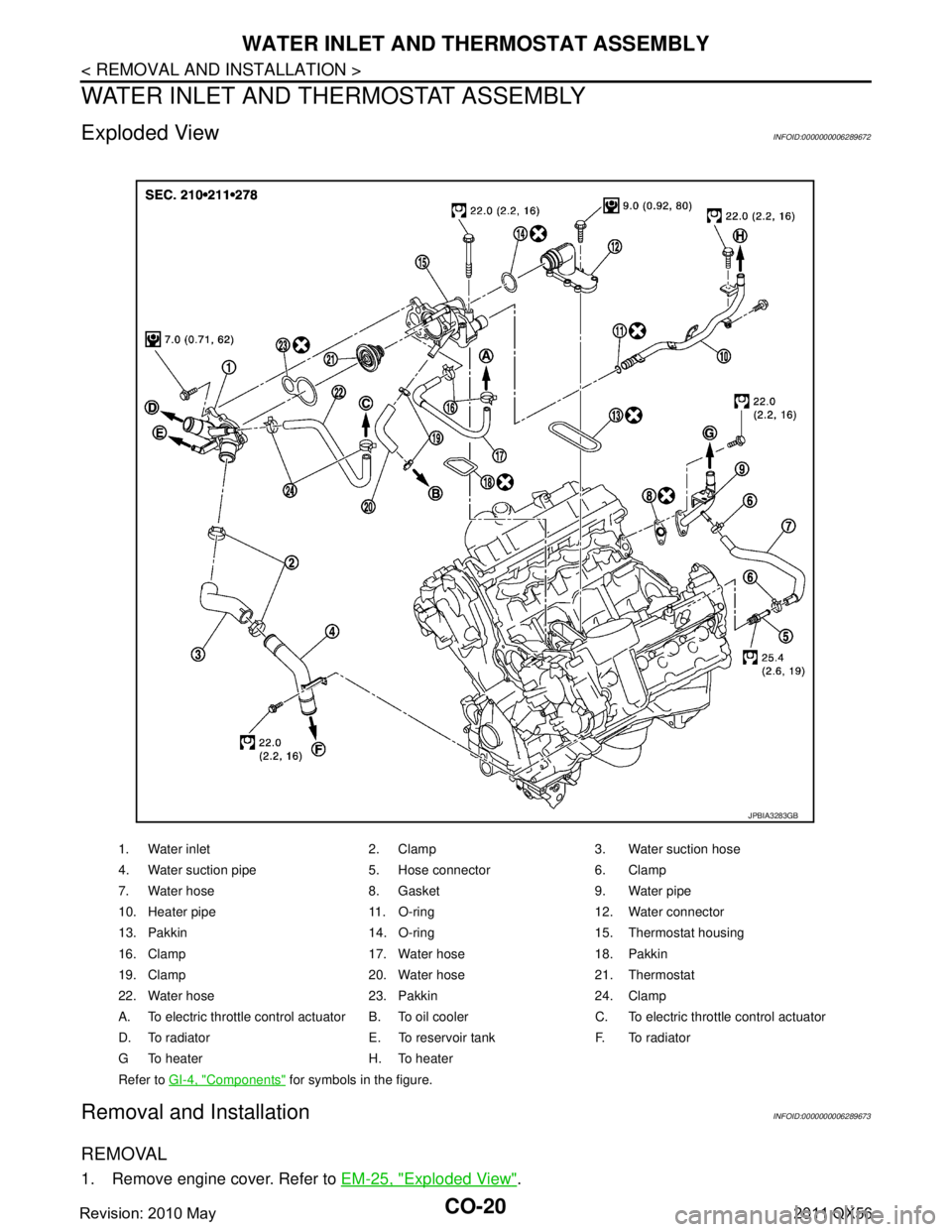

Exploded ViewINFOID:0000000006289672

Removal and InstallationINFOID:0000000006289673

REMOVAL

1. Remove engine cover. Refer to EM-25, "Exploded View".

1. Water inlet 2. Clamp 3. Water suction hose

4. Water suction pipe 5. Hose connector 6. Clamp

7. Water hose 8. Gasket 9. Water pipe

10. Heater pipe 11. O-ring 12. Water connector

13. Pakkin 14. O-ring 15. Thermostat housing

16. Clamp 17. Water hose 18. Pakkin

19. Clamp 20. Water hose 21. Thermostat

22. Water hose 23. Pakkin 24. Clamp

A. To electric throttle control actuator B. To o il cooler C. To electric throttle control actuator

D. To radiator E. To reservoir tank F. To radiator

G To heater H. To heater

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA3283GB

Revision: 2010 May2011 QX56

Page 963 of 5598

WATER INLET AND THERMOSTAT ASSEMBLYCO-21

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

2. Remove front under cover with power tool. Refer to

EXT-25, "Exploded View".

3. Drain engine coolant from drain plugs on radiator and cylinder block. Refer to CO-8, "

Draining" and EM-

103, "Setting".

CAUTION:

Perform this step when engine is cold.

Never spill engine coolant on drive belts.

4. Disconnect radiator hose (upper and lower). Refer to CO-13, "

Exploded View".

5. Remove intake manifold. Refer to EM-30, "

Exploded View".

6. Remove fuel feed tube. Refer to EM-43, "

Exploded View".

7. Remove water hose, water connector, heater pipes and heater hoses.

8. Remove thermostat housing.

9. Remove water inlet and thermostat.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Be careful not to spill engine coolant over en gine room. Use rag to absorb engine coolant.

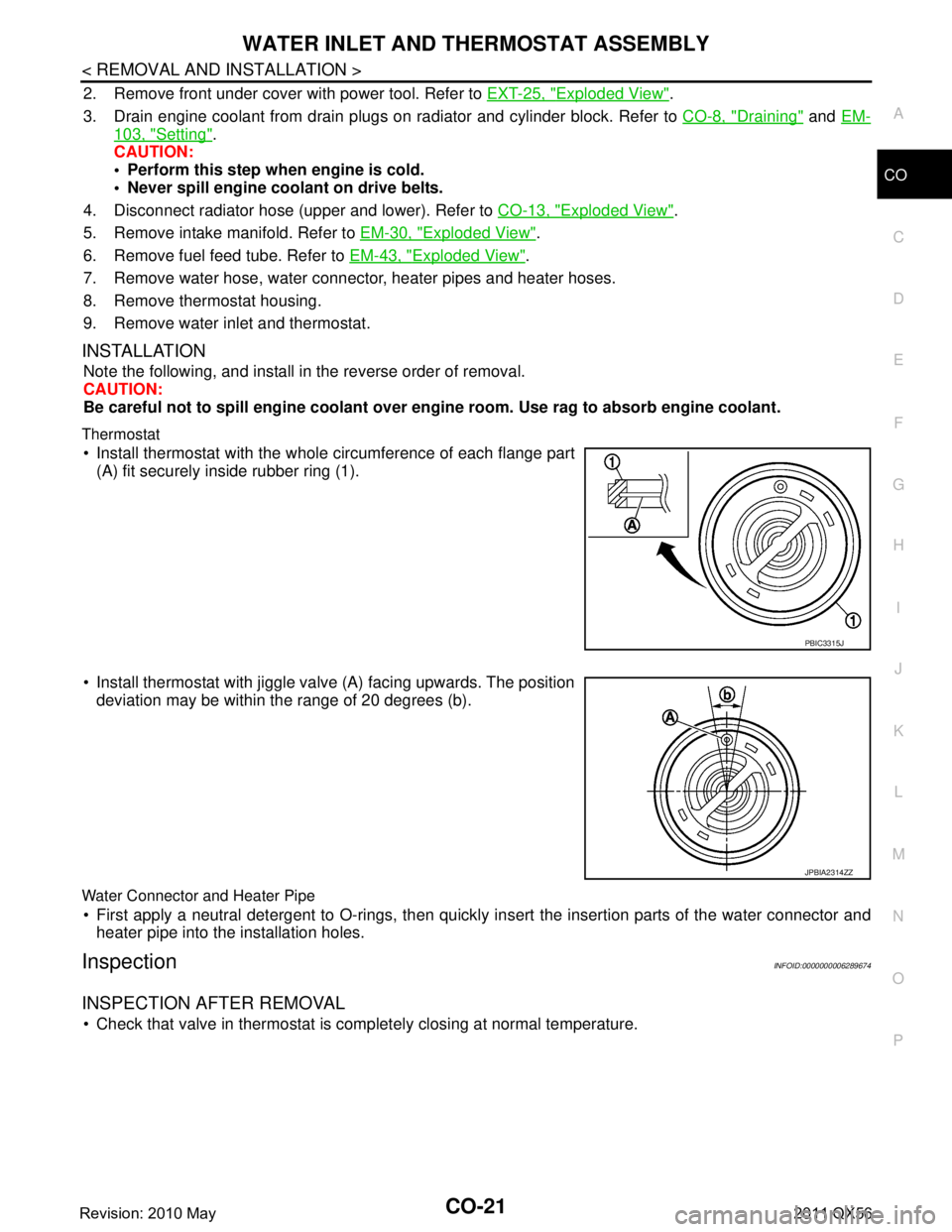

Thermostat

Install thermostat with the whole circumference of each flange part

(A) fit securely inside rubber ring (1).

Install thermostat with jiggle valve (A) facing upwards. The position deviation may be within the range of 20 degrees (b).

Water Connector and Heater Pipe

First apply a neutral detergent to O-rings, then quickly in sert the insertion parts of the water connector and

heater pipe into the installation holes.

InspectionINFOID:0000000006289674

INSPECTION AFTER REMOVAL

Check that valve in thermostat is co mpletely closing at normal temperature.

PBIC3315J

JPBIA2314ZZ

Revision: 2010 May2011 QX56

Page 964 of 5598

CO-22

< REMOVAL AND INSTALLATION >

WATER INLET AND THERMOSTAT ASSEMBLY

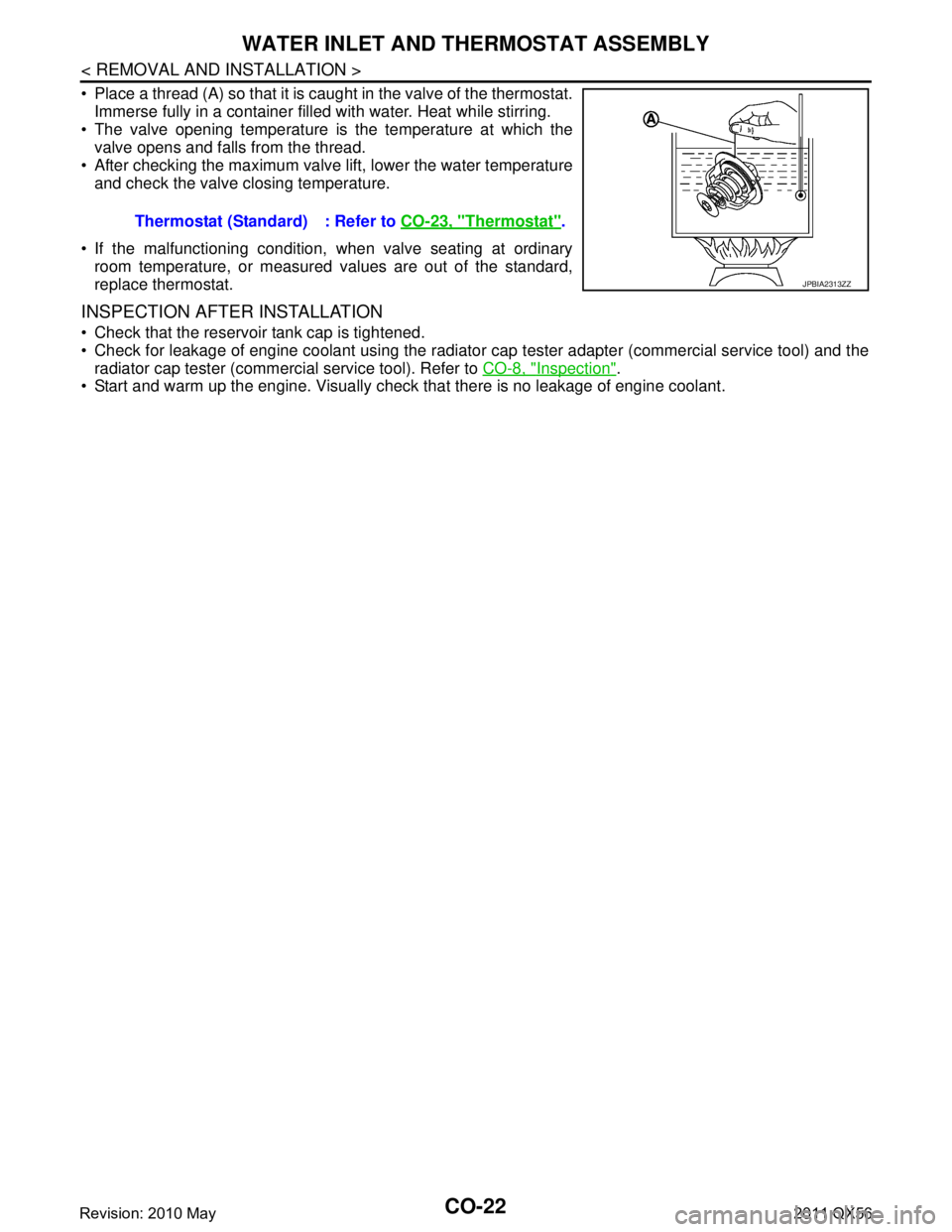

Place a thread (A) so that it is caught in the valve of the thermostat.Immerse fully in a container filled with water. Heat while stirring.

The valve opening temperature is the temperature at which the

valve opens and falls from the thread.

After checking the maximum valve lift, lower the water temperature and check the valve closing temperature.

If the malfunctioning condition, when valve seating at ordinary room temperature, or measured values are out of the standard,

replace thermostat.

INSPECTION AFTER INSTALLATION

Check that the reservoir tank cap is tightened.

Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-8, "

Inspection".

Start and warm up the engine. Visually chec k that there is no leakage of engine coolant.

Thermostat (Standard) : Refer to

CO-23, "

Thermostat".

JPBIA2313ZZ

Revision: 2010 May2011 QX56

Page 965 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

CO-23

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M A

CO

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

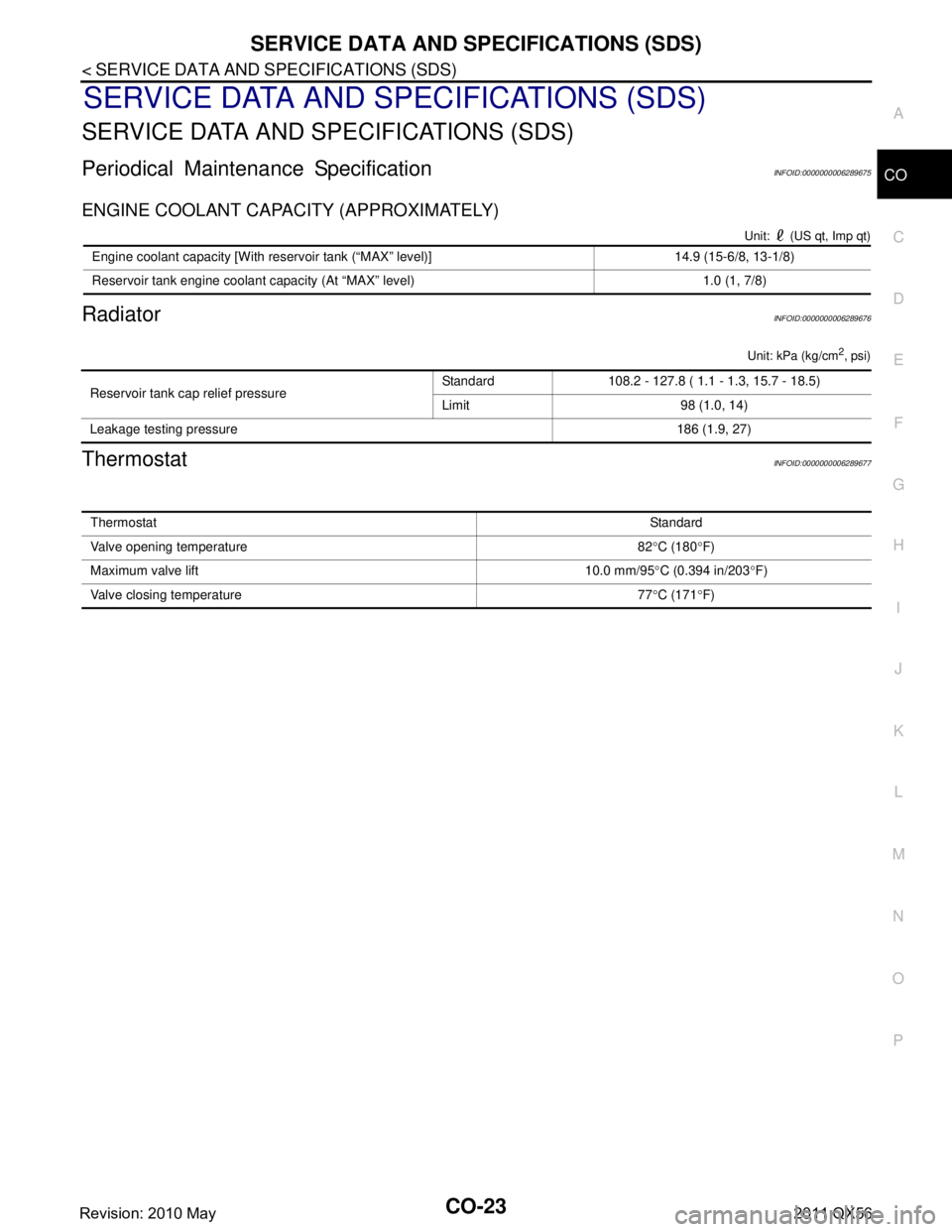

Periodical Maintenance SpecificationINFOID:0000000006289675

ENGINE COOLANT CAPACITY (APPROXIMATELY)

Unit: (US qt, Imp qt)

RadiatorINFOID:0000000006289676

Unit: kPa (kg/cm2, psi)

ThermostatINFOID:0000000006289677

Engine coolant capacity [With reservoir tank (“MAX” level)] 14.9 (15-6/8, 13-1/8)

Reservoir tank engine coolant capacity (At “MAX” level) 1.0 (1, 7/8)

Reservoir tank cap relief pressure

Standard 108.2 - 127.8 ( 1.1 - 1.3, 15.7 - 18.5)

Limit 98 (1.0, 14)

Leakage testing pressure 186 (1.9, 27)

ThermostatStandard

Valve opening temperature 82 °C (180 °F)

Maximum valve lift 10.0 mm/95 °C (0.394 in/203 °F)

Valve closing temperature 77 °C (171 °F)

Revision: 2010 May2011 QX56

Page 1542 of 5598

DLK-6

HAZARD WARNING LAMP : Diagnosis Proce-

dure .......................................................................

204

AUTOMATIC BACK DOOR FUNCTIONS DO

NOT CANCEL ................................................. .

206

Diagnosis Procedure ........................................... ..206

AUTOMATIC BACK DOOR ANTI-PINCH

FUNCTION DOES NOT OPERATE .................

207

Diagnosis Procedure ........................................... ..207

INTEGRATED HOMELINK TRANSMITTER

DOES NOT OPERATE ....................................

208

Diagnosis Procedure ........................................... ..208

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES .............................................................

209

Work Flow ............................................................ ..209

Inspection Procedure .............................................211

Diagnostic Worksheet ............................................213

REMOVAL AND INSTALLATION ..............215

HOOD .............................................................. .215

Exploded View ..................................................... ..215

HOOD ASSEMBLY ................................................ ..215

HOOD ASSEMBLY : Removal and Installation .....215

HOOD ASSEMBLY : Adjustme nt ........................ ..216

HOOD HINGE ......................................................... ..218

HOOD HINGE : Removal and Installation .............218

HOOD STAY .......................................................... ..218

HOOD STAY : Removal and Installation ...............218

HOOD STAY : Disposal .........................................218

RADIATOR CORE SUPPORT .........................220

Exploded View ..................................................... ..220

Removal and Installation .......................................220

FRONT FENDER .............................................222

Exploded View ..................................................... ..222

FRONT FENDER .................................................... ..222

FRONT FENDER : Removal and Installation ........222

FRONT FENDER DRIP COVER ............................ ..223

FRONT FENDER DRIP COVER : Removal and

Installation .............................................................

223

FRONT FENDER DUCT ......................................... ..223

FRONT FENDER DUCT : Removal and Installa-

tion .........................................................................

223

FRONT DOOR .................................................224

Exploded View ..................................................... ..224

DOOR ASSEMBLY ................................................ ..224

DOOR ASSEMBLY : Removal and Installation .....224

DOOR ASSEMBLY : Adjustme nt ........................ ..225

DOOR STRIKER .................................................... ..226

DOOR STRIKER : Removal and Installation ........226

DOOR HINGE ......................................................... .226

DOOR HINGE : Removal and Installation ............226

DOOR CHECK LINK .............................................. .226

DOOR CHECK LINK : Removal and Installation ..226

REAR DOOR ....................................................228

Exploded View ..................................................... .228

DOOR ASSEMBLY .................................................228

DOOR ASSEMBLY : Removal and Installation ....228

DOOR ASSEMBLY : Adjustme nt ..........................229

DOOR STRIKER .................................................... .230

DOOR STRIKER : Removal and Installation ........230

DOOR HINGE ......................................................... .230

DOOR HINGE : Removal and Installation ............230

DOOR CHECK LINK .............................................. .230

DOOR CHECK LINK : Removal and Installation ..230

BACK DOOR .................................................. ..232

Exploded View ..................................................... .232

BACK DOOR ASSEMBLY ......................................232

BACK DOOR ASSEMBLY : Removal and Installa-

tion ....................................................................... .

232

BACK DOOR ASSEMBLY : Adjustment ...............234

BACK DOOR STRIKER ......................................... .235

BACK DOOR STRIKER : Removal and Installa-

tion ........................................................................

235

BACK DOOR HINGE ............................................. .236

BACK DOOR HINGE : Removal and Installation ..236

BACK DOOR STAY ............................................... .236

BACK DOOR STAY : Removal and Installation ....236

BACK DOOR STAY : Disposal ............................ .237

BACK DOOR WEATHER-STRIP ........................... .237

BACK DOOR WEATHER-STRIP : Removal and

Installation .............................................................

237

HOOD LOCK ....................................................238

Exploded View ..................................................... .238

Removal and Installation .......................................238

Inspection ..............................................................239

FRONT DOOR LOCK .......................................240

Exploded View ..................................................... .240

DOOR LOCK .......................................................... .240

DOOR LOCK : Removal and Installation ..............240

INSIDE HANDLE .................................................... .241

INSIDE HANDLE : Removal and Installation ........241

OUTSIDE HANDLE ................................................ .241

OUTSIDE HANDLE : Removal and Installation ....241

REAR DOOR LOCK .........................................243

Revision: 2010 May2011 QX56

Page 1748 of 5598

DLK-212

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note t he position the seat is in and the load placed on the seat

when the noise is present. These conditions should be duplicated when verifying and isolating the cause of

the noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. Rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: 2010 May2011 QX56

Page 1751 of 5598

HOOD

DLK-215

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

REMOVAL AND INSTALLATION

HOOD

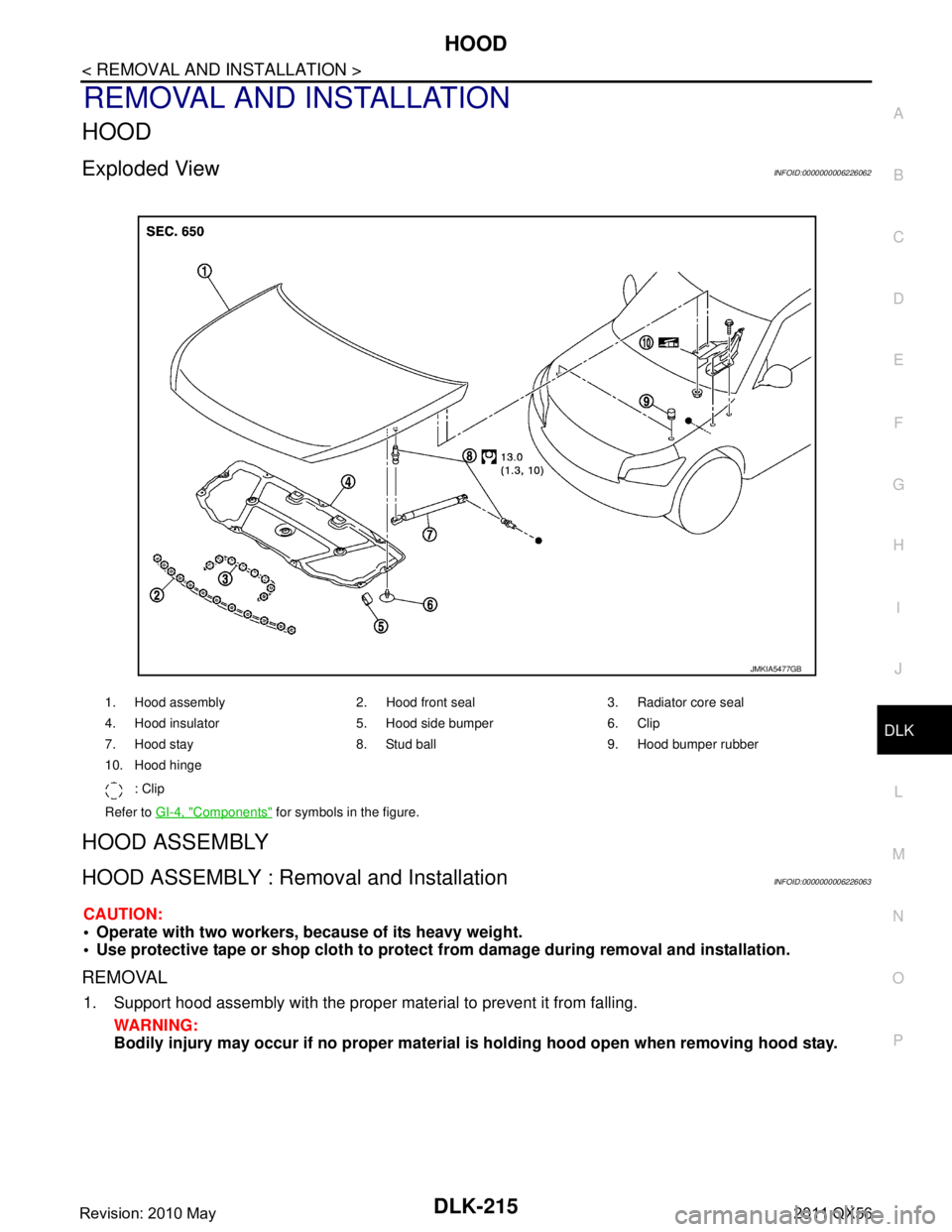

Exploded ViewINFOID:0000000006226062

HOOD ASSEMBLY

HOOD ASSEMBLY : Removal and InstallationINFOID:0000000006226063

CAUTION:

Operate with two workers, because of its heavy weight.

Use protective tape or shop cloth to protect from damage during removal and installation.

REMOVAL

1. Support hood assembly with the proper material to prevent it from falling.

WARNING:

Bodily injury may occur if no proper material is holding hood open when removing hood stay.

1. Hood assembly 2. Hood front seal 3. Radiator core seal

4. Hood insulator 5. Hood side bumper 6. Clip

7. Hood stay 8. Stud ball 9. Hood bumper rubber

10. Hood hinge

: Clip

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA5477GB

Revision: 2010 May2011 QX56

Page 1756 of 5598

DLK-220

< REMOVAL AND INSTALLATION >

RADIATOR CORE SUPPORT

RADIATOR CORE SUPPORT

Exploded ViewINFOID:0000000006226068

Removal and InstallationINFOID:0000000006226069

RADIATOR CORE SUPPORT UPPER

Removal

CAUTION:

When removing radiator core support upper, be careful not to damage the painted surface.

1. Remove bumper molding, bumper molding stay LH and RH. Refer to EXT-13, "

Removal and Installation".

2. Remove fixing clips, and then radiator upper seal.

3. Remove horn (LOW and HIGH). Refer to HRN-6, "

Removal and Installation".

4. Remove exhaust gas / outside oder sensor. Refer to HAC-151, "

Removal and Installation".

5. Disconnect refrigerant pressu re sensor harness connector.

1. Radiator upper seal 2. Radiator core support upper 3. Air guide seal LH

4. Air guide seal RH 5. Radiator side seal RH 6. Radiator lower seal RH

7. Radiator lower seal LH 8. Radiator side seal LH 9. Radiator core support main

Refer to for symbols in the figure.GI-4, "

Components"

JMKIA5479GB

Revision: 2010 May2011 QX56

Page 1757 of 5598

RADIATOR CORE SUPPORTDLK-221

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

6. Disconnect all harness clips.

7. Remove hood lock assembly. Refer to DLK-238, "

Removal and Installation".

8. Remove fixing clips of air guide seal.

9. Remove mounting bolts, and then remove power steering oil cooler. Refer to ST-54, "

Exploded View".

CAUTION:

Put a wooden block (A) under the oil cooler (1) to prevent

the oil cooler from falling.

10. Remove radiator mounting bolts. Refer to CO-13, "

Removal and Installation".

11. Remove mounting bolts, and then radiator core support upper.

Installation

Note the following items, and then install in the reverse order of removal.

CAUTION:

If aluminum plate remains to the body side when removing radiator core support upper, be sure to

pinch aluminum plate between radiator core support upper and hoodledge upper when installing

radiator core support upper, for preventing electric corrosion.

When installing radiator core support upper, be careful not to damage the painted surface.

RADIATOR CORE SUPPORT LOWER

Removal

1. Remove front bumper fascia, bumper retainer and Bumper retainer bracket CTR. Refer to EXT-13,

"Removal and Installation".

2. Remove fixing clips, and then air guide seal and radiator side seal.

3. Remove ambient sensor. Refer to HAC-147, "

Removal and Installation".

4. Remove crash zone sensor. Refer to SR-22, "

Removal and Installation".

5. Remove all harness clips.

6. Remove mounting bolts, and then remove radiator core support main.

Installation

Install in the reverse order of removal.

JMKIA5480ZZ

Revision: 2010 May2011 QX56