light INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5067 of 5598

STC-22

< SYMPTOM DIAGNOSIS >

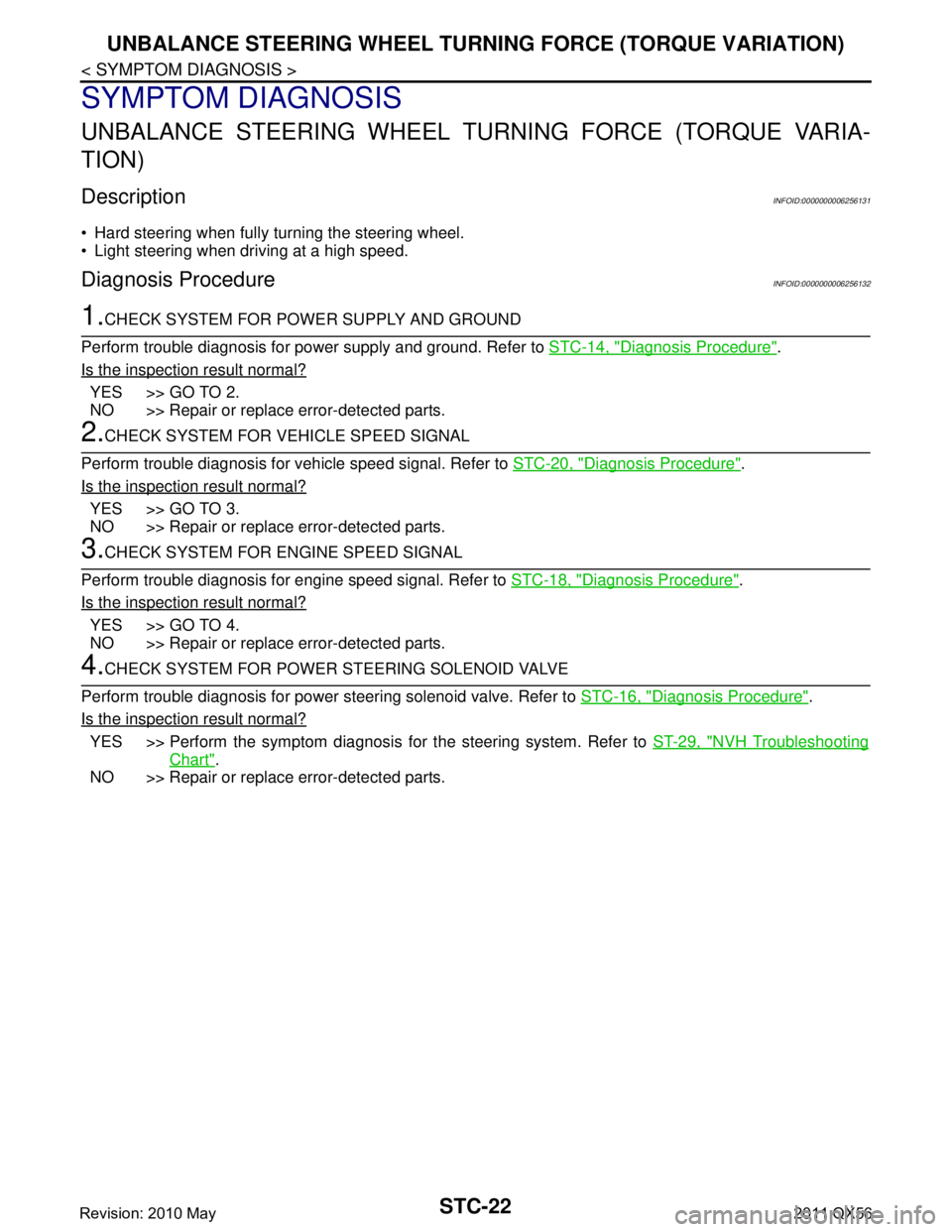

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

SYMPTOM DIAGNOSIS

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIA-

TION)

Description INFOID:0000000006256131

Hard steering when fully turning the steering wheel.

Light steering when driving at a high speed.

Diagnosis Procedure INFOID:0000000006256132

1.CHECK SYSTEM FOR POWER SUPPLY AND GROUND

Perform trouble diagnosis for power supply and ground. Refer to STC-14, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

2.CHECK SYSTEM FOR VEHICLE SPEED SIGNAL

Perform trouble diagnosis for vehicle speed signal. Refer to STC-20, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK SYSTEM FOR ENGINE SPEED SIGNAL

Perform trouble diagnosis for engine speed signal. Refer to STC-18, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK SYSTEM FOR POWER STEERING SOLENOID VALVE

Perform trouble diagnosis for power steering solenoid valve. Refer to STC-16, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> Perform the symptom diagnosis for the steering system. Refer to ST-29, "NVH Troubleshooting

Chart".

NO >> Repair or replace error-detected parts.

Revision: 2010 May2011 QX56

Page 5156 of 5598

![INFINITI QX56 2011 Factory Service Manual

TM-68

< ECU DIAGNOSIS INFORMATION >[7AT: RE7R01B]

TCM

ECU DIAGNOSIS INFORMATION

TCM

Reference ValueINFOID:0000000006226782

VALUES ON DIAGNOSIS TOOL

NOTE:

1. The CONSULT-III electrically displays shif INFINITI QX56 2011 Factory Service Manual

TM-68

< ECU DIAGNOSIS INFORMATION >[7AT: RE7R01B]

TCM

ECU DIAGNOSIS INFORMATION

TCM

Reference ValueINFOID:0000000006226782

VALUES ON DIAGNOSIS TOOL

NOTE:

1. The CONSULT-III electrically displays shif](/img/42/57033/w960_57033-5155.png)

TM-68

< ECU DIAGNOSIS INFORMATION >[7AT: RE7R01B]

TCM

ECU DIAGNOSIS INFORMATION

TCM

Reference ValueINFOID:0000000006226782

VALUES ON DIAGNOSIS TOOL

NOTE:

1. The CONSULT-III electrically displays shift timi

ng and lock-up timing (that is, operation timing of each

solenoid).

Check for time difference between actual shift timi ng and the CONSULT-III display. If the difference is

noticeable, mechanical parts (except solenoids, sens ors, etc.) may be malfunctioning. Check mechanical

parts in accordance with the specified diagnostic procedures.

2. Shift schedule (that implies gear position) on CONSULT-III may slightly differ from that is described in Ser-

vice Manual. This occurs because of the reasons as per the following:

- Actual shift schedule has more or less tolerance or allowance

- Shift schedule in Service Manual refers to the point where shifting starts

- Gear position on CONSULT-III indicates the point where shifting completes

3. Display of solenoid valves on CONSULT-III changes at t he start of shifting, while gear position is displayed

upon completion of shifting (which is computed by TCM).

CONSULT-III MONITOR ITEM

Item name Condition Value / Status (Approx.)

VHCL/S SE-A/T During driving Approximately equals the speed-

ometer reading.

ESTM VSP SIG During driving Approximately equals the speed-

ometer reading.

OUTPUT REV During driving (lock-up ON) Tachometer / Gear ratio

INPUT SPEED During driving (lock-up ON) Approximately equals the engine

speed.

F SUN GR REV During driving Revolution of front sun gear is indi-

cated.

F CARR GR REV During driving Revolution of front carrier is indi-

cated.

ENGINE SPEED Eng ine running Closely equals the tachometer

reading.

TC SLIP SPEED During driving Engine speed − Input speed

ACCELE POSI Accelerator pedal is released 0.0/8

Accelerator pedal is fully depressed 8.0/8

THROTTLE POSI Accelerator pedal is released 0.0/8

Accelerator pedal is fully depressed 8.0/8

ATF TEMP 1 Ignition switch ON Temperature of ATF in the oil pan is

indicated.

ATF TEMP 2 Ignition switch ON Temperature of ATF at the exit of

torque converter.

AT F T E M P S E 1 0 °C (32 ° F) – 20 °C (68 °F) – 80 °C (176 °F) 3.3 – 2.7 – 0.9 V

BATTERY VOLT Ignition switch ON Battery voltage (11 V – 14 V)

LINE PRES SOL During driving 0.2 – 0.6 A

TCC SOLENOID Slip lock-up is active 0.2 – 0.8 A

Lock-up is active 0.8 A

Other than the above 0 A

L/B SOLENOID Low brake is engaged 0.6 – 0.8 A

Low brake is disengaged 0 – 0.05 A

Revision: 2010 May2011 QX56

Page 5249 of 5598

![INFINITI QX56 2011 Factory Service Manual

SELECTOR LEVER POSITION INDICATORTM-161

< DTC/CIRCUIT DIAGNOSIS > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SELECTOR LEVER POSITION INDICATOR

Component Function CheckINFOID:0000000006226887

1.CH INFINITI QX56 2011 Factory Service Manual

SELECTOR LEVER POSITION INDICATORTM-161

< DTC/CIRCUIT DIAGNOSIS > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SELECTOR LEVER POSITION INDICATOR

Component Function CheckINFOID:0000000006226887

1.CH](/img/42/57033/w960_57033-5248.png)

SELECTOR LEVER POSITION INDICATORTM-161

< DTC/CIRCUIT DIAGNOSIS > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SELECTOR LEVER POSITION INDICATOR

Component Function CheckINFOID:0000000006226887

1.CHECK SELECTOR LEVER POSI TION INDICATOR (PART 1)

1. Turn ignition switch ON.

2. Check that each position indicator lamp of the selector lever position indicator turns on when shifting the selector lever from “P” to “M” position.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Go to TM-161, "

Diagnosis Procedure".

2.CHECK SELECTOR LEVER POSI TION INDICATOR (PART 2)

Check that the night illumination of the selector le ver position indicator turns on when setting the lighting

switch in 1st position.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to TM-161, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006226888

1.CHECK MALFUNCTIONING ITEM

Which item is abnormal?

Position indicator lamp>> GO TO 2.

Illumination lamp>> GO TO 9.

2.CHECK POWER SOURCE (PART 1)

1. Turn ignition switch OFF.

2. Disconnect A/T shift selector connector.

3. Turn ignition switch ON.

4. Check voltage between A/T shift selector vehicle side harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 6.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between A/T shift selector vehicle side harness connector terminal and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4.CHECK SHIFT POSITION SWITCH (PART 1)

1. Disconnect shift position switch connector.

2. Check continuity between A/T shift selector connec tor terminals and shift position switch connector termi-

nals.

A/T shift selector vehicle side harness connector

GroundVoltage (Approx.)

Connector Terminal

M57 13 Battery voltage

A/T shift selector vehicle side harness connector GroundContinuity

Connector Terminal

M57 4 Existed

Revision: 2010 May2011 QX56

Page 5251 of 5598

![INFINITI QX56 2011 Factory Service Manual

SELECTOR LEVER POSITION INDICATORTM-163

< DTC/CIRCUIT DIAGNOSIS > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> Re INFINITI QX56 2011 Factory Service Manual

SELECTOR LEVER POSITION INDICATORTM-163

< DTC/CIRCUIT DIAGNOSIS > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> Re](/img/42/57033/w960_57033-5250.png)

SELECTOR LEVER POSITION INDICATORTM-163

< DTC/CIRCUIT DIAGNOSIS > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> Repair or replace damaged parts.

9.CHECK POWER SOURCE (PART 2)

1. Turn ignition switch OFF.

2. Disconnect A/T shift selector connector.

3. Turn ignition switch ON.

4. Check voltage between A/T shift selector vehicle side harness connector terminals.

Is the inspection result normal?

YES >> GO TO 10.

NO >> Check illumination circuit. Refer to INL-34, "

Wiring Diagram".

10.CHECK SHIFT POSITION SWITCH (PART 2)

1. Disconnect shift position switch connector.

2. Check continuity between A/T shift selector connec tor terminals and shift position switch connector termi-

nals.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace damaged parts.

Component Inspection (Selecto r Lever Position Indicator)INFOID:0000000006226889

1.CHECK SELECTOR LEVER POSITION INDICATOR

Check that selector lever position indicator lamps turn on.

CAUTION:

Connect the fuse between the termina ls when applying the voltage.

A/T shift selector vehicle side harness connector

Condition Voltage (Approx.)

Connector Te r m i n a l

+ −

M57 9 10 Lighting switch 1ST Battery voltage

A/T shift selector connector Shift position switch connector Continuity

Connector Terminal Connector Terminal

M57 9

M281 9Existed

1, 2, 3, 4, 5, 8, 10, 12 Not existed

10 8Existed

1, 2, 3, 4, 5, 9, 10, 12 Not existed

Shift position switch harness connector Condition Status

Te r m i n a l

+ (fuse) −

110 Apply 12 V direct current between

terminals 1 and 10.

“M” mode indicato

r lamp turns on.

2

12Apply 12 V direct current between

terminals 2 and 12.

“P” position indicator lamp turns on.

3 Apply 12 V direct current between

terminals 3 and 12. “R” position indica

tor lamp turns on.

4 Apply 12 V direct current between

terminals 4 and 12.

“D” position indica

tor lamp turns on.

5 Apply 12 V direct current between

terminals 5 and 12. “N” position indica

tor lamp turns on.

98 Apply 12 V direct current between

terminals 9 and 8. Illumination lamp turns on.

Revision: 2010 May2011 QX56

Page 5334 of 5598

![INFINITI QX56 2011 Factory Service Manual

TM-246

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

13. Set the clutch spring compressor (SST: KV31102400) on

reverse brake spring retainer and install snap ring (fixing spri INFINITI QX56 2011 Factory Service Manual

TM-246

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

13. Set the clutch spring compressor (SST: KV31102400) on

reverse brake spring retainer and install snap ring (fixing spri](/img/42/57033/w960_57033-5333.png)

TM-246

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

13. Set the clutch spring compressor (SST: KV31102400) on

reverse brake spring retainer and install snap ring (fixing spring

retainer) in transmission case while compressing return spring.

CAUTION:

Securely assemble them using a flat-bladed screwdriverso that snap ring te nsion is slightly weak.

Be careful not to damage snap ring.

14. Install reverse brake drive plates, driven plates, dish plates and retaining plate in transmission case.

CAUTION:

Check order of plates.

15. Assemble N-spring.

16. Install reverse brake retaining plate in transmission case.

SCIA6700E

1: Snap ring

2 : Retaining plate

3 : Drive plate (eight pieces)

4 : Driven plate (eight pieces)

5: Dish plate

6: Dish plate

JSDIA1858ZZ

SCIA5249E

Revision: 2010 May2011 QX56

Page 5405 of 5598

WCS

WCS-1

DRIVER INFORMATION & MULTIMEDIA

C

DE

F

G H

I

J

K L

M B

SECTION WCS

A

O P

CONTENTS

WARNING CHIME SYSTEM

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

SYSTEM DESCRIPTION ..............................4

COMPONENT PARTS ................................... .....4

Component Parts Location .................................. ......4

Component Description .............................................4

Combination Meter ....................................................5

SYSTEM ..............................................................6

WARNING CHIME SYSTEM .......................................6

WARNING CHIME SYSTEM : System Diagram . ......6

WARNING CHIME SYSTEM : System Description

......

6

WARNING CHIME SYSTEM : Fail-Safe ...................7

LIGHT REMINDER WARNING CHIME ................. ......8

LIGHT REMINDER WARNING CHIME : System

Diagram .....................................................................

8

LIGHT REMINDER WARNING CHIME : System

Description ................................................................

8

FRONT FOG LIGHT REMINDER WARNING

CHIME .................................................................... ......

9

FRONT FOG LIGHT REMINDER WARNING

CHIME : System Diagram .......................................

10

FRONT FOG LIGHT REMINDER WARNING

CHIME : System Description ...................................

10

SEAT BELT WARNING CHIME ............................ ....10

SEAT BELT WARNING CHIME : System Diagram

....

11

SEAT BELT WARNING CHIME : System Descrip-

tion ...................................................................... ....

11

PARKING BRAKE RELEASE WARNING CHIME ....12

PARKING BRAKE RELEASE WARNING CHIME

: System Diagram ................................................ ....

12

PARKING BRAKE RELEASE WARNING CHIME

: System Description ................................................

12

DIAGNOSIS SYSTEM (COMBINATION

METER) .............................................................

14

CONSULT-III Function ............................................14

DIAGNOSIS SYSTEM (BCM) ...........................19

COMMON ITEM ..................................................... ....19

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

19

BUZZER ................................................................. ....20

BUZZER : CONSULT-III Function (BCM - BUZZ-

ER) ..........................................................................

20

ECU DIAGNOSIS INFORMATION ..............22

COMBINATION METER ...................................22

Reference Value .................................................. ....22

Fail-Safe ..................................................................29

DTC Index ...............................................................30

BCM (BODY CONTROL MODULE) .................31

List of ECU Reference .............................................31

WIRING DIAGRAM ......................................32

WARNING CHIME SYSTEM .............................32

Wiring Diagram .................................................... ....32

BASIC INSPECTION ...................................37

DIAGNOSIS AND REPAIR WORKFLOW ........37

Work Flow ............................................................ ....37

DTC/CIRCUIT DIAGNOSIS .........................39

POWER SUPPLY AND GROUND CIRCUIT ....39

COMBINATION METER ........................................ ....39

Revision: 2010 May2011 QX56

Page 5406 of 5598

WCS-2

COMBINATION METER : Diagnosis Procedure ....39

METER BUZZER CIRCUIT ................................40

Component Function Check ................................ ...40

Diagnosis Procedure .............................................40

SEAT BELT BUCKLE SWITCH SIGNAL CIR-

CUIT ...................................................................

41

Component Function Check .............................. ...41

Diagnosis Procedure .............................................41

Component Inspection ............................................42

PARKING BRAKE SWITCH SIGNAL CIR-

CUIT ...................................................................

43

Diagnosis Procedure ........................................... ...43

Component Inspection ............................................43

SYMPTOM DIAGNOSIS ............................44

THE LIGHT REMINDER WARNING DOES

NOT SOUND ................................................... ...

44

Description ........................................................... ...44

Diagnosis Procedure ...............................................44

THE SEAT BELT WARNING CONTINUES

SOUNDING, OR DOES NOT SOUND ...............

45

Description ........................................................... ...45

Diagnosis Procedure ...............................................45

THE PARKING BRAKE RELEASE WARNING

CONTINUES SOUNDING, OR DOES NOT

SOUND ..............................................................

46

Description ........................................................... ...46

Diagnosis Procedure ...............................................46

Revision: 2010 May2011 QX56

Page 5410 of 5598

WCS-6

< SYSTEM DESCRIPTION >

SYSTEM

SYSTEM

WARNING CHIME SYSTEM

WARNING CHIME SYSTEM : System DiagramINFOID:0000000006222683

WARNING CHIME SYSTEM : System DescriptionINFOID:0000000006222684

COMBINATION METER

The combination meter sounds the alarm buzzer install ed in the combination meter when receiving the buzzer

output signal transmitted from each unit.

BCM

BCM receives signals from various units and transmits a buzzer output signal to the combination meter via

CAN communication if it judges that the warning buzzer should be activated.

WARNING CHIME FUNCTION LIST

JSNIA3116GB

Warning functions Out line Warning judgment unit Refer to

Light reminder warning chime The warning chime sounds when the ignition

s w i t c h i s i n O F F o r A C C p o s i t i o n w i t h t h e c o m -

bination switch (lighting switch) in the 1st or

2nd position and the driver side door open. BCMWCS-8,

"LIGHT RE-

MINDER

WARNING

CHIME : Sys-

tem Descrip-

tion"

Front fog light reminder warning chime

The warning chime sounds when the ignition

switch is turned to LOCK, OFF or ACC posi-

tion from ON position, with combination switch

(lighting switch) is in AUTO position and the

front fog lamp switch in ON position. BCMWCS-10,

"FRONT FOG

LIGHT RE-

MINDER

WARNING

CHIME : Sys-

tem Descrip-

tion"

Revision: 2010 May2011 QX56

Page 5412 of 5598

WCS-8

< SYSTEM DESCRIPTION >

SYSTEM

LIGHT REMINDER WARNING CHIME

LIGHT REMINDER WARNING CHIME : System DiagramINFOID:0000000006222543

LIGHT REMINDER WARNING CHIME : System DescriptionINFOID:0000000006222544

WARNING CHIME OPERATION CONDITIONS

If all of the following conditions are fulfilled.

WARNING CHIME CANCEL CONDITIONS

Warning lamp/indicator lampABS warning lamp

The lamp turns ON by suspending communication.

VDC warning lamp

Brake warning lamp

IBA OFF indicator lamp

4WD warning lamp

Malfunction indicator lamp

VDC OFF indicator lamp

CRUISE warning lamp

Low tire pressure warning lamp The lamp blinking caused by suspending communication.

High beam indicator lamp

The lamp turns OFF by suspending communication.

Turn signal indicator lamp

Tail lamp indicator lamp

A/T CHECK indicator lamp

Key warning lamp

ATP warning lamp

Lane departure warning lamp

LDP ON indicator lamp

CRUISE indicator lamp

Oil pressure warning lamp

SNOW mode indicator lamp

TOW mode indicator lamp

CK SUSP indicator lamp

BSW indicator lamp

Function Specifications

JSNIA2421GB

Operation conditions

Ignition switch OFF or ACC position

Combination switch (Lighting

switch) 1st or 2nd position

Driver door Open [front door switch (driver side) ON]

Revision: 2010 May2011 QX56

Page 5413 of 5598

WCS

SYSTEMWCS-9

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

Warning is canceled if any of t he following conditions is fulfilled.

SIGNAL PATH

1. BCM requires warning chime output to combination meter when it judges light reminder warning chime is

necessary from signals below.

2. Combination meter sounds integrated buzzer, followi ng the warning chime output requirement (below sig-

nal) from BCM.

TIMING CHART

FRONT FOG LIGHT REMINDER WARNING CHIME

Operation conditions

Ignition switch ON

Combination switch (Lighting

switch) OFF or AUTO position

Driver door Close [front door switch (driver side) OFF]

Signal name Signal path

Ignition switch signal —

Combination switch signal Combination switch (Lighting switch) BCM

Driver door switch signal Front door switch (driver side) BCM

Signal name Signal path

Buzzer output signal BCM Combination meter

JSNIA2426GB

Revision: 2010 May2011 QX56