Coil INFINITI QX56 2011 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2646 of 5598

EM-84

< REMOVAL AND INSTALLATION >

CAMSHAFT

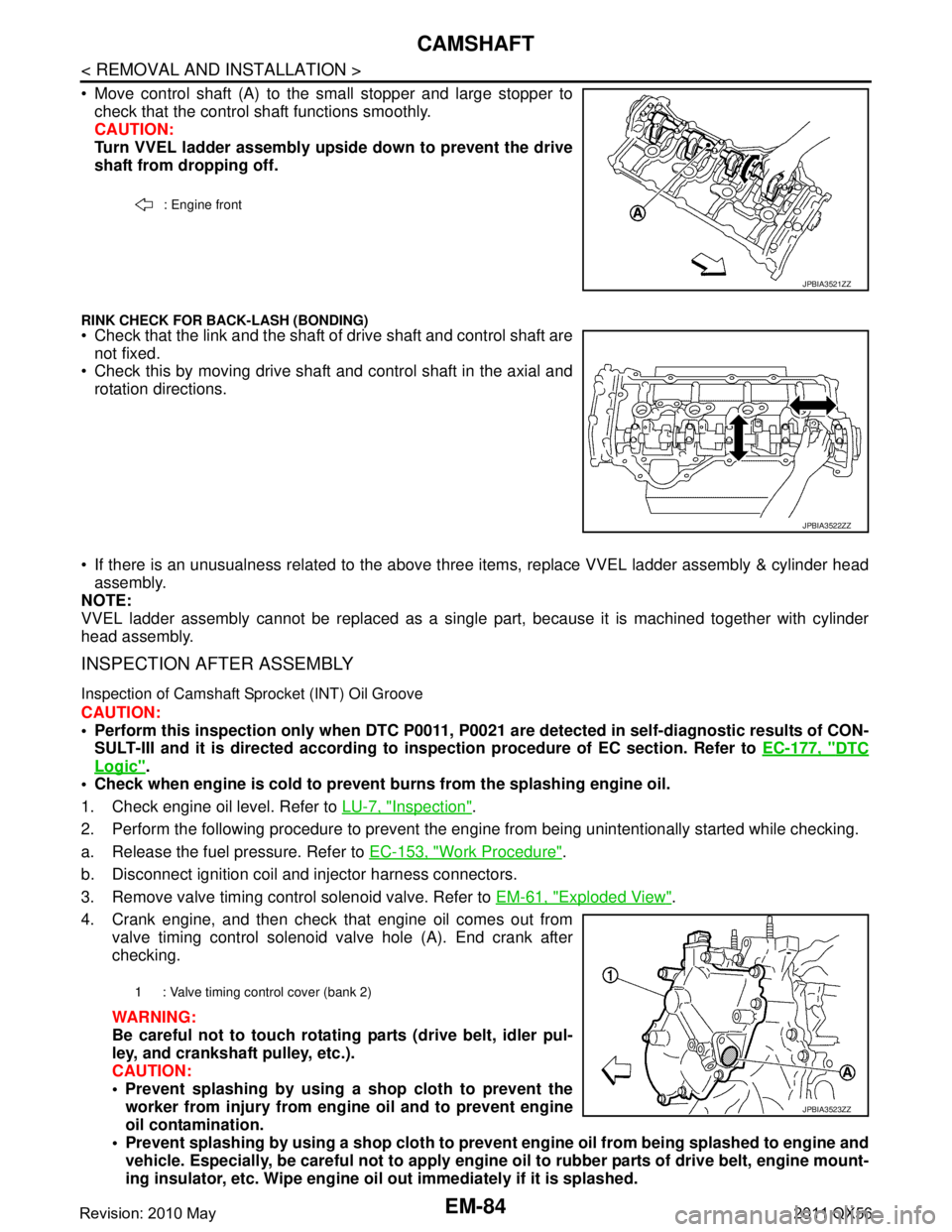

Move control shaft (A) to the small stopper and large stopper tocheck that the control shaft functions smoothly.

CAUTION:

Turn VVEL ladder assembly upside down to prevent the drive

shaft from dropping off.

RINK CHECK FOR BACK-LASH (BONDING) Check that the link and the shaft of drive shaft and control shaft are

not fixed.

Check this by moving drive shaft and control shaft in the axial and

rotation directions.

If there is an unusualness related to the above three items, replace VVEL ladder assembly & cylinder head

assembly.

NOTE:

VVEL ladder assembly cannot be replaced as a singl e part, because it is machined together with cylinder

head assembly.

INSPECTION AFTER ASSEMBLY

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

Perform this inspection only when DTC P0011, P 0021 are detected in self-diagnostic results of CON-

SULT-III and it is directed according to inspection procedure of EC section. Refer to EC-177, "

DTC

Logic".

Check when engine is cold to prevent burns from the splashing engine oil.

1. Check engine oil level. Refer to LU-7, "

Inspection".

2. Perform the following procedure to prevent the engine from being unintentionally started while checking.

a. Release the fuel pressure. Refer to EC-153, "

Work Procedure".

b. Disconnect ignition coil and injector harness connectors.

3. Remove valve timing control solenoid valve. Refer to EM-61, "

Exploded View".

4. Crank engine, and then check that engine oil comes out from valve timing control solenoid valve hole (A). End crank after

checking.

WARNING:

Be careful not to touch rotati ng parts (drive belt, idler pul-

ley, and crankshaft pulley, etc.).

CAUTION:

Prevent splashing by using a shop cloth to prevent the worker from injury from en gine oil and to prevent engine

oil contamination.

Prevent splashing by using a shop cloth to prevent engine oil from being splashed to engine and

vehicle. Especially, be careful not to apply engine oil to rubber parts of drive belt, engine mount-

ing insulator, etc. Wipe engine oil out immediately if it is splashed.

: Engine front

JPBIA3521ZZ

JPBIA3522ZZ

1 : Valve timing control cover (bank 2)

JPBIA3523ZZ

Revision: 2010 May2011 QX56

Page 2665 of 5598

ENGINE STAND SETTINGEM-103

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

UNIT DISASSEMBLY AND ASSEMBLY

ENGINE STAND SETTING

SettingINFOID:0000000006289579

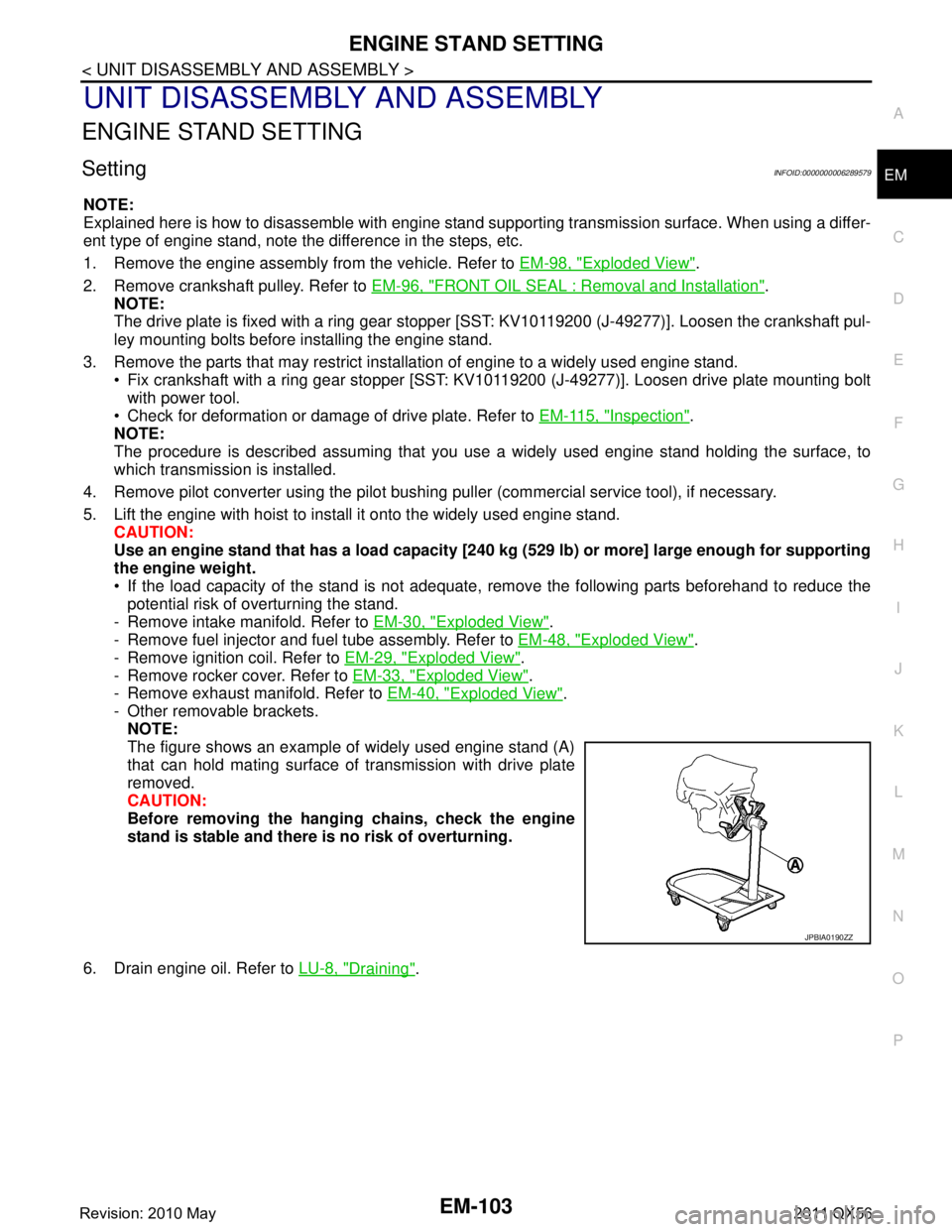

NOTE:

Explained here is how to disassemble with engine stand s

upporting transmission surface. When using a differ-

ent type of engine stand, note the difference in the steps, etc.

1. Remove the engine assembly from the vehicle. Refer to EM-98, "

Exploded View".

2. Remove crankshaft pulley. Refer to EM-96, "

FRONT OIL SEAL : Removal and Installation".

NOTE:

The drive plate is fixed with a ring gear stopper [SST: KV10119200 (J-49277)]. Loosen the crankshaft pul-

ley mounting bolts before installing the engine stand.

3. Remove the parts that may restrict installation of engine to a widely used engine stand. Fix crankshaft with a ring gear stopper [SST: KV10119200 (J-49277)]. Loosen drive plate mounting bolt

with power tool.

Check for deformation or damage of drive plate. Refer to EM-115, "

Inspection".

NOTE:

The procedure is described assuming that you us e a widely used engine stand holding the surface, to

which transmission is installed.

4. Remove pilot converter using the pilot bushing puller (commercial service tool), if necessary.

5. Lift the engine with hoist to inst all it onto the widely used engine stand.

CAUTION:

Use an engine stand that has a load capacity [240 kg (529 lb) or more] large enough for supporting

the engine weight.

If the load capacity of the stand is not adequate, remove the following parts beforehand to reduce the potential risk of overturning the stand.

- Remove intake manifold. Refer to EM-30, "

Exploded View".

- Remove fuel injector and fuel tube assembly. Refer to EM-48, "

Exploded View".

- Remove ignition coil. Refer to EM-29, "

Exploded View".

- Remove rocker cover. Refer to EM-33, "

Exploded View".

- Remove exhaust manifold. Refer to EM-40, "

Exploded View".

- Other removable brackets. NOTE:

The figure shows an example of widely used engine stand (A)

that can hold mating surface of transmission with drive plate

removed.

CAUTION:

Before removing the hang ing chains, check the engine

stand is stable and there is no risk of overturning.

6. Drain engine oil. Refer to LU-8, "

Draining".

JPBIA0190ZZ

Revision: 2010 May2011 QX56

Page 2667 of 5598

ENGINE UNITEM-105

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

ENGINE UNIT

DisassemblyINFOID:0000000006289580

1. Remove intake manifold. Refer to

EM-30, "Exploded View".

2. Remove exhaust manifold. Refer to EM-40, "

Exploded View".

3. Remove oil pan (lower). Refer to EM-54, "

Exploded View".

4. Remove ignition coil and spark plug. Refer to EM-23, "

Exploded View".

5. Remove rocker cover. Refer to EM-33, "

Exploded View".

6. Remove timing chain. Refer to EM-61, "

Exploded View".

7. Remove exhaust camshaft and VVEL ladder assembly. Refer to EM-74, "

Exploded View".

8. Remove cylinder head. Refer to EM-86, "

Exploded View".

AssemblyINFOID:0000000006289581

Assemble in the reverse order of disassembly.

Revision: 2010 May2011 QX56

Page 2719 of 5598

![INFINITI QX56 2011 Factory Owners Guide

COMPONENT PARTSEXL-9

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

FRONT COMBINATION LAMP : HID control unitINFOID:0000000006213890

Headlamp (LO) circuit is connected to HID c INFINITI QX56 2011 Factory Owners Guide

COMPONENT PARTSEXL-9

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

FRONT COMBINATION LAMP : HID control unitINFOID:0000000006213890

Headlamp (LO) circuit is connected to HID c](/img/42/57033/w960_57033-2718.png)

COMPONENT PARTSEXL-9

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

FRONT COMBINATION LAMP : HID control unitINFOID:0000000006213890

Headlamp (LO) circuit is connected to HID control unit integrated in the headlamp. Headlamp (LO) circuit turns

xenon headlamp ON.

For the details of HID control unit and the xenon headlamp, refer to EXL-8, "

FRONT COMBINATION LAMP :

Xenon Headlamp".

FRONT COMBINATION LAMP : High Beam SolenoidINFOID:0000000006213891

The high beam solenoid drives the mobile valve shade. And the mobile valve shade switches the high beam

and low beam of headlamp.

When the headlamp high relay is turned ON, magnetic force is applied to the high beam solenoid (1) by a current. The mobile

valve shade (2) is switched to the high beam position.

When the headlamp high relay is turned OFF, the current stops.

The mobile valve shade returns to the low beam position automati-

cally.

FRONT COMBINATION LAMP : Aiming MotorINFOID:0000000006213892

The headlamp levelizer adjusts the headlamp light axis upward and downward with the aiming motor inte-

grated in the front combination lamp.

FRONT COMBINATION LAMP : Swivel ActuatorINFOID:0000000006213893

SWIVEL ACTUATOR

The swivel actuator is installed in the headlamp unit. T he swivel actuator consists of the swivel motor and the

swivel position sensor.

SWIVEL MOTOR

The swivel motor is the two-phase step motor.

The swivel motor drives headlamp by exciting the two dr ive coils according to the drive signal from AFS con-

trol unit.

The rotation direction of the swivel motor is changeable by changing the exciting pattern.

SWIVEL POSITION SENSOR

The swivel position sensor detects the headlamp swivel angle to transmit t he swivel position sensor signal to

AFS control unit.

JSLIA0129ZZ

Revision: 2010 May2011 QX56

Page 2943 of 5598

FSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION FSU

A

B

FSU

N

O PCONTENTS

FRONT SUSPENSION

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

2

Precaution for Procedure without Cowl Top Cover ......3

Precautions for Suspension ......................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tools .......................................... ......4

Commercial Service Tools ........................................4

SYMPTOM DIAGNOSIS ...............................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

5

NVH Troubleshooting Chart ................................ ......5

PERIODIC MAINTENANCE ..........................6

FRONT SUSPENSION ASSEMBLY .............. .....6

Inspection ............................................................ ......6

WHEEL ALIGNMENT ..........................................7

Inspection ............................................................ ......7

Adjustment ................................................................7

REMOVAL AND INSTALLATION ................9

FRONT COIL SPRING AND SHOCK AB-

SORBER ............................................................

9

Exploded View ..................................................... .....9

Removal and Installation .........................................10

Disassembly and Assembly .....................................11

Inspection and Adjustment ......................................12

Disposal ...................................................................13

LOWER LINK ....................................................14

Exploded View .........................................................14

Removal and Installation .........................................14

Inspection ................................................................15

UPPER LINK ......................... ............................17

Exploded View ..................................................... ....17

Removal and Installation .........................................17

Inspection ................................................................18

FRONT STABILIZER ........................................20

Exploded View .........................................................20

Removal and Installation .........................................20

Inspection ................................................................20

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

21

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

21

Wheel Alignment ................................................. ....21

Ball Joint ..................................................................21

Wheel Height ...........................................................21

Revision: 2010 May2011 QX56

Page 2946 of 5598

FSU-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000006225636

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolsINFOID:0000000006225637

Tool number

(Kent-Moore No.)

Tool name Description

ST35652000

( − )

Shock absorber attachment Disassembling and assembling shock

absorber

ST3127S000

(J-25765-A)

Preload gauge Measuring rotating torque of ball joint

ZZA0807D

ZZA0806D

Tool name

Description

Power tool Loosening bolts and nuts

Spring compressor Removing and installing coil spring

PBIC0190E

S-NT717

Revision: 2010 May2011 QX56

Page 2951 of 5598

FRONT COIL SPRING AND SHOCK ABSORBERFSU-9

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

REMOVAL AND INSTALLATION

FRONT COIL SPRING AND SHOCK ABSORBER

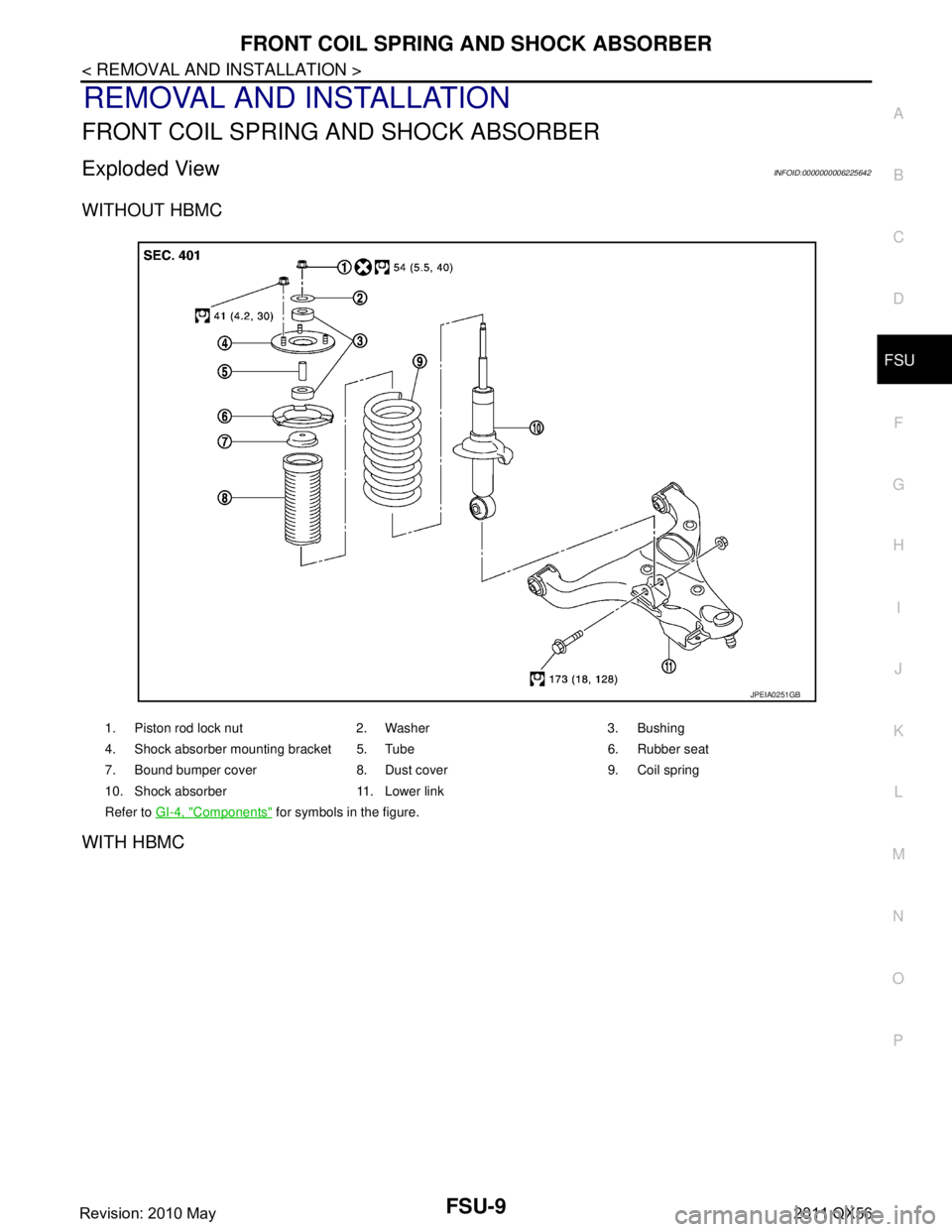

Exploded ViewINFOID:0000000006225642

WITHOUT HBMC

WITH HBMC

1. Piston rod lock nut 2. Washer 3. Bushing

4. Shock absorber mounting bracket 5. Tube 6. Rubber seat

7. Bound bumper cover 8. Dust cover 9. Coil spring

10. Shock absorber 11. Lower link

Refer to GI-4, "

Components" for symbols in the figure.

JPEIA0251GB

Revision: 2010 May2011 QX56

Page 2952 of 5598

FSU-10

< REMOVAL AND INSTALLATION >

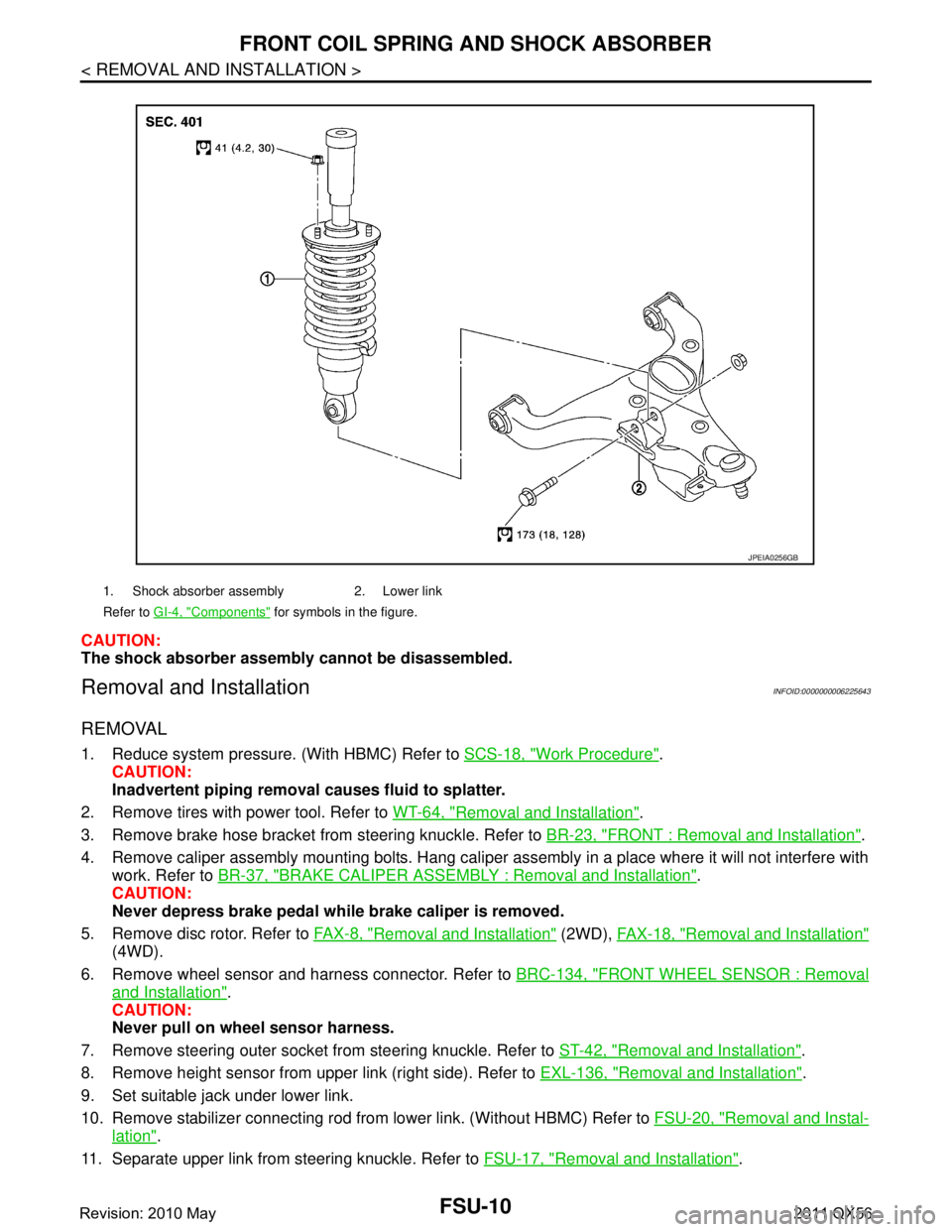

FRONT COIL SPRING AND SHOCK ABSORBER

CAUTION:

The shock absorber assembly cannot be disassembled.

Removal and InstallationINFOID:0000000006225643

REMOVAL

1. Reduce system pressure. (With HBMC) Refer to SCS-18, "Work Procedure".

CAUTION:

Inadvertent piping removal causes fluid to splatter.

2. Remove tires with power tool. Refer to WT-64, "

Removal and Installation".

3. Remove brake hose bracket from steering knuckle. Refer to BR-23, "

FRONT : Removal and Installation".

4. Remove caliper assembly mounting bolts. Hang caliper assembly in a place where it will not interfere with work. Refer to BR-37, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

CAUTION:

Never depress brake pedal while brake caliper is removed.

5. Remove disc rotor. Refer to FA X - 8 , "

Removal and Installation" (2WD), FAX-18, "Removal and Installation"

(4WD).

6. Remove wheel sensor and harness connector. Refer to BRC-134, "

FRONT WHEEL SENSOR : Removal

and Installation".

CAUTION:

Never pull on wheel sensor harness.

7. Remove steering outer socket fr om steering knuckle. Refer to ST-42, "

Removal and Installation".

8. Remove height sensor from upper link (right side). Refer to EXL-136, "

Removal and Installation".

9. Set suitable jack under lower link.

10. Remove stabilizer connecting rod from lower link. (Without HBMC) Refer to FSU-20, "

Removal and Instal-

lation".

11. Separate upper link from steering knuckle. Refer to FSU-17, "

Removal and Installation".

1. Shock absorber assembly 2. Lower link

Refer to GI-4, "

Components" for symbols in the figure.

JPEIA0256GB

Revision: 2010 May2011 QX56

Page 2953 of 5598

FRONT COIL SPRING AND SHOCK ABSORBERFSU-11

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

12. Separate drive shaft from steering knuckle. (4WD) Refer to FAX-22, "Removal and Installation".

13. Remove front tube assembly A and front tube asse mbly B from shock absorber. (With HBMC) Refer to

SCS-32, "

FRONT TUBE ASSEMBLY : Removal and Installation".

14. Remove shock absorber.

15. Perform inspection after removal. (With HBMC) Refer to FSU-12, "

Inspection and Adjustment".

INSTALLATION

Note the following, and install in the reverse order of removal.

Never tap on the ball joint cap of the stabilizer connecting rod with a hammer or a similar item when inserting

the stabilizer connecting rod into the lower link. (Without HBMC)

Perform final tightening of bolts and nuts at the shock absorber lower side (rubber bushing), under unladen

conditions with tires on level ground.

Perform inspection after installation. Refer to FSU-12, "

Inspection and Adjustment".

Perform adjustment after installation. (With HBMC) Refer to FSU-12, "

Inspection and Adjustment".

After replacing the shock absorber, always follow the disposal procedure to discard the shock absorber.

Refer to FSU-13, "

Disposal".

Disassembly and AssemblyINFOID:0000000006273960

CAUTION:

The shock absorber assembly can not be disassembled. (With HBMC)

DISASSEMBLY (WITHOUT HBMC)

CAUTION:

Never damage shock absorber piston rod wh en removing components from shock absorber.

1. Install shock absorber attachment [SST: ST35652000 ( −)]

(A) to shock absorber and secure it in a vise.

CAUTION:

When installing the shock ab sorber attachment to shock

absorber, wrap a shop cloth around shock absorber to pro-

tect it from damage.

2. Using a spring compressor (commercial service tool) (A), com- press coil spring between rubber seat and shock absorber until

coil spring with a spring compressor is free.

CAUTION:

Be sure a spring compresso r is securely attached coil

spring. Compress coil spring

3. Check coil spring with a spring compressor between rubber seat and shock absorber is free. And then remove piston rod lock nut

while securing the piston rod tip so that piston rod does not turn.

4. Remove washer, bushings, shock absorber mounting bracket, tube, rubber seat, bound bumper cover, dust cover from shock

absorber.

5. After removing coil spring with a spring compressor, then gradually release a spring compressor. CAUTION:

Loosen while making sure coil spri ng attachment position does not move.

6. Remove the shock absorber at tachment from shock absorber.

7. Perform inspection after disassembly. Refer to FSU-12, "

Inspection and Adjustment".

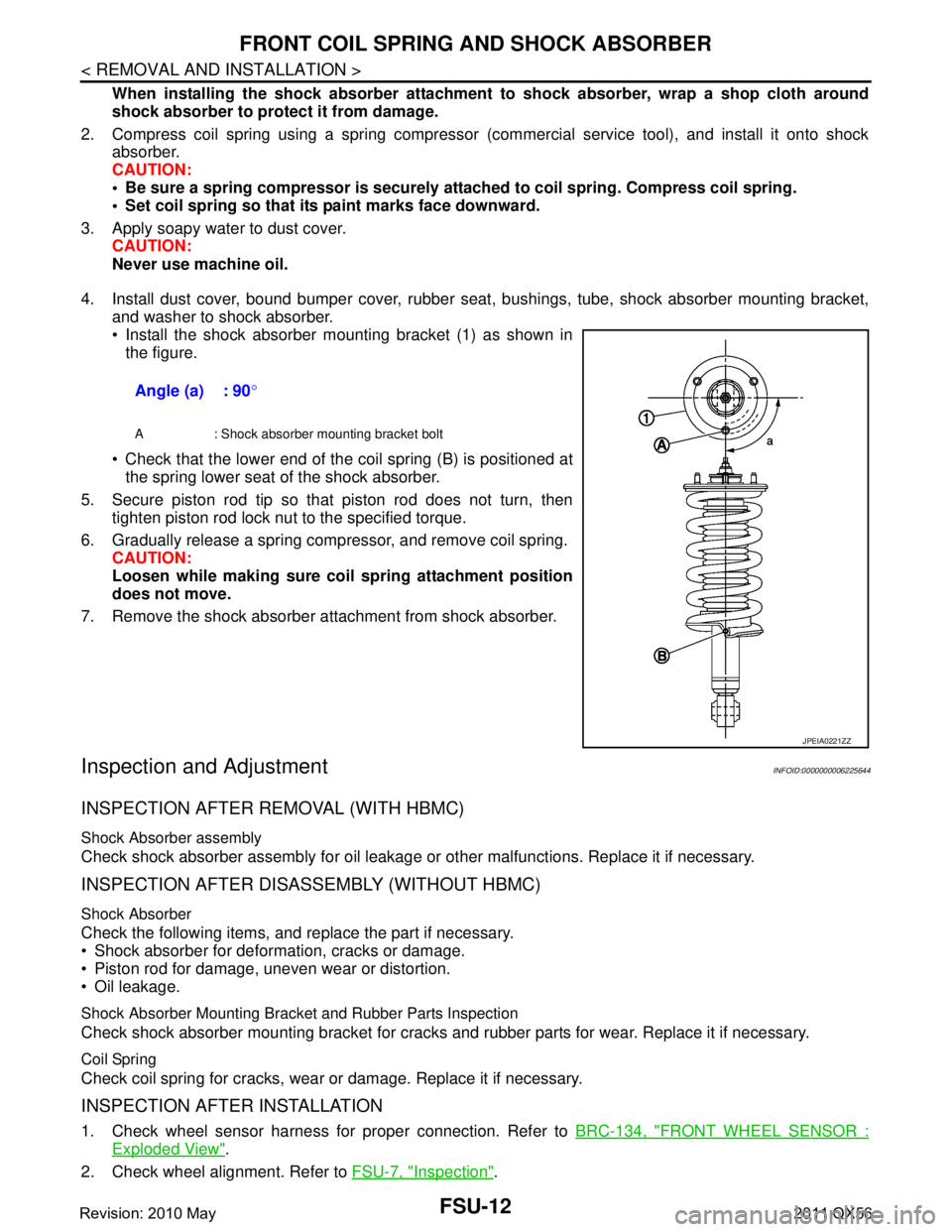

ASSEMBLY (WITHOUT HBMC)

1. Install shock absorber attachment [SST: ST35652000 ( −)] to shock absorber and secure it in a vise.

CAUTION:

JPEIA0006ZZ

JPEIA0168ZZ

Revision: 2010 May2011 QX56

Page 2954 of 5598

FSU-12

< REMOVAL AND INSTALLATION >

FRONT COIL SPRING AND SHOCK ABSORBER

When installing the shock absorber attachment to shock absorber, wrap a shop cloth around

shock absorber to protect it from damage.

2. Compress coil spring using a spring compressor (commercial service tool), and install it onto shock absorber.

CAUTION:

Be sure a spring compressor is securely attach ed to coil spring. Compress coil spring.

Set coil spring so that its paint marks face downward.

3. Apply soapy water to dust cover. CAUTION:

Never use machine oil.

4. Install dust cover, bound bumper cover, rubber seat , bushings, tube, shock absorber mounting bracket,

and washer to shock absorber.

Install the shock absorber mounting bracket (1) as shown in the figure.

Check that the lower end of the coil spring (B) is positioned at the spring lower seat of the shock absorber.

5. Secure piston rod tip so that piston rod does not turn, then tighten piston rod lock nut to the specified torque.

6. Gradually release a spring compressor, and remove coil spring. CAUTION:

Loosen while making sure co il spring attachment position

does not move.

7. Remove the shock absorber attachment from shock absorber.

Inspection and AdjustmentINFOID:0000000006225644

INSPECTION AFTER REMOVAL (WITH HBMC)

Shock Absorber assembly

Check shock absorber assembly for oil leakage or other malfunctions. Replace it if necessary.

INSPECTION AFTER DISASSEMBLY (WITHOUT HBMC)

Shock Absorber

Check the following items, and replace the part if necessary.

Shock absorber for deformation, cracks or damage.

Piston rod for damage, uneven wear or distortion.

Oil leakage.

Shock Absorber Mounting Bracket and Rubber Parts Inspection

Check shock absorber mounting bracket for cracks and rubber parts for wear. Replace it if necessary.

Coil Spring

Check coil spring for cracks, wear or damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness for proper connection. Refer to BRC-134, "FRONT WHEEL SENSOR :

Exploded View".

2. Check wheel alignment. Refer to FSU-7, "

Inspection".

Angle (a) : 90

°

A : Shock absorber mounting bracket bolt

JPEIA0221ZZ

Revision: 2010 May2011 QX56