Coil INFINITI QX56 2011 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2955 of 5598

FRONT COIL SPRING AND SHOCK ABSORBERFSU-13

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

3. Adjust neutral position of steering angle sensor. Refer to BRC-64, "Work Procedure".

4. Adjust levelizer adjustment of height sensor. Refer to EXL-61, "

LEVELIZER ADJUSTMENT : Special

Repair Requirement".

ADJUSTMENT AFTER INSTALLATION (WITH HBMC)

Bleed air from the HBMC. Refer to SCS-18, "Work Procedure".

DisposalINFOID:0000000006225645

WITHOUT HBMC

1. Set shock absorber horizontally with the piston rod fully extended.

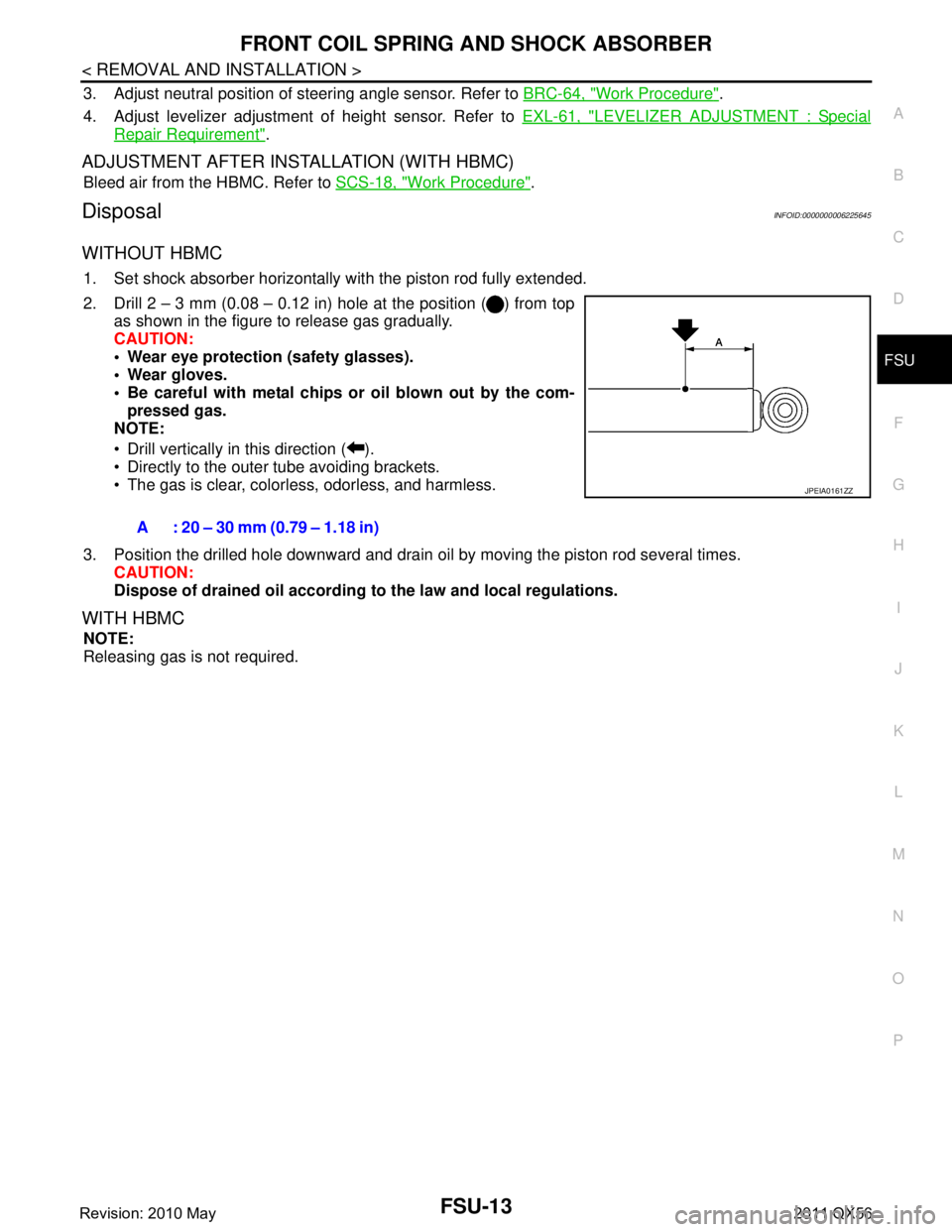

2. Drill 2 – 3 mm (0.08 – 0.12 in) hole at the position ( ) from top

as shown in the figure to release gas gradually.

CAUTION:

Wear eye protection (safety glasses).

Wear gloves.

Be careful with metal chips or oil blown out by the com-

pressed gas.

NOTE:

Drill vertically in this direction ( ).

Directly to the outer tube avoiding brackets.

The gas is clear, colorless, odorless, and harmless.

3. Position the drilled hole downward and drain oil by moving the piston rod several times. CAUTION:

Dispose of drained oil according to the law and local regulations.

WITH HBMC

NOTE:

Releasing gas is not required.A : 20 – 30 mm (0.79 – 1.18 in)

JPEIA0161ZZ

Revision: 2010 May2011 QX56

Page 3086 of 5598

HA-30

< REMOVAL AND INSTALLATION >

COMPRESSOR

REMOVAL AND INSTALLATION

COMPRESSOR

Exploded ViewINFOID:0000000006276162

REMOVAL

DISASSEMBLY

COMPRESSOR

COMPRESSOR : Removal and InstallationINFOID:0000000006276163

CAUTION:

1. High-pressure flexible hose 2. O-ring 3. Compressor

4. Low-pressure flexible hose

A. To condenser B. To evaporator

Refer to GI-4, "

Components" for symbols in the figure.

JMIIA0622GB

1. Clutch disc 2. Shim 3. Snap ring

4. Pulley assembly 5. Field coil 6. Compressor unit

Refer to GI-4, "

Components" for symbols in the figure.

JMIIA0805GB

Revision: 2010 May2011 QX56

Page 3088 of 5598

HA-32

< REMOVAL AND INSTALLATION >

COMPRESSOR

2. Remove center bolt, and then remove clutch disc.

3. Remove snap ring using external snap ring pliers.

4. Position center pulley puller on the end of the drive shaft, and remove pulley assembly using any commer-

cially available pulley puller.

To prevent pulley groove from being deformed, pulle r claws should be positioned into the edge of the pul-

ley assembly.

5. Disconnect field coil harness from compressor unit.

6. Remove screws, and then remove field coil.

INSTALLATION

1. Install field coil (1). Be sure to align the coil’s pin (2) with the hole in the compres-

sor’s front head.

2. Connect field coil harness to compressor unit.

3. Install pulley assembly (1) using installer (SST: J-41260) (A) and a hand press, and then install snap ring (2) using snap ring pli-

ers.

4. Install clutch disc on drive shaft, together with original shim(s). Press clutch disc down by hand.

5. Using holder to prevent clutch disc rotation. After tightening the bolt, check that the pulley rotates smoothly.

Break-in Operation

When replacing compressor clutch assembly, always carry out the break-in operation. This is done by engag-

ing and disengaging the clutch about thirty-times. Break-i n operation raises the level of transmitted torque.

InspectionINFOID:0000000006276165

CHECK DISC TO PULLEY CLEARANCE

Check the clearance (B) between pulley assembly (1) and clutch

disc (2) along the entire periphery with a feeler gauge (A).

Replace compressor if specified clearance is not obtained.

JMIIA0575ZZ

JMIIA0576ZZ

Clearance : Refer to HA-50, "Compressor".

JPIIA1566ZZ

Revision: 2010 May2011 QX56

Page 3118 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

HAC-12

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

COMPONENT PARTS

Aspirator

INFOID:0000000006275856

The aspirator generates the vacuum by the air blown from the heater

& cooling unit and draw INFINITI QX56 2011 Factory Workshop Manual

HAC-12

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

COMPONENT PARTS

Aspirator

INFOID:0000000006275856

The aspirator generates the vacuum by the air blown from the heater

& cooling unit and draw](/img/42/57033/w960_57033-3117.png)

HAC-12

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

COMPONENT PARTS

Aspirator

INFOID:0000000006275856

The aspirator generates the vacuum by the air blown from the heater

& cooling unit and draws the air of the passenger room to the front

in-vehicle sensor area via the aspirator duct.

Front Blower MotorINFOID:0000000006275857

The front blower motor utilizes a brush-less motor with a rotating

magnet. Quietness is improved comparing to a conventional motor

(brush motor) that rotates coil while brush functions as contact

points.

Front display Front display indicates operation status of ACCS (advanced climate control

system).

Heater & cooling unit as-

sembly Ionizer Ionizer generates an approximately equal proportional amount of positive

and negative ions in the air.

Preset switch Preset switch is integrated with front A/C control and AV operation switch.

Front A/C control operation signal is transmitted from preset switch to AV

control unit via communication line.

Component Description

RJIA1804E

RJIA2467J

ZHA152H

Revision: 2010 May2011 QX56

Page 3119 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

COMPONENT PARTSHAC-13

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Rear Blower MotorINFOID:0000000006275858

The rear blower motor utilizes a brush-less motor INFINITI QX56 2011 Factory Workshop Manual

COMPONENT PARTSHAC-13

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Rear Blower MotorINFOID:0000000006275858

The rear blower motor utilizes a brush-less motor](/img/42/57033/w960_57033-3118.png)

COMPONENT PARTSHAC-13

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Rear Blower MotorINFOID:0000000006275858

The rear blower motor utilizes a brush-less motor with a rotating

magnet. Quietness is improved comp aring to a conventional motor

(brush motor) that rotates coil while brush functions as contact

points.

Refrigerant Pressure SensorINFOID:0000000006275859

Description

Refrigerant pressure sensor is installed to upper porti on of liquid tank. The refrigerant pressure sensor con-

verts high-pressure side refrigerant pressure into vo ltage and outputs it to ECM. ECM operates cooling system

protection and idle speed control according to voltage value that is input.

Structure and operation

The refrigerant pressure sensor is a capacitance type sensor. It consists of a pressure detection area and a

signal processing area. The pressure detection area, wh ich is a variable capacity condenser, changes internal

static capacitance according to pressure force. The signal processing area detects the static capacitance of

the pressure detection area, converts the static capacitance into a voltage value, and transmits the voltage

value to ECM.

RJIA2467J

ZHA152H

PBIB2657E

Revision: 2010 May2011 QX56

Page 3689 of 5598

ENGINE MAINTENANCEMA-19

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

SPARK PLUG : Removal and InstallationINFOID:0000000006394839

REMOVAL

1. Remove engine cover. Refer to

EM-25, "Exploded View".

2. Remove ignition coil. Refer to EM-29, "

Exploded View".

3. Remove spark plug with a spark plug wrench (commercial ser- vice tool).

INSTALLATION

Note the following item, installa is the reverse order of removal.

CAUTION:

Install ignition coil marked wi th an identification mark (A) on

cylinder No. 5, 6, 7 and 8.

SPARK PLUG : InspectionINFOID:0000000006394840

INSPECTION AFTER REMOVAL

Use the standard type spark plug for normal condition.

CAUTION:

Never drop or impact spark plug.

Never use a wire brush for cleaning.

If plug tip is covered with carbon, use spark plug cleaner to

clean.

Measure spark plug gap. When it exceeds the limit, replace spark plug even if it is within the speci-

fied replacement mileage. Refer to EM-132, "

Spark Plug".

a : 14 mm (0.55 in)

JPBIA0030ZZ

: Engine front

JPBIA3471ZZ

Spark plug (Standard type) : Refer to EM-132, "Spark Plug".

Cleaner air pressure : Less than 588 kPa (5.9 bar, 6 kg/cm

2, 85 psi)

Cleaning time

: Less than 20 seconds

SMA773C

Revision: 2010 May2011 QX56

Page 3848 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

PCS

SYSTEMPCS-7

< SYSTEM DESCRIPTION > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/R monitors the voltage at the contact circuit and

excitation co INFINITI QX56 2011 Factory Workshop Manual

PCS

SYSTEMPCS-7

< SYSTEM DESCRIPTION > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/R monitors the voltage at the contact circuit and

excitation co](/img/42/57033/w960_57033-3847.png)

PCS

SYSTEMPCS-7

< SYSTEM DESCRIPTION > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/R monitors the voltage at the contact circuit and

excitation coil circuit of the ignition relay inside it.

IPDM E/R judges the ignition relay error if the volt age differs between the contact circuit and the excitation

coil circuit.

If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to alert the user to the ignition relay malfunc tion when the ignition switch is turned OFF.

FRONT WIPER PROTECTION FUNCTION

IPDM E/R detects front wiper stop position by a front wiper stop position signal.

When a front wiper stop position signal is in the conditi ons listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 seconds activation and 20 seconds stop.

NOTE:

This operation status can be confirmed on the IPDM E/ R “Data Monitor” that displays “BLOCK” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains

active for 90 seconds.

POWER CONTROL SYSTEM

Control part Fail-safe operation

Headlamp Turns ON the headlamp low relay when the ignition switch is turned ON

Turns OFF the headlamp low relay when the ignition switch is turned OFF

Headlamp high relay OFF

Parking lamp

License plate lamp

Illumination

Tail lamp Turns ON the tail lamp relay when the ignition switch is turned ON

Turns OFF the tail lamp relay when the ignition switch is turned OFF

Front wiper motor The status just before activation of fail-safe control is maintained until the ignition switch is

turned OFF while the front wiper is operating at LO or HI speed.

The wiper is operated at LO speed until the ignition switch is turned OFF if the fail-safe con- trol is activated while the front wiper is set in the INT mode and the front wiper motor is op-

erating.

Return automatically wiper to stop position when ignition switch is turned ON if fail-safe con- trol is activated while front wiper motor is operated and wiper stops in the other position than

stop position.

Front fog lamp Front fog lamp relay OFF

Horn Horn OFF

Ignition relay The status just before activation of fail-safe is maintained.

Starter motor Starter control relay OFF

Steering lock unit Steering lock relay OFF

Voltage judgment IPDM E/R judgment Operation

Ignition relay contact side Ignition relay excitation coil

side

ON ON Ignition relay ON normal —

OFF OFF Ignition relay OFF normal —

ON OFF Ignition relay ON stuck Detects DTC “B2098: IGN RELAY ON”

Turns ON the tail lamp relay for 10 min-

utes

OFF ON Ignition relay OFF stuck Detects DTC “B2099: IGN RELAY OFF”

Ignition switch Front wiper switch Front wiper stop position signal

ON OFF

The front wiper stop position signal (stop position) cannot be input for

10 seconds.

ON The front wiper stop position signal does not change for 10 seconds.

Revision: 2010 May2011 QX56

Page 3863 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

PCS-22

< ECU DIAGNOSIS INFORMATION >[IPDM E/R]

IPDM E/R

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/R monitors the voltage at the contact circuit and

excitation coil circuit of the igniti INFINITI QX56 2011 Factory Workshop Manual

PCS-22

< ECU DIAGNOSIS INFORMATION >[IPDM E/R]

IPDM E/R

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/R monitors the voltage at the contact circuit and

excitation coil circuit of the igniti](/img/42/57033/w960_57033-3862.png)

PCS-22

< ECU DIAGNOSIS INFORMATION >[IPDM E/R]

IPDM E/R

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/R monitors the voltage at the contact circuit and

excitation coil circuit of the ignition relay inside it.

IPDM E/R judges the ignition relay error if the volt age differs between the contact circuit and the excitation

coil circuit.

If the ignition relay cannot turn OFF due to contact seiz ure, it activates the tail lamp relay for 10 minutes to

alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

FRONT WIPER PROTECTION FUNCTION

IPDM E/R detects front wiper stop positi on by a front wiper stop position signal.

When a front wiper stop position signal is in the conditi ons listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 seconds activation and 20 seconds stop.

NOTE:

This operation status can be confirmed on the IPDM E/ R “Data Monitor” that displays “BLOCK” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains

active for 90 seconds.

DTC IndexINFOID:0000000006220174

NOTE:

The details of time display are as follows.

- CRNT: A malfunction is detected now.

- PAST: A malfunction was detected in the past.

IGN counter is displayed on FFD (Freeze Frame data).

- The number is 0 when is detected now.

- The number increases like 1 → 2 ··· 38 → 39 after returning to the normal condition whenever IGN OFF →

ON.

- The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

× : Applicable

Ignition relay The status just before activation of fail-safe is maintained.

Starter motor Starter control relay OFF

Steering lock unit Steering lock relay OFF Control part Fail-safe operation

Voltage judgment

IPDM E/R judgment Operation

Ignition relay contact side Ignition relay excitation coil

side

ON ON Ignition re lay ON normal —

OFF OFF Ignition relay OFF normal —

ON OFF Ignition relay ON stuck Detects DTC “B2098: IGN RELAY ON”

Turns ON the tail lamp relay for 10 min-

utes

OFF ON Ignition relay OFF stuck Detects DTC “B2099: IGN RELAY OFF”

Ignition switch Front wiper switch Front wiper stop position signal

ON OFF

The front wiper stop position signal (stop position) cannot be input for

10 seconds.

ON The front wiper stop position signal does not change for 10 seconds.

CONSULT display Fail-safe Refer to

No DTC is detected.

further testing

may be required. ——

U1000: CAN COMM CIRCUIT ×PCS-28

B2098: IGN RELAY ON ×PCS-29

Revision: 2010 May2011 QX56

Page 3870 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

PCS

B2098 IGNITION RELAY ON STUCKPCS-29

< DTC/CIRCUIT DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

B2098 IGNITION RELAY ON STUCK

DescriptionINFOID:0000000006220179

IPDM E/R operates the ign INFINITI QX56 2011 Factory Workshop Manual

PCS

B2098 IGNITION RELAY ON STUCKPCS-29

< DTC/CIRCUIT DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

B2098 IGNITION RELAY ON STUCK

DescriptionINFOID:0000000006220179

IPDM E/R operates the ign](/img/42/57033/w960_57033-3869.png)

PCS

B2098 IGNITION RELAY ON STUCKPCS-29

< DTC/CIRCUIT DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

B2098 IGNITION RELAY ON STUCK

DescriptionINFOID:0000000006220179

IPDM E/R operates the ignition relay when it receives

an ignition switch ON signal from BCM via CAN com-

munication.

Turn the ignition relay OFF by pressing the push-butt on ignition switch once when the vehicle speed is 4 km/

h (2.5 MPH) or less.

Turn the ignition relay OFF with the following operat ion when the vehicle speed is more than 4 km/h (2.5

MPH) or when an abnormal condition occurs in CAN communication from the combination meter (Emer-

gency OFF)

- Press and hold the push-button ignition switch for 2 seconds or more.

- Press the push-button ignition switch 3 times within 1.5 seconds.

NOTE:

The ignition relay does not turn ON for 3 seconds af ter emergency OFF even if the push-button ignition switch

is pressed.

DTC LogicINFOID:0000000006220180

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000006220181

1.PERFORM SELF DIAGNOSIS

1. Turn the ignition switch ON.

2. Erase “Self Diagnostic Result” of IPDM E/R.

3. Turn the ignition switch OFF, and wait for 1 second or more.

4. Turn the ignition switch ON. Check “Self Diagnostic Result” again.

Is DTC

“B2098” displayed?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> Refer to GI-40, "

Intermittent Incident".

DTCCONSULT-III dis-

play description DTC Detection Condit

ion Possible causes

B2098 IGN RELAY ON The ignition relay ON is detected for 1 second at ignition switch OFF

(CPU monitors the status at the contact and excitation coil circuits

of the ignition relay inside it) Ignition relay malfunction

Revision: 2010 May2011 QX56

Page 3871 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

PCS-30

< DTC/CIRCUIT DIAGNOSIS >[IPDM E/R]

B2099 IGNITION RELAY OFF STUCK

B2099 IGNITION RELAY OFF STUCK

DescriptionINFOID:0000000006220182

IPDM E/R operates the ignition relay when it receives

an INFINITI QX56 2011 Factory Workshop Manual

PCS-30

< DTC/CIRCUIT DIAGNOSIS >[IPDM E/R]

B2099 IGNITION RELAY OFF STUCK

B2099 IGNITION RELAY OFF STUCK

DescriptionINFOID:0000000006220182

IPDM E/R operates the ignition relay when it receives

an](/img/42/57033/w960_57033-3870.png)

PCS-30

< DTC/CIRCUIT DIAGNOSIS >[IPDM E/R]

B2099 IGNITION RELAY OFF STUCK

B2099 IGNITION RELAY OFF STUCK

DescriptionINFOID:0000000006220182

IPDM E/R operates the ignition relay when it receives

an ignition switch ON signal from BCM via CAN com-

munication.

Turn the ignition relay OFF by pressing the push-butt on ignition switch once when the vehicle speed is 4 km/

h (2.5 MPH) or less.

Turn the ignition relay OFF with the following operati on when the vehicle speed is more than 4 km/h (2.5

MPH) or when an abnormal condition occurs in CAN communication from the combination meter (Emer-

gency OFF)

- Press and hold the push-button ignition switch for 2 seconds or more.

- Press the push-button ignition switch 3 times within 1.5 seconds.

NOTE:

The ignition relay does not turn ON for 3 seconds af ter emergency OFF even if the push-button ignition switch

is pressed.

DTC LogicINFOID:0000000006220183

DTC DETECTION LOGIC

NOTE:

When IPDM E/R power supply voltage is low (Approx. 7 - 8 V for about 1 second), the “DTC: B2099” may be detected.

Diagnosis ProcedureINFOID:0000000006220184

1.PERFORM SELF DIAGNOSIS

1. Turn the ignition switch ON.

2. Erase “Self Diagnostic Result”.

3. Turn the ignition switch OFF.

4. Turn the ignition switch ON. Check “Self Diagnostic Result” again.

Is DTC

“B2099” displayed?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> Refer to GI-40, "

Intermittent Incident".

DTCCONSULT-III dis-

play description DTC Detection Condit

ion Possible causes

B2099 IGN RELAY OFF The ignition relay OFF is detected for 1 second at ignition switch ON

(CPU monitors the status at the contact and excitation coil circuits of

the ignition relay inside it) Ignition relay malfunction

Revision: 2010 May2011 QX56