rsu INFINITI QX56 2011 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4272 of 5598

REAR STABILIZERRSU-17

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

REAR STABILIZER

Exploded ViewINFOID:0000000006270956

Removal and InstallationINFOID:0000000006270957

REMOVAL

1. Remove stabilizer connecting rods.

2. Remove stabilizer clamps and stabilizer bushings.

3. Remove stabilizer bar.

4. Perform inspection after removal. Refer to RSU-17, "

Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

Tighten the mounting nut to the specified torque wh ile holding a hexagonal part of stabilizer connecting rod

side.

InspectionINFOID:0000000006270958

INSPECTION AFTER REMOVAL

Check stabilizer bar, stabilizer connecting rod, stabiliz er bushing and stabilizer clamp for deformation, cracks

or damage. Replace it if necessary.

1. Stabilizer bar 2. Stabilizer bushing 3. Stabilizer clamp

4. Stabilizer connecting rod 5. Front lower link

Refer to GI-4, "

Components" for symbols in the figure.

JPEIB0249GB

Revision: 2010 May2011 QX56

Page 4273 of 5598

RSU-18

< UNIT REMOVAL AND INSTALLATION >

REAR SUSPENSION MEMBER

UNIT REMOVAL AND INSTALLATION

REAR SUSPENSION MEMBER

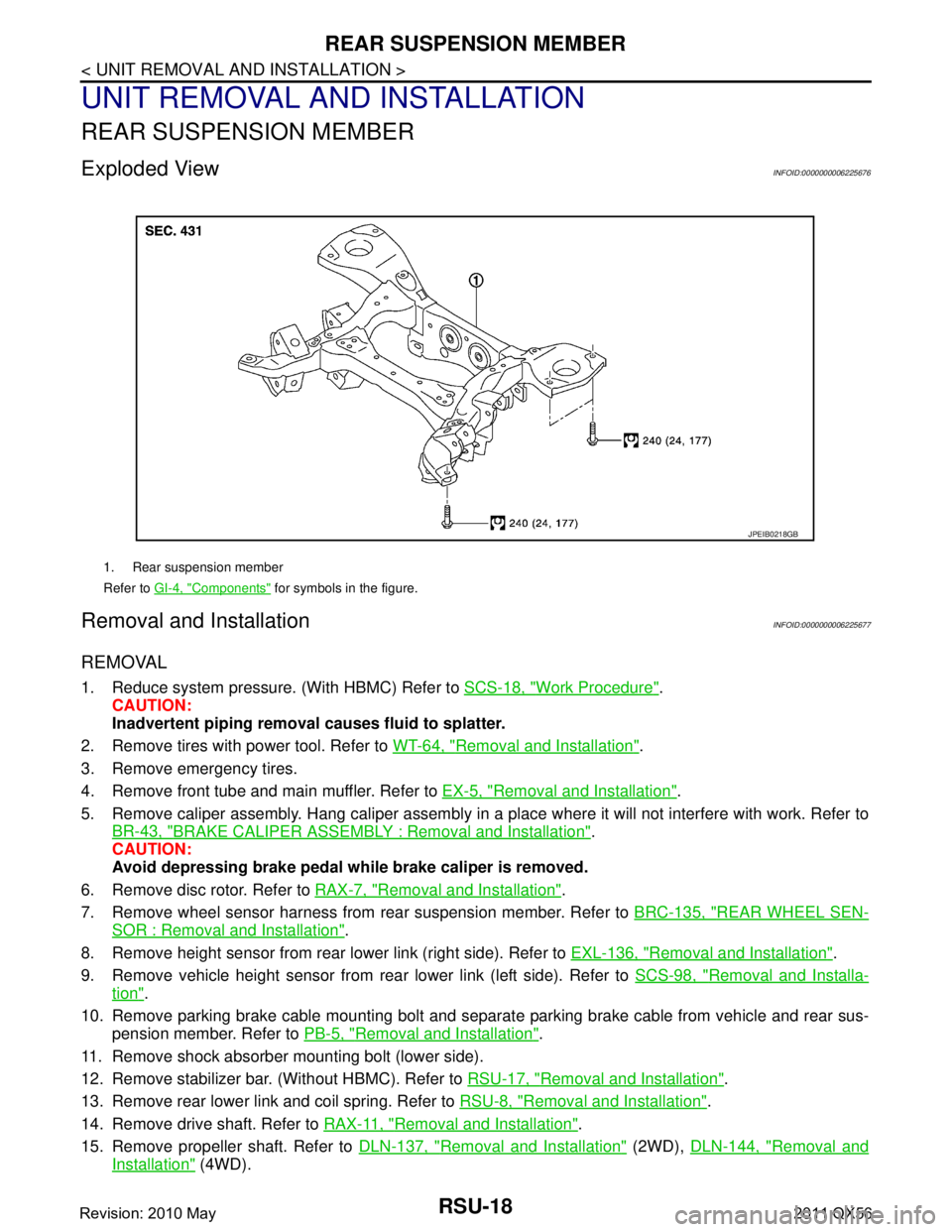

Exploded ViewINFOID:0000000006225676

Removal and InstallationINFOID:0000000006225677

REMOVAL

1. Reduce system pressure. (With HBMC) Refer to SCS-18, "Work Procedure".

CAUTION:

Inadvertent piping removal causes fluid to splatter.

2. Remove tires with power tool. Refer to WT-64, "

Removal and Installation".

3. Remove emergency tires.

4. Remove front tube and main muffler. Refer to EX-5, "

Removal and Installation".

5. Remove caliper assembly. Hang caliper assembly in a place where it will not interfere with work. Refer to BR-43, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

CAUTION:

Avoid depressing brake pedal wh ile brake caliper is removed.

6. Remove disc rotor. Refer to RAX-7, "

Removal and Installation".

7. Remove wheel sensor harness from rear suspension member. Refer to BRC-135, "

REAR WHEEL SEN-

SOR : Removal and Installation".

8. Remove height sensor from rear lower link (right side). Refer to EXL-136, "

Removal and Installation".

9. Remove vehicle height sensor from rear lower link (left side). Refer to SCS-98, "

Removal and Installa-

tion".

10. Remove parking brake cable mounting bolt and separa te parking brake cable from vehicle and rear sus-

pension member. Refer to PB-5, "

Removal and Installation".

11. Remove shock absorber mounting bolt (lower side).

12. Remove stabilizer bar. (Without HBMC). Refer to RSU-17, "

Removal and Installation".

13. Remove rear lower link and coil spring. Refer to RSU-8, "

Removal and Installation".

14. Remove drive shaft. Refer to RAX-11, "

Removal and Installation".

15. Remove propeller shaft. Refer to DLN-137, "

Removal and Installation" (2WD), DLN-144, "Removal and

Installation" (4WD).

1. Rear suspension member

Refer to GI-4, "

Components" for symbols in the figure.

JPEIB0218GB

Revision: 2010 May2011 QX56

Page 4274 of 5598

REAR SUSPENSION MEMBERRSU-19

< UNIT REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

16. Remove final drive. Refer to DLN-201, "Removal and Installation".

17. Remove rear tube assembly A and rear tube assembly B. (With HBMC) Refer to SCS-44, "

REAR TUBE

ASSEMBLY : Removal and Installation".

18. Set suitable jack under rear suspension member.

19. Slowly lower jack, then remove rear suspension member, suspension arm, front lower link, wheel hub and housing from vehicle as a unit.

20. Remove mounting bolts and nuts, then remove suspension arm, front lower link, wheel hub and housing from rear suspension member.

21. Perform inspection after removal. Refer to RSU-19, "

Inspection and Adjustment".

INSTALLATION

Note the following, and install in the reverse order of the removal.

Perform the final tightening of each of parts under unladen conditions, which were removed when removing

rear suspension assembly.

Perform inspection after installation. Refer to RSU-19, "

Inspection and Adjustment".

Perform adjustment after installation. (With HBMC) Refer to RSU-19, "

Inspection and Adjustment".

Inspection and AdjustmentINFOID:0000000006225678

INSPECTION AFTER REMOVAL

Check rear suspension member for deformation, cracks, or any other damage. Replace if necessary.

INSPECTION AFTER INSTALLATION

1. Adjust parking brake operation (stroke). Refer to PB-3, "Inspection and Adjustment".

2. Check wheel alignment. Refer to RSU-6, "

Inspection".

3. Adjust neutral position of steering angle sensor. Refer to BRC-64, "

Work Procedure".

4. Adjust levelizer adjustment of height sensor. Refer to EXL-61, "

LEVELIZER ADJUSTMENT : Special

Repair Requirement".

5. Check standard vehicle height setting of vehicle height sensor. Refer to SCS-67, "

Work Procedure".

6. Check wheel sensor harness for proper connection. Refer to BRC-135, "

REAR WHEEL SENSOR :

Exploded View"

ADJUSTMENT AFTER INSTALLATION (WITH HBMC)

Bleed air from the HBMC. Refer to SCS-18, "Work Procedure".

Revision: 2010 May2011 QX56

Page 4275 of 5598

RSU-20

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

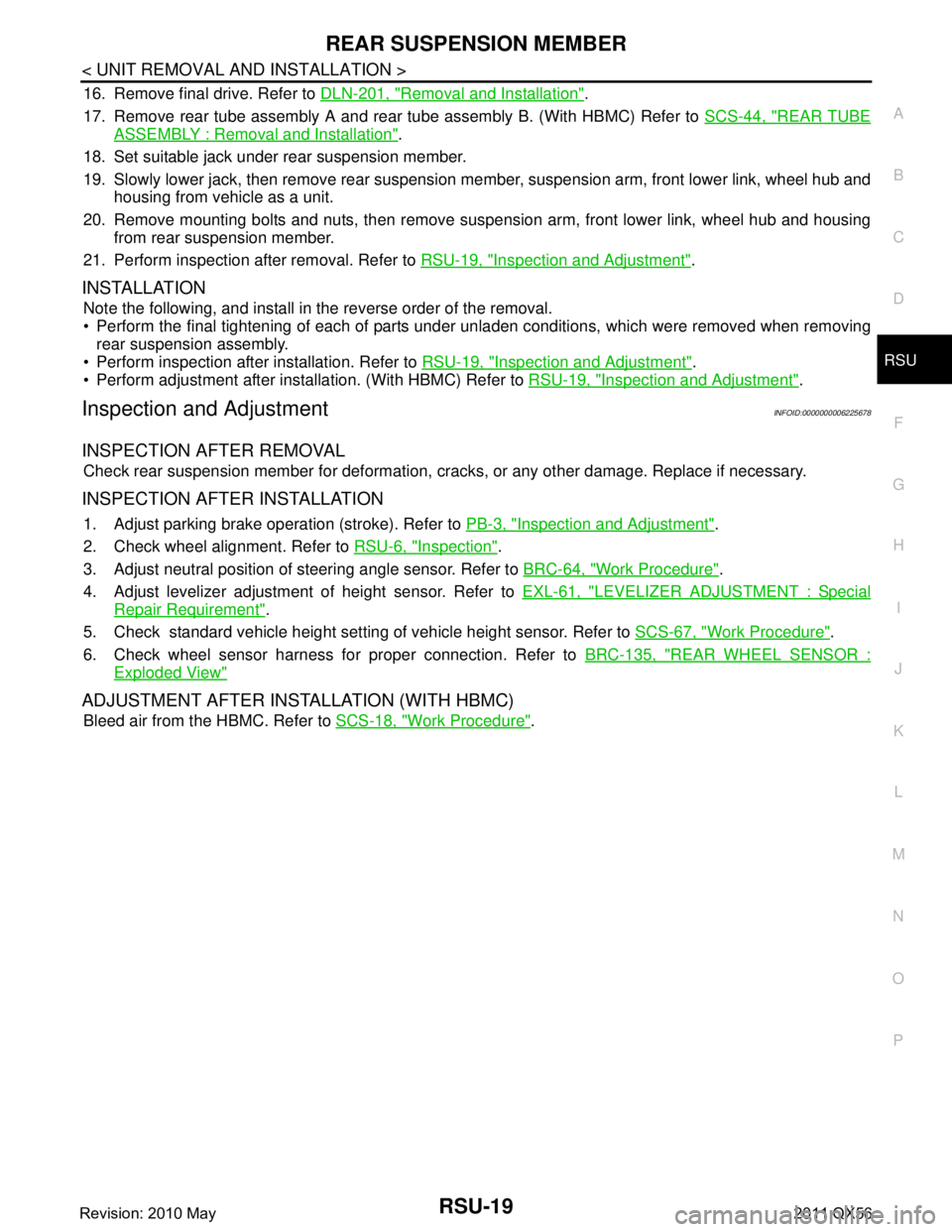

Wheel AlignmentINFOID:0000000006225679

Measure value under unladen* conditions.

*: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.

Ball JointINFOID:0000000006225680

Wheel HeightINFOID:0000000006225681

Measure value under unladen* conditions.

*: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.Item Standard

Camber

Degree minute (Decimal degree) Minimum –1

° 00 ′ (–1.00 °)

Nominal –0 ° 30 ′ (–0.50 °)

Maximum 0 ° 00 ′ (0.00 °)

Left and right difference 0 ° 45 ′ (0.75 °) or less

To e - i n Total toe-in

Distance

Minimum 0 mm (0 in)

Nominal In 3.4 mm (0.134 in)

Maximum In 6.8 mm (0.268 in)

Toe angle (left wheel or right wheel)

Degree minute (Decimal degree) Minimum 0

° 00 ′ (0.00 °)

Nominal In 0 ° 07 ′ (0.12 °)

Maximum In 0 ° 14 ′ (0.23 °)

Item Standard

Swing torque 0.5 – 6.4 N·m (0.06 – 0.65 kg-m, 5 – 56 in-lb)

Measurement on spring balance (groove position) Suspension arm 11.4 – 145.4 N (1.17 – 14.83 kg, 2.57 – 32.68 lb)

Front lower link 11.0 – 140.6 N (1.13 – 14.34 kg, 2.48 – 31.60 lb)

Rotating torque 0.5 – 6.4 N·m (0.06 – 0.65 kg-m, 5 – 56 in-lb)

Axial end play 0 mm (0 in)

Item Standard

Front (Hf) 903 mm (35.55 in)

Rear (Hr) 890 mm (35.04 in)

SFA746B

Revision: 2010 May2011 QX56

Page 4385 of 5598

![INFINITI QX56 2011 Factory Owners Guide

CHECK SHOCK ABSORBER FOR MALFUNCTIONSCS-25

< BASIC INSPECTION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

- Disconnect upper side pipe (B) of front shock absorber.

For rear shock absorber

- Disconne INFINITI QX56 2011 Factory Owners Guide

CHECK SHOCK ABSORBER FOR MALFUNCTIONSCS-25

< BASIC INSPECTION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

- Disconnect upper side pipe (B) of front shock absorber.

For rear shock absorber

- Disconne](/img/42/57033/w960_57033-4384.png)

CHECK SHOCK ABSORBER FOR MALFUNCTIONSCS-25

< BASIC INSPECTION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

- Disconnect upper side pipe (B) of front shock absorber.

For rear shock absorber

- Disconnect lower side pipe (B ) of rear shock absorber.

9. Install a leak check plug (SST: KV40108400) (A) to the removed pipe and tighten the leak check plug to the specified torque.

CAUTION:

O-ring must be free of scratches and damage.

Piping must be kept free of the intrusion of dust and dirt.

10. Loosen lock nuts of needle valves B and D of PPMU and then tighten needle valves B and D.

11. Loosening position of needle valve of PPMU varies according to shock absorber that is che cked. Loosen needle valve of PPMU

by approximately 2 rotations, as per the following table.

CAUTION:

Never loosen the needle valve more than required.

12. Set knob (A) of suspension oil pump to the direction as shown in the figure.

13. Apply pressure of up to 2.4 MPa.

14. Go to step 15 when oil comes out from lower portion of shock absorber which pipe is removed from. Go to step 16 when oil

does not come out.

15. Replace shock absorber, since shock absorber has internal leakage. Refer to FSU-10, "

Removal and Installation" (front),

RSU-8, "

Removal and Installation" (rear).

A : Lower side pipe

JSEIA0233ZZ

A : Upper side pipe

JSEIA0203ZZ

Tightening torque : 5.0 N·m (0.51 kg-m, 44 in-lb)

Shock absorber Loosening position of needle valve

Front LH C

Rear LH C

Front RH A

Rear RH A

JSEIA0210ZZ

JSEIA0191ZZ

Revision: 2010 May2011 QX56

Page 4390 of 5598

![INFINITI QX56 2011 Factory Owners Guide

SCS-30

< SYMPTOM DIAGNOSIS >[HBMC]

LARGE ROLL ANGLE

LARGE ROLL ANGLE

DescriptionINFOID:0000000006256018

During cornering, inclination of the vehi

cle to outer side of corner is large.

Inspection Pro INFINITI QX56 2011 Factory Owners Guide

SCS-30

< SYMPTOM DIAGNOSIS >[HBMC]

LARGE ROLL ANGLE

LARGE ROLL ANGLE

DescriptionINFOID:0000000006256018

During cornering, inclination of the vehi

cle to outer side of corner is large.

Inspection Pro](/img/42/57033/w960_57033-4389.png)

SCS-30

< SYMPTOM DIAGNOSIS >[HBMC]

LARGE ROLL ANGLE

LARGE ROLL ANGLE

DescriptionINFOID:0000000006256018

During cornering, inclination of the vehi

cle to outer side of corner is large.

Inspection ProcedureINFOID:0000000006256019

1.CHECK APPEARANCE

1. Visually check that the exterior parts (e.g. suspension spring) have no malfunctions.

2. Visually check tube and pipe for crush or oil leakage.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace damaged parts.

2.CHECK NEEDLE VALVE OF PPMU

Check that needle valves A and C are tightened to the specified

torque.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Tighten to the specified torque.

3.SYSTEM PRESSURE CHECK

Check system pressure. Refer to SCS-15, "

Work Procedure".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Perform adjustment of system pressure. Refer to SCS-18, "

Work Procedure".

4.CHECK INTERNAL LEAKAGE

Check internal leakage. Refer to SCS-20, "

Work Procedure".

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 5.

5.CHECK MALFUNCTIONING PART

Identify malfunctioning part. Refer to SCS-22, "

Work Procedure".

Does the pressure increase?

YES >> Replace the PPMU. Refer to SCS-39, "PPMU, MIDDLE TUBE ASSEMBLY, PPMU PIPE :

Removal and Installation".

NO >> GO TO 6.

6.CHECK SHOCK ABSORBER

Identify malfunctioning shock absorber. Refer to SCS-24, "

Work Procedure".

>> Replace identified shock absorber. Refer to FSU-10, "

Removal and Installation" (front), RSU-8,

"Removal and Installation" (rear).

Tightening torque : 8.3 N·

m (0.85 kg-m, 73 in-lb)

JSEIA0187ZZ

Revision: 2010 May2011 QX56

Page 5016 of 5598

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGST-29

< SYMPTOM DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

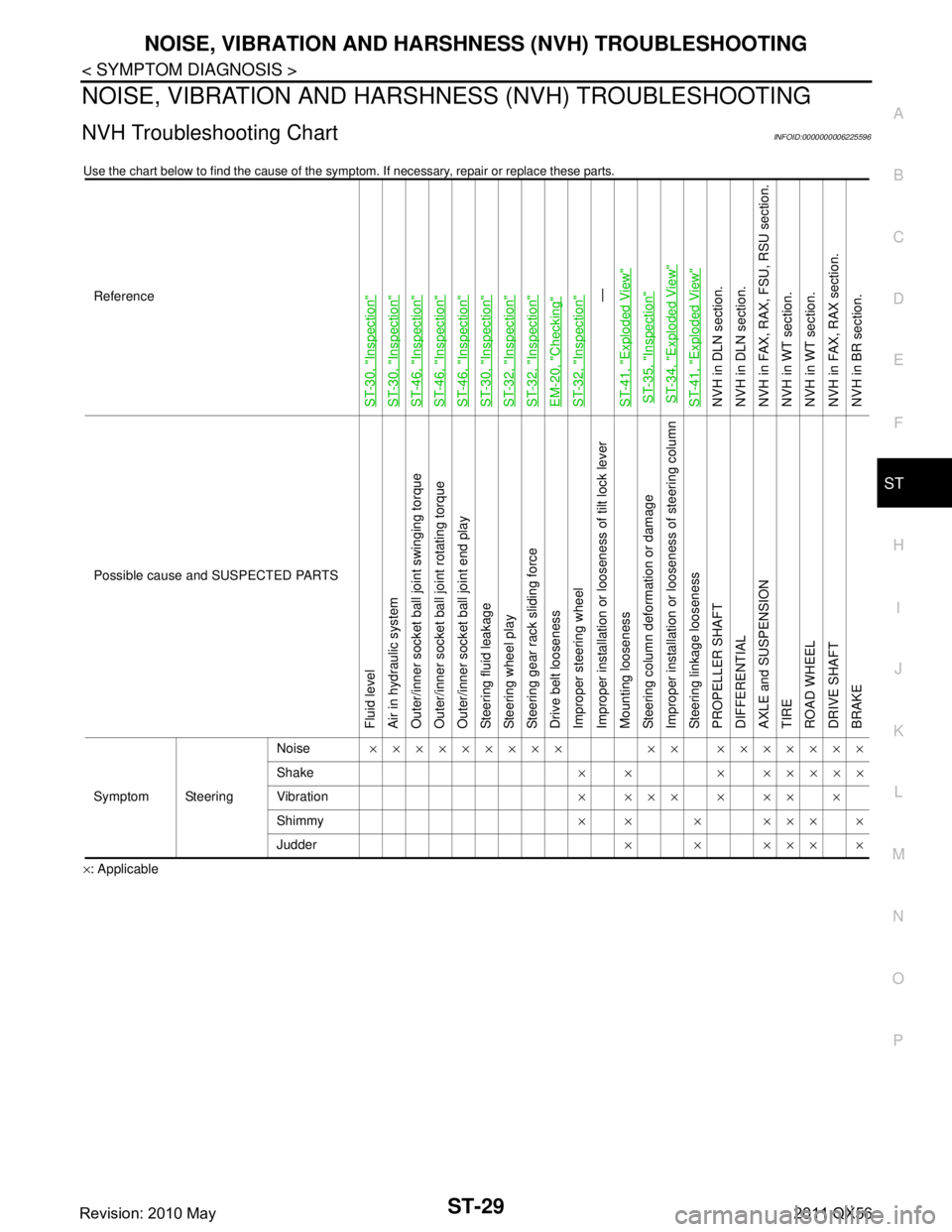

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000006225596

Use the chart below to find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference

ST-30, "

Inspection

"

ST-30, "

Inspection

"

ST-46, "

Inspection

"

ST-46, "

Inspection

"

ST-46, "

Inspection

"

ST-30, "

Inspection

"

ST-32, "

Inspection

"

ST-32, "

Inspection

"

EM-20, "

Checking

"

ST-32, "

Inspection

"—

ST-41, "

Exploded View

"

ST-35, "

Inspection

"

ST-34, "

Exploded View

"

ST-41, "

Exploded View

"

NVH in DLN section.

NVH in DLN section.

NVH in FAX, RAX, FSU, RSU section.

NVH in WT section.

NVH in WT section.

NVH in FAX, RAX section.

NVH in BR section.

Possible cause and SUSPECTED PARTS

Fluid level

Air in hydraulic system

Outer/inner socket ball joint swinging torque

Outer/inner socket ball joint rotating torque

Outer/inner socket ball joint end play

Steering fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting looseness

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

AXLE and SUSPENSION

TIRE

ROAD WHEEL

DRIVE SHAFT

BRAKE

Symptom Steering Noise

××××××××× ×× ×××××××

Shake × × × ×××××

Vibration ××××××××

Shimmy ×× × ××××

Judder ××××××

Revision: 2010 May2011 QX56

Page 5511 of 5598

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGWT-61

< SYMPTOM DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000006225544

Use the chart below to find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference

WT-64, "

Exploded View

"

WT-64, "

Inspection

"

WT-62, "

Adjustment

"

WT-69, "

Tire Air Pressure

"

WT-64, "

Inspection

"

—

—

WT-69, "

Tire Air Pressure

"

NVH in DLN section.

NVH in DLN section.

NVH in FAX and FSU sections.

NVH in RAX and RSU sections.

Refer to TIRES in this chart.

Refer to ROAD WHEEL in this chart.

NVH in FAX, RAX section.

NVH in BR section.

NVH in ST section.

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Out-of-round

Unbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

PROPELLER SHAFT

DIFFERENTIAL

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEELS

DRIVE SHAFT

BRAKE

STEERING

Symptom TIRESNoise

××××××× ×××× ××××

Shake ×××××× ×× ×× ××××

Vibration ×××××××

Shimmy ×××××××× ×× × ××

Judder ×

××××× × ×× × ××

Poor quality ride or

handling ×××××× × × ××

ROAD

WHEEL Noise

××× × ××××× ×××

Shake ××× × × ××× ×××

Shimmy, Judder ××× × ××× ××

Poor quality ride or

handling ××× × ×××

Revision: 2010 May2011 QX56