service INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1 of 5598

A

B

D

E

F

G

H

I

J

K

L

M

N

P

O

C

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

STRStarting System

ACCAccelerator Control System

CHYBRIDHBCHybrid Control System

HBBHybrid Battery System

HBRHybrid Brake System

DTRANSMISSION & DRIVE-

LINECLClutch

TMTransaxle & Transmission

DLNDriveline

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

SCSSuspension Control System

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGSTSteering System

STCSteering Control System

HRESTRAINTSSBSeat Belt

SBCSeat Belt Control System

SRSRS Airbag

SRCSRS Airbag Control System

IVENTILATION, HEATER &

AIR CONDITIONERVTLVentilation System

HAHeater & Air Conditioning System

HACHeater & Air Conditioning Control System

JBODY INTERIORINTInterior

IPInstrument Panel

SESeat

ADPAutomatic Drive Positioner

KBODY EXTERIOR,

DOORS, ROOF & VEHICLE

SECURITYDLKDoor & Lock

SECSecurity Control System

GWGlass & Window System

PWCPower Window Control System

RFRoof

HDHood

EXTExterior

BRMBody Repair

LDRIVER CONTROLSMIRMirrors

EXLExterior Lighting System

INLInterior Lighting System

WWWiper & Washer

DEFDefogger

HRNHorn

MELECTRICAL & POWER

CONTROLPWOPower Outlet

BCSBody Control System

LANLAN System

PCSPower Control System

CHGCharging System

PGPower Supply, Ground & Circuit Elements

NDRIVER INFORMATION &

MULTIMEDIAMWIMeter, Warning Lamp & Indicator

WCSWarning Chime System

SNSonar System

AVAudio, Visual & Navigation System

OCRUISE CONTROL &

DRIVER ASSISTANCECCSCruise Control System

DASDriver Assistance System

DMSDrive Mode System

PMAINTENANCEMAMaintenance

All rights reserved. No part

of this Service Manual may

be reproduced or stored in a

retrieval system, or transmit-

ted in any form, or by any

means, electronic, mechani-

cal, recording or otherwise,

without the prior written per-

mission of NISSAN MOTOR

CO., LTD.

Edition: May 2010

Publication No. SM1E-1Z62U0

Page 2 of 5598

FOREWORD

This manual contains maintenance and repair procedure for the 2011

INFINITI QX56.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in specifi-

cations and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of

the technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a

manner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician

and the tools and parts available. Accordingly, anyone using service

procedures, tools or parts which are not specifically recommended

by NISSAN must first be completely satisfied that neither personal

safety nor the vehicle’s safety will be jeopardized by the service

method selected.

Page 7 of 5598

ACC-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006289699

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Revision: 2010 May2011 QX56

Page 10 of 5598

ADP-1

BODY INTERIOR

C

DE

F

G H

I

K L

M

SECTION ADP

A

B

ADP

N

O P

CONTENTS

AUTOMATIC DRIVE POSITIONER

PRECAUTION ................ ...............................5

PRECAUTIONS .............................................. .....5

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description ............................................7

SYSTEM .............................................................11

AUTOMATIC DRIVE POSITIONER SYSTEM ....... ....11

AUTOMATIC DRIVE POSITIONER SYSTEM :

System Diagram ......................................................

11

AUTOMATIC DRIVE POSITIONER SYSTEM :

System Description .................................................

11

MANUAL FUNCTION ............................................ ....12

MANUAL FUNCTION : System Diagram ................13

MANUAL FUNCTION : System Description ............13

MEMORY FUNCTION ........................................... ....14

MEMORY FUNCTION : System Diagram ...............15

MEMORY FUNCTION : System Description ..........15

EXIT ASSIST FUNCTION ...................................... ....17

EXIT ASSIST FUNCTION : System Diagram .........17

EXIT ASSIST FUNCTION : Sy stem Description .....17

ENTRY ASSIST FUNCTION ................................. ....18

ENTRY ASSIST FUNCTION : System Diagram .....18

ENTRY ASSIST FUNCTION : System Description

....

18

INTELLIGENT KEY INTERLOCK FUNCTION ...... ....19

INTELLIGENT KEY INTERLOCK FUNCTION :

System Diagram ......................................................

20

INTELLIGENT KEY INTERLOCK FUNCTION :

System Description .................................................

20

Fail Safe .............................................................. ....21

DIAGNOSIS SYSTEM (DRIVER SEAT CON-

TROL UNIT) ......................................................

22

CONSULT-III Function ............................................22

ECU DIAGNOSIS INFORMATION ..............25

DRIVER SEAT CONTROL UNIT ......................25

Reference Value .................................................. ....25

Fail Safe ..................................................................30

DTC Index ...............................................................31

AUTOMATIC DRIVE POSITIONER CON-

TROL UNIT ........................................................

32

Reference Value ......................................................32

BCM (BODY CONTROL MODULE) .................35

List of ECU Reference .............................................35

WIRING DIAGRAM ......................................36

AUTOMATIC DRIVE POSITIONER SYSTEM ...36

Wiring Diagram .................................................... ....36

BASIC INSPECTION ...................................48

DIAGNOSIS AND REPAIR WORK FLOW .......48

Work Flow ............................................................ ....48

INSPECTION AND ADJUSTMENT ..................51

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL ............................... ....

51

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Description .....

51

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Special Re-

pair Requirement .....................................................

51

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ....

51

Revision: 2010 May2011 QX56

Page 11 of 5598

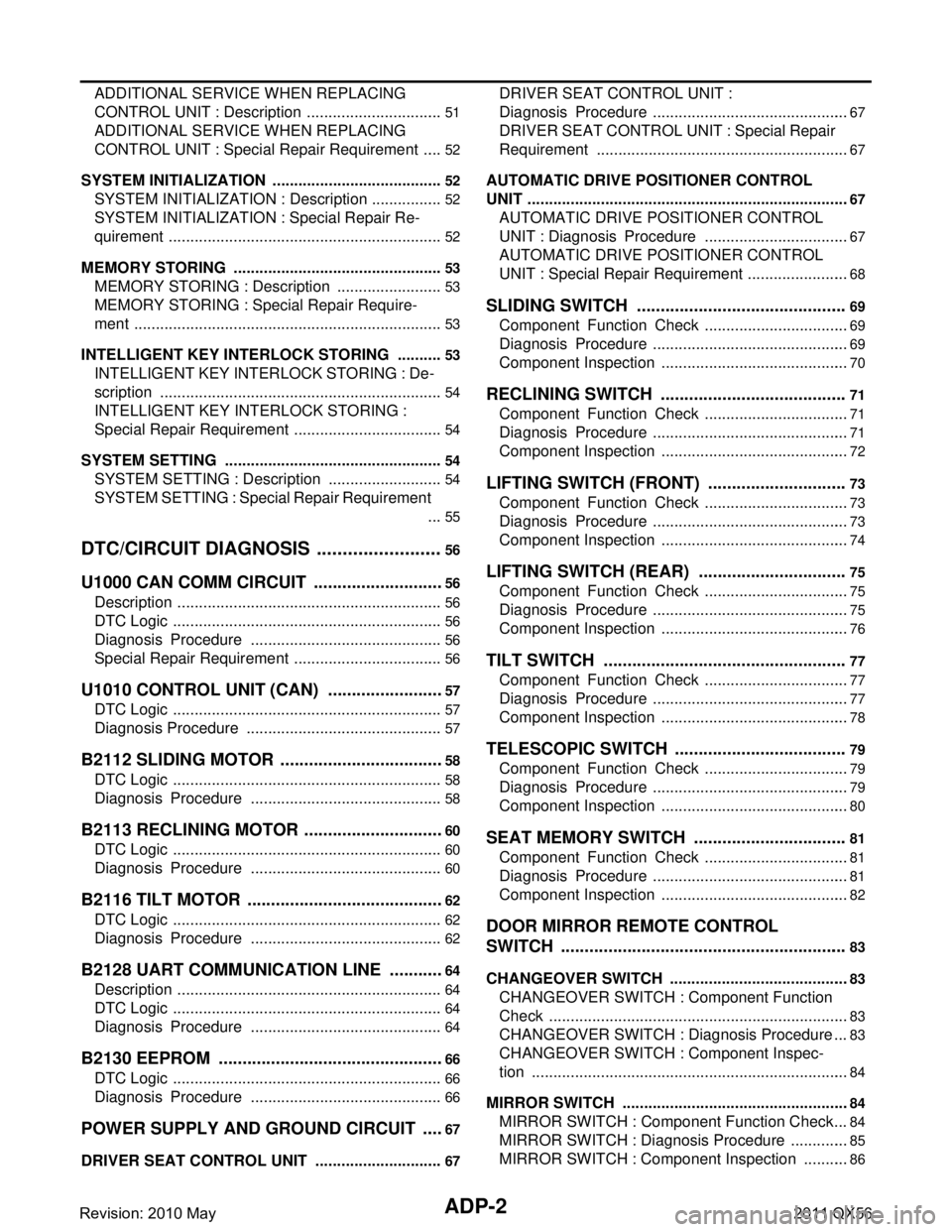

ADP-2

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ................................

51

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

52

SYSTEM INITIALIZATION . .......................................52

SYSTEM INITIALIZATION : Description .................52

SYSTEM INITIALIZATION : Special Repair Re-

quirement ............................................................. ...

52

MEMORY STORING .............................................. ...53

MEMORY STORING : Description .........................53

MEMORY STORING : Special Repair Require-

ment ........................................................................

53

INTELLIGENT KEY INTERLOCK STORING ........ ...53

INTELLIGENT KEY INTERLOCK STORING : De-

scription ..................................................................

54

INTELLIGENT KEY INTERLOCK STORING :

Special Repair Requirement ...................................

54

SYSTEM SETTING ...................................................54

SYSTEM SETTING : Descrip tion ...........................54

SYSTEM SETTING : Specia l Repair Requirement

...

55

DTC/CIRCUIT DIAGNOSIS ...................... ...56

U1000 CAN COMM CIRCUIT ......................... ...56

Description ........................................................... ...56

DTC Logic ...............................................................56

Diagnosis Procedure .............................................56

Special Repair Requirement ...................................56

U1010 CONTROL UNIT (CAN) .........................57

DTC Logic ............................................................ ...57

Diagnosis Procedure ..............................................57

B2112 SLIDING MOTOR ...................................58

DTC Logic ............................................................ ...58

Diagnosis Procedure .............................................58

B2113 RECLINING MOTOR ..............................60

DTC Logic ............................................................ ...60

Diagnosis Procedure .............................................60

B2116 TILT MOTOR ..........................................62

DTC Logic ............................................................ ...62

Diagnosis Procedure .............................................62

B2128 UART COMMUNICATION LINE ............64

Description ........................................................... ...64

DTC Logic ...............................................................64

Diagnosis Procedure .............................................64

B2130 EEPROM ................................................66

DTC Logic ............................................................ ...66

Diagnosis Procedure .............................................66

POWER SUPPLY AND GROUND CIRCUIT .....67

DRIVER SEAT CONTROL UNIT ........................... ...67

DRIVER SEAT CONTROL UNIT :

Diagnosis Procedure ..............................................

67

DRIVER SEAT CONTROL UNIT : Special Repair

Requirement ...........................................................

67

AUTOMATIC DRIVE POSITIONER CONTROL

UNIT ........................................................................ ...

67

AUTOMATIC DRIVE POSITIONER CONTROL

UNIT : Diagnosis Procedure ..................................

67

AUTOMATIC DRIVE POSITIONER CONTROL

UNIT : Special Repair Requirement ........................

68

SLIDING SWITCH .............................................69

Component Function Check ............................... ...69

Diagnosis Procedure ..............................................69

Component Inspection ............................................70

RECLINING SWITCH ........................................71

Component Function Check ............................... ...71

Diagnosis Procedure ..............................................71

Component Inspection ............................................72

LIFTING SWITCH (FRONT) ..............................73

Component Function Check ............................... ...73

Diagnosis Procedure ..............................................73

Component Inspection ............................................74

LIFTING SWITCH (REAR) ................................75

Component Function Check ............................... ...75

Diagnosis Procedure ..............................................75

Component Inspection ............................................76

TILT SWITCH ....................................................77

Component Function Check ............................... ...77

Diagnosis Procedure ..............................................77

Component Inspection ............................................78

TELESCOPIC SWITCH .....................................79

Component Function Check ............................... ...79

Diagnosis Procedure ..............................................79

Component Inspection ............................................80

SEAT MEMORY SWITCH .................................81

Component Function Check ............................... ...81

Diagnosis Procedure ..............................................81

Component Inspection ............................................82

DOOR MIRROR REMOTE CONTROL

SWITCH .............................................................

83

CHANGEOVER SWITCH ....................................... ...83

CHANGEOVER SWITCH : Component Function

Check ......................................................................

83

CHANGEOVER SWITCH : Diagnosis Procedure ...83

CHANGEOVER SWITCH : Component Inspec-

tion ..........................................................................

84

MIRROR SWITCH .................................................. ...84

MIRROR SWITCH : Component Function Check ...84

MIRROR SWITCH : Diagnosis Procedure ..............85

MIRROR SWITCH : Component Inspection ...........86

Revision: 2010 May2011 QX56

Page 14 of 5598

PRECAUTIONSADP-5

< PRECAUTION >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006248300

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Revision: 2010 May2011 QX56

Page 60 of 5598

INSPECTION AND ADJUSTMENTADP-51

< BASIC INSPECTION >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

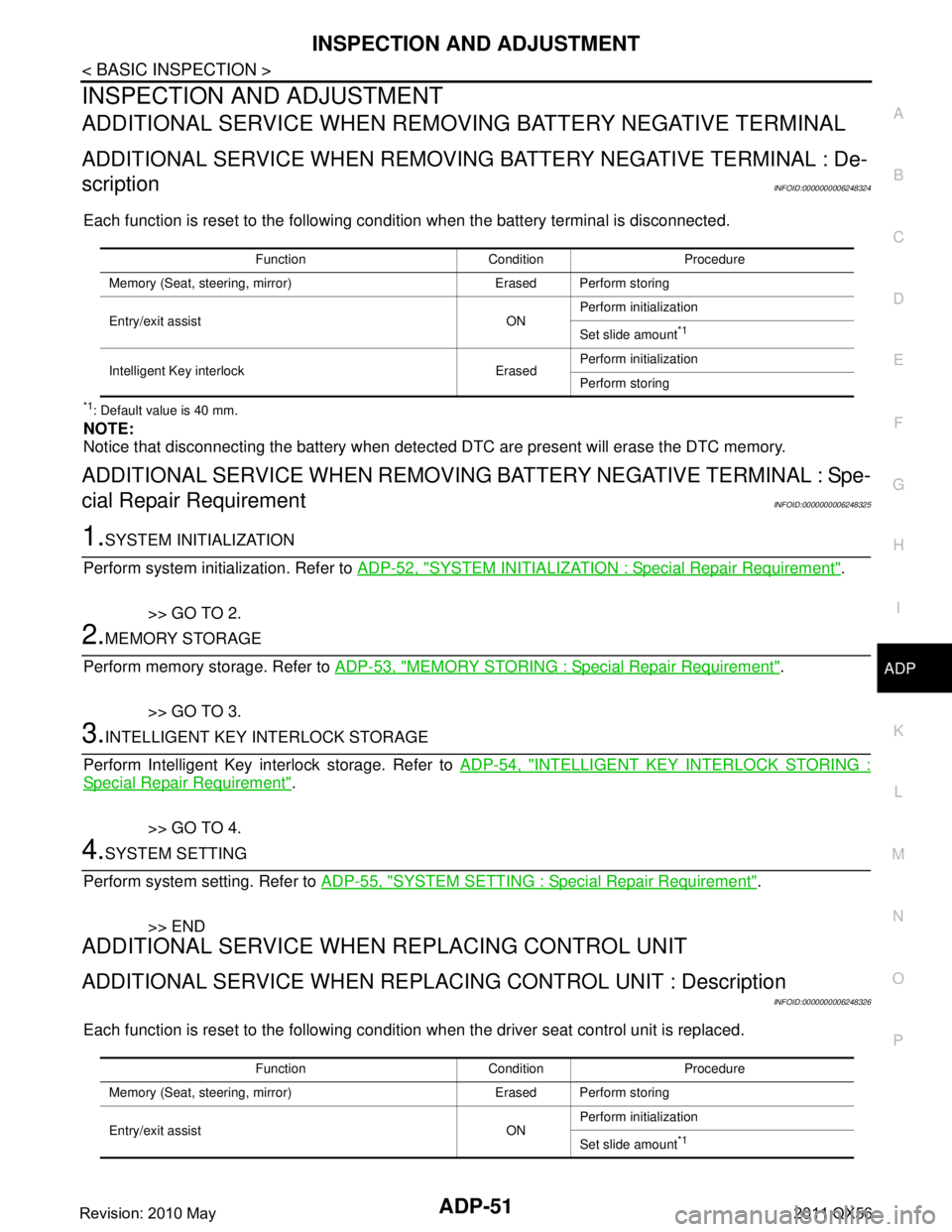

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : De-

scription

INFOID:0000000006248324

Each function is reset to the following condition when the battery terminal is disconnected.

*1: Default value is 40 mm.

NOTE:

Notice that disconnecting the battery when detect ed DTC are present will erase the DTC memory.

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Spe-

cial Repair Requirement

INFOID:0000000006248325

1.SYSTEM INITIALIZATION

Perform system initialization. Refer to ADP-52, "

SYSTEM INITIALIZATION : Special Repair Requirement".

>> GO TO 2.

2.MEMORY STORAGE

Perform memory storage. Refer to ADP-53, "

MEMORY STORING : Special Repair Requirement".

>> GO TO 3.

3.INTELLIGENT KEY INTERLOCK STORAGE

Perform Intelligent Key interlock storage. Refer to ADP-54, "

INTELLIGENT KEY INTERLOCK STORING :

Special Repair Requirement".

>> GO TO 4.

4.SYSTEM SETTING

Perform system setting. Refer to ADP-55, "

SYSTEM SETTING : Special Repair Requirement".

>> END

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000006248326

Each function is reset to the following condition when the driver seat control unit is replaced.

Function Condition Procedure

Memory (Seat, stee ring, mirror) Erased Perform storing

Entry/exit assist ON Perform initialization

Set slide amount

*1

Intelligent Key interlock Erased

Perform initialization

Perform storing

Function Condition Procedure

Memory (Seat, stee ring, mirror) Erased Perform storing

Entry/exit assist ON Perform initialization

Set slide amount

*1

Revision: 2010 May2011 QX56

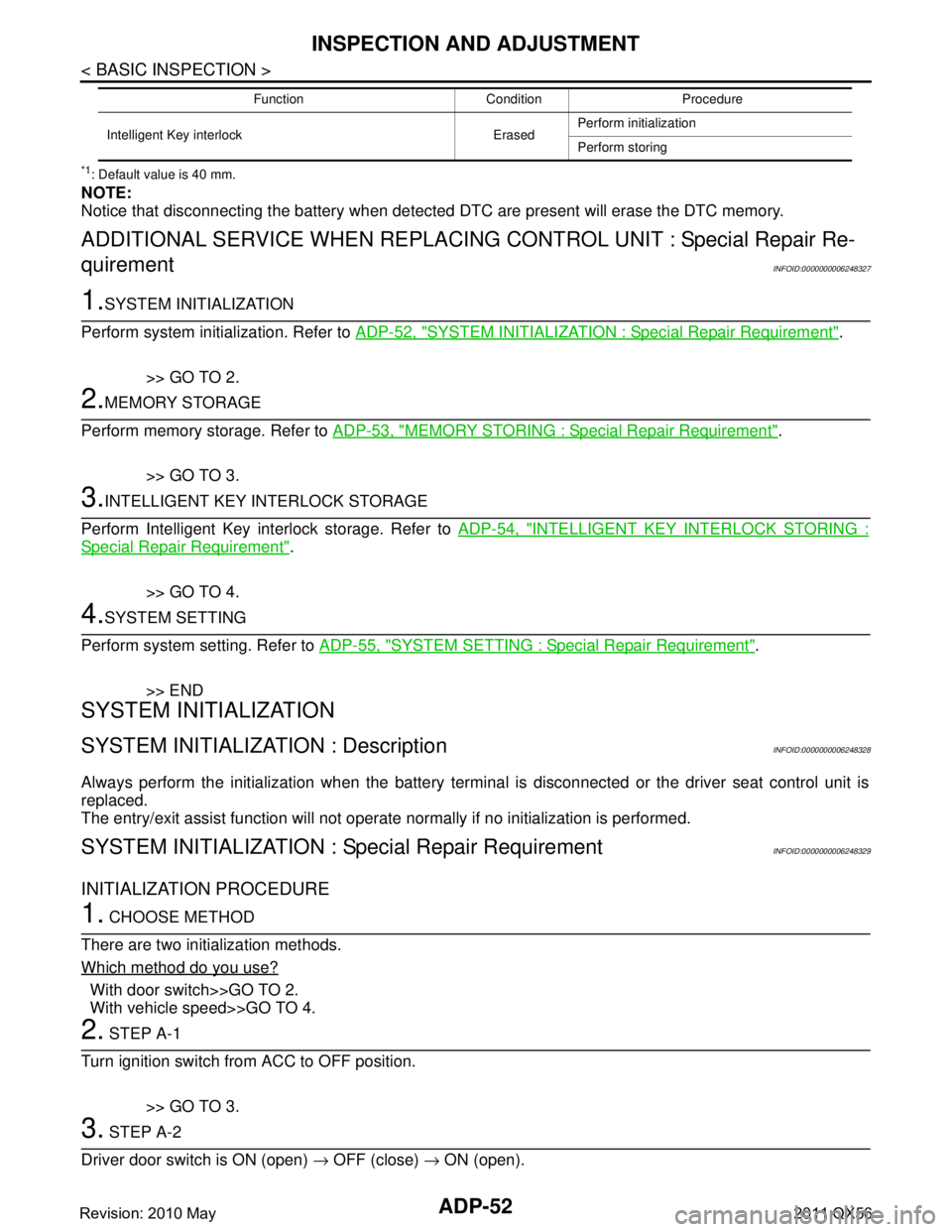

Page 61 of 5598

ADP-52

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

*1: Default value is 40 mm.

NOTE:

Notice that disconnecting the battery when detected DTC are present will erase the DTC memory.

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000006248327

1.SYSTEM INITIALIZATION

Perform system initialization. Refer to ADP-52, "

SYSTEM INITIALIZATION : Special Repair Requirement".

>> GO TO 2.

2.MEMORY STORAGE

Perform memory storage. Refer to ADP-53, "

MEMORY STORING : Special Repair Requirement".

>> GO TO 3.

3.INTELLIGENT KEY INTERLOCK STORAGE

Perform Intelligent Key interlock storage. Refer to ADP-54, "

INTELLIGENT KEY INTERLOCK STORING :

Special Repair Requirement".

>> GO TO 4.

4.SYSTEM SETTING

Perform system setting. Refer to ADP-55, "

SYSTEM SETTING : Special Repair Requirement".

>> END

SYSTEM INITIALIZATION

SYSTEM INITIALIZATION : DescriptionINFOID:0000000006248328

Always perform the initialization when the battery termi nal is disconnected or the driver seat control unit is

replaced.

The entry/exit assist function will not operate normally if no initialization is performed.

SYSTEM INITIALIZATION : Special Repair RequirementINFOID:0000000006248329

INITIALIZATION PROCEDURE

1. CHOOSE METHOD

There are two initialization methods.

Which method do you use?

With door switch>>GO TO 2.

With vehicle speed>>GO TO 4.

2. STEP A-1

Turn ignition switch from ACC to OFF position.

>> GO TO 3.

3. STEP A-2

Driver door switch is ON (open) → OFF (close) → ON (open).

Intelligent Key interlock Erased Perform initialization

Perform storing

Function Condition Procedure

Revision: 2010 May2011 QX56

Page 76 of 5598

POWER SUPPLY AND GROUND CIRCUITADP-67

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

POWER SUPPLY AND GROUND CIRCUIT

DRIVER SEAT CONTROL UNIT

DRIVER SEAT CONTROL UNIT : Diagnosis ProcedureINFOID:0000000006248353

1.CHECK FUSE

Check that the following fuse and fusible link are not fusing.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit.

2.CHECK DRIVER SEAT CONTROL UNIT POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit connector.

3. Check voltage between driver seat control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK DRIVER SEAT CONTROL UNIT GROUND CIRCUIT

Check continuity between the driver s eat control unit harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair or replace harness.

DRIVER SEAT CONTROL UNIT : Special Repair RequirementINFOID:0000000006248354

1.PERFORM ADDITIONAL SERVICE

Perform additional service when removing battery negative terminal.

>> Refer to ADP-51, "

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMI-

NAL : Description".

AUTOMATIC DRIVE POSITIONER CONTROL UNIT

AUTOMATIC DRIVE POSITIONER CO NTROL UNIT : Diagnosis Procedure

INFOID:0000000006248355

NOTE:

Do not disconnect the battery negative terminal and the dr iver seat control unit connector until DTC is con-

firmed with CONSULT-III.

1.CHECK FUSE

Check that the following fuse and fusible link are not fusing.

Signal name Fuse No.

Battery power supply K (50 A)

(+) (-)Voltage (V)

(Approx.)

Driver seat control unit

Connector Terminals B451 33 Ground Battery voltage

Driver seat control unit GroundContinuity

Connector Terminal

B451 43 Existed

Revision: 2010 May2011 QX56

Page 77 of 5598

ADP-68

< DTC/CIRCUIT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit.

2.CHECK AUTOMATIC DRIVE POSITIONER CONTROL UNIT POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit connector.

3. Check voltage between automatic drive posit ioner control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK AUTOMATIC DRIVE POSITION ER CONTROL UNIT GROUND CIRCUIT

Check continuity between the automatic drive positioner control unit harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair or replace harness.

AUTOMATIC DRIVE POSITIONER CONTROL UNIT : Special Repair Requirement

INFOID:0000000006248356

1.PERFORM ADDITIONAL SERVICE

Perform additional service when removing battery negative terminal.

>> Refer to ADP-51, "

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMI-

NAL : Description".

Signal name Fuse No.

Battery power supply K (50 A)

(+) (-)Voltage (V)

(Approx.)

Automatic drive positioner control unit

Connector Terminals M104 25 Ground Battery voltage

Automatic drive positioner control unit GroundContinuity

Connector Terminal

M104 30 Existed

Revision: 2010 May2011 QX56