wheel torque INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 351 of 5598

AV

MULTI AV SYSTEM SYMPTOMSAV-203

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

RELATED TO STEERING SWITCH

RELATED TO USB

NOTE:

Check that there is no malfunction of USB equipment main body before performing a diagnosis.

iPod® is a trademark of Apple inc., registered in the U.S. and other countries.

RELATED TO DVD MODE

RELATED TO FRONT AUXILIARY INPUT

It does not change to “Driver's

Audio Stage” mode. —Mode change signal circuit malfunction.

Refer to

AV- 1 7 7 , "

Diagnosis Procedure".

Satellite radio is not received. There is malfunction in the CONSULT-III

self-diagnosis result.

Refer to

AV- 3 9 , "

CONSULT-III Function".Perform detected DTC diagnosis.

Refer to

AV- 5 7 , "DTC Index".

There is no malfunction in the CON-

SULT-III self-dia gnosis result.

Refer to AV- 3 9 , "

CONSULT-III Function".Perform the following inspection procedure.

1. Check satellite radio antenna mounting nut for

looseness.

NOTE:

Tightening torque: 6.5 N-m (0.66 kg-m, 58 in-lb)

2. Visually check for satellite radio antenna feeder.

AM/FM radio is not received. Other audio sounds are normal. Antenna amp. ON signal circuit malfunction.

Antenna feeder malfunction.

Symptoms Check items Probable malfunction location

Symptoms Probable malfunction location

None of the steering switch operations work. Steering switch ground circuit malfunction.

Refer to

AV- 1 9 7 , "

Diagnosis Procedure".

Only specified switch cannot be operated. Steering switch malfunction.

Replace steering wheel. Refer to

ST-33, "

Exploded View".

Steering switch's “SOURCE”, “MENU UP”, “MENU DOWN“,

“ ” and “ENTER” switches do not work. Steering switch signal A circuit malfunction.

Refer to

AV- 1 9 3 , "

Diagnosis Procedure".

Steering switch's “ ”, “VOL UP”, “VOL DOWN” and “ ”

switches do not work. Steering switch signal B circuit malfunction.

Refer to

AV- 1 9 5 , "

Diagnosis Procedure".

Symptoms Check items Possible malfunction location / Action to take

iPod

® or USB memory can not

be recognized. —

USB harness malfunction.

USB connector malfunction.

Symptoms Check items Probable malfunction location

The disk cannot be removed. — Disk eject signal circuit malfunction.

Refer to

AV-176, "

Diagnosis Procedure".

DVD image is not displayed. Front display unit, headrest display unit

LH and RH are not displayed.

Perform CONSULT-III self-diagnosis.

Refer to

AV- 3 9 , "

CONSULT-III Function".

Headrest display unit LH and RH are nor-

mal. Composite image signal circuit between AV control unit

and front display unit.

Refer to

AV-167, "

Diagnosis Procedure".

Front display unit is normal. Refer to “RELATED TO HEADREST DISPLAY UNIT

AND REAR AUXILIARY INPUT”

DVD sound is not heard. No sound from all speakers.

Amp. ON signal circuit malfunction.

BOSE amp. power supply and ground circuits mal-

function.

Sound is not heard from woofer. Woofer power supply and ground circuit malfunction.

Sound signal (woofer) circuit malfunction.

Sound is heard only from specific places. Sound signals circuit of suspect system.

Revision: 2010 May2011 QX56

Page 474 of 5598

BR-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

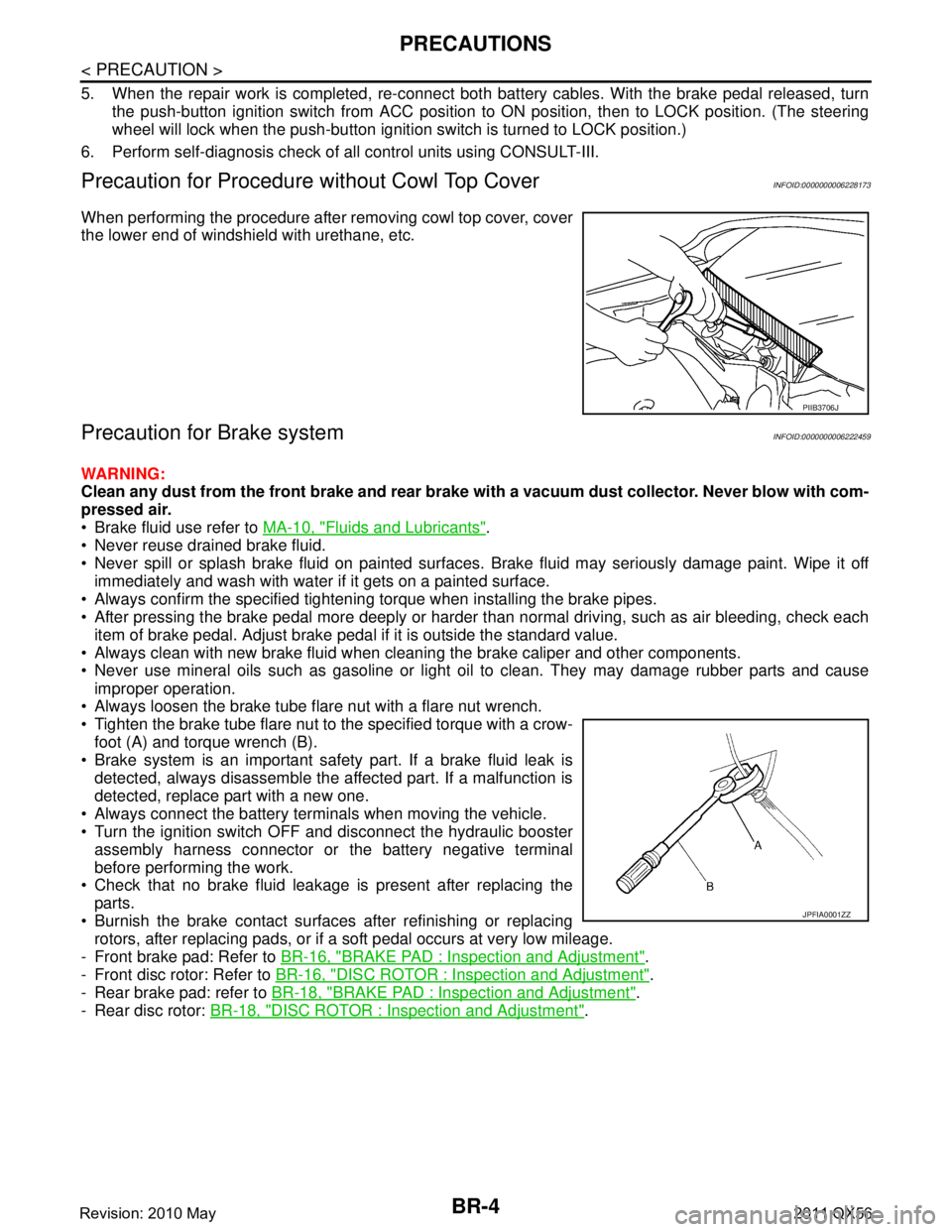

Precaution for Procedure without Cowl Top CoverINFOID:0000000006228173

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake systemINFOID:0000000006222459

WARNING:

Clean any dust from the front brake and rear brake wi th a vacuum dust collector. Never blow with com-

pressed air.

Brake fluid use refer to MA-10, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

Always confirm the specified tightening torque when installing the brake pipes.

After pressing the brake pedal more deeply or harder t han normal driving, such as air bleeding, check each

item of brake pedal. Adjust brake pedal if it is outside the standard value.

Always clean with new brake fluid when cleaning the brake caliper and other components.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause

improper operation.

Always loosen the brake tube flar e nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

Brake system is an important safety part. If a brake fluid leak is detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

Always connect the battery terminals when moving the vehicle.

Turn the ignition switch OFF and disconnect the hydraulic booster assembly harness connector or the battery negative terminal

before performing the work.

Check that no brake fluid leakage is present after replacing the

parts.

Burnish the brake contact surfaces after refinishing or replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

- Front brake pad: Refer to BR-16, "

BRAKE PAD : Inspection and Adjustment".

- Front disc rotor: Refer to BR-16, "

DISC ROTOR : Inspection and Adjustment".

- Rear brake pad: refer to BR-18, "

BRAKE PAD : Inspection and Adjustment".

- Rear disc rotor: BR-18, "

DISC ROTOR : Inspection and Adjustment".

PIIB3706J

JPFIA0001ZZ

Revision: 2010 May2011 QX56

Page 494 of 5598

BR-24

< REMOVAL AND INSTALLATION >

BRAKE PIPING

Never reuse the copper washer.

3. Install the brake hose L-pin by aligning it with the brake caliper assembly positioning hole, and tighten the union bolt (1) to the

specified torque.

4. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hose or brake tube are not twisted and

bent.

5. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

6. Tighten the brake hose mounting nuts to the specified torque. CAUTION:

Never reuse the brake hose mounting nuts.

7. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

8. Install tires with power tool. Refer to WT-64, "

Exploded View".

9. Perform inspection after installation. Refer to BR-24, "

FRONT : Inspection".

FRONT : InspectionINFOID:0000000006222478

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785 N (80 kg, 176 lb) and hold down the pedal for approx. 5 sec- onds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connection to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

REAR

JPFIA0012ZZ

Revision: 2010 May2011 QX56

Page 496 of 5598

BR-26

< REMOVAL AND INSTALLATION >

BRAKE PIPING

REAR : Removal and Installation

INFOID:0000000006222481

REMOVAL

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Remove tires with power tool.

2. Drain brake fluid. Refer to BR-10, "

Draining".

3. Loosen the flare nut with a flare nut wrench and separate the brake tube and the brake hose. CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strongly pull out the brake hose or brake tube.

Cover open end of brake hose or brake tube wh en disconnecting to prevent entrance of dirt.

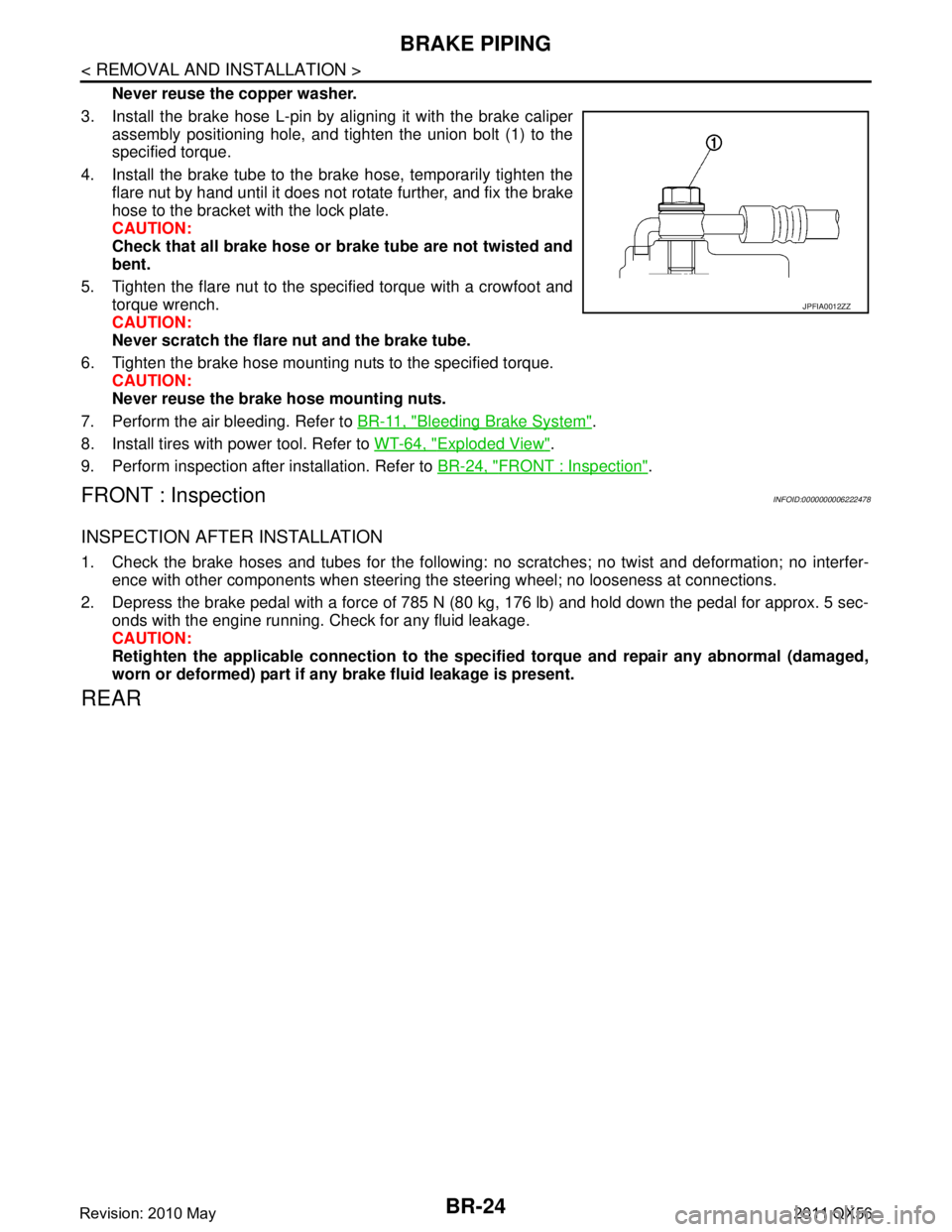

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse the copper washer.

2. Align the brake hose pin to the projection (A) of the brake caliper

assembly and tighten the union bolt (1) to the specified torque.

3. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hose or brake tube are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

6. Install tires with power tool. Refer to WT-64, "

Exploded View".

7. Perform inspection after installation. Refer to BR-26, "

REAR : Inspection".

REAR : InspectionINFOID:0000000006222482

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

1. Front disc brake 2. Connector 3. Hydraulic booster assembly

4. Rear disc brake

A. Brake hose B. Brake tube

: Flare nut

: Union bolt

JPFIA0099ZZ

Revision: 2010 May2011 QX56

Page 507 of 5598

FRONT DISC BRAKEBR-37

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE CALIPER ASSEMBLY : Removal and InstallationINFOID:0000000006222492

REMOVAL

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid m ay splash while removing the brake hose.

If the brake fluid or grease adheres to the brake cal iper assembly and disc rotor, quickly wipe it off.

1. Remove tires with power tool.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-10, "

Draining".

4. Separate brake hose from brake caliper assembly. Refer to BR-23, "

FRONT : Removal and Installation".

5. Remove torque member mounting bolts, and remove brake caliper assembly. CAUTION:

Never drop brake pad and brake caliper assembly.

6. Remove disc rotor. Refer to FA X - 8 , "

Removal and Installation" (2WD), FAX-18, "Removal and Installation"

(AWD).

INSTALLATION

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid m ay splash while removing the brake hose.

If the brake fluid or grease adheres to the brake cal iper assembly and disc rotor, quickly wipe it off.

1. Torque member 2. Sliding pin boot 3. Sliding pin

4. Piston boot 5. Piston 6. Piston seal

7. Cylinder body 8. Bleeder valve 9. Cap

: Apply rubber grease.

: Apply brake fluid.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0800GB

Revision: 2010 May2011 QX56

Page 514 of 5598

BR-44

< REMOVAL AND INSTALLATION >

REAR DISC BRAKE

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

If the brake fluid or grease adheres to the brake calip er assembly and disc rotor, quickly wipe it off.

1. Remove tires with power tool.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-10, "

Draining".

4. Separate brake hose from brake caliper assembly. Refer to BR-26, "

REAR : Removal and Installation".

5. Remove torque member mounting bolts, and remove brake caliper assembly. CAUTION:

Never drop brake pad and caliper assembly.

6. Remove disc rotor. Refer to RAX-7, "

Removal and Installation".

INSTALLATION

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

If the brake fluid or grease adheres to the brake calip er assembly and disc rotor, quickly wipe it off.

1. Install disc rotor. Refer to RAX-7, "

Removal and Installation".

2. Install the brake caliper assembly to the axle hous ing and tighten the torque member mounting bolts to the

specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake caliper assembly mounting face,

threads, mounting bolts. Wipe out any grease and moisture.

3. Install brake hose to brake caliper assembly. Refer to BR-26, "

REAR : Removal and Installation".

4. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

5. Check a drag of rear disc brake. If any drag is found, refer to BR-45, "

BRAKE CALIPER ASSEMBLY :

Inspection".

6. Install tires with power tool. Refer to WT-64, "

Exploded View".

BRAKE CALIPER ASSEMBLY : Disassembly and AssemblyINFOID:0000000006222500

DISASSEMBLY

NOTE:

Never remove the torque member, brake pads and pad retainers when disassembling and assembling the cyl-

inder body.

1. Remove the sliding pin bolt, and remove the cylinder body from the torque member.

CAUTION:

Fix the brake pad at suitable tape so that the brake pad will not drop.

2. Remove sliding pin boots from torque member.

3. Remove bushing from sliding pin bolt.

4. Place a wooden block as shown in the figure, and blow air from brake hose mounting hole to remove piston and piston boot.

CAUTION:

Never get fingers caught in the piston.

MAA0272D

Revision: 2010 May2011 QX56

Page 523 of 5598

![INFINITI QX56 2011 Factory Service Manual

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position INFINITI QX56 2011 Factory Service Manual

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position](/img/42/57033/w960_57033-522.png)

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006228176

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000006222556

WARNING:

Clean any dust from the front brake and rear brake using a vacuum dust collector. Never blow by com-

pressed air.

Brake fluid use refer to MA-10, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

Always confirm the specified tightening torque when installing the brake pipes.

After pressing the brake pedal more deeply or harder t han normal driving, such as air bleeding, check each

item of brake pedal. Adjust brake pedal if it is outside the standard value.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause

improper operation.

Always loosen the brake tube flar e nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

Always connect the battery terminal when moving the vehicle.

Turn the ignition switch OFF and disconnect the ABS actuator and

electric unit (control unit) harness connector or the battery negative

terminal before performing the work.

Check that no brake fluid leakage is present after replacing the parts.

Precaution for Brak e Control SystemINFOID:0000000006222557

Slight vibrations are felt on the brake pedal and the operation noises occur, when VDC function, TCS func-

tion, ABS function, EBD function, hill start assist function or brake limited slip differential (BLSD) function

operates. This is not a malfunction because it is caus ed by VDC function, TCS function, ABS function, EBD

function, hill start assist function or brake limited sl ip differential (BLSD) function that is normally operated.

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate or motor

operating noise may be heard from engine compartment. This is normal condition.

Brake stopping distance may become longer than models without ABS function depending on the road con-

ditions, when ABS function is operated on slippery r oad like rough road, gravel road or snowy road.

When a malfunction is indicated, always collect info rmation from the customer about conditions of occur-

rence, estimate cause and perform operation. Check brake booster operation, brake fluid level and brake

fluid leakage, as well as electrical system.

The optimum performance is achieved by control for V DC function, TCS function, ABS function, EBD func-

tion, hill start assist function or brake limited slip di fferential (BLSD) function when all of brakes, suspensions

PIIB3706J

JPFIA0001ZZ

Revision: 2010 May2011 QX56

Page 548 of 5598

![INFINITI QX56 2011 Factory Service Manual

SYSTEMBRC-31

< SYSTEM DESCRIPTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

During a cornering, brake force (brake fluid pressu re) is applied on front wheel and rear wheel on the inner

side o INFINITI QX56 2011 Factory Service Manual

SYSTEMBRC-31

< SYSTEM DESCRIPTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

During a cornering, brake force (brake fluid pressu re) is applied on front wheel and rear wheel on the inner

side o](/img/42/57033/w960_57033-547.png)

SYSTEMBRC-31

< SYSTEM DESCRIPTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

During a cornering, brake force (brake fluid pressu re) is applied on front wheel and rear wheel on the inner

side of turn. Moment directing towards the inner side of turn is generated. Understeer is prevented.

Applying braking during a cornering on a slippery road, when understeer tendency is judged large, engine

output is controlled as well as brake force (brake fluid pressure) of four wheels. Understeer tendency

decreases.

TCS FUNCTION

TCS FUNCTION : System DescriptionINFOID:0000000006222573

Wheel spin status of drive wheel is detected by wheel sensor of 4

wheels. Engine output and transmission shift status is controlled

so that slip rate of drive wheels is in appropriate level. When wheel

spin occurs on drive wheel, ABS ac tuator and electric unit (control

unit) perform brake force control of LH and RH drive wheels (apply

brake force by increasing brake fluid pressure of drive wheel) and

decrease engine torque by engine torque control. Wheel spin

amount decreases. Engine torque is controlled to appropriate

level.

TCS function can be switched to non-operational status (OFF) by

operating VDC OFF switch. In this case, VDC OFF indicator lamp

turns ON.

TCS function is not operate when 4WD mode is “4L”. (Models with

4WD system)

VDC warning lamp blinking while TCS function is in operation and indicates to the driver that the function is in operation.

Slight vibrations are felt on the brake pedal and the operation noises occur, when TCS function operates. This is not a malfunc-

tion because it is caused by TCS function that is normally oper-

ated.

CONSULT-III can be used to diagnose the system diagnosis.

Fail-safe function is adopted. W hen a malfunction occurs in TCS

function, the control is suspended for VDC function, TCS function,

hill start assist function and brake limited slip differential (BLSD)

function. The vehicle status becomes the same as models without VDC function, TCS function, hill start

assist function and brake limited slip differential (B LSD) function. However, ABS function and EBD function

are operated normally. Refer to BRC-25, "

Fail-safe".

SYSTEM DIAGRAM

NOTE:

JPFIC0137GB

JPFIC0138GB

JPFIC0139GB

Revision: 2010 May2011 QX56

Page 660 of 5598

![INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSBRC-143

< SYSTEM DESCRIPTION > [BRAKE ASSIST (WITH PREVIEW FUNCTION)]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Component DescriptionINFOID:0000000006248457

× : Applicable

13. Steering angle INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSBRC-143

< SYSTEM DESCRIPTION > [BRAKE ASSIST (WITH PREVIEW FUNCTION)]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Component DescriptionINFOID:0000000006248457

× : Applicable

13. Steering angle](/img/42/57033/w960_57033-659.png)

COMPONENT PARTSBRC-143

< SYSTEM DESCRIPTION > [BRAKE ASSIST (WITH PREVIEW FUNCTION)]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Component DescriptionINFOID:0000000006248457

× : Applicable

13. Steering angle sensor

Refer to BRC-10, "

Component Parts

Location"

14. ADAS control unit

Refer to DAS-13, "

Component Parts

Location"

A. Back side of engine room (RH) B. Front bumper (center) C. Upper side of brake pedal

D. Under side of instrument lower driver

panel

Component Function

Description

Vehicle-to-vehicle distance control mode

Conventional (fixed speed) cruise control mode Intelligent Brake Assist (IBA)

Brake Assist (with preview function)

ADAS control unit ×××× ADAS control unit calculates a target distance between vehicles

and a target speed, based on signals received from each sensor

and switch to transmit an engine torque command value to ECM

and a brake fluid pressure cont rol signal to ABS actuator and

electric unit (control unit) via CAN communication

ADAS control unit transmits buzzer output signal to combination

meter via CAN communication

ICC sensor ×××× ICC sensor detects light reflected from a vehicle ahead by irra-

diating laser forward and calculates a distance from the vehicle

ahead and a relative speed, based on the detected signal

ICC sensor transmits the presence/absence of vehicle ahead and the distance from the vehicle to ADAS control unit via ITS

communication

ECM ×××× ECM transmits the accelerator pedal position signal, ICC brake

switch signal, stop lamp switch signal, ICC steering switch sig-

nal, etc. to ADAS control unit via CAN communication

ECM controls the electric throttle control actuator based on the engine torque demand received from the ADAS control unit via

CAN communication

ABS actuator and electric unit

(control unit) ×××× ABS actuator and electric unit (c

ontrol unit) transmits the vehicle

speed signal (wheel speed), stop lamp signal and VDC/TCS/

ABS system operation condition to ADAS control unit via CAN

communication

ABS actuator and electric unit (c ontrol unit) controls the brake,

based on a brake fluid pressure control signal received from the

ADAS control unit via CAN communication

BCM ×BCM transmits the front wiper request signal to ADAS control unit

via CAN communication

TCM ××TCM transmits the signal related to A/T control to ADAS control

unit via CAN communication

Revision: 2010 May2011 QX56

Page 667 of 5598

![INFINITI QX56 2011 Factory Service Manual

BRC-150

< SYSTEM DESCRIPTION >[INTELLIGENT BRAKE ASSIST]

COMPONENT PARTS

Component Description

INFOID:0000000006248459

× : Applicable

13. Steering angle sensor

Refer to BRC-10, "

Component Parts

L INFINITI QX56 2011 Factory Service Manual

BRC-150

< SYSTEM DESCRIPTION >[INTELLIGENT BRAKE ASSIST]

COMPONENT PARTS

Component Description

INFOID:0000000006248459

× : Applicable

13. Steering angle sensor

Refer to BRC-10, "

Component Parts

L](/img/42/57033/w960_57033-666.png)

BRC-150

< SYSTEM DESCRIPTION >[INTELLIGENT BRAKE ASSIST]

COMPONENT PARTS

Component Description

INFOID:0000000006248459

× : Applicable

13. Steering angle sensor

Refer to BRC-10, "

Component Parts

Location"

14. ADAS control unit

Refer to DAS-13, "

Component Parts

Location"

A. Back side of engine room (RH) B. Front bumper (center) C. Upper side of brake pedal

D. Under side of inst rument lower driver

panel

Component Function

Description

Vehicle-to-vehicle distance control mode

Conventional (fixed speed) cruise control mode Intelligent Brake Assist (IBA)

Brake Assist (with preview function)

ADAS control unit ×××× ADAS control unit calculates a target distance between vehicles

and a target speed, based on signals received from each sensor

and switch to transmit an engine torque command value to ECM

and a brake fluid pres sure control signal to ABS actuator and

electric unit (control unit) via CAN communication

ADAS control unit transmits buzzer output signal to combination

meter via CAN communication

ICC sensor ×××× ICC sensor detects light reflected from a vehicle ahead by irra-

diating laser forward and calculates a distance from the vehicle

ahead and a relative speed, based on the detected signal

ICC sensor transmits the presence/absence of vehicle ahead and the distance from the vehicle to ADAS control unit via ITS

communication

ECM ×××× ECM transmits the accelerator pedal position signal, ICC brake

switch signal, stop lamp switch signal, ICC steering switch sig-

nal, etc. to ADAS control unit via CAN communication

ECM controls the electric throttle control actuator based on the engine torque demand received from the ADAS control unit via

CAN communication

ABS actuator and electric unit

(control unit) ×××× ABS actuator and electric unit (control unit) transmits the vehicle

speed signal (wheel speed), stop lamp signal and VDC/TCS/

ABS system operation condition to ADAS control unit via CAN

communication

ABS actuator and electric unit (control unit) controls the brake, based on a brake fluid pressure control signal received from the

ADAS control unit via CAN communication

BCM ×BCM transmits the front wiper request signal to ADAS control unit

via CAN communication

TCM ××TCM transmits the signal related to A/T control to ADAS control

unit via CAN communication

Revision: 2010 May2011 QX56