steering INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3393 of 5598

PRECAUTIONSIP-3

< PRECAUTION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of a ll control units using CONSULT-III.

ServiceINFOID:0000000006113090

Disconnect battery negative terminal in advance.

Disconnect air bag system line in advance.

Never tamper with or force air bag lid open, as this may adversely affect air bag performance.

Be careful not to scratch pad and other parts.

When removing or disassembling any part, be careful not to damage or deform it. Protect parts, that may get

in the way with a shop cloth.

When removing parts with a screwdriver or other tool, cover the tool surface with vinyl tape to protect parts.

Keep removed parts protected with a shop cloth.

If a clip is deformed or damaged, replace it.

If an unreusable part is removed, replace it with a new one.

Tighten bolts and nuts firmly to the specified torque.

After reassembly is complete, check that each part functions correctly.

Remove stains via the following procedure.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tightly. After wiping off the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3%), dip the cloth, then wipe off the stain with the

cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then wipe off the detergent completely. Then

wipe the area with a soft dry cloth.

Never use any organic solvent, such as thinner or benzine.

Revision: 2010 May2011 QX56

Page 3404 of 5598

IP-14

< REMOVAL AND INSTALLATION >

INSTRUMENT PANEL ASSEMBLY

Removal and Installation

INFOID:0000000006113098

WORK STEP

When removing instrument panel assembly, combination meter, front display unit, AV control unit, instrument

finisher A, instrument fini sher B, and center console assembly take st eps as per the order shown in the follow-

ing chart.

1. Optical sensor 2. Front defroster grille RH 3. Front defroster grille LH

4. Speaker grille LH 5. Squawker LH 6. Instrument finisher A

7. Combination meter 8. Cluster lid A 9. Push-button ignition switch

10. Illumination lamp 11. Socket and bulb 12. Instrument lower panel LH

13. Steering column upper cover 14. Steering column lower cover 15. Fuse block lid

16. Instrument center finisher LH 17. Instrument center finisher RH 18. Instrument lower cover

19. Illumination lamp 20. Socket and bulb 21. Glove box assembly

22. Socket and bulb 23. Illumination lamp 24. Instrument finisher B

25. Front passenger air bag module 26. Instrument panel assembly 27. Squawker RH

28. Speaker grille RH 29. Sunload sensor 30. Upper ventilator grille

31. Center speaker 32. Front display unit 33. AV control unit

34. Cluster lid D 35. Cluster lid C 36. Cluster lid C lower

37. Inner socket 38. Socket knob

: Clip

: Pawl

: Metal clip

Refer to GI-4, "

Components" for symbols in the figure.

PA R T S INSTRU-

MENT

PA N E L

ASSEMBLY COMBINA-

TION

METER FRONT

DISPLAY

UNIT AV c o n t r o l

unit INSTRU-

MENT

FINISHER A INSTRU-

MENT

FINISHER B CENTER

CONSOLE

ASSEMBLY

Instrument lower cover [1] [1] [1] [1] [1]

Glove box assembly [2] [2]

Front passenger air bag module

harness connector [3] [3]

Front passenger air bag module

mounting bolt [4] [4]

Selector lever knob [5] [2] [2] [5] [2]

Console finisher assembly [6] [3] [3] [6] [3]

Instrument center finisher RH [7] [4] [4] [7] [4]

Front body side welt RH [8] [8]

Front pillar garnish RH [9] [9]

Speaker grille RH [10] [10]

Squawker RH [11] [11]

Front defroster grille RH [12] [12]

Front defroster grille LH [13] [13]

Instrument center finisher LH [14] [5] [5] [14] [5]

Console rear finisher [15] [15] [6]

Center console assembly [16] [16] [7]

Front body side welt LH [17] [1] [1] [17]

Front pillar garnish LH [18] [18]

Speaker grille LH [19] [19]

Revision: 2010 May2011 QX56

Page 3405 of 5598

![INFINITI QX56 2011 Factory Service Manual

INSTRUMENT PANEL ASSEMBLYIP-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

[ ]:Number indicates step in removal procedures.

WARNING:

Before servicing, turn igni tion switch OFF, disc INFINITI QX56 2011 Factory Service Manual

INSTRUMENT PANEL ASSEMBLYIP-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

[ ]:Number indicates step in removal procedures.

WARNING:

Before servicing, turn igni tion switch OFF, disc](/img/42/57033/w960_57033-3404.png)

INSTRUMENT PANEL ASSEMBLYIP-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

[ ]:Number indicates step in removal procedures.

WARNING:

Before servicing, turn igni tion switch OFF, disconnect battery ne gative terminal, and wait 3 minutes or

more.

CAUTION:

When removing, always use a remover tool that is made of plastic.

REMOVAL

1. Remove instrument lower cover.

1. Pull disengaged pawls downward.

2. Pull back instrument lower cover.

3. Disconnect harness connectors.

Squawker LH [20] [20]

Instrument lower panel LH [21] [2] [2] [21]

Disconnect meter control switch

harness connector [22] [3] [3] [22]

Driver air bag module [23] [23]

Steering wheel [24] [24]

Steering column cover [25] [25]

Combination switch [26] [26]

Spiral cable [27] [27]

Cluster lid A [28] [4] [4] [28]

Combination meter [29] [5] [29]

Instrument finisher A [5]

Upper ventilator grille [30] [30]

Center speaker [31] [31]

Cluster lid C [32] [6] [6] [32]

Cluster lid C lower [33] [7] [33]

AV control unit [34] [8] [34]

Cluster lid D [35] [7] [35]

Front display unit [36] [8] [36]

instrument panel assembly

mounting screws and bolts [37] [37]

Squawker LH harness clip [38] [38]

Instrument panel assembly [39] [39]

Instrument finisher B [40]

PA R T S

INSTRU-

MENT

PA N E L

ASSEMBLY COMBINA-

TION

METER FRONT

DISPLAY UNIT AV c o n t r o l

unit INSTRU-

MENT

FINISHER A INSTRU-

MENT

FINISHER B CENTER

CONSOLE

ASSEMBLY

: Pawl

JMJIA3828ZZ

Revision: 2010 May2011 QX56

Page 3409 of 5598

INSTRUMENT PANEL ASSEMBLYIP-19

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

3. Remove center console assembly front fixing screws (B).

4. Lift up center console assembly back side, and then remove center console assembly.

17. Remove front body side welt LH. Refer to INT-20, "

BODY SIDE WELT : Removal and Installation".

18. Remove front pillar garnish LH. Refer to INT-19, "

FRONT PILLAR GARNISH : Removal and Installation".

19. Remove speaker grille LH. 1. Disengage speaker grille LH fixing pawls with remover tool (A).

2. Pull up speaker grille LH.

CAUTION:

Apply protective tape (B) on the part to protect it from dam-

age.

20. Remove squawker LH. Refer to AV-218, "

Removal and Installation".

21. Remove instrument lower panel LH. 1. Remove food opener lever fixing bolts. Refer to DLK-238, "

Removal and Installation"

2. Pull back instrument lower panel LH, and then disengage

the clips and pawl.

3. Disconnect harness connectors and aspirator duct.

22. Disconnect meter control s witch harness connector (A).

23. Remove driver air bag module. Refer to SR-11, "

Removal and Installation".

24. Remove steering wheel. Refer to ST-33, "

Removal and Installation".

JMJIA3898ZZ

: Pawl

JMJIA3839ZZ

: Clip

: Pawl

JMJIA3840ZZ

JMJIA3841ZZ

Revision: 2010 May2011 QX56

Page 3410 of 5598

IP-20

< REMOVAL AND INSTALLATION >

INSTRUMENT PANEL ASSEMBLY

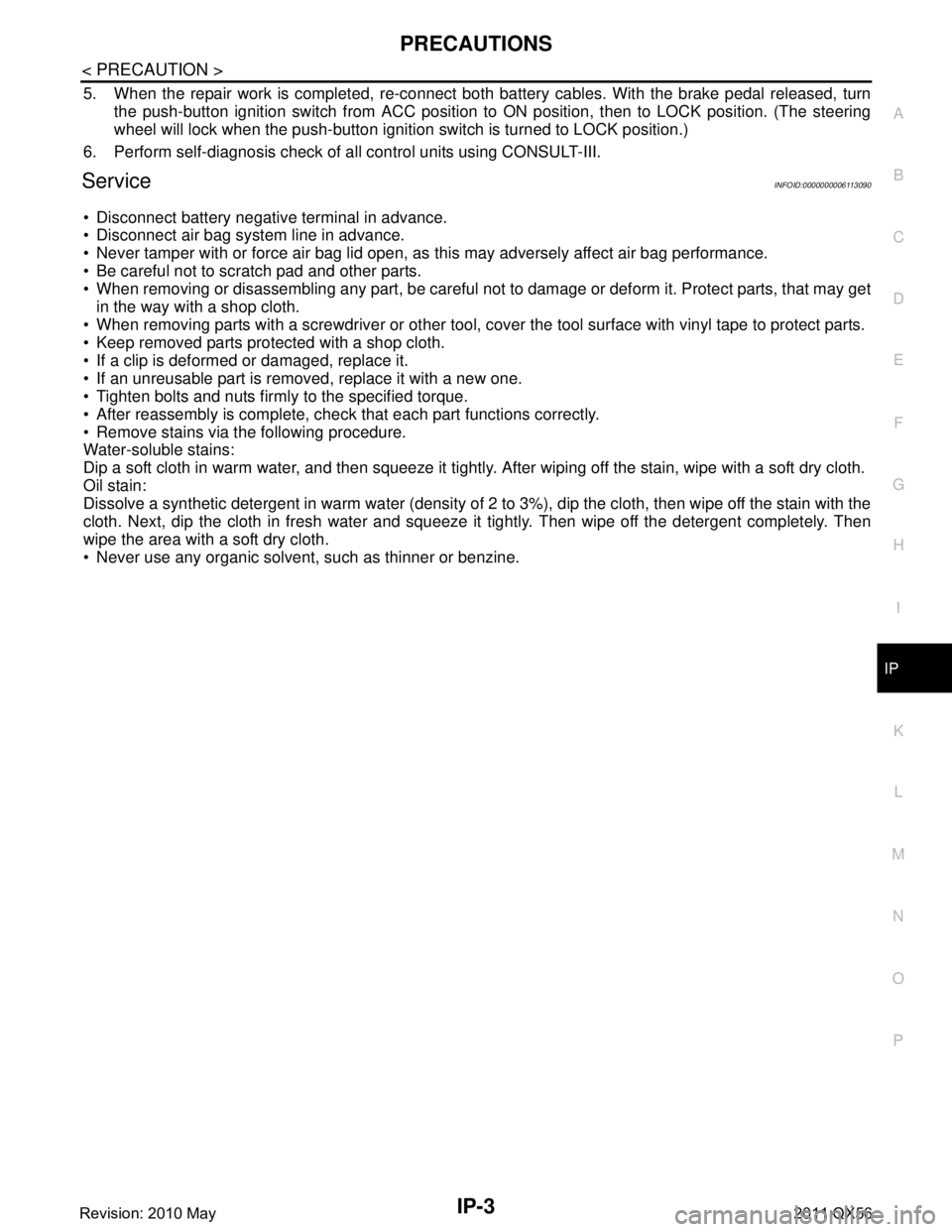

25. Remove steering column covers.1. Remove steering column cover fixing screws (A).

2. Pull up steering column upper cover (1), and then disen-gage steering column upper cove fixing pawls.

3. Remove steering column upper cover.

4. Pull down steering column lower cover (2), and then discon- nect ADP steering switch connector (with ADP).

5. Remove steering column lower cover.

26. Remove combination switch. Refer to BCS-82, "

Removal and Installation".

27. Remove spiral cable. Refer to SR-14, "

Removal and Installation".

28. Remove cluster lid A. 1. Pull back cluster lid A, and then disengage the clips and

pawls.

2. Disconnect harness connectors.

29. Remove combination meter. Refer to MWI-85, "

Removal and Installation".

30. Remove upper ventilator grille. 1. Disengage upper ventilator grille fixing clips and pawls with

remover tool (A)

2. Pull toward the arrow direction.

CAUTION:

Apply protective tape (B) on the part to protect it from dam-

age.

31. Remove center speaker. Refer to AV-221, "

Removal and Installation".

32. Remove cluster lid C. 1. Remove cluster lid C fixing screws (A).

2. Pull back cluster lid C, and then disengage the pawls and

metal clips.

3. Disconnect harness connectors.

: Pawl

JMJIA3842ZZ

: Clip

: Pawl

JMJIA3843ZZ

: Clip

: Pawl

JMJIA3844ZZ

: Pawl

: Metal Clip

JMJIA4228ZZ

Revision: 2010 May2011 QX56

Page 3433 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

TROUBLE DIAGNOSISLAN-13

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

NOTE:

When data link connector branch line is open, transmi

ssion and reception of CAN communicati INFINITI QX56 2011 Factory Service Manual

LAN

TROUBLE DIAGNOSISLAN-13

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

NOTE:

When data link connector branch line is open, transmi

ssion and reception of CAN communicati](/img/42/57033/w960_57033-3432.png)

LAN

TROUBLE DIAGNOSISLAN-13

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

NOTE:

When data link connector branch line is open, transmi

ssion and reception of CAN communication signals

are not affected. Therefore, no symptoms occur. However, be sure to repair malfunctioning circuit.

The model (all units on CAN communication system are Diag on CAN) cannot perform CAN diagnosis with

CONSULT-III if the following error occurs. The error is judged by the symptom.

Example: Main Line Between Data Link Connector and ABS Actuator and Electr ic Unit (Control Unit) Open Circuit

Unit name Major symptom

ECM

Normal operation.

BCM

EPS control unit

Combination meter

ABS actuator and electric

unit (control unit)

TCM

IPDM E/R

Error Difference of symptom

Data link connector branch line open circuit Normal operation.

CAN-H, CAN-L harness short-circuit Most of the units which are connected to the CAN communication

system enter fail-safe mode or are deactivated.

SKIB8740E

Unit name Major symptom

ECM Engine torque limiting is affected, and shift harshness increases.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front wip-

er switch being in the intermittent position.

EPS control unit The steering effort increases.

Combination meter The shift position indicator and OD OFF indicator turn OFF.

The speedometer is inoperative.

The odo/trip meter stops.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R When the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

Revision: 2010 May2011 QX56

Page 3434 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-14

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000006220519

CAN diagnosis on CONSULT-III extract INFINITI QX56 2011 Factory Service Manual

LAN-14

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000006220519

CAN diagnosis on CONSULT-III extract](/img/42/57033/w960_57033-3433.png)

LAN-14

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000006220519

CAN diagnosis on CONSULT-III extracts the root

cause by receiving the following information.

Response to the system call

Control unit diagnosis information

Self-diagnosis

CAN diagnostic support monitor

SKIB8741E

Unit name Major symptom

ECM Engine torque limiting is affected, and shift harshness increases.

Engine speed drops.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front

wiper switch being in the intermittent position.

The room lamp does not turn ON.

The engine does not start (if an error or malfunction occurs while turning the igni- tion switch OFF.)

The steering lock does not release (if an error or malfunction occurs while turning the ignition switch OFF.)

EPS control unit The steeri ng effort increases.

Combination meter The tachometer and the speedometer do not move.

Warning lamps turn ON.

Indicator lamps do not turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R When the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

Revision: 2010 May2011 QX56

Page 3443 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

HOW TO USE THIS SECTIONLAN-23

< HOW TO USE THIS MANUAL > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

HOW TO USE THIS MANUAL

HOW TO USE THIS SECTION

CautionINFOID:0000000006220525

This section describes INFINITI QX56 2011 Factory Service Manual

LAN

HOW TO USE THIS SECTIONLAN-23

< HOW TO USE THIS MANUAL > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

HOW TO USE THIS MANUAL

HOW TO USE THIS SECTION

CautionINFOID:0000000006220525

This section describes](/img/42/57033/w960_57033-3442.png)

LAN

HOW TO USE THIS SECTIONLAN-23

< HOW TO USE THIS MANUAL > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

HOW TO USE THIS MANUAL

HOW TO USE THIS SECTION

CautionINFOID:0000000006220525

This section describes information peculiar to a vehicle and inspection procedures.

For trouble diagnosis procedure, refer to

LAN-18, "

Trouble Diagnosis Procedure".

Abbreviation ListINFOID:0000000006220526

Unit name abbreviations in CONSULT-III CAN diagnosis and in this section are as per the following list.

Abbreviation Unit name

4WD Transfer control unit

A-BAG Air bag diagnosis sensor unit ABS ABS actuator and electric unit (control unit)

ADP Driver seat control unit AFS AFS control unitAPA Accelerator pedal actuator AV AV control unit

BCM BCM

CGW CAN gateway DLC Data link connector

E-SUS Air levelizer control module ECM ECM

HVAC A/C auto amp. ICC ADAS control unit

IPDM-E IPDM E/R LANE Lane camera unit

LASER ICC sensor M&A Combination meter

PSB Pre-crash seat belt control unit (driver side)

PWBD Automatic back door control module

RDR-L Side radar LH

RDR-R Side radar RH STRG Steering angle sensor TCM TCM

TPMS Low tire pressure warning control unit

Revision: 2010 May2011 QX56

Page 3446 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-26

< SYSTEM DESCRIPTION >[CAN]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006220530

1. Air bag diagnosis sensor unit 2. Lane camera unit 3. A/T assem INFINITI QX56 2011 Factory Service Manual

LAN-26

< SYSTEM DESCRIPTION >[CAN]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006220530

1. Air bag diagnosis sensor unit 2. Lane camera unit 3. A/T assem](/img/42/57033/w960_57033-3445.png)

LAN-26

< SYSTEM DESCRIPTION >[CAN]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006220530

1. Air bag diagnosis sensor unit 2. Lane camera unit 3. A/T assembly

4. AFS control unit 5. Transfer control unit 6. Low tire pressure warning control

unit

7. IPDM E/R 8. CAN gateway 9. ECM

10. A/C auto amp. 11. ICC sensor 12. AV control unit

13. BCM 14. ABS actuator an d electric unit (con-

trol unit) 15. Combination meter

16. Data link connector 17. Steering angle sensor 18. Accelerator pedal actuator

19. Driver seat control un it 20. Pre-crash seat be lt control unit (driv-

er side) 21. Air levelizer control module

22. ADAS control unit 23. Automatic back door control module 24. Side radar LH

25. Side radar RH

JSMIA0343ZZ

Revision: 2010 May2011 QX56

Page 3447 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

SYSTEMLAN-27

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : CAN

System Specification ChartINFOID:0000000006220532

Determine INFINITI QX56 2011 Factory Service Manual

LAN

SYSTEMLAN-27

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : CAN

System Specification ChartINFOID:0000000006220532

Determine](/img/42/57033/w960_57033-3446.png)

LAN

SYSTEMLAN-27

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : CAN

System Specification ChartINFOID:0000000006220532

Determine CAN system type from the following specification chart.

NOTE:

Refer to LAN-18, "

Trouble Diagnosis Procedure" for how to use CAN system specification chart.

×: Applicable

VEHICLE EQUIPMENT IDENTIFICATION INFORMATION

NOTE:

Body type Wagon

Axle 2WD 4WD

Engine VK56VD

Transmission A/T

Brake control VDC

ICC system ××

CAN system type 1 2 3 4 CAN communication unit

ECM ××××

Transfer control unit ××

ABS actuator and electric unit (control unit) ××××

TCM ××××

Air bag diagnosis sensor unit ××××

AFS control unit ××

AV control unit ××××

BCM ××××

CAN gateway ××

Data link connector ××××

A/C auto amp. ××××

Combination meter ××××

Steering angle sensor ××××

Low tire pressure warning control unit ××××

IPDM E/R ××××

Driver seat control unit ××××

Pre-crash seat belt control unit (driver side) ××

Air levelizer control module ××××

ADAS control unit ××

Automatic back door control module ××××

ITS communication unit

ADAS control unit ××

Side radar RH ××

Side radar LH ××

Lane camera unit ××

Accelerator pedal actuator ××

ICC sensor ××

Revision: 2010 May2011 QX56