suspension INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1 of 5598

A

B

D

E

F

G

H

I

J

K

L

M

N

P

O

C

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

STRStarting System

ACCAccelerator Control System

CHYBRIDHBCHybrid Control System

HBBHybrid Battery System

HBRHybrid Brake System

DTRANSMISSION & DRIVE-

LINECLClutch

TMTransaxle & Transmission

DLNDriveline

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

SCSSuspension Control System

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGSTSteering System

STCSteering Control System

HRESTRAINTSSBSeat Belt

SBCSeat Belt Control System

SRSRS Airbag

SRCSRS Airbag Control System

IVENTILATION, HEATER &

AIR CONDITIONERVTLVentilation System

HAHeater & Air Conditioning System

HACHeater & Air Conditioning Control System

JBODY INTERIORINTInterior

IPInstrument Panel

SESeat

ADPAutomatic Drive Positioner

KBODY EXTERIOR,

DOORS, ROOF & VEHICLE

SECURITYDLKDoor & Lock

SECSecurity Control System

GWGlass & Window System

PWCPower Window Control System

RFRoof

HDHood

EXTExterior

BRMBody Repair

LDRIVER CONTROLSMIRMirrors

EXLExterior Lighting System

INLInterior Lighting System

WWWiper & Washer

DEFDefogger

HRNHorn

MELECTRICAL & POWER

CONTROLPWOPower Outlet

BCSBody Control System

LANLAN System

PCSPower Control System

CHGCharging System

PGPower Supply, Ground & Circuit Elements

NDRIVER INFORMATION &

MULTIMEDIAMWIMeter, Warning Lamp & Indicator

WCSWarning Chime System

SNSonar System

AVAudio, Visual & Navigation System

OCRUISE CONTROL &

DRIVER ASSISTANCECCSCruise Control System

DASDriver Assistance System

DMSDrive Mode System

PMAINTENANCEMAMaintenance

All rights reserved. No part

of this Service Manual may

be reproduced or stored in a

retrieval system, or transmit-

ted in any form, or by any

means, electronic, mechani-

cal, recording or otherwise,

without the prior written per-

mission of NISSAN MOTOR

CO., LTD.

Edition: May 2010

Publication No. SM1E-1Z62U0

Page 476 of 5598

BR-6

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000006222461

Use the chart below to find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference page

BR-16

,

BR-18

BR-16

, BR-18

BR-36

, BR-42

BR-16

, BR-18

BR-16

, BR-18

BR-16

, BR-18

BR-16

, BR-18

BR-16

, BR-18

BR-16

, BR-18

BR-16

, BR-18

NVH in PB section

NVH in DLN section

NHV in DLN section

NVH in FAX, RAX and FSU, RSU section

NVH in WT section

NVH in WT section

NVH in FAX, RAX section

NVH in ST section

Possible cause and

SUSPECTED PARTS

Pads damaged

Pads uneven wear

Shims damaged

Rotor imbalance

Rotor damage

Rotor runout

Rotor deformation

Rotor deflection

Rotor rust

Rotor thickness variation

Drum out of round

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TIRE

ROAD WHEEL

DRIVE SHAFT

STEERING

Symptom BRAKE Noise

××× ×× ×××

××

Shake ×××××

××

Shimmy, Judder ××××××× ××× ×

Revision: 2010 May2011 QX56

Page 523 of 5598

![INFINITI QX56 2011 Factory Service Manual

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position INFINITI QX56 2011 Factory Service Manual

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position](/img/42/57033/w960_57033-522.png)

BRC-6

< PRECAUTION >[WITH VDC]

PRECAUTIONS

5. When the repair work is completed, re-connect bot

h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006228176

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000006222556

WARNING:

Clean any dust from the front brake and rear brake using a vacuum dust collector. Never blow by com-

pressed air.

Brake fluid use refer to MA-10, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

Always confirm the specified tightening torque when installing the brake pipes.

After pressing the brake pedal more deeply or harder t han normal driving, such as air bleeding, check each

item of brake pedal. Adjust brake pedal if it is outside the standard value.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause

improper operation.

Always loosen the brake tube flar e nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

Always connect the battery terminal when moving the vehicle.

Turn the ignition switch OFF and disconnect the ABS actuator and

electric unit (control unit) harness connector or the battery negative

terminal before performing the work.

Check that no brake fluid leakage is present after replacing the parts.

Precaution for Brak e Control SystemINFOID:0000000006222557

Slight vibrations are felt on the brake pedal and the operation noises occur, when VDC function, TCS func-

tion, ABS function, EBD function, hill start assist function or brake limited slip differential (BLSD) function

operates. This is not a malfunction because it is caus ed by VDC function, TCS function, ABS function, EBD

function, hill start assist function or brake limited sl ip differential (BLSD) function that is normally operated.

When starting engine or when starting vehicle just after starting engine, brake pedal may vibrate or motor

operating noise may be heard from engine compartment. This is normal condition.

Brake stopping distance may become longer than models without ABS function depending on the road con-

ditions, when ABS function is operated on slippery r oad like rough road, gravel road or snowy road.

When a malfunction is indicated, always collect info rmation from the customer about conditions of occur-

rence, estimate cause and perform operation. Check brake booster operation, brake fluid level and brake

fluid leakage, as well as electrical system.

The optimum performance is achieved by control for V DC function, TCS function, ABS function, EBD func-

tion, hill start assist function or brake limited slip di fferential (BLSD) function when all of brakes, suspensions

PIIB3706J

JPFIA0001ZZ

Revision: 2010 May2011 QX56

Page 524 of 5598

![INFINITI QX56 2011 Factory Service Manual

PRECAUTIONSBRC-7

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

and tires installed on the vehicle are the specified si ze and parts. Brake performance and controllability may

be negativ INFINITI QX56 2011 Factory Service Manual

PRECAUTIONSBRC-7

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

and tires installed on the vehicle are the specified si ze and parts. Brake performance and controllability may

be negativ](/img/42/57033/w960_57033-523.png)

PRECAUTIONSBRC-7

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

and tires installed on the vehicle are the specified si ze and parts. Brake performance and controllability may

be negatively affected when other parts than the specified are installed.

Brake stopping distance may become longer and steering stability may be negatively affected, when tires in

different size and combination or other parts than the specified are used.

When a radio (including wiring), antenna and antenna lead line are located near ABS actuator and electric

unit (control unit), a malfunction or improper operation ma y occur for the control of VDC function, TCS func-

tion, ABS function, EBD function, hill start assist func tion or brake limited slip differential (BLSD) function.

When the following items are replaced by other parts than genuine parts or modified, ABS warning lamp, brake warning lamp and VDC warning lamp may turn ON, and the control may not operate normally for VDC

function, TCS function, ABS function, EB D function, hill start assist function or brake limited slip differential

(BLSD) function.

- Suspension component parts (shock absorber, spring, bushing and others)

- Tire and wheel (other than the specified size)

- Brake component parts (brake pad, disc rotor, brake caliper and others)

- Engine component parts (ECM, muffler and others)

- Body reinforcement component parts (rollover bar, tower bar and others)

When suspension, tire and brake component parts are excessively worn or deteriorated and the vehicle is

driven, ABS warning lamp, brake warning lamp and VDC warning lamp may tu\

rn ON, and the control may

not operate normally for VDC function, TCS function, ABS function, EBD function, hill start assist function or

brake limited slip differential (BLSD) function.

ABS warning lamp, brake warning lamp and VDC warning lamp may turn ON, when only front wheel or rear wheel is rotated using a free roller. This is not a ma lfunction, because it is caused by wheel speed difference

between wheel that is rotated and wheel that is not rota ted. In this case, perform self-diagnosis, check self-

diagnosis results, and erase memory.

When power supply voltage is not normal, ABS warning lamp, brake warning lamp and VDC warning lamp

turn ON. ABS actuator and electric unit (control unit) st ops control for VDC function, TCS function, ABS func-

tion, EBD function, hill start assist function or brake limited slip differential (BLSD) function. Ordinary brake

operates. After power supply returns to normal, ABS warning lamp, brake warning lamp and VDC warning

lamp turn OFF. The control becomes operative for VD C function, TCS function, ABS function, EBD function,

hill start assist function or brake li mited slip differential (BLSD) function.

VDC warning lamp may turn ON and VDC function or TCS function may not normally operate, when driving

on a special road the is extremely slanted (bank in a circ uit course). This is not a malfunction if the status

returns to normal for VDC function or TCS function after the engine is started again. In this case, perform

self-diagnosis, check self-diagnosis results, and erase memory.

A malfunction in yaw rate/side/decel G sensor syste m may be detected when the vehicle sharply turns dur-

ing a spin turn, acceleration turn or drift driving while VDC function or TCS function are OFF (VDC OFF

switch is pressed and VDC OFF indicator lamp is in ON st atus). This is not a malfunction if the status returns

to normal for VDC function or TCS function after the engine is started again. In this case, perform self-diag-

nosis, check self-diagnosis results, and erase memory

Precaution for Harness RepairINFOID:0000000006222558

Solder the repair part, and wrap it with tape. [Twisted wire fray must be 110 mm (4.33 in) or less.]

SKIB8766E

Revision: 2010 May2011 QX56

Page 581 of 5598

![INFINITI QX56 2011 Factory Service Manual

BRC-64

< BASIC INSPECTION >[WITH VDC]

ADJUSTMENT OF STEERING ANGLE

SENSOR NEUTRAL POSITION

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

DescriptionINFOID:0000000006222588

Always adjust the n INFINITI QX56 2011 Factory Service Manual

BRC-64

< BASIC INSPECTION >[WITH VDC]

ADJUSTMENT OF STEERING ANGLE

SENSOR NEUTRAL POSITION

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

DescriptionINFOID:0000000006222588

Always adjust the n](/img/42/57033/w960_57033-580.png)

BRC-64

< BASIC INSPECTION >[WITH VDC]

ADJUSTMENT OF STEERING ANGLE

SENSOR NEUTRAL POSITION

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

DescriptionINFOID:0000000006222588

Always adjust the neutral position of steering angle sensor before driving when the following operation is per-

formed.

× : Required —: Not required

Work ProcedureINFOID:0000000006222589

ADJUST THE NEUTRAL POSITION OF STEERING ANGLE SENSOR

CAUTION:

Always use CONSULT-III when adju sting the neutral position of steering angle sensor. (It cannot be

adjusted other than with CONSULT-III.)

1.CHECK THE VEHICLE STATUS

Stop vehicle with front wheels in the straight-ahead position.

Does the vehicle stay in the straight-ahead position?

YES >> GO TO 2.

NO >> Steer the steering wheel to the st raight-ahead position. Stop the vehicle.

2.ADJUST NEUTRAL POSITION OF STEERING ANGLE SENSOR

With CONSULT-III.

1. Turn the ignition switch ON.

CAUTION:

Never start engine.

2. Select “ABS”, “WORK SUPPORT” and “ST AN GLE SENSOR ADJUSTMENT” in this order.

3. Select “START”. CAUTION:

Never touch steering wheel while adjusting steering angle sensor.

4. After approx. 10 seconds, select “END”.

5. Turn ignition switch OFF and then turn it ON again. CAUTION:

Be sure to perform the operation above.

>> GO TO 3.

3.CHECK DATA MONITOR

With CONSULT-III.

1. The vehicle is either pointing straight ahead or t he vehicle needs to be moved. Stop when it is pointing

straight ahead.

Procedure Adjust the neutral position of steering angle sensor

Removing/ installing ABS actuator and electric unit (control unit) —

Replacing ABS actuator and electric unit (control unit) —

Removing/installing steering angle sensor ×

Replacing steering angle sensor ×

Removing/installing steering components ×

Replacing steering components ×

Removing/installing suspension components ×

Replacing suspension components ×

Removing/installing tire —

Replacing tire —

Tire rotation —

Adjusting wheel alignment. ×

Revision: 2010 May2011 QX56

Page 583 of 5598

![INFINITI QX56 2011 Factory Service Manual

BRC-66

< BASIC INSPECTION >[WITH VDC]

CALIBRATION OF DECEL G SENSOR

CALIBRATION OF DECEL G SENSOR

DescriptionINFOID:0000000006222590

CAUTION:

Always perform the decel G sensor cal

ibration before dri INFINITI QX56 2011 Factory Service Manual

BRC-66

< BASIC INSPECTION >[WITH VDC]

CALIBRATION OF DECEL G SENSOR

CALIBRATION OF DECEL G SENSOR

DescriptionINFOID:0000000006222590

CAUTION:

Always perform the decel G sensor cal

ibration before dri](/img/42/57033/w960_57033-582.png)

BRC-66

< BASIC INSPECTION >[WITH VDC]

CALIBRATION OF DECEL G SENSOR

CALIBRATION OF DECEL G SENSOR

DescriptionINFOID:0000000006222590

CAUTION:

Always perform the decel G sensor cal

ibration before driving when the following operation is per-

formed.

NOTE:

Yaw rate/side/decel G sensor calibration is performed when performing the decel G sensor calibration.

× : Required —: Not required

Work ProcedureINFOID:0000000006222591

Decel G sensor calibration

CAUTION:

Always use CONSULT-III for the d ecel G sensor calibration. (It cannot be adjusted other than with

CONSULT-III.)

NOTE:

Yaw rate/side/decel G sensor calibration is performed when performing the decel G sensor calibration.

1.CHECK THE VEHICLE STATUS

1. Steer the steering wheel to the straight- ahead position. Stop the vehicle on level surface.

2. Stop the engine.

3. Turn the ignition switch OFF.

Is the vehicle stopped in the straight-ahead position on level surface?

YES >> GO TO 2.

NO >> Steer the steering wheel to the straight- ahead position. Stop the vehicle on level surface.

2.PERFORM DECEL G SENSOR CALIBRATION

CAUTION:

Never allow passenger or load on the vehicle.

Never apply vibration to the vehicle body when opening or closing door during calibration.

With CONSULT-III.

1. Turn the ignition switch ON.

CAUTION:

Never start engine.

2. Select “ABS”, “WORK SUPPORT”, “DECEL G-SENSOR CALIBRATION” in this order.

3. Select “START”.

4. After approx. 10 seconds, select “END”.

5. Turn ignition switch OFF and then turn it ON again. CAUTION:

Be sure to perform the operation above.

Procedure Decel G sensor calibration

Removing/ installing ABS actuator and electric unit (control unit) —

Replacing ABS actuator and electric unit (control unit) ×

Removing/installing steering components —

Replacing steering components —

Removing/installing suspension components —

Replacing suspension components —

Removing/installing tire —

Replacing tire —

Tire rotation —

Adjusting wheel alignment. —

Removing/installing yaw rate/side/decel G sensor ×

Replacing yaw rate/side/decel G sensor ×

Revision: 2010 May2011 QX56

Page 679 of 5598

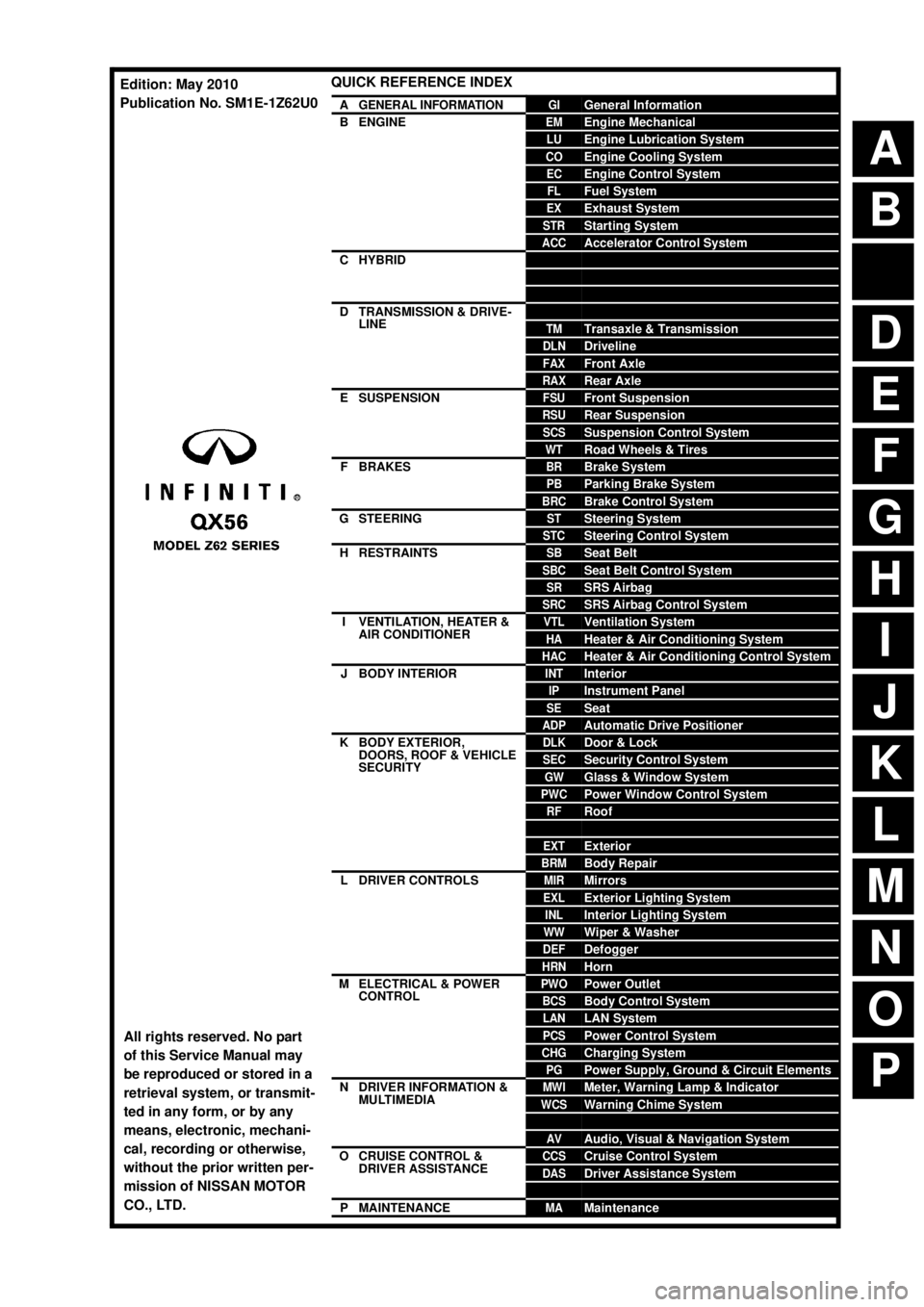

BRM-4

< PRECAUTION >

REPAIRING HIGH STRENGTH STEEL

PRECAUTION

REPAIRING HIGH STRENGTH STEEL

High Strength Steel (HSS)INFOID:0000000006248484

High strength steel is used for body panels in order to reduce vehicle weight.

Accordingly, precautions in repairing automotive bodies made of high strength steel are described below:

Read the following precautions when repairing HSS:

1. Additional points to consider

Tensile strength Major applicable parts 440 - 780 MPa Rear floor reinforcement

2nd seat mounting member assembly

Front seat mounting rear crossmember assembly

Front floor reinforcement

2nd crossmember (Lower)

Side radiator core support

Radiator core support main assembly

Front side member assembly

4th crossmember

2nd seat mounting crossmember

Rear side member

Rear crossmember

Inner side roof rail

Upper inner front pillar

Inner center pillar

Upper front pillar reinforcement

Lower center pillar brace

Front pillar brace

Outer sill reinforcement

Front roof rail

Rear roof rail

Radiator guard crossmember assembly

2nd crossmember assembly

2nd crossmember reinforcement

Front side member assembly

Front bound bumper bracket assembly

Lower front link mounting bracket assembly

Center side member assembly

Fuel tank protector assembly

Rear suspension mounting bracket assembly

Rear shock absorber bracket assembly

Rear side member assembly

Rear end gusset

Rear end crossmember assembly

980 - 1350 MPa Lower dash center reinforcement

(Lower dash Component part)

Inner sill

Rear seat crossmember

(2nd seat mounting crossmember component part)

Inner center pillar (Upper)

Upper outer center pillar reinforcement

(Lower center pillar brace component part)

Front bumper crossmember assembly

Revision: 2010 May2011 QX56

Page 689 of 5598

BRM-14

< PREPARATION >

BODY COMPONENT PARTS

NOTE:

For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

Tensile strength column shows the largest strength value of a part in the component part.

CAUTION:

If the high strength steel (ultra high strength steel) of this is broken, replace by assembly for the supply part. No. Parts name

Tensile strength

(MPa) Both sided anti-corrosive

precoated steel sections

1. Frame assembly Refer to No.2−36

2. Front bumper crossmember assembly T=1.8 mm

(0.071 in)

980

caution—

3. 2nd crossmember assembly 440 —

4. 2nd crossmember reinforcement (RH & LH) 440 —

5. 1st cab mounting bracket (RH & LH) Under 440 —

6. Front side member assembly (RH & LH) 540 —

7. Front suspension bracket assembly (RH & LH) Under 440 —

8. Engine mounting bracket assembly (RH & LH) Under 440 —

9. 2nd cab mounting bracket assembly (RH & LH) Under 440 —

10. 3way connector bracket assembly (RH & LH) Under 440 —

11. Piping bracket assembly (RH & LH) Under 440 —

12. Front bound bumper bracket assembly (RH & LH) 540 —

13. Lower front link mounting bracket assembly (RH & LH) 440 —

14. Diagonal member complete (RH & LH) 540 —

15. Rear engine mounting gusset assembly Under 440 —

16. Rear engine mounting member complete Under 440 —

17. Front fuel tank protector (RH & LH) Under 440 —

18. 3rd cab mounting bracket assembly (RH & LH) Under 440 —

19. Center side member assembly (RH & LH) 540 —

20. 6th crossmember assembly Under 440 —

21. Exhaust bracket (Front) Under 440 —

22. Fuel tank protector (RH & LH Rear) Under 440 —

23. Heat insulator bracket Under 440 —

24. Fuel tank protector assembly (RH & LH) 540 —

25. Rear suspension mounting bracket assembly (RH & LH) 540 —

26. 4th cab body mounting bracket assembly (RH & LH) Under 440 —

27. Rear brake hose bracket (RH & LH) Under 440 —

28. Rear shock absorber bracket assembly (RH & LH) 540 —

29. Rear side member assembly (RH & LH) 540 —

30. 5th cab body bracket (RH & LH) Under 440 —

31. 7th crossmember assembly Under 440 —

32. Exhaust bracket (Rear) Under 440 —

33. Spare wheel crossmember assembly Under 440 —

34. Front under cover bracket assembly Under 440 —

35. Rear end gusset (RH & LH) 440 —

36. Rear end crossmember assembly 540 —

Revision: 2010 May2011 QX56

Page 1254 of 5598

![INFINITI QX56 2011 Factory Service Manual

DAS

HANDLING PRECAUTIONDAS-289

< SYSTEM DESCRIPTION > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

- When driving without normal tire conditions (for example, tire wear, low tire pressure, installation INFINITI QX56 2011 Factory Service Manual

DAS

HANDLING PRECAUTIONDAS-289

< SYSTEM DESCRIPTION > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

- When driving without normal tire conditions (for example, tire wear, low tire pressure, installation](/img/42/57033/w960_57033-1253.png)

DAS

HANDLING PRECAUTIONDAS-289

< SYSTEM DESCRIPTION > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

- When driving without normal tire conditions (for example, tire wear, low tire pressure, installation of spare tire, tire chains, non-standard wheels).

- When the vehicle is equipped with non-origi nal brake parts or suspension parts.

- When towing a trailer or other vehicle.

Excessive noise will interfere with the warning chime sound, and the chime may not be heard.

The functions of the LDP system (warning and brake control assist) may or may not operate properly under

the following conditions:

- On roads where there are multiple parallel lane marker s; lane markers that are faded or not painted clearly;

yellow painted lane markers; non-standard lane markers or lane markers covered with water, dirt or snow,

etc.

- On roads where discontinued lane markers are still detectable.

- On roads where there are sharp curves.

- On roads where there are sharply contrasting objects, such as shadows, snow, water, wheel ruts, seams or

lines remaining after road repairs (The LDP syste m could detect these items as lane markers.).

- On roads where the traveling lane merges or separates.

- When the vehicle's traveling direction does not align with the lane marker.

- When traveling close to other vehicle in front of the vehicle, which obstructs the lane camera unit detection

range.

- When rain, snow or dirt adheres to the windshield in front of the lane camera unit.

- When the headlights are not bright due to dirt on the lens or if the aiming is not adjusted properly.

- When strong light enters the lane camera unit (For example, the light directly shines on the front of the vehi-

cle at sunrise or sunset.)

- When a sudden change in brightness occurs (For exampl e, when the vehicle enters or exits a tunnel or

under a bridge.)

While the LDP system is operating, driver may hear a sound of brake operation. This is normal and indicates

that the LDP system is operating properly.

Revision: 2010 May2011 QX56

Page 1307 of 5598

![INFINITI QX56 2011 Factory Service Manual

DAS-342

< BASIC INSPECTION >[LDW & LDP]

CAMERA AIMING ADJUSTMENT

3. Mark point “E” on the line “LH” at the

positions 3850 mm (151.57 in) from point “A”.

4. Draw line “RH” passing thr INFINITI QX56 2011 Factory Service Manual

DAS-342

< BASIC INSPECTION >[LDW & LDP]

CAMERA AIMING ADJUSTMENT

3. Mark point “E” on the line “LH” at the

positions 3850 mm (151.57 in) from point “A”.

4. Draw line “RH” passing thr](/img/42/57033/w960_57033-1306.png)

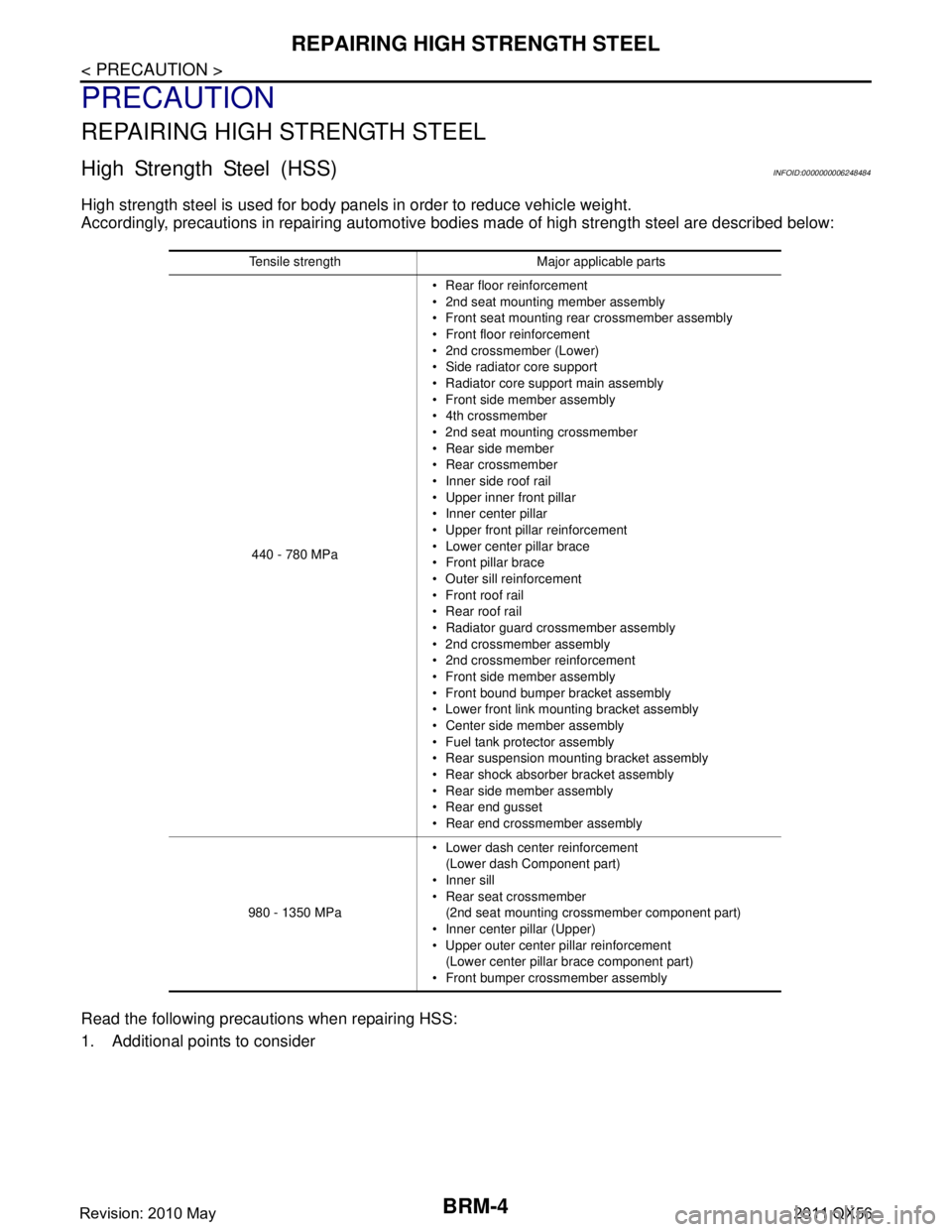

DAS-342

< BASIC INSPECTION >[LDW & LDP]

CAMERA AIMING ADJUSTMENT

3. Mark point “E” on the line “LH” at the

positions 3850 mm (151.57 in) from point “A”.

4. Draw line “RH” passing through points “C” and “D” on the right side of vehicle in the same way as step 2. NOTE:

Approximately 4 m (13.12 ft) or more from the front end of vehicle.

5. Mark point “F” on the line “RH” at the positions 3850 mm (151.57 in) from point “C”.

6. Draw line “FW” passing through the points “E” and “F” on the front side of vehicle.

7. Mark point “X” at the center of point “E” and “F” on the line “FW”.

CAUTION:

Make sure that “E” to “X” is equal to “F” to “X”.

8. Position the center of the ri ght target to point of “X”.

>> Go to DAS-342, "

Work Procedure (Camera Aiming

Adjustment)".

Work Procedure (Camera Aiming Adjustment)INFOID:0000000006223737

CAUTION:

Perform the adjustment under unloaded vehicle condition.

1.CHECK VEHICLE HEIGHT

Measure the wheelarch height. Calculate “Dh”.

NOTE:

“Dh” may be calculated as a minus value.

>> GO TO 2.

2.CAMERA AIMING ADJUSTMENT

CAUTION:

Operate CONSULT-III outside the vehic le, and close all the doors. (To retain vehicle attitude appropri-

ately)

1. Select “Work Support” on “L ANE CAMERA” with CONSULT-III.

2. Select “AUTO AIM”.

3. Confirm the following items;

- The target should be accurately placed.

- The vehicle should be stopped.

4. Select “Start” to perform camera aiming. CAUTION:

Never select “Start” when the target is not accurately placed.

Wait 5 seconds or more after selecting “Start”.

5. Input “Dh”, and then select “Start”.

CAUTION:

Never change “Ht” and “Dt”.

6. Confirm the displayed item.

- “Normally Completed”: Select “Completion”.

- “SUSPENSION”, “X AIMING NG Y”, “ABNORMALL Y COMPLETED”: Perform the following services.

JPOIA0173GB

Dh [mm] = (Hfl + Hfr) ÷ 2 − 903

where, Hfl: Front left wheelarch height [mm]

Hfr: Front right wh eelarch height [mm]

JSOIA0361ZZ

Revision: 2010 May2011 QX56