BATTERY INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3029 of 5598

INSPECTION AND ADJUSTMENTGI-65

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O PINSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Re-

quired Procedure After Battery Disconnection

INFOID:0000000006344676

*: Not equipped. SYSTEM ITEM REFERENCE

Front automatic air

conditioning system Temperature setting trimmer (Front)

HAC-68, "

FRONT AUTOMATIC

AIR CONDITIONING SYSTEM :

Temperature Setting Trimmer

(Front)"

Foot position setting trimmer

HAC-68, "

FRONT AUTOMATIC

AIR CONDITIONING SYSTEM :

Foot Position Setting Trimmer"

Inlet port memory function* —

Inlet port memory function (FRE)

HAC-69, "

FRONT AUTOMATIC

AIR CONDITIONING SYSTEM :

Inlet Port Memory

Function (FRE)"

Inlet port memory function (REC) HAC-69, "

FRONT AUTOMATIC

AIR CONDITIONING SYSTEM :

Inlet Port Memory Function (REC)"

ACCS (Advanced Cli-

mate Control System)Exhaust gas / outside odor detecting sensor sensitivity adjustment func-

tion

HAC-70, "

ACCS (ADVANCED

CLIMATE CONTROL SYSTEM) :

Exhaust Gas / Outside Odor De-

tecting Sensor Sensitivity Adjust-

ment Function"

Auto intake switch interlocking movement change function

HAC-70, "

ACCS (ADVANCED

CLIMATE CONTROL SYSTEM) :

Auto Intake Switch Interlocking

Movement Change Function"

Clean switch interlocking movement change function* —

Rear automatic air

conditioning system Temperature setting trimmer (Rear) HAC-69, "

REAR AUTOMATIC AIR

CONDITIONING SYSTEM : Tem-

perature Setting

Trimmer (Rear)"

Automatic drive posi-

tioner Automatic drive positioner system ADP-51, "

ADDITIONAL SERVICE

WHEN REMOVING BATTERY

NEGATIVE TERMINAL : Descrip-

tion"

Power window control Power window control system

PWC-31, "Description"

Sunroof system* Sunroof system —

Sunshade system* Sunshade system —

Rear view monitor* Rear view monitor predictive course line center position adjustment —

Around view monitor Predictive course line center position adjustment AV- 111 , "

Description"

Automatic back door

systemAutomatic back door system DLK-80, "

ADDITIONAL SERVICE

WHEN REMOVING BATTERY

NEGATIVE TERMINAL : Descrip-

tion"

Engine oil level read* Engine oil level read —

Revision: 2010 May2011 QX56

Page 3030 of 5598

GW-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G H

I

J

L

M

SECTION GW

A

B

GW

N

O P

CONTENTS

GLASS & WINDOW SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

2

Precaution for Procedure without Cowl Top Cover ......3

Handling for Adhesive and Primer ............................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tools ........................................ ......4

Commercial Service Tools .......................................4

SYMPTOM DIAGNOSIS ...............................5

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................

5

Work Flow ........................................................... ......5

Inspection Procedure ................................................7

Diagnostic Worksheet ...............................................9

REMOVAL AND INSTALLATION ...............11

WINDSHIELD GLASS .................................... ....11

Exploded View .................................................... ....11

Removal and Installation .........................................12

Inspection ................................................................13

SIDE WINDOW GLASS ....................................14

Exploded View ..................................................... ....14

Removal and Installation .........................................15

Inspection ................................................................15

BACK DOOR WINDOW GLASS ......................16

Exploded View ..................................................... ....16

Removal and Installation .........................................16

Inspection ................................................................17

FRONT DOOR GLASS .....................................19

Exploded View .........................................................19

Removal and Installation .........................................19

Inspection and Adjustment ......................................20

FRONT REGULATOR .......................................21

Exploded View .........................................................21

Removal and Installation .........................................21

Disassembly and Assembly .....................................21

Inspection and Adjustment ......................................22

REAR DOOR GLASS .......................................23

Exploded View .........................................................23

Removal and Installation .........................................23

Inspection and Adjustment ......................................25

REAR REGULATOR .........................................26

Exploded View .........................................................26

Removal and Installation .........................................26

Disassembly and Assembly .....................................27

Inspection and Adjustment ......................................27

Revision: 2010 May2011 QX56

Page 3031 of 5598

GW-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006257243

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation after Battery Disconnect

INFOID:0000000006257244

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect bot h battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the bat tery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 3032 of 5598

PRECAUTIONSGW-3

< PRECAUTION >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006108039

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Handling for Adhesive and PrimerINFOID:0000000006108040

Do not use an adhesive which is past its usable date. Shel f life of this product is limited to six months after

the date of manufacture. Carefully adhere to the ex piration or manufacture date printed on the box.

Keep primers and adhesive in a cool, dry place. I deally, they should be stored in a refrigerator.

Open the seal of the primer and adhesive just before application. Discard the remainder.

Before application, be sure to shake the primer container to stir the contents. If any floating material is found,

do not use it.

If any primer or adhesive contacts the skin, wipe it off with gasoline or equivalent and wash the skin with

soap.

When using primer and adhesive, always observe the precautions in the instruction manual.

PIIB3706J

Revision: 2010 May2011 QX56

Page 3056 of 5598

REAR REGULATORGW-27

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

8. Operate the power window switch to raise or lower the door win- dow until the glass mounting bolts can be seen.

9. Remove the rear door glass mounting bolts.

10. Raise rear door glass up and hold it with a suction lifter (A).

11. Disconnect rear door power window motor harness connector.

12. Remove rear door regulator mounting nuts.

13. Remove rear door power window motors mounting bolts.

14. Remove rear door regulator from rear door panel.

INSTALLATION

Install in the reverse order of removal.

Disassembly and AssemblyINFOID:0000000006220834

DISASSEMBLY

Remove rear power window motor from rear door regulator.

ASSEMBLY

Assemble in the reverse order of disassembly.

Inspection and AdjustmentINFOID:0000000006220835

SYSTEM INITIALIZATION

Initialize the system if any of t he following work has been done. Refer to ADP-51, "ADDITIONAL SERVICE

WHEN REMOVING BATTERY NEGATIVE TERMINAL : Description".

Initialization

Follow the steps below after installing each component to the vehicle. Refer to ADP-51, "ADDITIONAL SER-

VICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Special Repair Requirement".

FITTING INSPECTION

Check that the glass is fit securely into the sash groove.

Lower the glass slightly [approximately 10 to 20 mm (0.394 to 0.787 in)], and check that the clearance to the

sash is parallel. Loosen the regulator mounting bolts, guide rail mounting bolts, and glass and guide rail

mounting bolts to correct the glass position if the clearance between the glass and sash is not parallel.

: Bolt

JMKIA1789ZZ

PIIB3511J

Revision: 2010 May2011 QX56

Page 3057 of 5598

HA-1

VENTILATION, HEATER & AIR CONDITIONER

C

DE

F

G H

J

K L

M

SECTION HA

A

B

HA

N

O P

CONTENTS

HEATER & AIR CONDITIONING SYSTEM

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Precaution for Procedure without Cowl Top Cover ......4

Precautions For Refrigerant System Service ............4

Service Equipment ....................................................6

PREPARATION ............................................9

PREPARATION .............................................. .....9

Special Service Tool ........................................... ......9

Commercial Service Tool ........................................12

Sealant or/and Lubricant .........................................12

SYSTEM DESCRIPTION .............................13

COMPONENT PARTS ................................... ....13

Component Parts Location .................................. ....13

Component Description ...........................................13

SYSTEM .............................................................14

System Diagram .................................................. ....14

System Description .................................................14

BASIC INSPECTION ...................................16

DIAGNOSIS AND REPAIR WORKFLOW ..... ....16

Work Flow ........................................................... ....16

REFRIGERANT ..................................................18

Description .......................................................... ....18

Leak Test ................................................................18

Recycle Refrigerant .................................................20

Charge Refrigerant ..................................................20

LUBRICANT ................................................... ....22

Description .......................................................... ....22

Inspection ............................................................ ....22

Perform Lubricant Return Operation .......................22

Lubricant Adjusting Procedure for Components

Replacement Except Compressor ...........................

22

Lubricant Adjusting Procedure for Compressor

Replacement ...........................................................

23

PERFORMANCE TEST ....................................25

Inspection ................................................................25

SYMPTOM DIAGNOSIS ..............................27

REFRIGERATION SYSTEM SYMPTOMS ........27

Trouble Diagnosis For Unusual Pressure ............ ....27

Symptom Table .......................................................27

NOISE ................................................................29

Symptom Table .......................................................29

REMOVAL AND INSTALLATION ...............30

COMPRESSOR .................................................30

Exploded View ..................................................... ....30

COMPRESSOR ..........................................................30

COMPRESSOR : Removal and Installation ............30

MAGNET CLUTCH ................................................ ....31

MAGNET CLUTCH : Removal and Installation of

Compressor Clutch ..................................................

31

Inspection ................................................................32

COOLER PIPE AND HOSE ..............................33

Exploded View .........................................................33

HIGH-PRESSURE FLEXIBLE HOSE ........................34

HIGH-PRESSURE FLEXIBLE HOSE : Removal

and Installation .................................................... ....

34

LOW-PRESSURE FLEXIBLE HOSE ..................... ....35

LOW-PRESSURE FLEXIBLE HOSE : Removal

and Installation ........................................................

35

HIGH-PRESSURE PIPE ............................................35

Revision: 2010 May2011 QX56

Page 3059 of 5598

PRECAUTIONSHA-3

< PRECAUTION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006276136

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006276137

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 3060 of 5598

HA-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006276138

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions For Refrigerant System ServiceINFOID:0000000006276139

GENERAL REFRIGERANT PRECAUTION

WARNING:

Never breathe A/C refrigerant an d lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Use only approved reco very/recycling equipment to discharge HFC-134a (R-134a) refrigerant.

Ventilate work area before resuming service if acci dental system discharge occurs. Additional health

and safety information may be obtained from refrigerant and lubricant manufacturers.

Never release refrigerant into the air. Use appro ved recovery/recycling recharging equipment to cap-

ture the refrigerant each time an ai r conditioning system is discharged.

Wear always eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

Never store or heat refrigerant containers above 52 °C (126 °F).

Never heat a refrigerant container with an open flame; Place the bottom of the container in a warm

pail of water if container warming is required.

Never intentionally drop, puncture, or incinerate refrigerant containers.

Keep refrigerant away from open flames: pois onous gas is produced if refrigerant burns.

Refrigerant displaces oxygen, therefore be certain to work in well ventilated areas to prevent suffo-

cation.

Never pressure test or leakage test HFC-134a (R- 134a) service equipment and/or vehicle air condi-

tioning systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a)

have been shown to be combusti ble at elevated pressures. These mixtures, if ignited, may cause

injury or property damage. Additional health and safety information may be obtained from refriger-

ant manufacturers.

WORKING WITH HFC-134a (R-134a)

CAUTION:

CFC-12 (R-12) refrigerant and HFC-134a (R-134a) re frigerant are not compatible. These regrigerants

must never be mixed, even in the smallest amount s. Compressor malfunction is likely occur if the

refrigerants are mixed.

Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. Compressor malfunction is likely to occur if lubricant other than that specified is used.

The specified HFC-134a (R-134a) lu bricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precauti ons must be observed:

- Cap (seal) immediately the compon ent to minimize the entry of moisture from the atmosphere when

removing refrigerant components from a vehicle.

- Never remove the caps (unseal) until just before co nnecting the components when installing refrig-

erant components to a vehicle. Connect all refr igerant loop components as quickly as possible to

minimize the entry of moisture into system.

- Use only the specified lubricant from a sealed contai ner. Reseal immediately containers of lubricant.

Lubricant becomes moisture saturated and should not be used without proper sealing.

PIIB3706J

Revision: 2010 May2011 QX56

Page 3065 of 5598

PREPARATIONHA-9

< PREPARATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

PREPARATION

PREPARATION

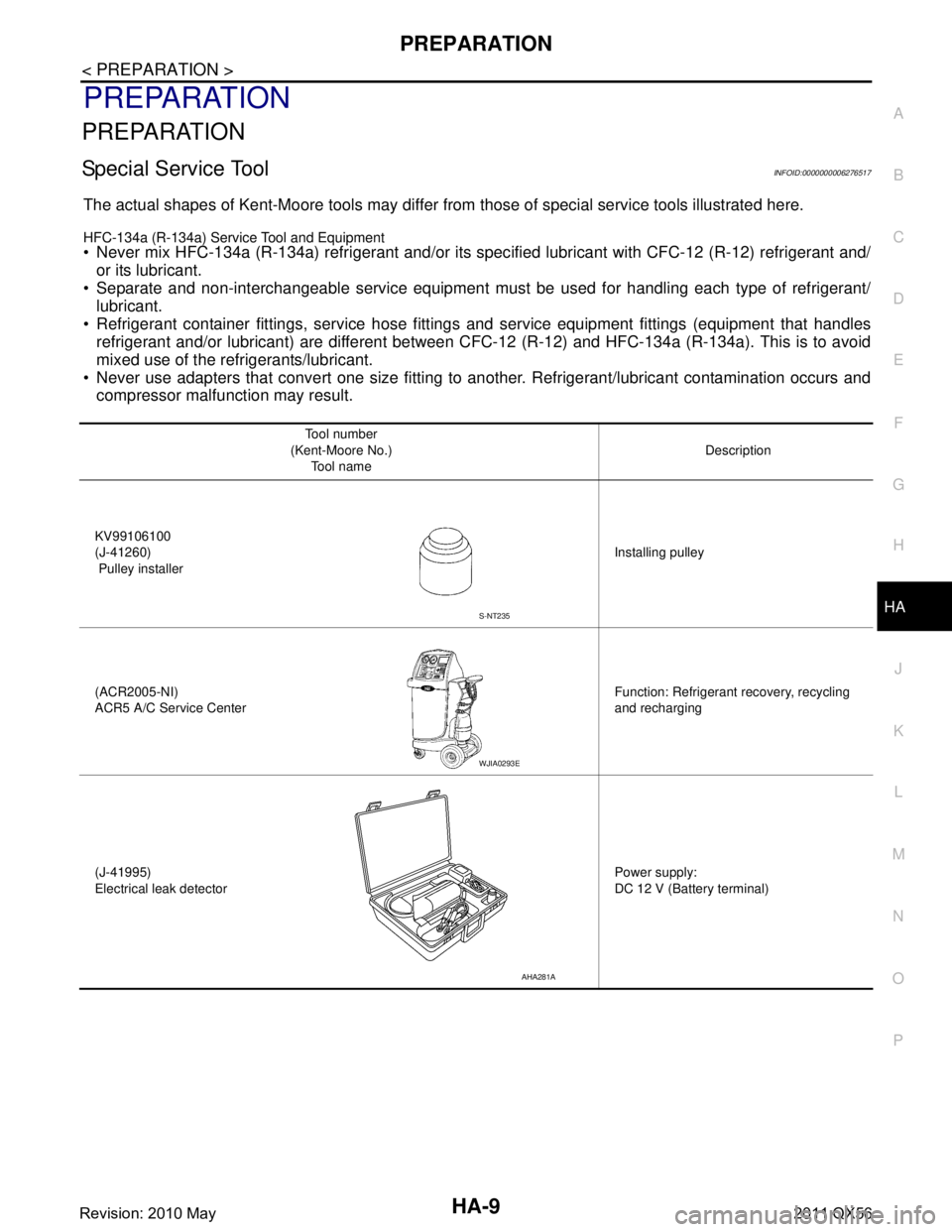

Special Service ToolINFOID:0000000006276517

The actual shapes of Kent-Moore tools may differ fr om those of special service tools illustrated here.

HFC-134a (R-134a) Service Tool and Equipment

Never mix HFC-134a (R-134a) refrigerant and/or its spec ified lubricant with CFC-12 (R-12) refrigerant and/

or its lubricant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/

lubricant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment that handles

refrigerant and/or lubricant) are different between CF C-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Never use adapters that convert one size fitting to another. Refrigerant/lubricant contamination occurs and

compressor malfunction may result.

Tool number

(Kent-Moore No.) Tool name Description

KV99106100

(J-41260)

Pulley installer Installing pulley

(ACR2005-NI)

ACR5 A/C Se rvice Center Function: Refrigerant recovery, recycling

and recharging

(J-41995)

Electrical leak detector Power supply:

DC 12 V (Battery terminal)

S-NT235

WJIA0293E

AHA281A

Revision: 2010 May2011 QX56

Page 3066 of 5598

HA-10

< PREPARATION >

PREPARATION

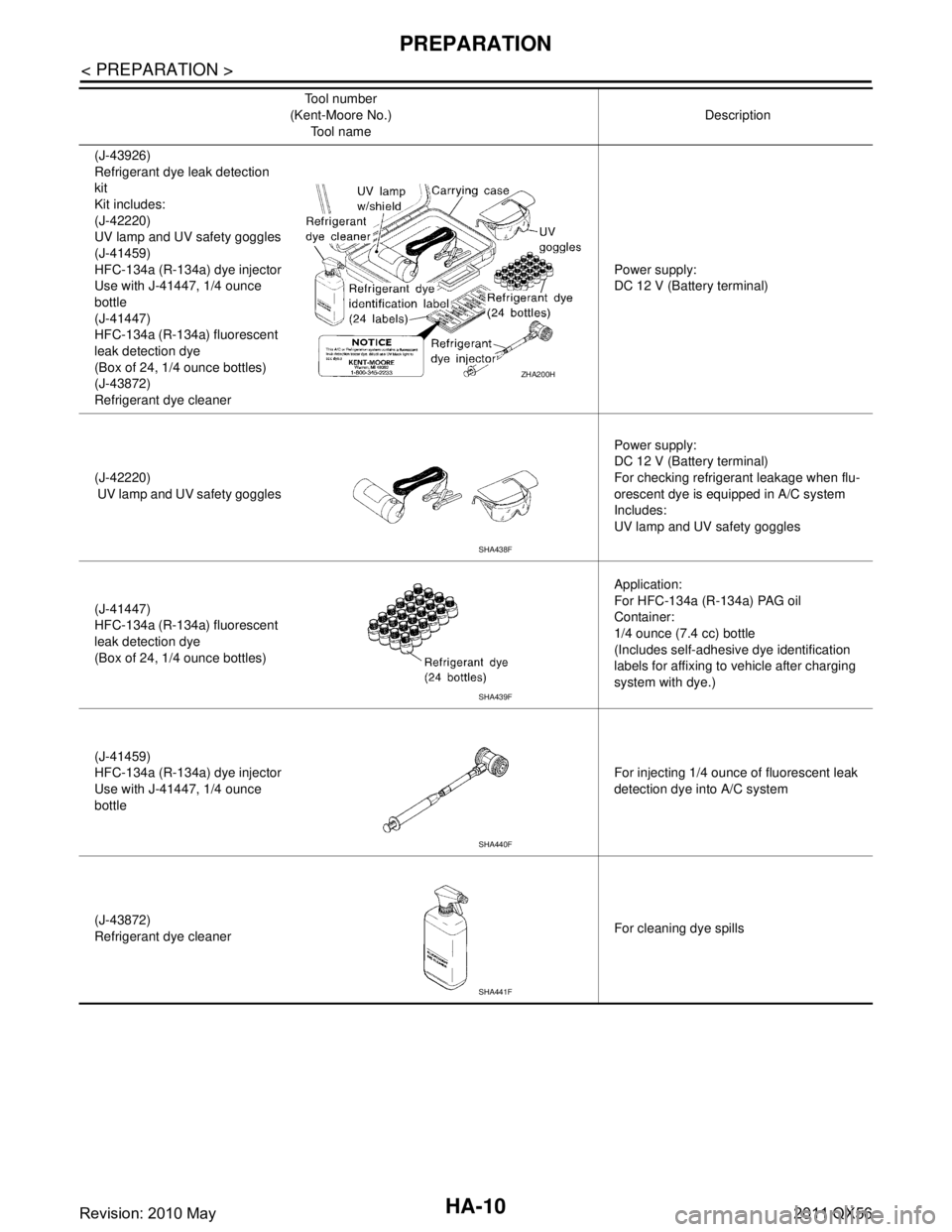

(J-43926)

Refrigerant dye leak detection

kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

HFC-134a (R-134a) dye injector

Use with J-41447, 1/4 ounce

bottle

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)

(J-43872)

Refrigerant dye cleanerPower supply:

DC 12 V (Battery terminal)

(J-42220)

UV lamp and UV safety goggles Power supply:

DC 12 V (Battery terminal)

For checking refrigerant leakage when flu-

orescent dye is equipped in A/C system

Includes:

UV lamp and UV safety goggles

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles) Application:

For HFC-134a (R-134a) PAG oil

Container:

1/4 ounce (7.4 cc) bottle

(Includes self-adhesive dye identification

labels for affixing to vehicle after charging

system with dye.)

(J-41459)

HFC-134a (R-134a) dye injector

Use with J-41447, 1/4 ounce

bottle For injecting 1/4 ounce of fluorescent leak

detection dye into A/C system

(J-43872)

Refrigerant dye cleaner For cleaning dye spills

Tool number

(Kent-Moore No.)

Tool name Description

ZHA200H

SHA438F

SHA439F

SHA440F

SHA441F

Revision: 2010 May2011 QX56