tires INFINITI QX56 2011 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4266 of 5598

REAR SHOCK ABSORBERRSU-11

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

Inadvertent piping removal causes fluid to splatter.

2. Remove tires with power tool. Refer to WT-64, "

Removal and Installation".

3. Remove height sensor from rear lower link (right side). Refer to EXL-136, "

Removal and Installation".

4. Remove vehicle height sensor from rear lower link (left side). Refer to SCS-98, "

Removal and Installa-

tion".

5. Remove air tube from shock absorber assembly. Refer to SCS-95, "

Removal and Installation".

6. Remove middle tube assembly from shock absorber assembly. (With HBMC) Refer to SCS-44, "

REAR

TUBE ASSEMBLY : Removal and Installation".

7. Remove shock absorber mounting bolt (lower side).

8. Remove piston rod lock nut.

9. Remove bracket, bushings, and shock absorber. (With HBMC)

10. Remove washers, bushings, and shock absorber. (Without HBMC)

11. Perform inspection after removal. Refer to RSU-11, "

Inspection and Adjustment".

INSTALLATION

Note the following, and install in the reverse order of removal.

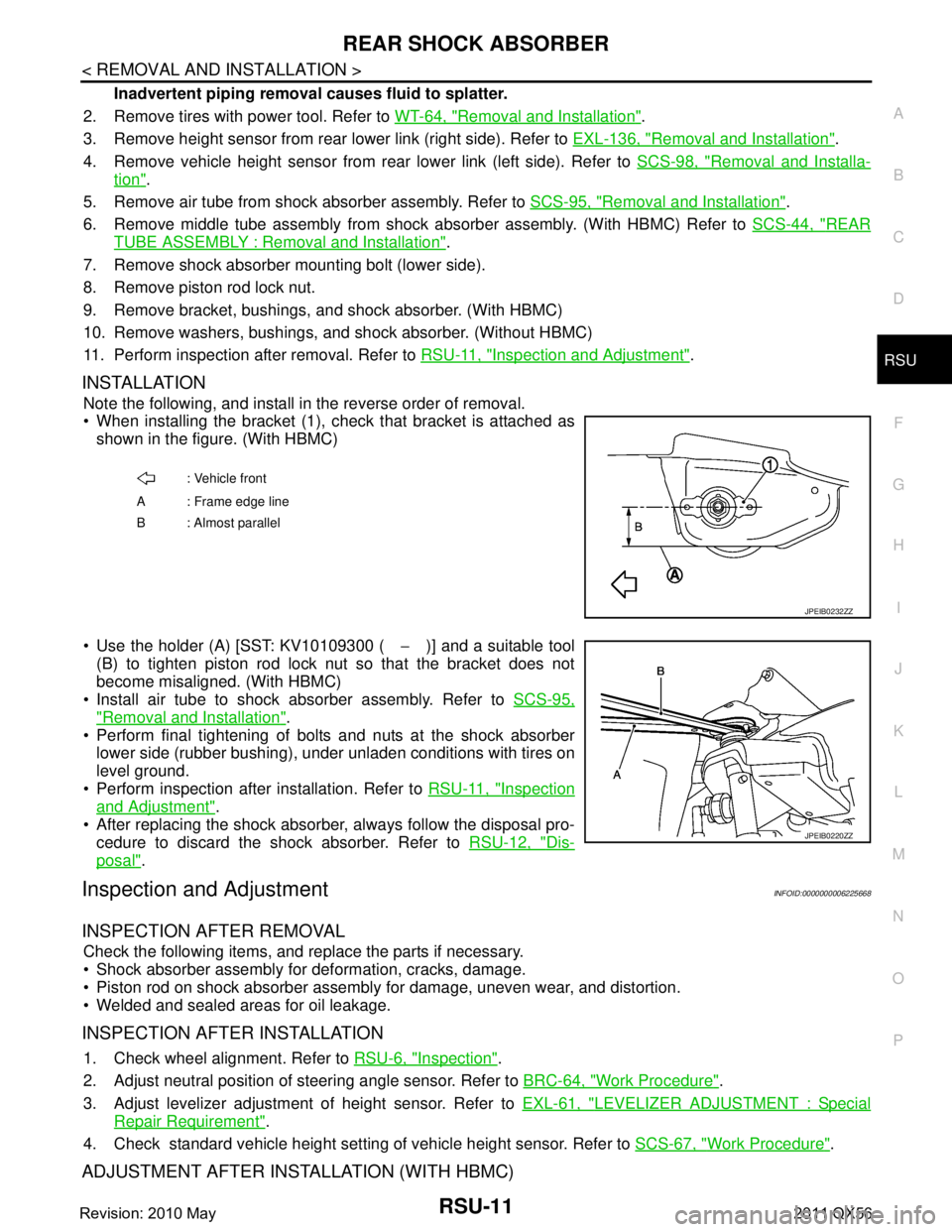

When installing the bracket (1), check that bracket is attached as

shown in the figure. (With HBMC)

Use the holder (A) [SST: KV10109300 ( −)] and a suitable tool

(B) to tighten piston rod lock nut so that the bracket does not

become misaligned. (With HBMC)

Install air tube to shock absorber assembly. Refer to SCS-95,

"Removal and Installation".

Perform final tightening of bolts and nuts at the shock absorber

lower side (rubber bushing), under unladen conditions with tires on

level ground.

Perform inspection after installation. Refer to RSU-11, "

Inspection

and Adjustment".

After replacing the shock absorber, always follow the disposal pro- cedure to discard the shock absorber. Refer to RSU-12, "

Dis-

posal".

Inspection and AdjustmentINFOID:0000000006225668

INSPECTION AFTER REMOVAL

Check the following items, and replace the parts if necessary.

Shock absorber assembly for deformation, cracks, damage.

Piston rod on shock absorber assembly for damage, uneven wear, and distortion.

Welded and sealed areas for oil leakage.

INSPECTION AFTER INSTALLATION

1. Check wheel alignment. Refer to RSU-6, "Inspection".

2. Adjust neutral position of steering angle sensor. Refer to BRC-64, "

Work Procedure".

3. Adjust levelizer adjustment of height sensor. Refer to EXL-61, "

LEVELIZER ADJUSTMENT : Special

Repair Requirement".

4. Check standard vehicle height setting of vehicle height sensor. Refer to SCS-67, "

Work Procedure".

ADJUSTMENT AFTER INSTALLATION (WITH HBMC)

: Vehicle front

A : Frame edge line

B: Almost parallel

JPEIB0232ZZ

JPEIB0220ZZ

Revision: 2010 May2011 QX56

Page 4268 of 5598

SUSPENSION ARMRSU-13

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

SUSPENSION ARM

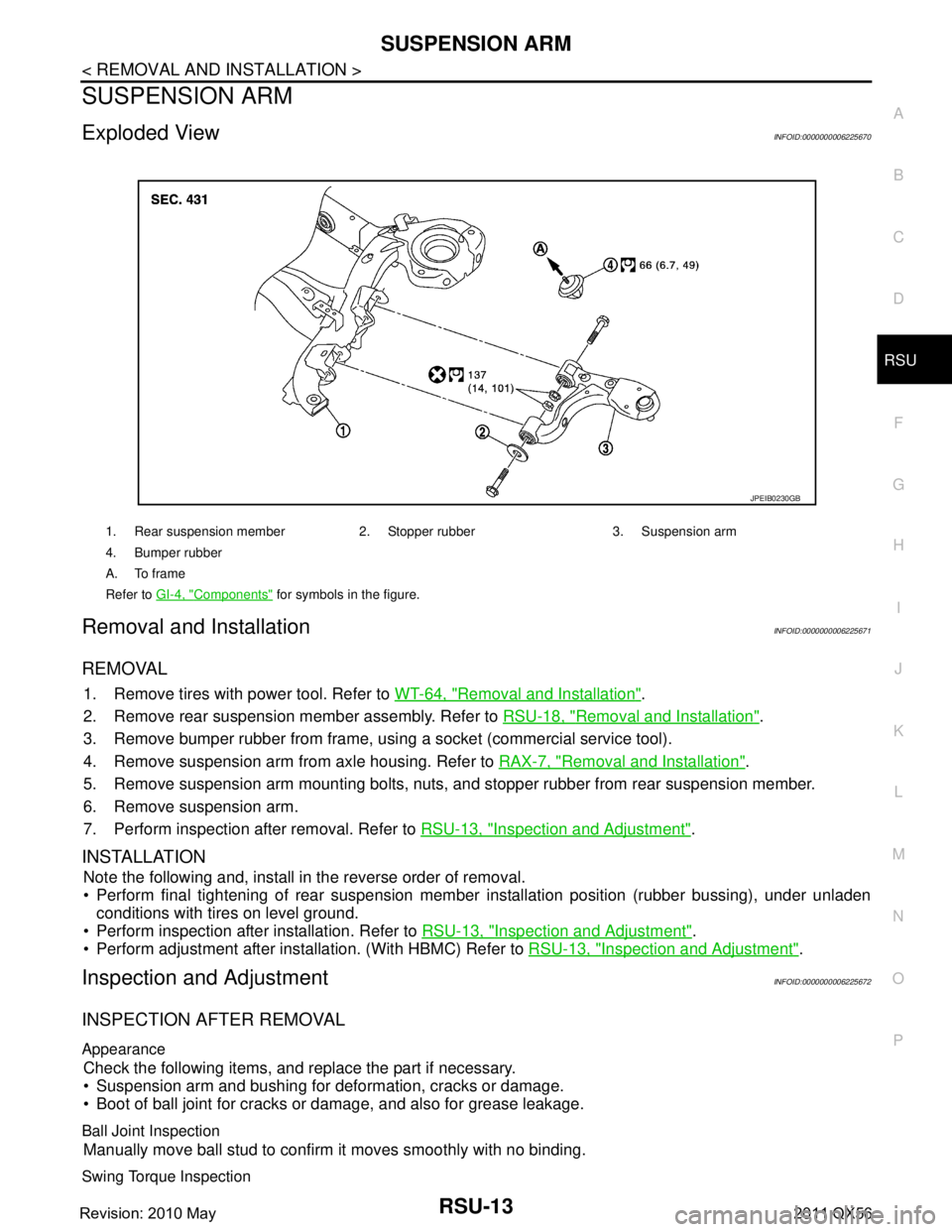

Exploded ViewINFOID:0000000006225670

Removal and InstallationINFOID:0000000006225671

REMOVAL

1. Remove tires with power tool. Refer to WT-64, "Removal and Installation".

2. Remove rear suspension member assembly. Refer to RSU-18, "

Removal and Installation".

3. Remove bumper rubber from frame, usi ng a socket (commercial service tool).

4. Remove suspension arm from axle housing. Refer to RAX-7, "

Removal and Installation".

5. Remove suspension arm mounting bolts, nuts, and stopper rubber from rear suspension member.

6. Remove suspension arm.

7. Perform inspection after removal. Refer to RSU-13, "

Inspection and Adjustment".

INSTALLATION

Note the following and, install in the reverse order of removal.

Perform final tightening of rear suspension mem ber installation position (rubber bussing), under unladen

conditions with tires on level ground.

Perform inspection after installation. Refer to RSU-13, "

Inspection and Adjustment".

Perform adjustment after installation. (With HBMC) Refer to RSU-13, "

Inspection and Adjustment".

Inspection and AdjustmentINFOID:0000000006225672

INSPECTION AFTER REMOVAL

Appearance

Check the following items, and replace the part if necessary.

Suspension arm and bushing for deformation, cracks or damage.

Boot of ball joint for cracks or damage, and also for grease leakage.

Ball Joint Inspection

Manually move ball stud to confirm it moves smoothly with no binding.

Swing Torque Inspection

1. Rear suspension member 2. Stopper rubber 3. Suspension arm

4. Bumper rubber

A. To frame

Refer to GI-4, "

Components" for symbols in the figure.

JPEIB0230GB

Revision: 2010 May2011 QX56

Page 4270 of 5598

FRONT LOWER LINKRSU-15

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

FRONT LOWER LINK

Exploded ViewINFOID:0000000006225673

Removal and InstallationINFOID:0000000006225674

REMOVAL

1. Remove tires with power tool. Refer to WT-64, "Removal and Installation".

2. Set suitable jack under rear lower link.

3. Remove shock absorber mounting bolts from front lower link. Refer to RSU-10, "

Exploded View".

4. Remove stabilizer connecting rod. (Without HBMC) Refer to RSU-17, "

Removal and Installation".

5. Remove front lower link mounting bolts and nuts from axle housing.

6. Remove front lower link mounting bolt, nuts, stopper rubbers, eccentric disc, and adjusting bolt from rear

suspension member, and remove front lower link.

7. Perform inspection after removal. Refer to RSU-15, "

Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

Perform final tightening of rear suspension mem ber and axle installation position (rubber bushing), under

unladen conditions with tires on level ground.

Perform inspection after installation. Refer to RSU-15, "

Inspection".

InspectionINFOID:0000000006225675

INSPECTION AFTER REMOVAL

Appearance

Check the following items, and replace the part if necessary.

Front lower link and bushing for deformation, cracks or damage.

Boot of ball joint for cracks or damage, and also for grease leakage.

Ball Joint Inspection

Manually move ball stud to confirm it moves smoothly with no binding.

Swing Torque Inspection

1. Move the ball joint at least ten times by hand to check for smooth movement.

1. Rear suspension member 2. Adjusting bolt 3. Stopper rubber

4. Front lower link 5. Eccentric disc

Refer to GI-4, "

Components" for symbols in the figure.

JPEIB0231GB

Revision: 2010 May2011 QX56

Page 4273 of 5598

RSU-18

< UNIT REMOVAL AND INSTALLATION >

REAR SUSPENSION MEMBER

UNIT REMOVAL AND INSTALLATION

REAR SUSPENSION MEMBER

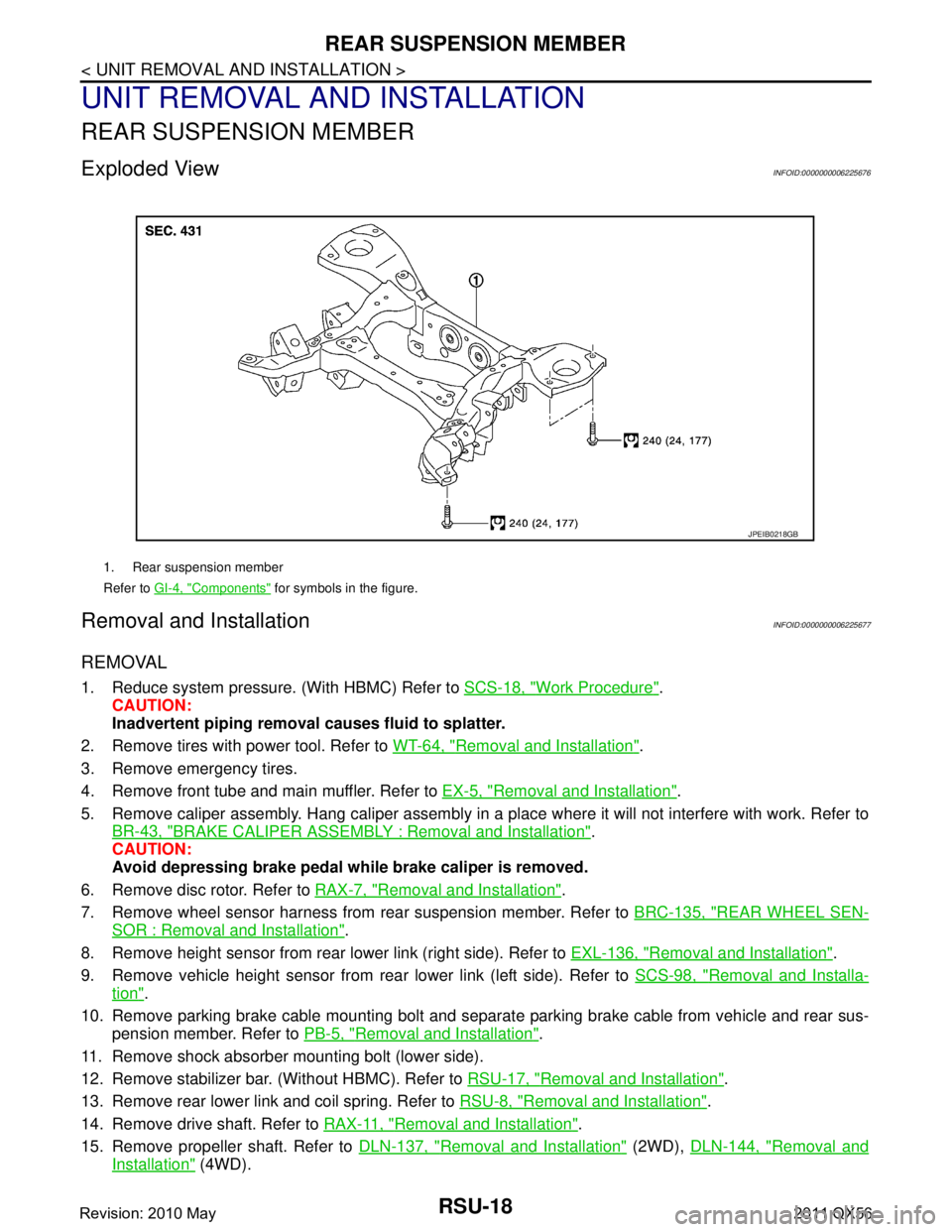

Exploded ViewINFOID:0000000006225676

Removal and InstallationINFOID:0000000006225677

REMOVAL

1. Reduce system pressure. (With HBMC) Refer to SCS-18, "Work Procedure".

CAUTION:

Inadvertent piping removal causes fluid to splatter.

2. Remove tires with power tool. Refer to WT-64, "

Removal and Installation".

3. Remove emergency tires.

4. Remove front tube and main muffler. Refer to EX-5, "

Removal and Installation".

5. Remove caliper assembly. Hang caliper assembly in a place where it will not interfere with work. Refer to BR-43, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

CAUTION:

Avoid depressing brake pedal wh ile brake caliper is removed.

6. Remove disc rotor. Refer to RAX-7, "

Removal and Installation".

7. Remove wheel sensor harness from rear suspension member. Refer to BRC-135, "

REAR WHEEL SEN-

SOR : Removal and Installation".

8. Remove height sensor from rear lower link (right side). Refer to EXL-136, "

Removal and Installation".

9. Remove vehicle height sensor from rear lower link (left side). Refer to SCS-98, "

Removal and Installa-

tion".

10. Remove parking brake cable mounting bolt and separa te parking brake cable from vehicle and rear sus-

pension member. Refer to PB-5, "

Removal and Installation".

11. Remove shock absorber mounting bolt (lower side).

12. Remove stabilizer bar. (Without HBMC). Refer to RSU-17, "

Removal and Installation".

13. Remove rear lower link and coil spring. Refer to RSU-8, "

Removal and Installation".

14. Remove drive shaft. Refer to RAX-11, "

Removal and Installation".

15. Remove propeller shaft. Refer to DLN-137, "

Removal and Installation" (2WD), DLN-144, "Removal and

Installation" (4WD).

1. Rear suspension member

Refer to GI-4, "

Components" for symbols in the figure.

JPEIB0218GB

Revision: 2010 May2011 QX56

Page 4369 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

STRUCTURE AND OPERATIONSCS-9

< SYSTEM DESCRIPTION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

STRUCTURE AND OPERATION

Hydraulic Body-Moti on Control SystemINFOID:0000000006256001

Shock AbsorberINFOID: INFINITI QX56 2011 Factory Workshop Manual

STRUCTURE AND OPERATIONSCS-9

< SYSTEM DESCRIPTION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

STRUCTURE AND OPERATION

Hydraulic Body-Moti on Control SystemINFOID:0000000006256001

Shock AbsorberINFOID:](/img/42/57033/w960_57033-4368.png)

STRUCTURE AND OPERATIONSCS-9

< SYSTEM DESCRIPTION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

STRUCTURE AND OPERATION

Hydraulic Body-Moti on Control SystemINFOID:0000000006256001

Shock AbsorberINFOID:0000000006256002

The use of accumulator-generated pressure responsive to driving conditions or pressure generated by oil flow

to the upper/lower chamber improves the steering stabili ty at curving, in addition to the running performance

and a ride quality during off-road travel.

FRONT SIDE

Oil enters from oil inlet outlet hole (A) and flows into lower chamber (3) via outside oil path of cylinder inside.

Oil enters from oil inlet outlet hole (B) and flows into upper chamber (1). With the pressure difference between

oil flowed into the upper chamber and lower chamber, the piston (2) moves up and down and conveys a force

generated through this motion to the tires.

1. Middle tube assembly RH 2. Accumulator assembly RH 3. Front tube assembly A

4. Front tube assembly B 5. Accumulator assembly LH 6. PPMU pipe A

7. PPMU assembly 8. Middle tube assembly LH 9. PPMU pipe B

10. Rear tube assembly A 11. Rear tube assembly B

:Vehicle front

JSEIA0228ZZ

Revision: 2010 May2011 QX56

Page 4370 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

SCS-10

< SYSTEM DESCRIPTION >[HBMC]

STRUCTURE AND OPERATION

REAR SIDE

Oil enters from oil inlet outlet hole (A) and flows into upper

chamber (1). Oil enters from oil inlet outlet hole (B)

and flows INFINITI QX56 2011 Factory Workshop Manual

SCS-10

< SYSTEM DESCRIPTION >[HBMC]

STRUCTURE AND OPERATION

REAR SIDE

Oil enters from oil inlet outlet hole (A) and flows into upper

chamber (1). Oil enters from oil inlet outlet hole (B)

and flows](/img/42/57033/w960_57033-4369.png)

SCS-10

< SYSTEM DESCRIPTION >[HBMC]

STRUCTURE AND OPERATION

REAR SIDE

Oil enters from oil inlet outlet hole (A) and flows into upper

chamber (1). Oil enters from oil inlet outlet hole (B)

and flows into lower chamber (3) via outside oil path of cylinder inside. With the pressure difference between

oil flowed into the upper chamber and lower chamber, the piston (2) moves up and down and conveys a force

generated through this motion to the tires.

PPMUINFOID:0000000006256003

PPMU stands for Passive Pressure Maintenance Unit.

System pressure increases according to increase of oil volume due to oil temperature increase. Sudden rise in system pressure can be controlled by feeding the increased oil into the PPMU.

Oil flows into oil chamber via PPMU pipe A and PPM U pipe B by influence of pressure change, pushes gas

spring of nitrogen gas, and pools.

1. Upper chamber 2. Piston 3. Lower chamber

A. Oil inlet outlet hole B. Oil inlet outlet hole

: Vehicle upper

JSEIA0173ZZ

1. Upper chamber 2. Piston 3. Lower chamber

A. Oil inlet outlet hole B. Oil inlet outlet hole

:Vehicle upper

JSEIA0245ZZ

Revision: 2010 May2011 QX56

Page 4380 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

SCS-20

< BASIC INSPECTION >[HBMC]

CHECK INTERNAL LEAKAGE

CHECK INTERNAL LEAKAGE

Work ProcedureINFOID:0000000006256012

CAUTION:

Clean surrounding areas of

oil injection jack using steam before sta INFINITI QX56 2011 Factory Workshop Manual

SCS-20

< BASIC INSPECTION >[HBMC]

CHECK INTERNAL LEAKAGE

CHECK INTERNAL LEAKAGE

Work ProcedureINFOID:0000000006256012

CAUTION:

Clean surrounding areas of

oil injection jack using steam before sta](/img/42/57033/w960_57033-4379.png)

SCS-20

< BASIC INSPECTION >[HBMC]

CHECK INTERNAL LEAKAGE

CHECK INTERNAL LEAKAGE

Work ProcedureINFOID:0000000006256012

CAUTION:

Clean surrounding areas of

oil injection jack using steam before starting operation, since there may

be mud on it.

Clean oil pressure gauge (special service tool: KV40108000) jack with steam before use.

1. Remove protector of PPMU.

2. Remove cap of oil injection jack.

3. Install an oil pressure gauge (SST: KV40108000) (A) to oil injec- tion jack.

CAUTION:

Jack must be securely inserted until a click sound can beheard.

Pressure reducing valve (B) of the oil pressure gauge

must be closed.

4. Loosen needle valves A, C, and E of PPMU by approximately 2 rotations. CAUTION:

Never loosen the needle valve more than required.

5. Lift up the vehicle. CAUTION:

Check that tires never contact the ground.

6. Tighten needle valves C and E of PPMU.

7. Loosen lock nut of needle valve D of PPMU and then tighten needle valve D.

8. Lift down the vehicle. CAUTION:

Check that the lift is fully lowered.

9. Write down a value of the oil pressure gauge after 5 minutes.

10. Tighten needle valve A of PPMU.

11. Loosen lock nut of needle valve B of PPMU and then tighten needle valve B.

12. Loosen needle valve C of PPMU by approximately 2 rotations. CAUTION:

Never loosen the needle valve more than required.

13. Read a value of oil pressure gauge.

14. Compare difference of reading with pressure reading in step 9.

15. Tighten needle valves A, C, and E of PPMU to the specified torque.

16. Loosen needle valves B and D of PPMU by approximatel y 2 rotations and then tighten lock nut to the

specified torque.

CAUTION:

Never loosen the needle valve more than required.

JSEIA0186ZZ

Pressure difference

0.1 MPa or more : Normal

0.1 MPa or less : Malfunction

: 8.3 N·m (0.85 kg-m, 73 in-lb)

JSEIA0187ZZ

Revision: 2010 May2011 QX56

Page 4382 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

SCS-22

< BASIC INSPECTION >[HBMC]

CHECK FOR MALFUNCTION

CHECK FOR MALFUNCTION

Work ProcedureINFOID:0000000006256013

CAUTION:

Clean surrounding areas of

oil injection jack using steam before start INFINITI QX56 2011 Factory Workshop Manual

SCS-22

< BASIC INSPECTION >[HBMC]

CHECK FOR MALFUNCTION

CHECK FOR MALFUNCTION

Work ProcedureINFOID:0000000006256013

CAUTION:

Clean surrounding areas of

oil injection jack using steam before start](/img/42/57033/w960_57033-4381.png)

SCS-22

< BASIC INSPECTION >[HBMC]

CHECK FOR MALFUNCTION

CHECK FOR MALFUNCTION

Work ProcedureINFOID:0000000006256013

CAUTION:

Clean surrounding areas of

oil injection jack using steam before starting operation, since there may

be mud on it.

Clean oil pressure gauge (special service tool: KV40108000) jack with steam before use.

1. Remove protector of PPMU.

2. Remove cap of oil injection jack.

3. Install an oil pressure gauge (SST: KV40108000) (A) to oil injec- tion jack.

CAUTION:

Jack must be securely inserted until a click sound can beheard.

Pressure reducing valve (B) of the oil pressure gauge

must be closed.

4. Loosen needle valves A, C, and E of PPMU by approximately 2 rotations.

CAUTION:

Never loosen the needle valve more than required.

5. Lift up the vehicle. CAUTION:

Check that tires never contact the ground.

6. Tighten needle valves A and C of PPMU.

7. Loosen lock nuts of needle valves B and D of PPMU and then tighten needle valves B and D.

8. Write down a value of the oil pressure gauge.

9. Lift down the vehicle. CAUTION:

Check that the lift is fully lowered.

10. Read a value of oil pressure gauge.

11. Compare difference of reading with pressure reading in step 8.

12. Tighten needle valves A, C, and E of PPMU to the specified torque.

13. Loosen needle valves B and D of PPMU by approximatel y 2 rotations and then tighten lock nut to the

specified torque.

CAUTION:

Never loosen the needle valve more than required.

JSEIA0186ZZ

Pressure change

Pressure increases : PPMU malfunction

Pressure does not change : Shock absorber malfunction

Tightening torque : 8.3 N· m (0.85 kg-m, 73 in-lb)

Tightening torque : 20 N·m (2.0 kg-m, 15 ft-lb)

JSEIA0187ZZ

Revision: 2010 May2011 QX56

Page 4387 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

CHECK ORIFICE FOR CLOGGINGSCS-27

< BASIC INSPECTION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

CHECK ORIFICE FOR CLOGGING

Work ProcedureINFOID:0000000006256015

CAUTION:

Clean surrounding areas of o INFINITI QX56 2011 Factory Workshop Manual

CHECK ORIFICE FOR CLOGGINGSCS-27

< BASIC INSPECTION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

CHECK ORIFICE FOR CLOGGING

Work ProcedureINFOID:0000000006256015

CAUTION:

Clean surrounding areas of o](/img/42/57033/w960_57033-4386.png)

CHECK ORIFICE FOR CLOGGINGSCS-27

< BASIC INSPECTION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

CHECK ORIFICE FOR CLOGGING

Work ProcedureINFOID:0000000006256015

CAUTION:

Clean surrounding areas of oil inj ection jack using steam before starting operation, since there may

be mud on it.

Clean oil pressure gauge (special service tool: KV40108000) jack with steam before use.

1. Remove protector of PPMU.

2. Remove cap of oil injection jack.

3. Install an oil pressure gauge (SST: KV40108000) (A) to oil injec- tion jack.

CAUTION:

Jack must be securely inserted until a click sound can beheard.

Pressure reducing valve (B) of the oil pressure gauge

must be closed.

4. Loosen needle valves A, C, and E of PPMU by approximately 2 rotations.

CAUTION:

Never loosen the needle valve more than required.

5. Lift up the vehicle. CAUTION:

Check that tires never contact the ground.

6. Tighten needle valves A, C, and E of PPMU.

7. Lift down the vehicle. CAUTION:

Check that the lift is fully lowered.

8. Loosen pressure reducing valve (A) of oil pressure gauge and then lower pressure.

CAUTION:

Be careful since oil drains sw iftly from oil drain hole (B).

9. Check that reading of oil pressure gauge is 0 MPa. Close pres- sure reducing valve.

10. Loosen needle valve E of PPMU by approximately 2 rotations. CAUTION:

Never loosen the needle valve more than required.

11. Write down a value of the oil pressure gauge.

12. Tighten needle valve E of PPMU.

13. Loosen pressure reducing valve of oil pressure gauge and then lower pressure. CAUTION:

Be careful since oil drains swiftly from oil drain hole.

14. Check that reading of oil pressure gauge is 0 MPa. Close pressure reducing valve.

15. Loosen needle valve A of PPMU by approximately 2 rotations. CAUTION:

Never loosen the needle valve more than required.

16. Read a value of the oil pressure gauge after 5 minutes.

17. Compare difference of reading with pressure reading in step 11.

JSEIA0186ZZ

JSEIA0187ZZ

JSEIA0188ZZ

Revision: 2010 May2011 QX56

Page 4427 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

STANDARD VEHICLE HEIGHT SETTINGSCS-67

< BASIC INSPECTION > [AIR LEVELIZER CONTROL SYSTEM]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

STANDARD VEHICL E HEIGHT SETTING

DescriptionINFOID:0000000006256060

Air lev INFINITI QX56 2011 Factory Workshop Manual

STANDARD VEHICLE HEIGHT SETTINGSCS-67

< BASIC INSPECTION > [AIR LEVELIZER CONTROL SYSTEM]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

STANDARD VEHICL E HEIGHT SETTING

DescriptionINFOID:0000000006256060

Air lev](/img/42/57033/w960_57033-4426.png)

STANDARD VEHICLE HEIGHT SETTINGSCS-67

< BASIC INSPECTION > [AIR LEVELIZER CONTROL SYSTEM]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

STANDARD VEHICL E HEIGHT SETTING

DescriptionINFOID:0000000006256060

Air levelizer control module enables precise control, by acquiring memorized standard vehicle height and sig-

nal (vehicle height) from vehicle height sensor. For this reason, always set standard vehicle height after per-

forming the following operations.

Removal and installation or replacement of vehicle height sensor

Replacement of air levelizer control module

Work ProcedureINFOID:0000000006256061

1.CLEAR STANDARD VEHICLE HEIGHT

With CONSULT-III

1. Lift up the vehicle. CAUTION:

Check that tires never contact the ground.

2. Start the engine.

3. Select “COMPRESSOR” in “Active Test” in “E-SUS”.

4. Touch “ON” and wait 60 seconds or more.

5. Touch “OFF”.

6. Select “CLEAR HEIGHT INI” in “Work Support” in “E-SUS”.

7. Touch “Start”.

8. Touch “Clear”. NOTE:

CONSULT-III continues indicating "EXECUTING". The completion of the standard vehicle height erasing

can be checked by the CK SUSP indicator lamp ON condition.

Does CK SUSP indicator lamp turn ON?

YES >> GO TO 2.

NO >> Perform step 1 again.

2.ADJUST STANDARD VEHICLE HEIGHT

With CONSULT-III

1. Select “ADJUST HEIGHT INI” in “Work Support” in “E-SUS”.

2. Touch “Start”.

3. Touch “Initial 1”. NOTE:

CONSULT-III continues indicating "EXECUTING". T he completion of the standard vehicle height adjust-

ment can be checked by the CK SUSP indicator lamp OFF condition.

Does CK SUSP indicator lamp turn OFF?

YES >> GO TO 3.

NO >> Perform step 1 again.

3. ADJUST VEHICLE HEIGHT

With CONSULT-III

1. Lift down the vehicle. CAUTION:

Check that the lift is fully lowered.

2. Select “STANDARD HEIGHT LEVEL” in “Work Support” in “E-SUS”.

3. Touch “Start”.

4. Touch “Revert” and wait 120 seconds or more.

5. Although CONSULT-III continues indicating "EXECUTIN G", select “VHCL HGT CNVSN VL” in “Data Mon-

itor” in “E-SUS”.

Is value within

−15 – 15 mm?

YES >> GO TO 4.

NO >> Perform step 1 again.

4.CHECK DTC

With CONSULT-III

Revision: 2010 May2011 QX56