tires INFINITI QX56 2011 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 511 of 5598

REAR DISC BRAKEBR-41

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

REAR DISC BRAKE

BRAKE PAD

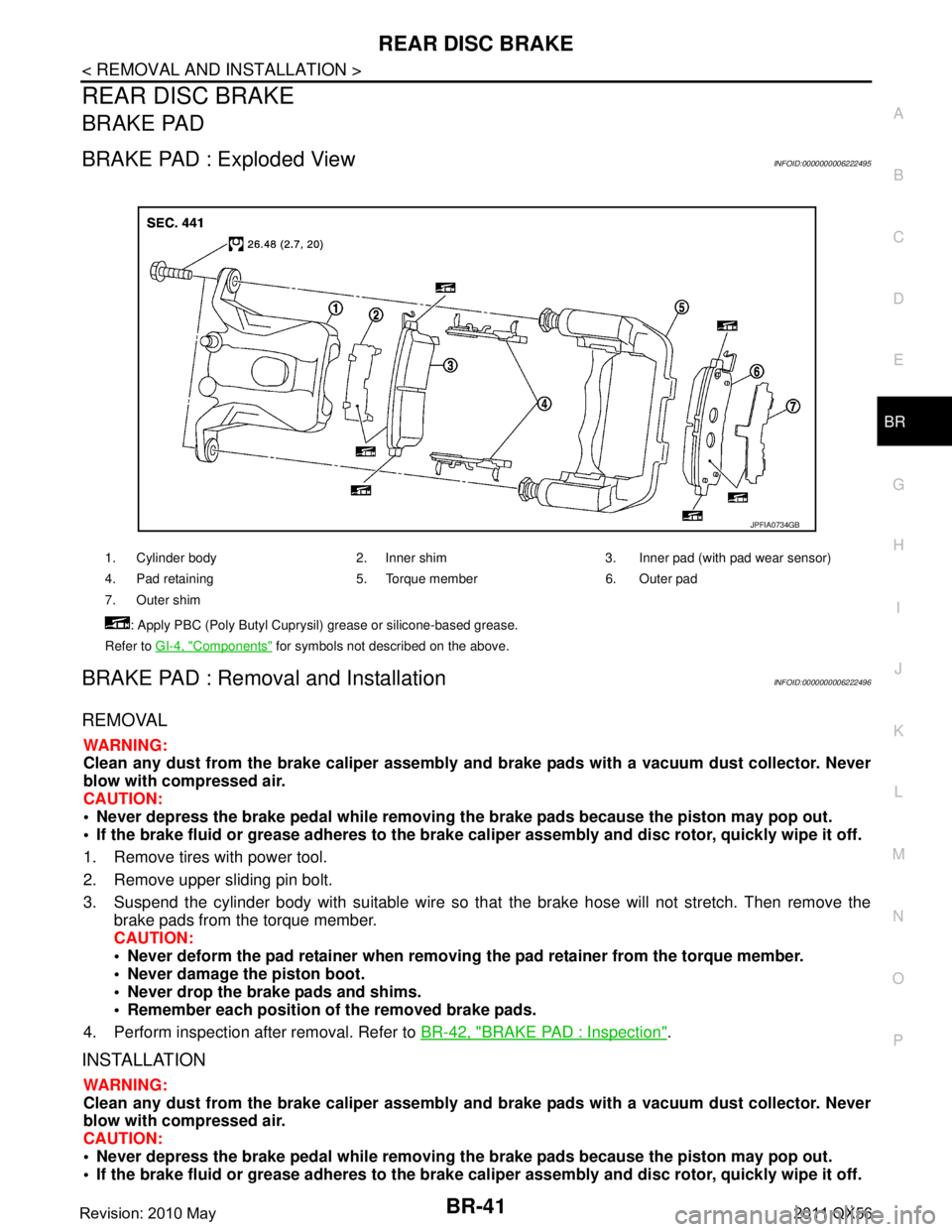

BRAKE PAD : Exploded ViewINFOID:0000000006222495

BRAKE PAD : Removal and InstallationINFOID:0000000006222496

REMOVAL

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never depress the brake pedal while removing th e brake pads because the piston may pop out.

If the brake fluid or grease adheres to the brake cal iper assembly and disc rotor, quickly wipe it off.

1. Remove tires with power tool.

2. Remove upper sliding pin bolt.

3. Suspend the cylinder body with suitable wire so that the brake hose will not stretch. Then remove the

brake pads from the torque member.

CAUTION:

Never deform the pad retainer when removing the pad retainer from the torque member.

Never damage the piston boot.

Never drop the brake pads and shims.

Remember each position of the removed brake pads.

4. Perform inspection after removal. Refer to BR-42, "

BRAKE PAD : Inspection".

INSTALLATION

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never depress the brake pedal while removing th e brake pads because the piston may pop out.

If the brake fluid or grease adheres to the brake cal iper assembly and disc rotor, quickly wipe it off.

1. Cylinder body 2. Inner shim 3. Inner pad (with pad wear sensor)

4. Pad retaining 5. Torque member 6. Outer pad

7. Outer shim

: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0734GB

Revision: 2010 May2011 QX56

Page 512 of 5598

BR-42

< REMOVAL AND INSTALLATION >

REAR DISC BRAKE

1. Install the torque member if the pad retainers has been removed.CAUTION:

Securely assemble the pad retainers so that it wi ll not be lifted up from the torque member.

Never deform the pad retainers.

2. Apply PCB (Poly Butyl Cuprysil) grease or silicone-based grease to the matching faces (A) between the brake pad and

shim, and install the shims to brake pads.

CAUTION:

Always replace the shims when replacing the brake pad.

3. Apply PCB (Poly Butyl Cuprysil) grease or silicone-based grease to the matching faces (B) between the brake pad and

torque member.

4. Install cylinder body to the torque member. CAUTION:

Never damage the piston boot.

When replacing brake pad with new one, check a brakefluid level in the reservoir tank because brake flui d returns to reservoir tank when pressing pis-

ton in.

NOTE:

Use a disc brake piston tool to easily press piston.

5. Install the upper sliding pin bolt and tighten it to the specified torque.

6. Depress the brake pedal several times to check that no drag feel is present for the front disc brake. Refer

to BR-42, "

BRAKE PAD : Inspection".

7. Install tires with power tool. Refer to WT-64, "

Exploded View".

BRAKE PAD : InspectionINFOID:0000000006222497

INSPECTION AFTER REMOVAL

Replace the shims if rust is excessively attached.

Eliminate rust on the pad retainers and the torque mem ber. Replace them if rust is excessively attached.

INSPECTION AFTER INSTALLATION

1. Check a drag of rear disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads. Refer to BR-41, "

BRAKE PAD : Removal and Installation".

3. Press the piston. Refer to BR-41, "

BRAKE PAD : Removal and Installation".

4. Install brake pads. Refer to BR-41, "

BRAKE PAD : Removal and Installation".

5. Depress the brake pedal several times.

6. Check a drag of rear disc brake again. If any drag is found, disassemble the caliper. Refer to BR-44,

"BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces brake pads and disc rotor after refinishing or replacing brake pads, or if a soft pedal occurs at very low mileage. Refer to BR-18, "

BRAKE PAD : Inspection and Adjustment".

BRAKE CALIPER ASSEMBLY

BRAKE CALIPER ASSEMBLY : Exploded ViewINFOID:0000000006222498

REMOVAL

JPFIA0741ZZ

Revision: 2010 May2011 QX56

Page 514 of 5598

BR-44

< REMOVAL AND INSTALLATION >

REAR DISC BRAKE

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

If the brake fluid or grease adheres to the brake calip er assembly and disc rotor, quickly wipe it off.

1. Remove tires with power tool.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-10, "

Draining".

4. Separate brake hose from brake caliper assembly. Refer to BR-26, "

REAR : Removal and Installation".

5. Remove torque member mounting bolts, and remove brake caliper assembly. CAUTION:

Never drop brake pad and caliper assembly.

6. Remove disc rotor. Refer to RAX-7, "

Removal and Installation".

INSTALLATION

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

If the brake fluid or grease adheres to the brake calip er assembly and disc rotor, quickly wipe it off.

1. Install disc rotor. Refer to RAX-7, "

Removal and Installation".

2. Install the brake caliper assembly to the axle hous ing and tighten the torque member mounting bolts to the

specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake caliper assembly mounting face,

threads, mounting bolts. Wipe out any grease and moisture.

3. Install brake hose to brake caliper assembly. Refer to BR-26, "

REAR : Removal and Installation".

4. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

5. Check a drag of rear disc brake. If any drag is found, refer to BR-45, "

BRAKE CALIPER ASSEMBLY :

Inspection".

6. Install tires with power tool. Refer to WT-64, "

Exploded View".

BRAKE CALIPER ASSEMBLY : Disassembly and AssemblyINFOID:0000000006222500

DISASSEMBLY

NOTE:

Never remove the torque member, brake pads and pad retainers when disassembling and assembling the cyl-

inder body.

1. Remove the sliding pin bolt, and remove the cylinder body from the torque member.

CAUTION:

Fix the brake pad at suitable tape so that the brake pad will not drop.

2. Remove sliding pin boots from torque member.

3. Remove bushing from sliding pin bolt.

4. Place a wooden block as shown in the figure, and blow air from brake hose mounting hole to remove piston and piston boot.

CAUTION:

Never get fingers caught in the piston.

MAA0272D

Revision: 2010 May2011 QX56

Page 524 of 5598

![INFINITI QX56 2011 Factory User Guide

PRECAUTIONSBRC-7

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

and tires installed on the vehicle are the specified si ze and parts. Brake performance and controllability may

be negativ INFINITI QX56 2011 Factory User Guide

PRECAUTIONSBRC-7

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

and tires installed on the vehicle are the specified si ze and parts. Brake performance and controllability may

be negativ](/img/42/57033/w960_57033-523.png)

PRECAUTIONSBRC-7

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

and tires installed on the vehicle are the specified si ze and parts. Brake performance and controllability may

be negatively affected when other parts than the specified are installed.

Brake stopping distance may become longer and steering stability may be negatively affected, when tires in

different size and combination or other parts than the specified are used.

When a radio (including wiring), antenna and antenna lead line are located near ABS actuator and electric

unit (control unit), a malfunction or improper operation ma y occur for the control of VDC function, TCS func-

tion, ABS function, EBD function, hill start assist func tion or brake limited slip differential (BLSD) function.

When the following items are replaced by other parts than genuine parts or modified, ABS warning lamp, brake warning lamp and VDC warning lamp may turn ON, and the control may not operate normally for VDC

function, TCS function, ABS function, EB D function, hill start assist function or brake limited slip differential

(BLSD) function.

- Suspension component parts (shock absorber, spring, bushing and others)

- Tire and wheel (other than the specified size)

- Brake component parts (brake pad, disc rotor, brake caliper and others)

- Engine component parts (ECM, muffler and others)

- Body reinforcement component parts (rollover bar, tower bar and others)

When suspension, tire and brake component parts are excessively worn or deteriorated and the vehicle is

driven, ABS warning lamp, brake warning lamp and VDC warning lamp may tu\

rn ON, and the control may

not operate normally for VDC function, TCS function, ABS function, EBD function, hill start assist function or

brake limited slip differential (BLSD) function.

ABS warning lamp, brake warning lamp and VDC warning lamp may turn ON, when only front wheel or rear wheel is rotated using a free roller. This is not a ma lfunction, because it is caused by wheel speed difference

between wheel that is rotated and wheel that is not rota ted. In this case, perform self-diagnosis, check self-

diagnosis results, and erase memory.

When power supply voltage is not normal, ABS warning lamp, brake warning lamp and VDC warning lamp

turn ON. ABS actuator and electric unit (control unit) st ops control for VDC function, TCS function, ABS func-

tion, EBD function, hill start assist function or brake limited slip differential (BLSD) function. Ordinary brake

operates. After power supply returns to normal, ABS warning lamp, brake warning lamp and VDC warning

lamp turn OFF. The control becomes operative for VD C function, TCS function, ABS function, EBD function,

hill start assist function or brake li mited slip differential (BLSD) function.

VDC warning lamp may turn ON and VDC function or TCS function may not normally operate, when driving

on a special road the is extremely slanted (bank in a circ uit course). This is not a malfunction if the status

returns to normal for VDC function or TCS function after the engine is started again. In this case, perform

self-diagnosis, check self-diagnosis results, and erase memory.

A malfunction in yaw rate/side/decel G sensor syste m may be detected when the vehicle sharply turns dur-

ing a spin turn, acceleration turn or drift driving while VDC function or TCS function are OFF (VDC OFF

switch is pressed and VDC OFF indicator lamp is in ON st atus). This is not a malfunction if the status returns

to normal for VDC function or TCS function after the engine is started again. In this case, perform self-diag-

nosis, check self-diagnosis results, and erase memory

Precaution for Harness RepairINFOID:0000000006222558

Solder the repair part, and wrap it with tape. [Twisted wire fray must be 110 mm (4.33 in) or less.]

SKIB8766E

Revision: 2010 May2011 QX56

Page 543 of 5598

![INFINITI QX56 2011 Factory User Guide

BRC-26

< SYSTEM DESCRIPTION >[WITH VDC]

SYSTEM

ABS FUNCTION

ABS warning lamp and VDC warning lamp in combinati

on meter turn ON when a malfunction occurs in system

[ABS actuator and electric unit (co INFINITI QX56 2011 Factory User Guide

BRC-26

< SYSTEM DESCRIPTION >[WITH VDC]

SYSTEM

ABS FUNCTION

ABS warning lamp and VDC warning lamp in combinati

on meter turn ON when a malfunction occurs in system

[ABS actuator and electric unit (co](/img/42/57033/w960_57033-542.png)

BRC-26

< SYSTEM DESCRIPTION >[WITH VDC]

SYSTEM

ABS FUNCTION

ABS warning lamp and VDC warning lamp in combinati

on meter turn ON when a malfunction occurs in system

[ABS actuator and electric unit (control unit)]. The c ontrol is suspended for VDC function, TCS function, ABS

function, hill start assist function and brake limited sl ip differential (BLSD) function. The vehicle status

becomes the same as models without VDC function, TCS f unction, ABS function, hill start assist function and

brake limited slip differential (BLSD) function. However, EBD function is operated normally.

NOTE:

ABS self-diagnosis sound may be heard the same as in the normal condition, because self-diagnosis is per-

formed when ignition switch turns ON and when vehicle initially starts.

EBD FUNCTION

ABS warning lamp, brake warning lamp and VDC warning lamp in combination meter turn ON when a mal-

function occurs in system [ABS actuator and electric unit (control unit)]. The control is suspended for VDC

function, TCS function, ABS function, EBD function, hill start assist function and brake limited slip differential

(BLSD) function. The vehicle status becomes the sa me as models without VDC function, TCS function, ABS

function, EBD function, hill star t assist function and brake limited slip differential (BLSD) function.

DTC Malfunction detected condition Fail-safe condition

C1101 When an open circuit is detected in rear RH wheel sensor circuit.

The following functions are sus-

pended.

VDC function

TCS function

ABS function

EBD function (only when both 2 rear wheels are malfunctioning)

hill start assist function

Brake limited slip differential

(BLSD) function

C1102 When an open circuit is detected in rear LH wheel sensor circuit.

C1103 When an open circuit is detected in front RH wheel sensor circuit.

C1104 When an open circuit is detected in front LH wheel sensor circuit.

C1105

When power supply voltage of rear RH wheel sensor is low.

When distance between rear RH wheel sensor and rear RH wheel sensor rotor is

large.

When installation of rear RH wheel sensor or rear RH wheel sensor rotor is not

normal.

C1106 When power supply voltage of rear LH wheel sensor is low.

When distance between rear LH wheel sensor and rear LH wheel sensor rotor is

large.

When installation of rear LH wheel sensor or rear LH wheel sensor rotor is not nor- mal.

C1107 When power supply voltage of front RH wheel sensor is low.

When distance between front RH wheel sensor and front RH wheel sensor rotor

is large.

When installation of front RH wheel sensor or front RH wheel sensor rotor is not normal.

C1108 When power supply voltage of front LH wheel sensor is low.

When distance between front LH wheel sensor and front LH wheel sensor rotor is

large.

When installation of front LH wheel sensor or front LH wheel sensor rotor is not normal.

C1109 When ignition voltage is 10 V or less.

When ignition voltage is 16 V or more. The following functions are sus-

pended.

VDC function

TCS function

ABS function

EBD function

hill start assist function

Brake limited slip differential

(BLSD) function

C 1111

When a malfunction is detected in motor or motor relay.

When a low pressure malfunction is detected in accumulator.

When a malfunction is detected in accumulator pressure sensor.

C 111 5 When difference in wheel speed between any wheel and others is detected during

the vehicle is driven, because of installation of other tires than specified. The following functions are sus-

pended.

VDC function

TCS function

ABS function

hill start assist function

Brake limited slip differential

(BLSD) function

C 111 6

When stop lamp switch signal is not input when brake pedal depress.

When stop lamp switch signal is not input when stop lamp relay operates.

C 111 8

*1When a malfunction is detected in transfer control unit system.

Revision: 2010 May2011 QX56

Page 566 of 5598

![INFINITI QX56 2011 Factory User Guide

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)BRC-49

< ECU DIAGNOSIS INFORMATION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

C 111 5 When difference in wheel speed between any wheel and others is d INFINITI QX56 2011 Factory User Guide

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)BRC-49

< ECU DIAGNOSIS INFORMATION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

C 111 5 When difference in wheel speed between any wheel and others is d](/img/42/57033/w960_57033-565.png)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)BRC-49

< ECU DIAGNOSIS INFORMATION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

C 111 5 When difference in wheel speed between any wheel and others is detected during

the vehicle is driven, because of installation of other tires than specified. The following functions are sus-

pended.

VDC function

TCS function

ABS function

hill start assist function

Brake limited slip differential

(BLSD) function

C 111 6

When stop lamp switch signal is not input when brake pedal depress.

When stop lamp switch signal is not input when stop lamp relay operates.

C 111 8

*1When a malfunction is detected in transfer control unit system.

C1120 When a malfunction is detec ted in front LH ABS IN valve.

The following functions are sus-

pended.

VDC function

TCS function

ABS function

EBD function

hill start assist function

Brake limited slip differential (BLSD) function

C1121 When a malfunction is detec

ted in front LH ABS OUT valve.

C1122 When a malfunction is detected in front RH ABS IN valve.

C1123 When a malfunction is det ected in front RH ABS OUT valve.

C1124 When a malfunction is detected in rear LH ABS IN valve.

C1125 When a malfunction is detected in rear LH ABS OUT valve.

C1126 When a malfunction is det ected in rear RH ABS IN valve.

C1127 When a malfunction is detected in rear RH ABS OUT valve.

C1130 When a malfunction is detected in ECM system. The following functions are sus-

pended.

VDC function

TCS function

hill start assist function

Brake limited slip differential

(BLSD) function

C1140 When a malfunction is detected in actuator relay. The following functions are sus-

pended.

VDC function

TCS function

ABS function

EBD function

hill start assist function

Brake limited slip differential

(BLSD) function

C1142

*2When a malfunction is detected in master cylinder pressure sensor or control pres-

sure sensor. The following functions are sus-

pended.

VDC function

TCS function

hill start assist function

Brake limited slip differential

(BLSD) function

C1143 When a malfunction is detected in steering angle sensor.

C1144 When neutral position adjustment of steering angle sensor is not complete.

C1145

When a malfunction is detected in yaw rate signal.

When yaw rate signal is not continuously received for 2 seconds or more.

When side G signal is not continuously received for 2 seconds or more.

When decel G signal is not continuously received for 2 seconds or more.

The following functions are sus-

pended.

VDC function

TCS function

ABS function

hill start assist function

Brake limited slip differential

(BLSD) function

C1146 When a malfunction is detected in side/decel G signal.

C1155

When brake fluid level low signal is detected.

When an open circuit is detected in brake fluid level switch circuit.

C1160 When calibration of yaw rate/side/decal G sensor is not complete.

C1164 When a malfunction is detected in cut valve 1. The following functions are sus- pended.

VDC function

TCS function

ABS function

EBD function

hill start assist function

Brake limited slip differential (BLSD) function

C1165 When a malfunction is detected in cut valve 2.

C1166 When a malfunction is detected in suction valve 1.

C1167 When a malfunction is detected in suction valve 2. DTC Malfunction detected condition Fail-safe condition

Revision: 2010 May2011 QX56

Page 594 of 5598

![INFINITI QX56 2011 Factory User Guide

C1115 WHEEL SENSORBRC-77

< DTC/CIRCUIT DIAGNOSIS > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

C1115 WHEEL SENSOR

DTC LogicINFOID:0000000006222601

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CH INFINITI QX56 2011 Factory User Guide

C1115 WHEEL SENSORBRC-77

< DTC/CIRCUIT DIAGNOSIS > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

C1115 WHEEL SENSOR

DTC LogicINFOID:0000000006222601

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CH](/img/42/57033/w960_57033-593.png)

C1115 WHEEL SENSORBRC-77

< DTC/CIRCUIT DIAGNOSIS > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

C1115 WHEEL SENSOR

DTC LogicINFOID:0000000006222601

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK DTC DETECTION

With CONSULT-III.

1. Start engine and drive vehicle at approx. 30 km/h (19 MPH) or more for approx. 1 minute.

2. Perform self-diagnosis for “ABS”.

Is DTC

“C 111 5” detected?

YES >> Proceed to diagnosis procedure. Refer to BRC-77, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006222602

CAUTION:

For wheel sensor, never check between terminals.

1.CHECK TIRE

1. Turn the ignition switch OFF.

2. Check tire air pressure, wear and size. Refer to WT-69, "

Tire Air Pressure".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Adjust air pressure. Or replace tire. Refer to WT-69, "

Tire Air Pressure".

2.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) POWER SUPPLY SYSTEM

Check ABS actuator and electric unit (cont rol unit) power supply system. Refer to BRC-113, "

Diagnosis Proce-

dure".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK WHEEL SENSOR HARNESS

1. Disconnect ABS actuator and electric unit (control unit) harness connector.

2. Disconnect wheel sensor harness connector.

3. Check continuity between ABS actuator and electr ic unit (control unit) harness connector and wheel sen-

sor harness connector. (Check continuity when steering wheel is steered to RH and LH, or center harness

in wheel housing is moved.)

Measurement connector and termi nal for power supply circuit

DTC Display Item Malfunction detected condition Possible causes

C 111 5 ABS SENSOR

[ABNORMAL SIGNAL] When difference in wheel speed between any wheel

and others is detected during the vehicle is driven,

because of installation of other tires than specified. Harness or connector

Wheel sensor

Sensor rotor

ABS actuator and electric unit

(control unit)

ABS actuator and electric unit (control unit) Wheel sensor Continuity

Connector Terminal Connector Terminal

E36 20 E22 (Front LH wheel)

1 Existed

33 E39 (Front RH wheel)

22 C10 (Rear LH wheel)

35 C11 (Rear RH wheel)

Revision: 2010 May2011 QX56

Page 949 of 5598

OVERHEATING CAUSE ANALYSISCO-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

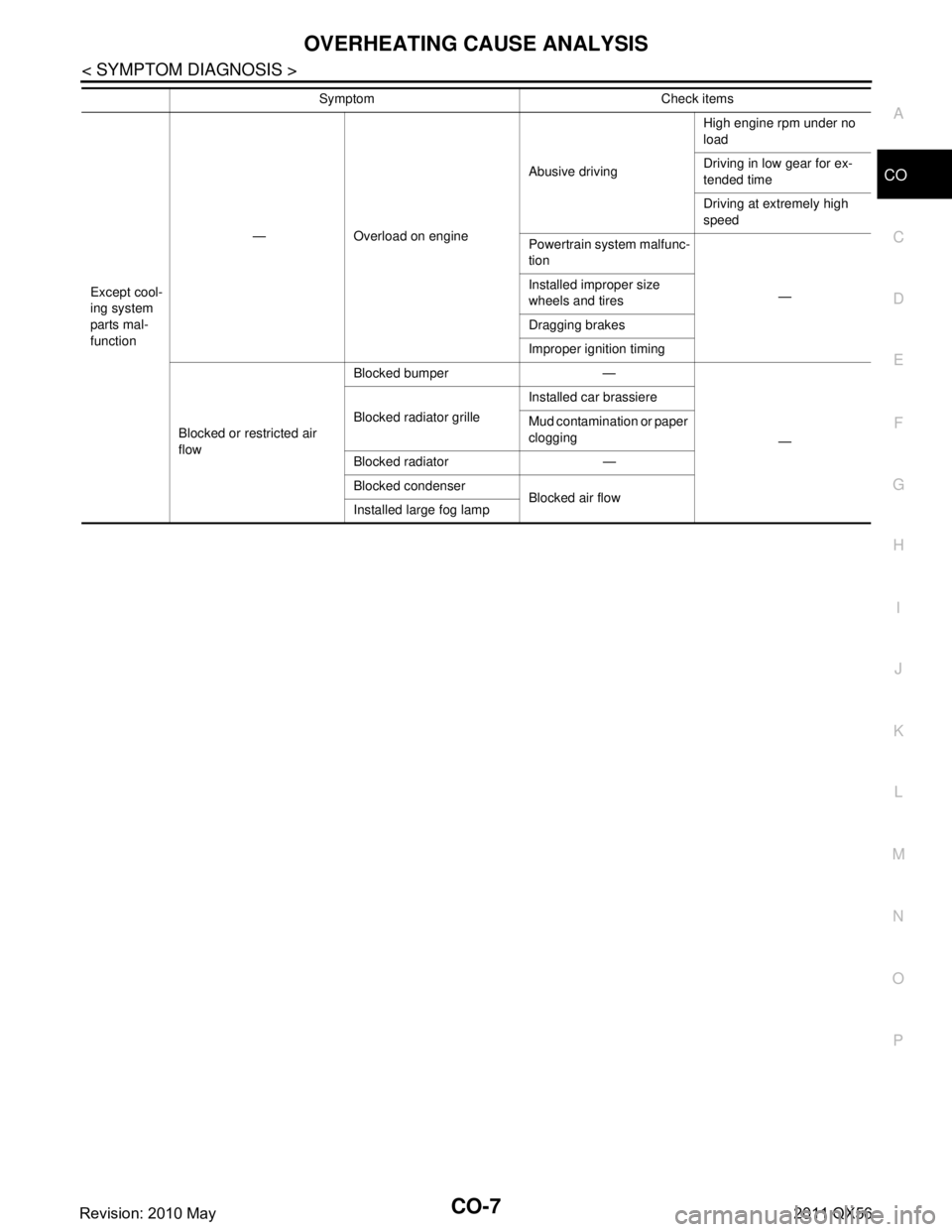

Except cool-

ing system

parts mal-

function — Overload on engine

Abusive driving

High engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

—

Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flow Blocked bumper —

—

Blocked radiator grille

Installed car brassiere

Mud contamination or paper

clogging

Blocked radiator —

Blocked condenser Blocked air flow

Installed large fog lamp

Symptom Check items

Revision: 2010 May2011 QX56

Page 1809 of 5598

![INFINITI QX56 2011 Factory User Guide

PRECAUTIONSDLN-7

< PRECAUTION > [TRANSFER: ATX90A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push INFINITI QX56 2011 Factory User Guide

PRECAUTIONSDLN-7

< PRECAUTION > [TRANSFER: ATX90A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push](/img/42/57033/w960_57033-1808.png)

PRECAUTIONSDLN-7

< PRECAUTION > [TRANSFER: ATX90A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of a ll control units using CONSULT-III.

Service Notice or Precautions for TransferINFOID:0000000006222211

CAUTION:

Use Genuine NISSAN Transfer Fluid. Refer to MA-10, "

Fluids and Lubricants".

Never reuse transfer fluid, once it has been drained.

Check the fluid level or repl ace the fluid only with the vehicle parked on level ground.

During removal or installati on, keep inside of transfer clear of dust or dirt.

Replace all tires at the same time. Always use tir es of the proper size and the same brand and pat-

tern. Fitting improper size and unusually worn tires applies excessive force to vehicle mechanism

and can cause longitudinal vibration.

Disassembly should be done in a clean work area, it is preferable to work in dustproof area.

Before proceeding with disassembly, thoroughly clean the transfer. It is important to prevent the

internal parts from becoming contamin ated by dirt or other foreign matter.

All parts should be carefully cl eaned with a general purpose, non-flammable solvent before inspec-

tion or reassembly.

Check for the correct installation status prior to removal or disassembly. If matching marks are

required, be certain they do not interfere wit h the function of the parts when applied.

Check appearance of the disassembled parts for damage, deformation, and unusual wear. Replace

them with a new ones if necessary.

Gaskets, seals and O-rings should be replaced any time the transfer is disassembled.

In principle, tighten bolts or nu ts gradually in several steps workin g diagonally from inside to out-

side. If tightening sequence is specified, use it.

Observe the specified torque when assembling.

Clean and flush the parts su fficiently and blow-dry them.

Be careful not to damage sliding surfaces and mating surfaces.

Clean inner parts with lint-free cloth or towels . Do not use cotton work gloves and rags to prevent

adhering fibers.

Revision: 2010 May2011 QX56

Page 1822 of 5598

![INFINITI QX56 2011 Factory User Guide

DLN-20

< SYSTEM DESCRIPTION >[TRANSFER: ATX90A]

SYSTEM

4WD Warning Lamp

Turns ON when there is a malfunction in 4WD system. 4W

D warning lamp indicates the vehicle is in fail-safe

mode.

Also turn INFINITI QX56 2011 Factory User Guide

DLN-20

< SYSTEM DESCRIPTION >[TRANSFER: ATX90A]

SYSTEM

4WD Warning Lamp

Turns ON when there is a malfunction in 4WD system. 4W

D warning lamp indicates the vehicle is in fail-safe

mode.

Also turn](/img/42/57033/w960_57033-1821.png)

DLN-20

< SYSTEM DESCRIPTION >[TRANSFER: ATX90A]

SYSTEM

4WD Warning Lamp

Turns ON when there is a malfunction in 4WD system. 4W

D warning lamp indicates the vehicle is in fail-safe

mode.

Also turns ON when ignition switch is turned ON, fo r the purpose of lamp check. Turns OFF approximately

for 1 second after the engine starts if system is normal.

ATP Warning Lamp

When the A/T shift selector is in P position, the vehicle may move if the transfer case in neutral. ATP warning

lamp is turned on to indicate this condition to the driver.

CONDITION FOR OPERATE WARNING BUZZER

For preventing an incorrect operation during 4H ⇔4L switching, warning buzzer sounds from inside of transfer

control unit and warns the driver, when certain conditions are satisfied.

4WD SYSTEM : Fail-SafeINFOID:0000000006303692

If any malfunction occurs in 4WD electrical system, and control unit detects the malfunction, 4WD warning

lamp on combination meter turns ON to indicate system malfunction.

When 4WD warning lamp is ON, vehicle changes to rear-wheel drive or shifts to 4-wheel drive (front-wheels

still have some driving torque).

Condition 4WD warning lamp

Lamp check Turns ON when ignition switch is turned ON. Turns OFF ap-

prox. 1 second after the engine start.

4WD system malfunction ON

Protection function is activated due to heavy load to transfer assem-

bly. (4WD system is not malfunctioning.) Quick blinking: 2 times/second

(Blinking in approx. 1 minute and then turning OFF)

Large difference in diameter of front/rear tires Slow blinking: 1 time/2 seconds

(Continuing to blink until turning ignition switch OFF)

Other than above (system normal) OFF

Condition Warning buzzer

4WD shift status A/T shift selector Engine speed

4H⇔4L N range 350

− 1.600 rpm OFF

Under 350 rpm or over 1.600 rpm ON

Except N range Always

Revision: 2010 May2011 QX56