check engine INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3035 of 5598

GW-6

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-cl utch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

Tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

Feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

Placing a piece of paper between components that you suspect are causing the noise.

Looking for loose components and contact marks. Refer to GW-7, "

Inspection Procedure".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loos ening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A Nissan Squeak and Rattle Kit (J-43980) is available through your authorized Nissan Parts

Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Departm ent for the latest parts information.

The following materials are contained in the Nissan Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94 ×5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-

71L02:15 ×25 mm (0.59 ×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-

50Y00: 10 mm (0.39 in) thick, 50 ×50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97in)

FELT CLOTHTAPE

Used to insulate where movement does not occu r. Ideal for instrument panel applications.

Revision: 2010 May2011 QX56

Page 3062 of 5598

HA-6

< PRECAUTION >

PRECAUTIONS

Turn the compressor shaft by hand more than five turns in both directions after compressor service

operation. This distributes equall y lubricant inside the compressor. Let the engine idle and operate

the compressor for one hour after the compressor is installed.

Apply voltage to the new one and check for norma l operation after replacing the compressor magnet

clutch.

LEAK DETECTION DYE

CAUTION:

The A/C system contains a fluorescent leak detect ion dye used for locating refrigerant leakages. An

ultraviolet (UV) lamp is required to il luminate the dye when inspecting for leakages.

Wear always fluorescence enhancing UV safety goggles to protect eyes and enhance the visibility of

the fluorescent dye.

The fluorescent dye leak detector is not a replacem ent for an electrical leak detector. The fluorescent

dye leak detector should be used in conjunction with an electrical leak detector to pin-point refriger-

ant leakages.

Read and follow all manufacture’ s operating instructions and precau tions prior to performing the

work for the purpose of safet y and customer’s satisfaction.

A compressor shaft seal should not necessarily be repaired because of dye seepage. The compres-

sor shaft seal should only be repaired after conf irming the leakage with an electrical leak detector.

Remove always any remaining dye from the leakage area after repairs are completed to avoid a mis-

diagnosis during a future service.

Never allow dye to come into contact with painted body panels or interior components. Clean imme-

diately with the approved dye cl eaner if dye is spilled. Fluorescent dye left on a surface for an

extended period of time cannot be removed.

Never spray the fluorescent dye cleaning agent on hot surfaces (eng ine exhaust manifold, etc.).

Never use more than one refrigerant dye bottle [1/4 ounce (7.4 cc)] per A/C system.

Leak detection dyes for HFC-134a (R-134a) and CFC- 12 (R-12) A/C systems are different. Never use

HFC-134a (R-134a) leak detection dye in CFC-12 (R- 12) A/C system, or CFC-12 (R-12) leak detection

dye in HFC-134a (R-134a) A/C system, or A/C system damage may result.

The fluorescent properties of the dye remains fo r three or more years unless a compressor malfunc-

tion occurs.

NOTE:

Identification

Vehicles with factory installed fluorescent dye have a green label.

Vehicles without factory installed fluorescent dye have a blue label.

Service EquipmentINFOID:0000000006276140

RECOVERY/RECYCLING RECHARGING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Never

introduce any refrigerant other than that specified into the machine.

ELECTRICAL LEAK DETECTOR

Be certain to follow the manufacturer’s instruct ions for tester operation and tester maintenance.

VACUUM PUMP

Revision: 2010 May2011 QX56

Page 3075 of 5598

REFRIGERANTHA-19

< BASIC INSPECTION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

Never look directly into UV lamp light source.

NOTE:

For continuous operating time of UV lamp, fo llow the manufacturer operating instructions.

Illuminate piping joints from different angles us ing UV lamp and check that there is no leakage.

Use a mirror in area that is difficult to see to check refrigerant leakage.

Refrigerant leakage from evaporator can be detected by soaking cotton swab or a similar material with

drain hose water and illuminating it using UV lamp.

Dust, dirt, and packing materials adhesive used for condenser, evaporator, and other locations may flu- oresce. Be careful not to misidentify leakage.

5. Repair or replace parts where refrigerant leak age occurs and wipe off fluorescent leak detection dye.

NOTE:

Completely wipe off fluorescent leak detection dy e from gaps between parts, screw threads, and others

using a cotton swab or similar materials.

6. Use a UV lamp to check that no fluorescent leak detection dye remains after finishing work. WARNING:

Never look directly into UV lamp light source.

NOTE:

For continuous operating time of UV lamp, fo llow the manufacturer operating instructions.

Dust, dirt, and packing materials adhesive used for condenser, evaporator, and other locations may flu-

oresce. Be careful not to misidentify leakage.

CHECK REFRIGERANT LEAKAGE USIN G ELECTRICAL LEAK DETECTOR

WARNING:

Never check refrigerant leakage while the engine is running.

CAUTION:

Be careful of the following items so that in accurate checks or misidentifications are avoided.

Never allow refrigerant vapor, shop chemical vapors, cigarette smoke, or others around the vehicle.

Always check refrigerant leakage in a low air flow environment so that refrigerant may not disperse

when leakage occurs.

1. Stop the engine.

2. Connect recovery/recycling/recharging equipment or manifold gauge set to A/C service valve.

3. Check that A/C refrigerant pressure is 345 kPa (3.52 kg/cm

2, 50 psi) or more when temperature is 16 °C

(61 °F) or more. When pressure is lower than the spec ified value, recycle refrigerant completely and fill

refrigerant to the specified level.

NOTE:

Leakages may not be detected if A/C refri gerant pressure is 345 kPa (3.52 kg/cm

2, 50 psi) or less when

temperature is less than 16 °C (61 °F).

4. Clean area where refrigerant leakage check is per formed, and check refrigerant leakage along all sur-

faces of pipe connections and A/C system com ponents using electrical leak detector probe.

CAUTION:

Continue checking when a leakage is found. Always continue and complete checking along all

pipe connections and A/C system co mponents for additional leakage.

When a leakage is detected, clean leakage area using compressed air and check again.

When checking leakage of cooling unit inside, al ways clean inside of drain hose so that the

probe surface may not be exposed to water or dirt.

NOTE:

Always check leakage starting from high-pressure side and continue to low-pressure side.

When checking leakage of cooling unit inside, operate blower fan motor for 15 minutes or more at the maximum fan speed while the engine is stopped, and then insert electrical leak detector probe into drain

hose and hold for 10 minutes or more.

When disconnecting shut-off valve that is connected to A/C service valve, always evacuate remaining

refrigerant so that misidentification can be avoided.

5. Repair or replace parts where refrigerant leak age is detected. (Leakage is detected but leakage area is

unknown. GO TO 6.)

6. Start the engine and set A/C control in the following conditions. A/C switch ON

Air flow: VENT (ventilation)

Intake door position: Recirculation

Revision: 2010 May2011 QX56

Page 3076 of 5598

HA-20

< BASIC INSPECTION >

REFRIGERANT

Temperature setting: Full cold

Fan speed: Maximum speed set

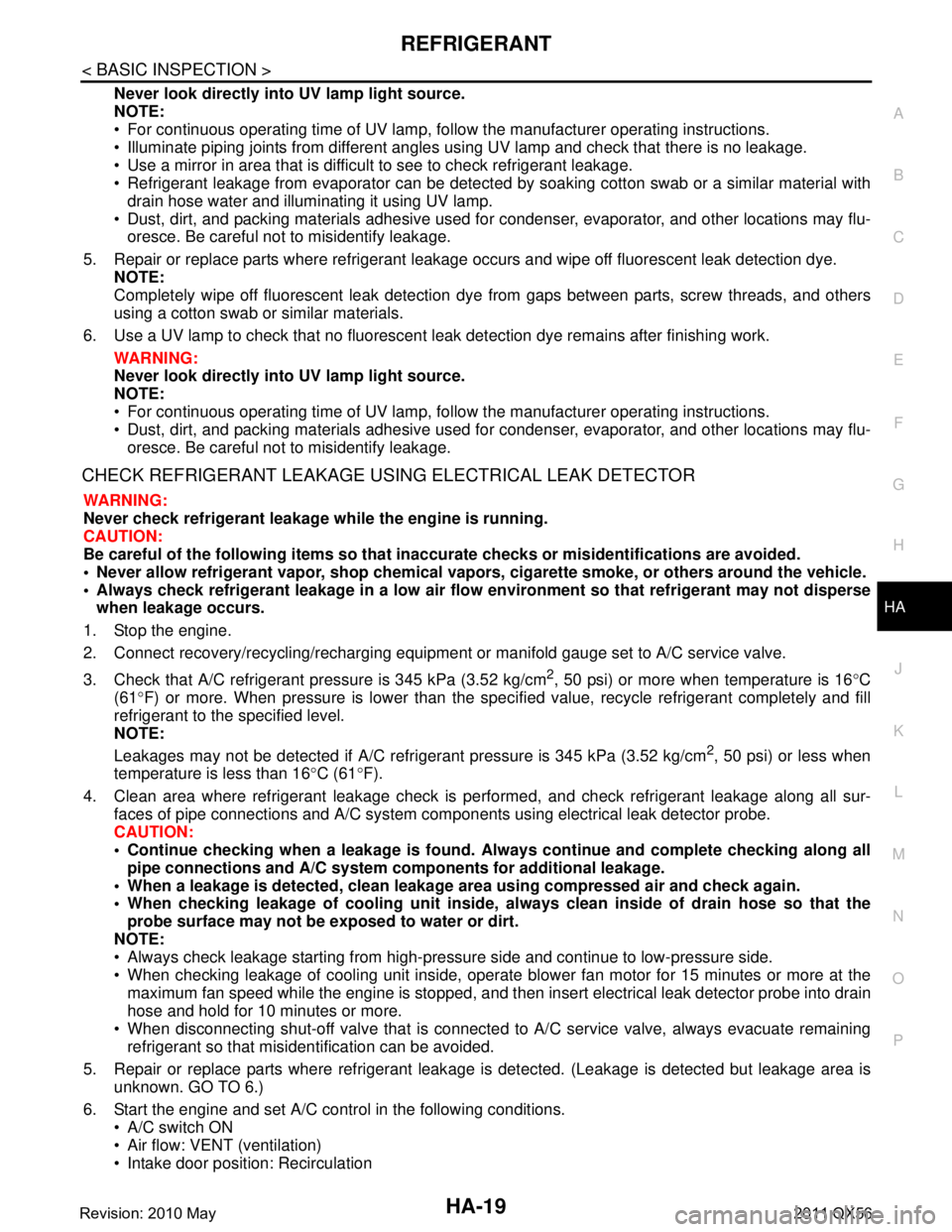

7. Run the engine at approximately 1,500 rpm for 2 minutes or more.

8. Stop the engine. Check again for refrigerant leakage. GO TO 4.

WARNING:

Be careful not to get burned when the engine is hot.

NOTE:

Start refrigerant leakage check immediately after the engine is stopped.

When refrigerant circulation is stopped, pressure on the low-

pressure side rises gradually, and after this, pressure on the

high-pressure side falls gradually.

The higher the pressure is, the easier it is to find the refriger-

ant leakage.

Recycle RefrigerantINFOID:0000000006276151

WARNING:

Always use HFC-134a for A/C refrigerant. If CFC-12 is accidentally charged, compressor is damaged

due to insufficient lubrication.

Always observe and follow precaution s described on refrigerant container. Incorrect handling may

result in an explosion of refrigerant co ntainer, frostbite, or the loss of eyesight.

Never breathe A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose, or

throat.

Never allow HFC-134a to be exposed to an open flam e or others because it generates poisonous gas

when in contact with high temperature ob jects. Keep workshop well ventilated.

1. Perform lubricant return operation. Refer to HA-22, "

Perform Lubricant Return Operation". (If refrigerant or

lubricant leakage is detected in a large am ount, omit this step, and then GO TO 2.)

CAUTION:

Never perform lubricant return op eration if a large amount of refrigerant or lubricant leakage is

detected.

2. Check gauge pressure readings of recovery/recyc ling/recharging equipment. When remaining pressure

exists, recycle refrigerant from high-pressure hose and low-pressure hose.

NOTE:

Follow manufacturer instructions for the handling or maintenance of the equipment. Never fill the equip-

ment with non-specified refrigerant.

3. Remove A/C service valve cap from the vehicle.

4. Connect recovery/recycling/rechargi ng equipment to A/C service valve.

5. Operate recovery/recycling/recharging equipm ent, and recycle refrigerant from the vehicle.

6. Evacuate air for 10 minutes or more to remove any remaining refrigerant integrated to compressor lubri-

cant, etc.

7. Refrigerant recycle operation is complete.

Charge RefrigerantINFOID:0000000006276152

WARNING:

Always use HFC-134a for A/C refrigerant. If CFC-12 is accidentally charged, compressor is damaged

due to insufficient lubrication.

Always observe and follow precaution s described on refrigerant container. Incorrect handling may

result in an explosion of refrigerant co ntainer, frostbite, or the loss of eyesight.

Never breathe A/C refrigerant and lubricant vapor or mist. Exposure my irritate eyes, nose, or throat.

Never allow HFC-134a to be exposed to an open flam e or others because it generates poisonous gas

when in contact with high temperature ob jects. Keep workshop well ventilated.

1. Connect recovery/recycling/recharging equipment to the A/C service valve.

SHA839E

Revision: 2010 May2011 QX56

Page 3078 of 5598

HA-22

< BASIC INSPECTION >

LUBRICANT

LUBRICANT

DescriptionINFOID:0000000006276153

MAINTENANCE OF LUBRICANT LEVEL

The compressor lubricant is circulating in the system together with the refrigerant. It is necessary to fill com-

pressor with lubricant when replacing A/C system pa rts or when a large amount of refrigerant leakage is

detected. It is important to always maintain lubricant level within the specified level. Otherwise, the following

conditions may occur.

Insufficient lubricant amount: Stuck compressor

Excessive lubricant amount: Insufficient cooling (caused by insufficient heat exchange)

InspectionINFOID:0000000006276154

If a compressor is malfunctioning (internal noise, insufficient cooling), check the compressor oil.

1.COMPRESSOR OIL JUDGMENT

1. Remove the compressor. Refer to HA-30, "

Exploded View".

2. Sample a compressor oil and judge on the figure.

Judgement result 1>>Replace compressor only.

Judgement result 2>>Replace compressor and liquid tank.

Perform Lubricant Return OperationINFOID:0000000006276155

CAUTION:

If a large amount of refrigerant or lubricant leakag e is detected, never perform lubricant return opera-

tion.

1. Start the engine and set to the following conditions.

Engine speed: Idling to 1,200 rpm

A/C switch: ON

Fan speed: Maximum speed set

Intake door position: Recirculation

Temperature setting: Full cold

2. Perform lubricant return operation for approximately 10 minutes.

3. Stop the engine.

4. Lubricant return operation is complete.

Lubricant Adjusting Procedure for Comp onents Replacement Except Compressor

INFOID:0000000006276156

Fill with lubricant for the amount that is calculated according to the following conditions.

Example: Lubricant amount to be added when replacing evapor ator and liquid tank [m (Imp fl oz.)] = 35 (1.2)

+ 20 (0.7) + 5 (0.2) + α

Name A/C System Oil Type S

JSIIA0927GB

Revision: 2010 May2011 QX56

Page 3081 of 5598

PERFORMANCE TESTHA-25

< BASIC INSPECTION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

PERFORMANCE TEST

InspectionINFOID:0000000006276158

INSPECTION PROCEDURE

1. Connect recovery/recycling/recharging equipment (for HFC-134a) or manifold gauge.

2. Start the engine, and set to the following condition.

Test condition

3. Maintain test condition until A/C system becomes stable. (Approximately 10 minutes)

4. Check that test results of “recirculating-to-disc harge air temperature” and “ambient air temperature-to-

operating pressure” are within the specified value.

5. When test results are within the specified value, inspection is complete. If any of test result is out of the specified value, perform diagnosis by gauge pressure. Refer to HA-27,

"Symptom Table".

RECIRCULATING-TO-DISCHARGE AIR TEMPERATURE TABLE

FRONT

REAR

Surrounding condition Indoors or in the shade (in a well-ventilated place)

Vehicle conditionDoor Closed

Door glass Full open

Hood Open

Engine speed Idle speed

A/C condition (front/rear) Temperature control switch or dial Full cold

A/C switch ON

Air outlet VENT (ventilation)

Intake door position Recirculation

Fan speed Maximum speed set

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature from center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 – 60 20 (68) 6.8 - 8.8 (44 - 48)

25 (77) 10.4 -

12.9 (51 - 55)

30 (86) 13.9 - 16.9 (57 - 63)

35 (95) 17.3 - 20.8 (63 - 70)

60 – 70 20 (68) 8.8 - 10.8 (48 - 52)

25 (77) 12.9 -

15.4 (55 - 60)

30 (86) 16.9 - 19.9 (63 - 68)

35 (95) 20.8 - 24.3 (70 - 76)

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature from rear ventilator grille A RH*

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 – 60 20 (68) 11.4 -

13.4 (53 - 56)

25 (77) 15.8 - 18.3 (60 - 65)

30 (86) 20.9 - 23.9 (70 - 75)

35 (95) 25.9 - 29.4 (79 - 85)

Revision: 2010 May2011 QX56

Page 3092 of 5598

HA-36

< REMOVAL AND INSTALLATION >

COOLER PIPE AND HOSE

9. Partly remove rear half of front fender protector RH. Refer to EXT-23, "FENDER PROTECTOR : Exploded

View".

10. Remove high-pressure pipe.

INSTALLATION

Note the following items, and install in the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant. Refer to HA-18, "

Leak Test".

LOW-PRESSURE PIPE

LOW-PRESSURE PIPE : Removal and InstallationINFOID:0000000006276176

CAUTION:

Perform lubricant return operation before each re frigeration system disassembly. However, if a large

amount of refrigerant or lubrican t is detected, never perform lubricant return operation. Refer to HA-

22, "Perform Lubricant Return Operation".

REMOVAL

1. Use a refrigerant collecting equipment (for HF C-134a) to discharge the refrigerant. Refer to HA-22, "Per-

form Lubricant Return Operation".

2. Drain engine coolant from cooling system. Refer to CO-8, "

Draining".

3. Remove engine cover. Refer to EM-25, "

Removal and Installation".

4. Remove mouting bolt (A) and fixing pawls, and then remove relay box (1).

5. Remove mounting bolts (A), and then remove relay box bracket(1).

6. Remove front water outlet tube assembly mounting nut.

7. Remove mounting nuts, and then disconnec t mounting bracket from the vhiecle.

8. Remove mounting bolt, and then disconnect low-pressure pipe from low-pressure flexible hose. CAUTION:

Cap or wrap the joint of the A/C piping with suitab le material such as vinyl tape to avoid the entry

of air.

9. Remove mounting bolt, and then disconnect low-pressure pipe from expansion valve. CAUTION:

: Pawl

JMIIA0798ZZ

JMIIA0799ZZ

Revision: 2010 May2011 QX56

Page 3099 of 5598

A/C UNIT ASSEMBLYHA-43

< REMOVAL AND INSTALLATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

Perform lubricant return operati on before each refrigeration system disassembly. However, if a large

amount of refrigerant or lubricant is detected, n ever perform lubricant return operation. Refer to HA-

22, "Perform Lubricant Return Operation".

REMOVAL

1. Use a refrigerant collecting equipment (for HF C-134a) to discharge the refrigerant. Refer to HA-20, "Recy-

cle Refrigerant". (If equipped)

2. Drain engine coolant from cooling system. Refer to CO-8, "

Draining".

3. Remove clamps, and then disconnect front heater outlet hose from heater pipe.

CAUTION:

Some coolant may spill when heater hoses are disconnected.

Close off the coolant inlet and outlet on the heater core (2 locations) with shop cloths.

4. Remove mounting bolt, and then disconnect low-pressure pipe and high-pressure pipe from expansion valve.

CAUTION:

Cap or wrap the joint of the A/C piping and expan sion valve with suitable material such as vinyl

tape to avoid the entry of air.

5. Remove instrument panel assembly. Refer to IP-14, "

Removal and Installation".

6. Remove steering column mounting bolt and nuts. Refer to ST-34, "

Removal and Installation".

7. Move steering column assembly to a position where it does not inhibit work.

8. Disconnect harness clips, harness connectors, ground bol ts and blackets from steering member, and then

move the vehicle harness to the position without hindrance for work.

9. Remove mounting nuts, and then remove instrument stay (RH and LH).

10. Remove A/C unit assembly mounting bolts.

11. Remove mounting bolts, and then remove steering member from the vehicle.

12. Disconnect drain hose from A/C unit assembly, and then remove A/C unit assembly from the vehicle.

13. Remove mounting bolts, and then disconnect heater & cooling unit and blower unitassembly.

INSTALLATION

Note the following items, and install in the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant. Refer to HA-18, "

Leak Test".

NOTE:

Refer to CO-9, "

Refilling" when filling radiator with engine coolant.

EVAPORATOR

EVAPORATOR : Removal and InstallationINFOID:0000000006276184

REMOVAL

1. Remove heater & cooling unit assembly. Refer to HA-41, "Exploded View".

2. Remove heater core. Refer to HA-44, "

HEATER CORE : Removal and Installation".

3. Remove mounting screws, and then remove evaporator pipe cover.

4. Remove air mix door motor (RH). Refer to HAC-153, "

AIR MIX DOOR MOTOR : Removal and Installa-

tion".

5. Remove mounting screws, and then remove A/C cover.

6. Remove foot duct LH. Refer to VTL-11, "

FLOOR DUCT 1 : Removal and Installation".

7. Remove mounting screws, and then remove A/C lower case.

8. Remove intake sensor. Refer to HAC-150, "

Removal and Installation".

9. Remove evaporator assembly from heater & cooling unit assembly.

10. Remove mounting bolts, and then remove evaporator from evaporator assembly.

CAUTION:

Cap or wrap the joint of the evaporator and evaporat or pipe assembly with suitable material such as

vinyl tape to avoid the entry of air.

Revision: 2010 May2011 QX56

Page 3105 of 5598

REAR A/C UNITHA-49

< REMOVAL AND INSTALLATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

5. Pull out heater core (1) from rear A/C unit assembly.

INSTALLATION

Note the following item, and install in the reverse order of removal.

NOTE:

Refer to CO-9, "

Refilling" when filling radiator with engine coolant.

EXPANSION VALVE

EXPANSION VALVE : Removal and InstallationINFOID:0000000006276192

REMOVAL

1. Remove rear A/C unit assembly. Refer to HA-47, "REAR A/C UNIT ASSEMBLY : Removal and Installa-

tion".

2. Disassembly rear A/C unit assembly.

3. Remove mounting bolts, and then disconnect rear exp ansion valve assembly from rear evaporator pipe

assembly and rear cooler pipe assembly.

INSTALLATION

Note the following items, and install in the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant. Refer to HA-18, "

Leak Test".

JMIIA0685ZZ

Revision: 2010 May2011 QX56

Page 3145 of 5598

![INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (HVAC)HAC-39

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

DIAGNOSIS SYSTEM (HVAC)

DescriptionINFOID:0000000006275884

Air conditioning system INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (HVAC)HAC-39

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

DIAGNOSIS SYSTEM (HVAC)

DescriptionINFOID:0000000006275884

Air conditioning system](/img/42/57033/w960_57033-3144.png)

DIAGNOSIS SYSTEM (HVAC)HAC-39

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

DIAGNOSIS SYSTEM (HVAC)

DescriptionINFOID:0000000006275884

Air conditioning system performs self-diagnosis, operat ion check, function diagnosis, and various settings

using diagnosis function of each control unit.

CONSULT-III FunctionINFOID:0000000006275885

CONSULT-III performs the following functions via CAN communication with A/C auto amp.

NOTE:

Diagnosis should be performed with engine running. D oor motor operation speeds become slower and NO

results may be returned even for normal operation if battery voltage drops below 12 V during self-diagnosis.

SELF-DIAGNOSIS RESULTS

Refer to HAC-45, "DTC Index".

DATA MONITOR

Display item list

ECU Diagnostic item

(CONSULT-III)

A/C auto amp. HVACSelf Diagnostic Result

Data Monitor

Active Test

Work support

AV c o n t r o l u n i t MULTI AV

Self Diagnostic Result

Multi AV system on board diagnosis function

ECM ENGINESelf Diagnostic Result

Data Monitor

IPDM E/R IPDM E/RSelf Diagnostic Result

Data Monitor

Auto active test

Diagnostic mode Description

Self diagnostic result Displays the diagnosis results judged by A/C auto amp.

Data monitor Displays the input/output signal of A/C auto amp.

Active test The signals used to activate each device are forcibly supplied from A/C auto amp.

Work support Changes the setting for each setting function.

ECU identification Displays the part number of A/C auto amp.

Monitor item [Unit] Description

AMB TEMP SEN [ °C ( °F)] Ambient sensor value converted from ambient sensor signal received from ambient sen-

sor

IN-VEH TEMP [ °C ( °F)] Front in-vehicle sensor value converted from front in-vehicle sensor signal received from

front in-vehicle sensor

INT TEMP SEN [ °C ( °F)] Intake sensor value converted from intake sensor signal received from intake sensor

SUNLOAD SEN [w/m

2]Sunload sensor value converted from sunload sensor signal (driver side) received from

sunload sensor

AMB SEN CAL [ °C ( °F)] Ambient temperature value calculated by A/C auto amp.

IN-VEH CAL [ °C ( °F)] In-vehicle temperature (front side) value calculated by A/C auto amp.

INT TEMP CAL [ °C ( °F)] Front evaporator fin temperature value calculated by A/C auto amp.

SUNL SEN CAL [w/m

2]Sunload value (driver side) calculated by A/C auto amp.

Revision: 2010 May2011 QX56